Page is loading ...

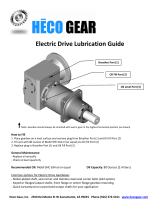

CRT36

i

This manual provides information and procedures to safely operate and maintain this WACKER model. For your

own safety and protection from injury, carefully read, understand and observe the safety instructions described

in this manual. THE INFORMATION CONTAINED IN THIS MANUAL WAS BASED ON MACHINES IN PRODUC-

TION AT THE TIME OF PUBLICATION. WACKER CORPORATION RESERVES THE RIGHT TO CHANGE ANY

PORTION OF THIS INFORMATION WITHOUT NOTICE.

Diese Betriebsanleitung enthält Informationen und Verfahren, um dieses WACKER Gerät sicher zu bedienen und zu

warten. Für Ihre Sicherheit und zur Verhinderung von Verletzungen, diese Betriebsanleitung bitte genau durchlesen

und die Angaben befolgen. DIE HIERIN ENTHALTENEN INFORMATIONEN SIND AKTUELL ZUM ZEITPUNKT DER

VERÖFFENTLICHUNG. ÄNDERUNGSRECHT VORBEHALTEN.

Este manual contiene información y procedimientos que son necesarios para operar y mantener esta máquina

WACKER. Para su propia seguridad y protección, lea por favor este manual cuidadosamente y observe todas las

instrucciones de seguridad descritas en este manual. TODA LA INFORMACION EN ESTE MANUAL SE BASA EN

MAQUINAS EN PRODUCCION VEGENTE A PARTIR DE LA FECHA DE PUBLICACION. TODOS DERECHOS

RESERVADOS POR WACKER CORPORACION.

Ce manuel fournit des informations et des procédures destinées à utiliser et à entretenir en toute sécurité cette machine

WACKER. Pour votre propre sécurité et afin d’éviter tout accident, lisez, comprenez et respectez soigneusement les

consignes de sécurité décrites dans ce manuel. LES INFORMATIONS CONTENUES DANS CE MANUEL SONT

BASEES SUR LES MACHINES EN COURS DE PRODUCTION AU MOMENT DE LA PUBLICATION. WACKER

CORPORATION SE RESERVE LE DROIT DE MODIFIER TOUTE PARTIE DE CES INFORMATIONS SANS

PREAVIS.

This manual is divided into the sections listed below:

Diese Betriebsanleitung ist in folgende Kapitel eingeteilt:

Este manual está compuesto por las siguientes secciones:

Ce manuel contient les sections suivantes:

Item Number / Artikel-Nummer / Número de referencia / Numéro de référence :

0007512, 0007513

1A Operation (English)

1B Betriebsanweisungen (Deutsch)

1C Operación (Español)

1D Instructions d’Opération (Français)

2 Parts / Teile / Repuestos / Pièces

Engine exhaust, some of its constituents, and certain vehicle

components contain or emit chemicals known to the State of

California to cause cancer and birth defects or other

reproductive harm.

!

WARNING

CRT36

iii

PATENT PENDING

111545

This machine may be covered by one or more of the following patents:

Dieses Gerät ist unter einem oder mehreren der folgenden Patente geschützt:

Puede ser que las patentes a continuación sean válidas para esta máquina:

Cette machine peut être protégée sous les brevets d’invention ci-dessous :

111891

OF THESE U.S. PATENTS:

