62.9719 Page 7

6. INSTALLATION

Please refer to §1. for implementation and responsibility.

6.1 ELECTRICAL CONNECTION

Check and ensure that the mains voltage matches the voltage

given on the specification plate. The specification plate is

located on the left-hand side of the right-hand console.

Important

• The electrical connections must satisfy local house installa-

tion regulations.

• The valid, national, local regulations of the electricity-sup-

ply inspection authorities responsible must be observed.

• The corresponding arrangements must be made on-site for

the earthing connection and fuse protection for the appli-

ances. The appliance must be earthed.

• At the place marked with a , the appliance must be

connected to a potential equalization system with a mini-

mum conductor cross-section of 10 mm² (0.016 inch²). The

correspondingly marked connection terminal must be used

for this purpose. When set up in block configuration, all

appliances must be interconnected as potential equalisa-

tion.

• The appliance is designed for connection to a fixed power

supply. If the appliance is installed against a wall, the sup-

ply must pass through the prescribed place of the rear

panel or through a prescribed place of the inner side panel.

• After the appliance has been assembled, the shock protec-

tion of all live parts and insulated parts must be checked.

• An isolating device working on all poles and with a mini-

mum contact opening of 3 mm (0.12“) must be provided on

site.

• When faulty-current circuit breakers are used, ones for a

rated breaking current of 30 mA or more should be used.

• When using faulty-current circuit breakers (both existing

faulty-current circuit breakers in the installation as well as

for new installations), only one pulse-current sensitive

faulty-current circuit breaker may be connected in series on

these appliances.

• All field wiring conductors shall be suitable rated for the

maximal voltage involved (300V / 600 V).

Connection

Each appliance is accompanied by a complete connection and

wiring schematic. This contains full details of the technical

specifications (electrical rating, voltage, amperage, etc.). The

power connection is via an on-site electric cable, an appropri-

ate length of which protrudes from the floor or the wall.

The terminal box is located under the cover (A) in the right

console. The right-hand cover is marked with a symbol.

The cover must be removed to connect the appliance to the

electricity supply. This is done as described in §5.1.2. and

§5.2.2. respectively. The power cable comes out of the floor or

the wall inside the appliance. The power connection must be

made in accordance with the connection diagram. The cover

must be correctly refitted after the power connection has been

made.

Additional terminals for power optimizing systems (EO/SI) or

potential-free contacts (PK) for the external monitoring of the

appliance are available as options. These connections are

made according to the electrical schematic

The connection bolts on the frame are marked as follows:

Earth conductor Potential equalization

POWER OPTIMIZATION SYSTEMS (EO)

Appliances in major kitchens are frequently attached to electri-

cal power monitoring systems. The purpose of these systems

is to avoid the occurrence of current load peaks when the

appliances are simultaneously under full load. In this way, both

investment costs in the electricity network as well as, to a

greater degree, connection charges for electricity can be

saved. The following methods are used to achieve this:

• The appliances are connected to a power grid maximum

current monitor which arranges for individual appliances to

switch off in accordance with the power ceiling set.

• Power limiting systems are a more sophisticated method.

Current peaks are eliminated without any noticeable influ-

ence on cooking processes. On the basis of a continuous

comparison of the actual current consumption of the entire

establishment with a predetermined maximum current limit,

appliances are switched on and off for very short times in

accordance with the program data specific to the appli-

ances.

Wiring

Power monitoring devices require the following information

from all appliances:

• Position of the ON-OFF switch

• Operating status of thermostats, electronic controllers, etc.

If an appliance has several controllers, each circuit is allo-

cated its own control circuit.

This information is passed on to the monitoring device via 4

different lines.

Line A signalizes the switching status (heating on or off) of

the appliance (24÷230V) and is connected to the

secondary side of the power switch.

Line B signalizes the operating status (heating on or off) of

the appliance and is connected to the thermostat or

controller pcb respectively. Lines A and B may not be

of different voltages.

