Page is loading ...

Instruction

Manual

2-Component Sensor

Fz, Mz

Type 9345B, 9365B

9345B_002-553e-03.23

Foreword

9345B_002-553e-03.23 Page 1

Foreword

Thank you for choosing a Kistler quality product character-

ized by technical innovation, precision and long life.

Information in this document is subject to change without

notice. Kistler reserves the right to change or improve its

products and make changes in the content without obliga-

tion to notify any person or organization of such changes

or improvements.

© 2011 … 2023 Kistler Group. Kistler Group products are

protected by various intellectual property rights. For more

details visit www.kistler.com. The Kistler Group includes

Kistler Holding AG and all its subsidiaries in Europe, Asia,

the Americas and Australia.

Kistler Group

Eulachstraße 22

8408 Winterthur

Switzerland

Tel. +41 52 224 11 11

info@kistler.com

www.kistler.com

2-Component Sensor Fz, Mz, Type 9345B, 9365B

Page 2 9345B_002-553e-03.23

Content

1. Introduction............................................................................................................................... 4

2. Important Notes ........................................................................................................................ 5

2.1 For Your Safety ................................................................................................................ 5

2.2 Unpacking ....................................................................................................................... 6

2.3 Notes on Using the 2-Component Sensor .......................................................................... 6

3. General Description ................................................................................................................... 7

3.1 What is the Purpose of the 2-Component Sensor? ............................................................. 7

3.2 Design and Functional Principle of the 2-Component Sensor Type 9345B and 9365B .......... 8

4. Installation and Startup .............................................................................................................. 9

4.1 Important Information ...................................................................................................... 9

4.2 Installation of the 2-Component Sensor ............................................................................ 9

4.3 Overview of Adaptation Possibilities Type 9345B and 9365B............................................ 11

4.3.1 Adaptation A: Installation in Shaft with Adapter for Shaft Journal with Pin............ 14

4.3.2 Adaptation B: Installation in Shaft with Adapter Flange ........................................ 16

4.3.3 Adaptation C: Installation in Shaft with Integrated Flange .................................... 18

4.3.4 Adaptation D: Deep Drawing Tool with Centric Ejection Tool ............................... 20

4.3.5 Adaptation E: Punch with Centric Ejection Bore ................................................... 21

4.3.6 Adaptation F: Riveting Tool ................................................................................ 22

4.3.7 Adaptation G: Adapter Flange for Wrenches with External Square Head ............... 23

4.3.8 Adaptation H: Screw Plate with Spring Assembly ................................................. 24

4.3.9 Adaptation I: Desktop Installation with Mounting Flange .................................... 25

4.4 Basic Circuit and Cabling of the Measuring Chain ............................................................ 27

4.4.1 Notes on Cabling the Measuring Chain ............................................................... 27

5. Operation ................................................................................................................................ 29

5.1 Setting the Charge Amplifier ........................................................................................... 29

5.2 Polarity of the Measuring Signal ...................................................................................... 29

5.3 Resolution of the Measuring Signal ................................................................................. 30

5.4 Quasistatic Measurements .............................................................................................. 30

6. Calibration and Maintenance ................................................................................................... 33

6.1 In-Situ Calibration of Force Sensors ................................................................................. 33

6.1.1 Working Point Calibration by Peak Value Comparison for Fz ................................ 33

6.1.1.1 Test System Requirements ................................................................... 34

6.1.1.2 Reference 2-Component Sensor (2CS) Installation ................................ 34

6.1.1.3 Load Application ................................................................................. 35

6.1.1.4 Calibration Process Worksheet ............................................................. 36

6.1.2 Working Point Calibration by Peak Value Comparison for Mz ............................... 38

6.1.2.1 Test System Requirements ................................................................... 38

6.1.2.2 Reference 2-Component Sensor (2CS) Installation ................................ 39

6.1.2.3 Load Application ................................................................................. 39

6.1.2.4 Calibration Process Worksheet ............................................................. 41

6.2 Kistler Calibration Service ................................................................................................ 44

6.3 Maintenance Work......................................................................................................... 44

Content

9345B_002-553e-03.23 Page 3

7. Troubleshooting ...................................................................................................................... 45

7.1 Fault-Finding and Remedy .............................................................................................. 45

7.2 Repairing the 2-Component Sensor ................................................................................. 46

8. Technical Data ......................................................................................................................... 47

8.1 2-Component Sensor Type 9345B, 9365B ....................................................................... 47