4643611; 4555238; 5564375; 5586630; 4419048

WACKER MACHINES PROTECTED BY ONE OR MORE

1A-1

CRT36

Operating Information

1A

Table of Contents

1.1 Safety Notes ............................................................................................ 1A-2

1.2 Laws Pertaining to Spark Arresters.......................................................... 1A-2

1.3 Operating Safety ...................................................................................... 1A-3

1.4 Service Safety.......................................................................................... 1A-4

1.5 Dimensions .............................................................................................. 1A-4

1.6 Technical Data......................................................................................... 1A-5

1.7 Description............................................................................................... 1A-6

1.8 Before Starting .......................................................................................... 1A-6

1.9 Starting .................................................................................................... 1A-6

1.10 Operating ................................................................................................. 1A-7

1.11 Stopping................................................................................................... 1A-7

1.12 Steering ................................................................................................... 1A-8

1.13 Pitch Adjustment ...................................................................................... 1A-8

1.14 Periodic Maintenance Schedule............................................................... 1A-9

1.15 Trowel Gear Box...................................................................................... 1A-9

1.16 Drive Belts ............................................................................................. 1A-10

1.17 Control Linkage Lubrication ................................................................... 1A-10

1.18 Control Lever Adjustment (Forward or Backward) ................................. 1A-11

1.19 Righthand Control Lever Adjustment (Right or Left)............................... 1A-11

1.20 Compensating for Bent Trowel Arms ..................................................... 1A-11

1.21 Lift Lever Adjustment ............................................................................. 1A-12

1.22 Transporting Trowels ............................................................................. 1A-13

1.23 Mounting Floating Disc (CRT36 ASN only) ............................................ 1A-14

1.24 Battery Jump Start Procedure................................................................ 1A-14

1.25 Troubleshooting ...................................................................................... 1A-15

1A OPERATION CRT36

1

1A-2

1.1 Safety Notes

This manual contains NOTES, CAUTIONS, and WARNINGS which must be followed to reduce the possibility of

improper service, damage to the equipment, or personal injury. Read and follow all NOTES, CAUTIONS and

WARNINGS included in instructions.

Note: Contains additional

information important to a procedure.

CAUTION: Provides information important to prevent

errors which could damage machine or components.

Warns of conditions or practices which

could lead to personal injury or death!

WARNING

1.2 Laws Pertaining to Spark Arresters

Notice: Some states require that in certain locations spark arresters be used on internal combustion engines. A spark

arrester is a device designed to prevent the discharge of sparks or flames from the engine exhaust. It is often required

when operating equipment on forested land to reduce the risk of fires. Consult the engine distributor or local authorities

and make sure you comply with regulations regarding spark arresters.

CRT36 OPERATION 1A

1A-3

1.3 Operating Safety

Familiarity and proper training are required for the safe operationof this equipment! Equipment operated improperly or

by untrained personnel can be dangerous! Read the operating instructions contained in both this manual and the engine

manual and familiarize yourself with the location and proper use of all controls.

Read operating and safety instructions before us-

ing the Riding Trowel and operate the machine in

accordance with the manufacturer’s instructions.

Inspect your Riding Trowel for damage or tamper-

ing that can sometimes occur during shipping. If

damage is found, file claim with your carrier imme-

diately. Mark freight bill of lading as damaged

shipment.

Do not operate your Riding Trowel if any guards

have been removed or if the “Safety Kill Switch” is

not operational.

Only trained personnel should be allowed to oper-

ate your Riding Trowel. Never allow more than one

person on the trowel while it is in operation.

No foreign objects such as buckets, tools, or

materials should ever be attached or allowed to

ride on the Trowel during operation.

Do not attempt to fill fuel tank or oil sump while

engine is running. Allow engine to cool 5 minutes

before refueling.

Never attempt to operate the Trowel on steeply

inclined surfaces.

Do not use over-the-counter hardware to replace

manufacturer's hardware.

HEALTH HAZARD: When operating machines

with gas engines in confined areas, the fumes

MUST be ventilated!

Always wear safety goggles and gloves when

operating the Riding Trowel.

WARNING

1A OPERATION CRT36

1

1A-4

1.4 Service Safety

Poorly maintained equipment can become a safety hazard! In order for the equipment to operate safely and properly

over a long period of time, periodic maintenance and occasional repairs are necessary.

in. (mm)

1.5 Dimensions

1011SD67

48 (1219)

41 (1041)

CRT36 ASO - 76.5 (1943)

CRT36 ASN - 81.5 (2070)

WARNING

DO NOT attempt to clean or service machine

while it is running. Rotating parts can cause

severe injury.

DO NOT crank a flooded engine with the

spark plug removed on gasoline-powered

engines. Fuel trapped in the cylinder will

squirt out the spark plug opening.

DO NOT test for spark on gasoline-powered

engines if engine is flooded or the smell of

gasoline is present. A stray spark could ignite

fumes.