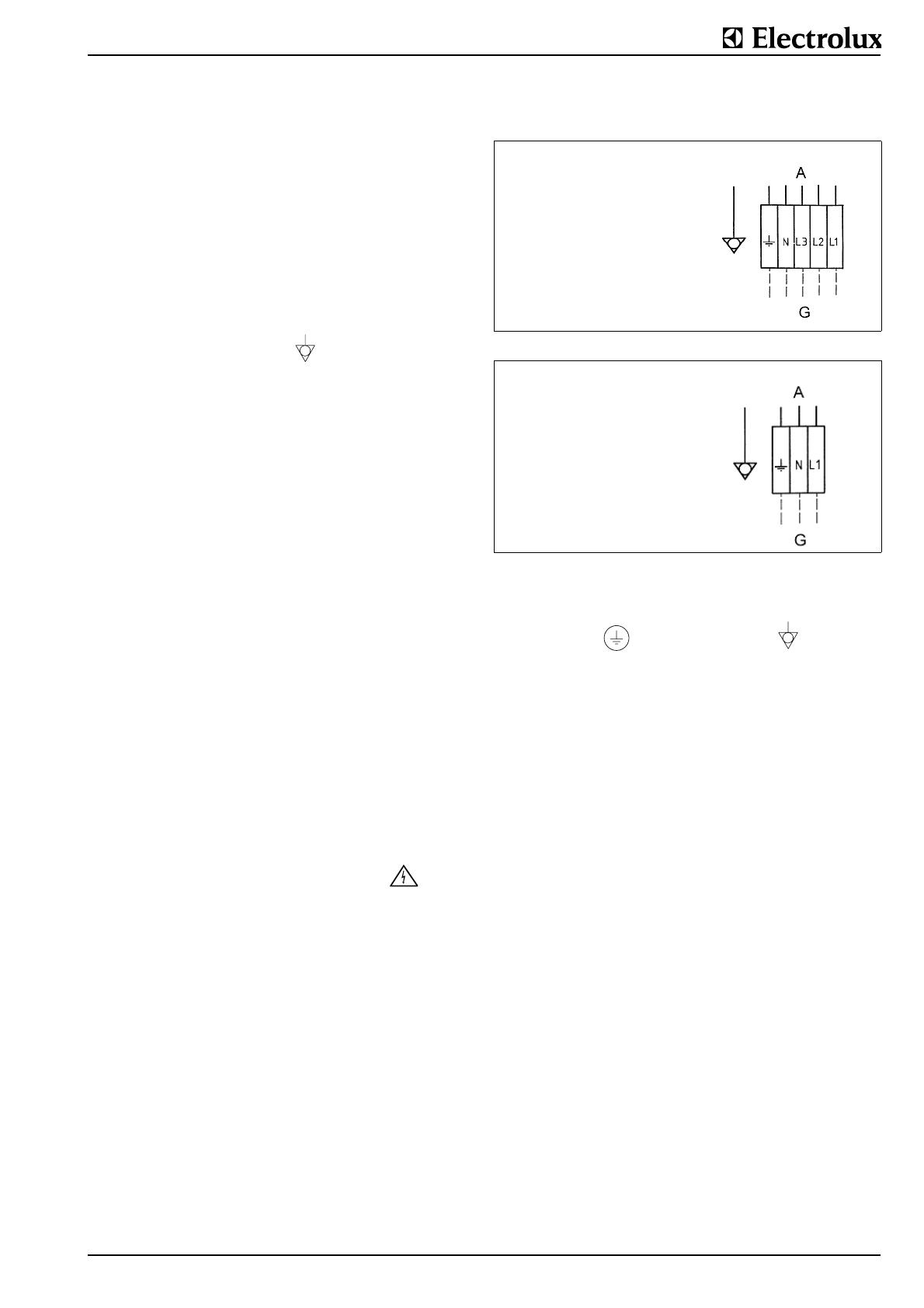

Mains connection for

electrically heated appliances

A = Mains connection

G = Appliance outputs

Fig.6 Mains connection 200-440V/3~N

