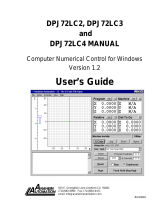

Screen and keys

6

General description of the interface.

A. Icon (customizable) identifying the manufacturer.

Clicking with the mouse or pressing on a touch-

screen, the CNC shows the task window (same as

pressing the keystroke sequence [CTRL]+[A]) that

shows the list of the work modes, user modes, OEM

modes and CNC hotkey modes.

B. Icon showing the status of the program of the active

channel:

C. Program selected in the active channel for execution.

Clicking with the mouse or pressing a touch-screen

has the same effect as the [Main-Menu] key, which

shows the initial screen of the CNC.

D. Number of the last Nxxxx label executed. The bottom

icon indicates whether the Single-block execution

mode is active.

E. Number of channels available and active channel

(indicated in blue). Icons indicate which execution

mode (Manual, Automatic or MDI), or simulated

execution (theoretical, G functions, G S M and T

functions, fast and fast [S=0]) is found in each

channel. Clicking with the mouse or pressing a touch-

screen to access the desired channel, doing it on the

icon of the active channel, has the same effect as the

[ESC] key.

F. Active work mode (automatic, manual, etc.) selected

screen number and total number of screens

available. System clock. By clicking on the active

work mode, the CNC shows the list of available

pages and which ones are visible.

G. Active CNC message. If the "+" symbol is displayed

on the right hand side of the CNC message, this

means that there are other CNC messages on other

channels.

H. PLC messages. If the "+" symbol appearing on the

right of the PLC message is blue, this means that

there is more than 1 active PLC message. To see the

other active messages, click it with the mouse or tap

it on the touch-screen or press [CTRL + M].