DO NOT use gasoline or other types of fuels

or flammable solvents to clean parts,

especially in enclosed areas. Fumes from

fuels and solvents can become explosive.

ALWAYS operate machine with all safety

devices and guards in place and in working

order.

ALWAYS keep area around muffler free of debris

such as leaves, paper, cartons, etc. A hot muffler

could ignite them, starting a fire.

ALWAYS replace worn or damaged compo-

nents with spare parts designed and recom-

mended by WACKER.

ALWAYS disconnect spark plug on machines

equipped with gasoline engines, before servicing,

to avoid accidental start-up.

CRT36 OPERATION 1A

1A-5

1.6 Technical Data

Sound and Vibration Specifications

Engine CRT36 ASO CRT36 ASN

Honda GX620QAF Honda GX620QAF

20 (15) 20 (15)

15 (246) 15 (246)

BPR6ES (NGK) BPR6ES (NGK)

0.028–0.031 (0.70–0.80) 0.028–0.031 (0.70–0.80)

3800 3800

1200 1200

12 12

4.15 (15.7) 4.15 (15.7)

4.7 (4.5) 4.7 (4.5)

approx. 2.5 approx. 2.5

mechanical ramp mechanical ramp

Yes Yes

42 (1200) 42 (1200)

SAE 10W30 SG,SF/CC,CD SAE 10W30 SG,SF/CC,CD

Trowel

* Use only Mobil Oil SHC 634 synthetic oil.

The required sound specifications, per Appendix 1, Paragraph 1.7.4.f of the EC-Machine Regulations, are:

- the sound pressure level at operator’s location (L

pA

) = 92 dB(A)

- the sound power level (L

WA

) = 111.3 dB(A)

These sound values were determined according to ISO 3744 for the sound power level (L

WA

) and ISO 6081 for the

sound pressure level (L

pA

) at the operator’s location.

The weighted effective acceleration value, determined according to ISO 8662, is: 0.5 m/s

2

for whole body; 1.8 m/

s

2

for hand/arm.

The sound and vibration specifications were obtained with the unit operating on wet concrete at nominal engine

speed.

Length in. (mm) 76.5 (1943) 81.5 (2070)

Width in. (mm) 41 (1041) 41 (1041)

Operating Weight lbs. (kg) 490 (223) 480 (218)

Detachable Guard Rings Yes Yes

Troweling Width in. (mm) 70.5 (1791) 73.5 (1867)

Troweling Area ft

2

(m

2

) 17.5

(1.63) 17.5

(1.63)

Travel Speed ft. (m)/min 230 (70) 230 (70)

Rotor Speed rpm 125 113

Pitch Range 0–20

o

0–20

o

Gear Box standard duty standard duty

Safety Switch Yes (foot style) Yes (foot style)

Gear Box Lubrication * oz. (l) 25 (0.74) 25 (0.74)

Engine Make & Model

Rated Power Hp (kW)

Piston Displacement in

3

(cm

3

)

Spark Plug type

Electrode gap in (mm)

Operating Speed rpm

Idle Speed rpm

Battery Volts

Fuel Capacity gal. (l)

Fuel Consumption qt. (l)/hr

Running Time hours

Centrifugal Clutch type

Low Oil Shutdown/Alert

Engine Oil Capacity oz. (ml)

Engine Lubrication oil grade

1A OPERATION CRT36

1

1A-6

1.7 Description

The Riding Trowel is a modern, high production machine. Finishing rate will vary

depending on operator skill and job

conditions. The Riding Trowel has eight finishing blades. The standard-duty gearboxes are designed to provide

exceptional performance, low maintenance, and trouble-free use under some of the worst conditions.

All WACKER Riding Trowels are equipped with a safety kill switch and a low oil shutdown for added job safety and engine

protection. Operating time between fuel refills is approximately 2-1/2 to 3 hours with rotor speeds between 80 and 125

rpm.

Riding Trowels are the most technically advanced trowels on the market today. With proper maintenance and use, your

Riding Trowel will provide you with exceptional service.

1.8 Before Starting

Before starting trowel, check the following:

- oil level in engine

- oil level in trowel gearboxes

- fuel level

- condition of air filter

- condition of trowel arms and blades

Grease trowel arms daily.

