IMI CORNELIUS INC. 2004

March 2, 2004

630460064INS

1 Rev A

IMI CORNELIUS INC g One Cornelius Place g Anoka, MN 55303-6234

Telephone (800) 238-3600 Facsimile (800) 535-4321

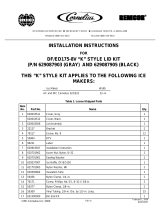

INSTALLATION INSTRUCTIONS, BIN STAT KIT, P/N 630000408

These Bin Stat kits apply to all “I” Series Ice makers

Table 1. Loose–Shipped Parts

Item No. Part No. Name Qty.

1 630900413 Spacer, Hex 5/8” Long x 8–32 SS 1

2 70894 Screw MA 08–32 TRPH 24 SS 1

3 51348 Spacer 1

4 630000413 Thermostat Asy 1

5 620037008 Bin Stat Support 1

6 630460064INS Installation Instruction, Thermostat 1

7 168833002 Washer SR 4W SS E#8 1

1. Disconnect power.

2. Remove front cover of the unit and the electrical box cover plate.

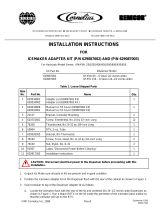

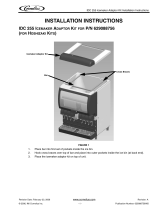

3. Carefully insert the coiled capillary tube through the bottom hole in the electrical box where the elec-

trical wires are coming through (see Figure 4).

4. If there is not a hole already in the chassis base, drill a ½” hole in the chassis base as indicated in

Figure 3.

5. Straighten approximately 12” of cap tube to go through hole. Re–coil the remainder. Do not disturb

coiled end.

6. Insert the “1/4” diameter wire form support into the coiled end of capillary tube and insert the assem-

bly through the hole in the chassis base. Route capillary tube to follow support as closely as pos-

sible.

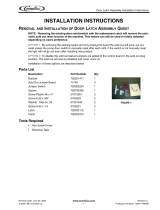

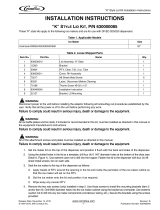

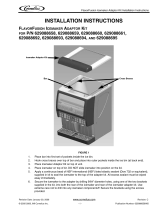

7. Remove the 8–32 nut (closest to the ½” DIA hole) that holds the compartment wall to the base. The

adapter kits that have a single level, adapter kits P/N’s 02390, 630200153, 08006, 02388, 08004,

630000191 and 08010) require a 7/8” high spacer be used to mount the binstat support. Thread the

8–32 x 5/8” hex spacer on to the compartment stud. Then fasten the thermostat support to the hex

spacer using the ¼” high plastic spacer, #8 flat washer and 8–32 x ¾” long phil. head screw. The

spacers are not to be used on the elevated adapter kits. Refer to Figure 2.

8. Any excess capillary tubing must be pulled back into the compressor compartment to prevent ice

from damaging it during dispenser operation.

9. Seal ½” diameter hole with sealant (RTV).

IMI CORNELIUS INC. 2004

March 2, 2004

630460064INS

2 Rev A

10. To mount bin thermostat in electrical box:

A. Clean the mounting area by rubbing briskly with Scotch Brite pad (see Figure 4 for location).

B. Wipe down the cleaned area with rubbing alcohol and let dry.

C. Pull paper strip off of double sided tape on thermostat mounting bracket.

D. Being sure that bin thermostat is facing the correct direction, (see Figure 4) affix the thermostat

in the electrical box. Press firmly down on the mounting bracket to bound the tape.