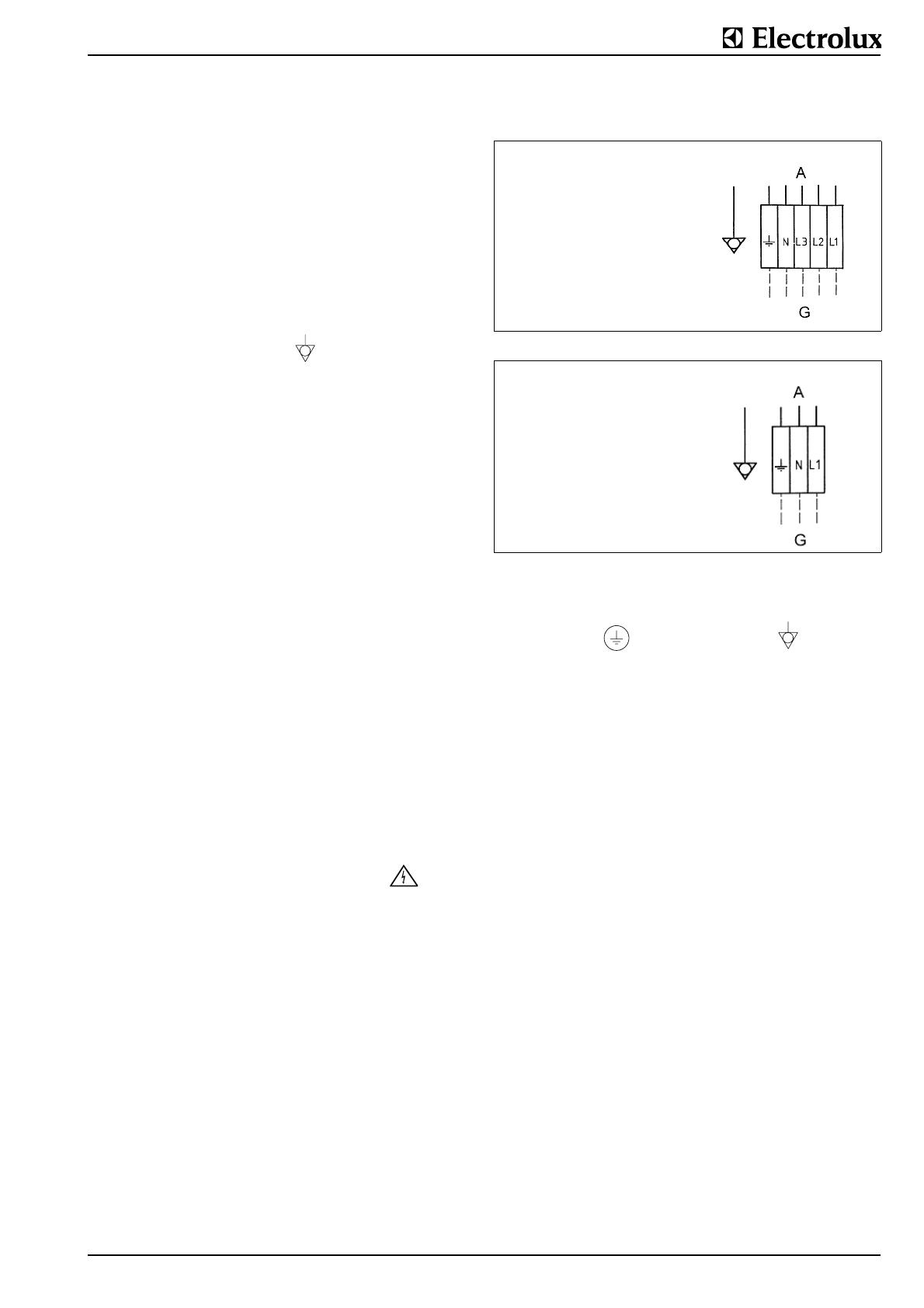

Mains connection for

appliances without stirring

systems with steam or hot

water

A = Mains connection

G = Appliance outputs

Fig.7 Mains connection 200-250V/1~N