1.9 Starting

Before starting, the operator must know the location and

function of all controls.

1. Pull choke knob (j) out to the closed position to start

a cold engine. The choke may not be needed if the

engine is warm or the air temperature is hot. In this

case, keep choke open by pushing knob in. Push

down left and right foot pedals, turn engine switch

(m), and hold it until engine starts.

CAUTION: Operating the starter motor for more

than 5 seconds can damage the motor. If engine fails

to start, release the switch and wait 10 seconds before

operating starter again.

Note: The engine is equipped with an oil alert light (n)

which will come on if engine oil level gets too low.

Continuing to run the engine with the oil alert light on

can damage the engine.

2. Open choke as engine warms up.

3. Allow engine to warm up before operating trowel.

a

b

c

d

e

f

g

h

i

1011SD68

j

o

1015SD88

k

m

n

l

CRT36 OPERATION 1A

1A-7

1.10 Operating

To utilize your WACKER Riding Trowel to its fullest

capacity, the machine should be driven in the direction

that the operator is facing. This will finish the widest

possible area, while giving the operator an excellent view

of the slab surface about to be troweled. When the

machine reaches the end of the slab, make a 180 degree

U-turn, and repeat the straight line of direction to the other

end of the slab.

To familiarize a new operator with the Riding Trowel the

following steps should be taken:

1. Point out the location of all controls.

a - right pitch control

b - control level (left/right)

c - control lever (forward/reverse)

d - operator’s seat

e - left pitch control

f - fuel tank

g - left foot pedal (safety kill switch)

h - right foot pedal (throttle control)

i - battery/tool box

j - engine choke control

k - hourmeter

l - light switch

m -engine switch

n - oil alert light

o - seat locking pin

2. With the operator in the seat, show him the functions

of the control levers (b,c) and how to start the ma-

chine.

A hard concrete slab with water on the surface is an ideal

place for an operator to practice with the machine. For this

practice, pitch the blades up approximately 1/4" on the

leading edge. Start by making the machine hover in one

spot, and then practice driving the machine in a straight

line and making 180 degree turns. Best control is achieved

at full rpm.

CAUTION: DO NOT run the trowel during engine warm-

up or at an rpm that will cause the centrifugal clutch to

partially engage or slip. This will burn the clutch!

CAUTION: DO NOT use excessive pressure on the

control levers. Excessive pressure does not increase the

reaction time of the machine and can damage steering

controls.

1.11 Stopping

To stop trowel movement, return control levers (b,c) to

their neutral position and release pressure on right foot

pedal (h).

Note: On units equipped with the optional cruise control,

pull cruise lever up. This will release the right foot pedal

and reduce engine speed to disengage the clutch.

To stop engine, release left foot pedal

(g).

1A OPERATION CRT36

1

1A-8

2

1

4

6

3

5

1011SD70

1.12 Steering

A slight "feathering" motion, forward and backward with

the left hand control arm, is required to move in a straight

path to the left or right, while operating the right hand

control arm. See illustration.

1 - forward

2 - reverse

3 - rotate clockwise

4 - rotate counter-clockwise

5 - left sideways

6 - right sideways

1 Wet surface working stage

2 Wet plastic working stage

3 Plastic working stage

4 Semi-hard working stage

5 Hard finishing stage

(burnishing)

Working Conditions of Concrete

Suggested Working Pitch

b

a

20

o

Maximum Pitch

Additional Pitch

Additional Pitch

Slight Pitch

5

o

10

o

15

o

Flat (No Pitch)

1011SD71

1011SD95

1.13 Pitch Adjustment

When changing or setting pitch (angle of trowel blades), slow the machine down, set desired pitch on left side of the

machine, then adjust right side to match.

To increase pitch, turn pitch control clockwise (a). Use pitch indicator (b) to adjust pitch equally on both right and left

trowel blades.

0°

20°

5

4

3

2

1

CRT36 OPERATION 1A

1A-9

1.14 Periodic Maintenance Schedule

The chart below lists basic trowel and engine maintenance. Refer to engine manufacturer’s Operation Manual for

additional information on engine maintenance. A copy of the engine Operator’s Manual was supplied with the machine

when it was shipped.