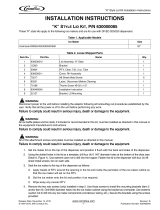

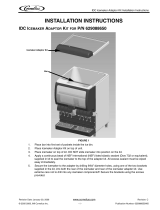

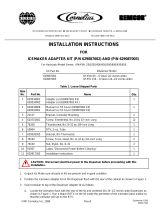

11. Connect the bin thermostat lead to the circuit board (see Figure 1).

12. Turn bin stat adjustment screw clockwise until it stops. Then turn it counterclockwise 1/8 of a turn.

13. Reinstall the front cover of the electrical box and the ice machine and reconnect the power. Verify

that the Bin Stat is working by holding ice on the coiled bare capillary tube. The bin stat will allow the

ice machine cycle to complete and harvest ice. Then the ice machine will shut down. Remove the ice

from the capillary tube and warm the tube with hand heat. The ice machine should start in approxi-

mately 60 seconds.

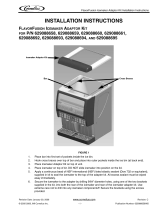

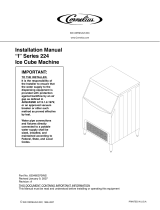

Processor

Figure 1

SW4–2 ON

SW4–3 ON

BE CONNECTED TO J4 AND

6 CURTAIN SWITCH MUST

DUAL CURTAINS

SW4–1 OFF

J5,J6, OR J7.

ON OFF DUMP EVERY THIRD HARVEST

OFF ON DUMP EVERY SEVENTH HARVEST

ON ON FLAKER

OFF OFF DUMP EVERY HARVEST (FACTORY SETTING)

DUE TO UPGRADING OF CIRCUIT BOARD

NOTE LOCATION OF SENSORS AND WIRE

CONNECTIONS ON NEW BOARD.

FOLLOW SETTINGS #1–#4 FOR HARVEST SETTINGS.

FOLLOW SETTINGS #5–#7 FOR NUMBER OF CURTAINS.

36430001

(Manufacturing Date)

S3–2

Error

SINGLE CURTAIN

SW4–1 ON

SW4–2 ON

SW4–3 ON

5 CURTAIN SWITCH CONNECTED

TO ANY BIN CONNECTOR (J4–J7).

SW4

SW4

SW4

S3–2

S3–2

S3–2

Off

7

6

5

Off

1 2

On

1 2

3

3

Off

On

1

On

2 3

S3–1

S3–1

S3–1

4

3

2

Off

Off

On

Off

On

On

4

2

3

TOP TWO PINS OF STACKING

PLUG BIN THERMOSTAT ON

DUMP CYCLE

DIP SWITCH

DIP SWITCH

WATER CURTAIN

CABLE PLUG

S3–1 S3–2

1

Switches

Bin

Curtain

Switch

Selection

3

4

2

1

Com

Out

In

Stack

312

Off

YL

YL

YL

YL

Thickness

Bridge

Suction line

Sensor

pot.

Manual

S3–1

Harvest/Test

On

Micro

Off

Switch

On

RD

S3–2S3–11

Off

On

External Error

LED Connection

#6 BL Condenser Fan

BE CONNECTED TO J4,J5,J6, AND J7.

7 CURTAIN SWITCH MUST

SW4–1 OFF

SW4–2 OFF

SW4–3 OFF

FOUR CURTAINS

Comp.

Triac

GR

Transformer

Cond.

Valve

Dump

Water

Valve

GR

GR

Fan

Gas

Hot

GR

GR

Cond.

Triac

#2 RD L2

#1 BR L1

#3 RD Hot Gas

#7 YL Water Pump

#5 BL P.S.

#4 BL

IMI CORNELIUS INC. 2004

March 2, 2004

630460064INS

3 Rev A

IMI CORNELIUS INC. 2004

March 2, 2004

630460064INS

4 Rev A

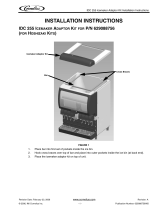

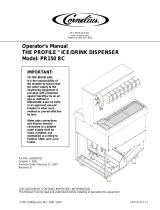

1/4 SPACER

FIGURE 2

8–32 X 3/4 PHMS

5/8 SPACER

8–32 NUT (PART OF ICEMAKER)

WASHER

WASHER

620037008, BIN STAT SUPT

620037008, BIN STAT SUPT.