Daily

Every

100 hrs.

Every

300 hrs.

Grease trowel arms.

Check oil level in gearbox.

Check fuel level.

Check engine oil level.

Inspect air filter. Replace as needed.

Check and tighten external hardware.

Grease control linkage.

Check and adjust drive belt.

Change engine oil.

Clean and check spark plug - .030" (.75 mm).

Check fuel filter.

Check and adjust valve clearance.

Replace oil filter.

Replace spark plug.

Replace fuel filter.

Grease trowel gearbox.

Every

50 hrs.

Every 400 hours

* Check engine oil twice daily (every 4 hours).

** Check new belts after first 10 hours of operation.

*** Change engine oil after first 20 hours of operation.

*

**

***

Every

20 hrs.

1.15 Trowel Gearbox

1. Check gear box sight gage for correct oil level daily (every 8 hours). Add oil if oil level is below halfway line of

sightglass. To add oil, tilt trowel back and remove sightglass. Add oil through sightglass opening. Replace sightglass

and check oil level. DO NOT fill past the 3/4 full point.

Use only Mobil Oil SHC 634 synthetic oil.

Gearbox capacity: 25 oz. (0.74 l).

2. Each gearbox has a grease fitting on the top cover that must be greased (2 shots only) every 400 operating hours.

Use only Mobilelith SHC 220 extended pressure grease.

To service engine, pull seat locking pin out and

tilt seat back.

1A OPERATION CRT36

1

1A-10

1.16 Drive Belts

To tighten belts:

1. Loosen the two jam nuts on top of engine mounting

plate located on back of trowel.

2. Turn all jam nuts counterclockwise an equal number

of turns to raise engine until correct belt tension is

attained. Maximum belt play should be from 1/2" to

3/4" (13mm to 19mm) at the center of the span. New

belts should be re-tensioned after the first 10-12 hours

of operation.

3. Retighten all jam nuts.

To replace belts:

1. Loosen jam nuts on engine mounting plate and lower

engine to relieve tension on belts.

2. Remove belt guard.

3. Loosen set screws

(a) and (b) on spider mount (c).

4. Remove six attaching bolts (d) on inside of spider

assembly (e) and slide spider mount (c) toward

gearbox so as to allow the inside spider assembly (e)

to be removed intact.

5. Remove and install belts through opening created by

removal of (e).

6. Reverse procedure for assembly. Do not overtighten

spider assemblies. Tighten screws (n) so that wash-

ers (m) are compressed halfway into discs.

New belts should be re-tensioned after the first 10-12

hours of use. Maximum belt play should be from 1/2" to

3/4" (13mm to 19mm) at the center of the span.

1011SD78

a

c

e

d

b

d

m

n

m

e

1011SD79

c

1011SD79

e

1012SD15

1.17 Control Linkage Lubrication

The control linkage is equipped with seven grease fittings

to lubricate pivot points. Grease control linkage once a

week, or every 20 hours, to prevent wear and ensure

good movement and smooth response of control levers.

Use a general purpose grease and add one to two shots

of grease at each fitting.

CRT36 OPERATION 1A

1A-11

1.18 Control Lever Adjustment

(Forward or Backward)

The control levers should line up evenly. If levers appear

out of adjustment they can be re-adjusted forward or

backward as follows:

1. Remove bolts

(f).

2. Loosen jam nuts

(g).

3. Extend linkage to adjust control levers forward.

4. Shorten linkage to adjust control levers backward.

5. After levers have been adjusted to the desired posi-

tion, reassemble bolts

(f) and tighten jam nuts (g).

1011SD75

l

k

g

f

f

1011SD76

i

h

j

“V”

1011SD77

1.19 Righthand Control Lever

Adjustment (Right or Left)

The righthand lever should be set to the same angle as

that of the left to form a perfect “V”. Should levers come

out of adjustment, adjust the right hand lever as follows:

1. Remove bolt (h).

2. Loosen jam nuts (i).

3. Shorten linkage (j) to move control lever to the left.

4. Extend linkage to move control lever to the right.

5. After control lever has been adjusted to desired posi-

tion, reassemble bolt (h) and tighten jam nuts (i).

1.20 Compensating for Bent

Trowel Arms

1. Loosen nut (l) slightly.

2. Adjust bolt (k) until trowel blade is level.

3. Tighten nut.

1A OPERATION CRT36

1

1A-12

a

b

1011SD73

c

e

f

d

d

f

geh

1.20 Lift Lever Adjustment

Damage to, or replacement of, a trowel arm can change

the adjustment of the lift lever. This can unbalance the

trowel arms and cause the trowel to wobble during

operation. To operate smoothly, the lift lever on all the

arms must be adjusted equally. All arms should be

adjusted at the same time to ensure that the trowel is

balanced correctly.

Adjust trowel arms using optional adjusting tool as de-

scribed below.

Note: Make sure that there is no pitch in the blades

before attempting to remove trowel arms.

1. Block up pressure plate using wooden blocks (b).

2. If machine is equipped with stabilizer ring, remove

ring from trowel arms.

3. Remove blades from trowel arms.

4. Loosen hex head screws (a) on spider which secure

trowel arms in place (do not remove screws).

5. Remove trowel arms from spider with lift levers in

place.

6. Clean flats on trowel arm before placing it in the

adjusting tool (c) to make sure it lies flat.

7. The adjusting tool comes with three different size

spacers (d). Use the medium length spacer to

adjust the CRT 46ASO, CRT 36ASN, and

CRT 36ASO. Use the tall spacer to adjust the

CRT 46KHN and the CRT 46KHO equipped with the

heavy-duty gearboxes.

8. Insert trowel arm into adjusting tool as shown and

tighten socket head bolts (e) down on the trowel arm

to hold it in place.

9. Move adjusting tool arm (f) over carriage bolts (g) on

lift levers as shown. Loosen jam nut (h) and adjust

the carriage bolt so that the top of the bolt is touching

the bottom of the adjusting tool arm.

10. Tighten jam nut to secure adjustment in place. Re-

peat procedure for remaining arms.

11. Attach blades to arms. Secure arms to spider with

hex head screws.

12. Attach stabilizer ring to arms, if equipped.

1011SD84

1011SD74

CRT36 OPERATION 1A

1A-13

1.22 Transporting Trowels

Optional dolly jacks are available for short moves or to aid

in servicing the trowel.

Install dolly jacks as follows:

1. Inspect dolly jacks for damage and serviceability.

2. Place riding trowel on firm, level ground.

3. Tie steering levers

(i) to frame to prevent them from

tipping forward when lifting trowel.

4. With the front dolly jack (j), fully insert extension tube

in holes

(k) in the main frame of the riding trowel. The

front dolly jack is equipped with short extension tubes;

the rear dolly jack has the long extension tubes.

5. Insert extension tubes of the rear dolly jack (l) into

holes in the rear of the main frame. Rear holes are

located directly opposite those of the front.

6. Turn jack handles clockwise to lift trowel, counter-

clockwise to lower trowel.

CAUTION: The dolly jack lifting system is designed for

short moves only and to aid in servicing the trowel. It is not

a substitute for a towing system or trailer.

An optional lifting bridle (m) is available and is recom-

mended for use when lifting the trowel. Attach bridle to

each of the four lifting eyes (n) on the trowel.

CAUTION: Make sure the lifting device has enough

weight bearing capacity to lift machine safely.

1011SD82

1011SD83

l

j

1011SD81

k

i

m

n

1012SD17

1A OPERATION CRT36

1

1A-14

1.23 Mounting Floating Disc

(CRT36 ASN only)

Certain applications may require the use of a floating

disc. An optional floating disc is available for use on

machines with non-overlapping blades.

To mount discs

(a), lift trowel off the ground (engine off)

and position disc against blades. Turn disc either to the

right or left to engage clip angles (b) as shown. Remem-

ber, the right-hand trowel blades turn counterclockwise;

the left-hand blades turn clockwise.

1.24 Battery Jump Start Procedure

Occasionally, it may be necessary to jump start a weak

battery. If jump starting is necessary, the following proce-

dure is recommended to prevent starter damage, battery

damage, and personal injuries.