BIN STAT SUPT ASY FOR ALL

ELEVATED ADAPTOR LID KITS

CAPILLARY ASY

CAPILLARY TUBE

ICEMAKER E-BOX

ELEVATED

ADAPTOR KIT

SINGLE LEVEL

ADAPTOR KIT

COIL CAPILLARY TUBE

AROUND BIN STAT SUPT

8–32 STUD (PART OF ICEMAKER)

BIN STAT SUPT ASY FOR

SINGLE LEVEL ADAPTOR KIT NO:

02388, 08004,630000191, 02390,

630200153, 08006, & 08010

IMI CORNELIUS INC. 2004

March 2, 2004

630460064INS

5 Rev A

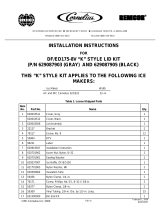

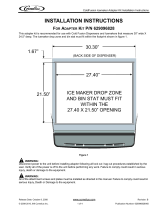

OF UNIT WITHOUT COVER.

* DIMENSION IS FROM FRONT

TOP VIEW OF 1230 CHASSIS PLATE

RIGHT HAND LINER

LEFT HAND LINER

ICE

DROP

ZONE

ICE

ZONE

DROP

DROP

ZONE

ICE

ZONE

DROP

ICE

4.25*

1.50

15.41

1/2” DRILL

ELECTRICAL BOX ASY

CLEAN MOUNTING AREA WITH

SCOTCH BRITE PAD,

THEN WIPE AREA DOWN WITH

RUBBING ALCOHOL AND LET DRY

THERMOSTAT KIT ASY

630000408

COIL

Figure 4

TO CHASSIS

PLATE

Figure 3

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

Cornelius P/N 630460064 User manual

- Type

- User manual

- This manual is also suitable for

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Cornelius P/N 629088650 User manual

Cornelius P/N 629088650 User manual

-

Cornelius Hoshizaki KM250 Installation guide

Cornelius Hoshizaki KM250 Installation guide

-

Cornelius Door Latch User manual

Cornelius Door Latch User manual

-

Cornelius P/N 629087002 User manual

Cornelius P/N 629087002 User manual

-

Cornelius Pressurized Liquid Base Beverage Dispense User manual

Cornelius Pressurized Liquid Base Beverage Dispense User manual

-

Cornelius P/N 629088756 User manual

Cornelius P/N 629088756 User manual

-

Cornelius 90221 User manual

Cornelius 90221 User manual

-

Cornelius 629096828 User manual

Cornelius 629096828 User manual

-

Cornelius 629096828 User manual

Cornelius 629096828 User manual

-

Cornelius P/N 631500109 User manual

Other documents

-

Scotsman 11-0616-21 Bin-Stat - 17-3494-01 Operating instructions

-

Scotsman KBT46 - Use with ID200, ID250 and NME454, NME654 or NME954 Operating instructions

-

Scotsman KBT43 - Use with ID200, ID250 and C0322, C0522, F0522, F0822, F1222, F1522, N0422, N0622, N0922, N1322 Operating instructions

-

Scotsman KBT44 - Use with ID200, ID250 and C0330, C0530, C0630, C0830, C1030, CME256, CME506, CME656, CME806, CME1056 Operating instructions

-

Scotsman KBT42 - Use with ID150 and C0322, C0522, C0722, N0422, N0622, N0922, N1322 Operating instructions

-

IMI Cornelius, Inc. IACS224E50 Installation guide

IMI Cornelius, Inc. IACS224E50 Installation guide

-

IMI Cornelius, Inc. IWCS227E60 Installation guide

-

Scotsman Nugget Ice & Dispenser Kit KDIL-N-CFF - 17-3136-01 Operating instructions

-

IMI Cornelius, Inc. PR150 BC Operating instructions

IMI Cornelius, Inc. PR150 BC Operating instructions

-

Scotsman KBT34-2X - 17-3229-01 Operating instructions