Jump starting a battery incorrectly can cause

battery to explode, resulting in severe personal

injury or death. Do not smoke or allow an ignition

sources near the battery, and do not jump start a

frozen battery.

WARNING

WARNING

Electrical arcing can cause severe personal injury.

Do not allow positive and negative cable ends to

touch.

1. Disconnect engine load.

2. Use a battery of the same voltage (12V) as is used

with your engine.

3. Attach one end of the positive booster cable (red) to

the positive (+) terminal of the booster battery. Attach

the other end to the terminal of your engine battery.

4. Attach one end of the negative booster cable (black)

to the negative (-) terminal of the booster battery.

Attach other end of negative cable to a solid chassis

ground on your engine.

a

1011SD72

b

b

5. Jump starting in any other manner may result in

damage to the battery or the electrical system.

CAUTION: Overcranking the engine can cause starter

damage. Allow 5 minutes for starter to cool if engaged for

longer than 30 seconds.

6. Turn ignition switch to on to start engine.

CAUTION: When using lights or high amperage draw

accessories idle the engine for a period of 20 minutes to

bring the battery to charge state.

CRT36 OPERATION 1A

1A-15

1.25 Troubleshooting

Engine does not start.

Machine out of balance,

wobbling excessively.

Poor handling; excessive

range in control lever

movement.

Machine does not move.

Machine does not respond

correctly to control lever

movement.

Trowel noisy.

1. Safety kill switch is not engaged.

2. Oil alert shutdown feature is acti-

vated.

3. Engine problem.

1. Operator is over-steering.

2. Trowel arm(s) bent.

3. Trowel blade(s) bent.

4. Main shaft(s) bent due to ma-

chine being dropped.

5. Trowel arm lift levers misaligned.

1. Worn bushings due to lack of lu-

brication.

2. Control arm lever adjustment has

moved or control arm has been

bent.

3. Lower control arm(s) bent. This

can be caused by lifting machine

from underneath using a forklift or

by dropping machine.

1. Drive belts loose.

2. Vacuum between bottom of

blades and surface of concrete.

3. Key sheared in upper or lower

drive pulley or in main shaft.

1. Sheared key.

1. Trowel blades have become mis-

aligned and are contacting each

other during rotation.

2. Sheared key.

1. Press left foot pedal to engage switch.

Check for damaged switch.

2. Add oil to engine.

3. Consult engine manufacturer’s service

manual.

1. The movement of each gearbox is con-

trolled by “stops” to provide the correct

relationship of the control arm move-

ment to machine movement. Exces-

sive pressure on control arms in any

direction will not increase reaction time

and can damage steering controls

causing machine to wobble.

2. Replace trowel arm(s).

3. Replace trowel blade(s).

4. Replace main shafts(s).

5. Adjust lift levers with adjusting tool

(Section 1.21).

1. Replace bushings and lubricate at least

every 20 hours (Section 1.17).

2. Reset control arm lever

(Sections 1.18, 1.19).

3. Replace lower control arm(s). Use lift-

ing eye provided on machine for lifting.

1. Tighten drive belts (Section 1.16).

2. Change pitch on blades to break suc-

tion.

3. Replace damaged key.

1. Check all keys in drive system.

1. Replace damaged blades. Align blades

so that one set represents a (+) and the

other an (x) when viewed from above.

2. Check all keys in drive system.

Problem Cause Remedy

2-1

2

CRT 36

Trowels / Betonglätter / Alisadora de concreto / Truelle mécanique

Table of Contents / Inhaltsverzeichnis / Indice / Table des Matières

2.1 Part Numbers - Boldface / Fettgedruckte Nummern / Números de partes en negritas

/Numéros de pièce - en caractères gras .......................................................................................2

2.2 Symbols / Kurzzeichen / Símbolos / Symboles ............................................................................. 3

2.3 Engine and Console / Motor und Konsole / Motor y Consola / Moteur et Console........................4

2.4 Fuel System / Kraftstoffsystem / Sistema de Combustible / Système d’Essence..........................6

2.5 Flex Drive / Antriebswelle / Eje motor / Arbre d'entraînement .......................................................8

2.6 Clutch, Belt and Belt Guard /Kupplung, Riemen und Riemenschutz/

Embrague, correa y protección de correa /Embrayage, courroie et protection de courroie ........ 10

2.7 Electrical / Elektronik / Electrónica / Electronique........................................................................ 12

2.8 Gear Box - Right / Getriebegehäuse-rechts/Caja de engranajes-derecha /

Boîte de vitesses-droite ...............................................................................................................14

2.9 Gear Box - Left / Getriebegehäuse-links/Caja de engranajes-izquierda /

Boîte de vitesses-gauche ...........................................................................................................16

2.10 Frame / Konsole / Base / Base .................................................................................................... 18

2.11 Steering Lever / Steuerhebel / Palanca de dirección / Levier de direction .................................. 20

2.12 Crosshead and Pivot Box / Getriebegehäusekonsole und Gelenkkasten / Caja de pivo

Ménsula de caja de engranajes/Boîte du pivot et Console de boîte de vitesses.........................22

2.13 Pitch Control - Left / Schrägstellungsregler-links /Regulador de inclinación-izquierda /

Contrôle d’inclinaison-gauche .....................................................................................................24

2.14 Pitch Control - Right / Schrägstellungsregler-rechts /Regulador de inclinación-derecha /

Contrôle d’inclinaison-droite ........................................................................................................ 26

2.15 Control Panel / Schalttafel / Tablero de mando / Tableau de commande ...................................28

2.16 Throttle Control Pedal / Fußtritt / Controlador de pedal / Commande par pédale .......................29

2.17 Wiring Schematic / Schaltplan / Diagrama de cables / Schéma de câblage ............................... 30

2-2

2

CRT 36

Les numéros de pièces imprimés en caractères gras dans les Listes des Pièces

Détachées de ce manuel sont les pièces détachées recommandées par la WACKER

Corporation. Cela veut dire que ces pièces sont sujettes à usure dans des conditions

de travail normales et peuvent nécessiter de l’entretien ou leur remplacement. Nous

recommandons que vous disposez d’un stock de ces pièces pour pouvoir satisfaire

la demande d’entretien de cette machine. Le client doit decider lui-même de la

quantité exacte de pièces de rechange qu’il disposera dans ses stocks.

Los números de partes en negritas en las Listas Ilustradas de Partes son los

repuestos recomendados, ésto quiere decir que estas partes se desgastarán bajo

circunstancias de funcionamiento normales y pueden requerir servicio periódico o su

reemplazo. Se recomienda que el cliente mantenga un abastecimiento adecuado de

estas partes para poder satisfacer la demanda requerida por el servicio a la máquina.

La cantidad de repuestos que el cliente necesitará para reparaciones dependerá de

la póliza de servicio de cada cliente.

Bei den in den Ersatzteillisten fettgedruckten Nummern handelt es sich um

empfohlene Ersatzteile. Dies bedeutet, daß diese Teile bei normalen

Anwendungsbedingungen natürlicher Abnutzung ausgesetzt sind und gelegentlich

ersetzt oder überarbeitet werden müssen. Es wird geraten, diese Teile auf Lager

bereit zu haben, um für Service-Arbeiten an diesem Gerät vorbereitet zu sein.

Lagerbestände für diese und andere Teile, welche für ausgiebigere Reparaturarbeiten

benötigt werden, können je nach Service-Gewohnheiten der einzelnen Kunden

variieren.

Part Numbers appearing in boldface type are recommended spare parts. This

means that these parts are subject to wear under normal operating conditions and

may require periodic service or replacement. It is recommended that these items be

stocked to meet the expected service requirements of this model. Actual stocking

quantities of these and other parts used in more extensive repairs will depend on the

service practices of each customer.

2.1 Part Numbers - Boldface / Fettgedruckte Nummern / Números de partes en negritas

/Numéros de pièce - en caractères gras

2-4

2

CRT 36

1011SD96

2.3 Engine and Console / Motor und Konsole / Motor y Consola / Moteur et Console

1

6

5

8

2

3

3

2

9

7

4

3

4

3

6

10

7

9

10

11

/