8.2 Dimensions Type 9345B and 9365B ................................................................................ 49

8.3 Dimensions Included Accessories ..................................................................................... 50

8.3.1 Centering Ring for Type 9345B and 9365B ......................................................... 50

8.4 Dimensions of Accessories (Optional) .............................................................................. 51

8.4.1 Flange for Type 9345B and 9365B ...................................................................... 51

8.5 Accessories Included ....................................................................................................... 52

8.6 Accessories (Optional) .................................................................................................... 52

9. Annex...................................................................................................................................... 53

9.1 Glossary ......................................................................................................................... 53

9.2 Measurement Uncertainty .............................................................................................. 56

9.3 Linearity ......................................................................................................................... 57

9.4 Frequency Range............................................................................................................ 59

9.5 Influence of Temperature ................................................................................................ 60

9.6 Index ............................................................................................................................. 62

Total Pages 63

2-Component Sensor Fz, Mz, Type 9345B, 9365B

9345B_002-553e-03.23 Seite 4

1. Introduction

Please take the time to thoroughly read this instruction

manual. It will help you with the installation, maintenance,

and use of this product.

To the extent permitted by law Kistler does not accept any

liability if this instruction manual is not followed or prod-

ucts other than those listed under Accessories are used.

Kistler offers a wide range of products for use in measuring

technology:

Piezoelectric sensors for measuring force, torque, strain,

pressure, acceleration, shock, vibration and acoustic

emission

Strain gage sensor systems for measuring force and

moments

Piezoresistive pressure sensors and transmitters

Signal conditioners, indicators and calibrators

Electronic control and monitoring systems as well as

software for specific measurement applications

Wireless data transmission modules

Kistler also develops and produces measuring solutions for

the application fields of engines, vehicles, manufacturing,

plastics and biomechanics sectors.

Our product and application brochures will provide you

with an overview of our product range. Detailed data

sheets are available for almost all products.

If you need additional help beyond what can be found ei-

ther on-line or in this manual, please contact Kistler's ex-

tensive support organization.

Important Notes

9345B_002-553e-03.23 Page 5

2. Important Notes

It is essential for you to study the following notes, which

are for your personal safety during work, and to ensure

long term, fault-free operation of this product.

2.1 For Your Safety

This product has been thoroughly tested and has left

the factory in a perfectly safe condition. In order to

maintain this condition and ensure safe operation, com-

pliance is required with the instructions and warning

notes in this instruction manual.

The 2-component sensor must be installed, operated

and maintained only by persons who are familiar with

this product and who are adequately qualified for the

work involved.

If it is to be assumed that safe operation is no longer

possible, the equipment must be shut down and made

safe against being accidentally started up.

Safe operation must be assumed to be no longer possi-

ble when

the 2-component sensor shows visible signs of dam-

age,

the 2-component sensor has been overloaded,

the 2-component sensor is no longer operating,

has been in lengthy storage under unsuitable condi-

tions and,

has been subjected to rough transport conditions.

Install the 2-component sensor in position as prescribed.

Details can be found in Section 4.2.

Secure all parts mounted on the 2-component sensor

according to anticipated moments!

2-Component Sensor Fz, Mz, Type 9345B, 9365B

Page 6 9345B_002-553e-03.23

2.2 Unpacking

Check all packaging for transport damage. Report any such

damage to the transporters and to the authorized Kistler

distributor.

Check accessories delivered (see Section 8.5) before first

use of the equipment. Report any missing parts to the au-

thorized Kistler distributor.

2.3 Notes on Using the 2-Component Sensor

The 2-component sensor must be used only under the

environmental and operating conditions specified.

With piezoelectric sensors, insulation resistance is of

crucial importance; it must be approx. 5·1013 Ω (but not

less than 1013 Ω).

In order to preserve this value, all plug-and-socket con-

nections must be kept absolutely clean and dry. The in-

sulation resistance can be measured with the insulation

tester Type 5493.

Protect the connector of the 2-component sensor

against contamination and do not touch it with your

fingers (connector front). Fit the cover supplied over the

connector when it is not in use.

A high-insulation cable is used to connect the

2-component sensor to a charge amplifier. Once at-

tached, it should if possible remain connected to the

sensor. Use only specified connecting cables.

Protect the 2-component sensor when it is not in use by

storing it in its original packaging.

General Description

9345B_002-553e-03.23 Page 7

3. General Description

3.1 What is the Purpose of the 2-Component Sensor?

2-component sensors are used to measure dynamic and

quasistatic torques.

The 2-component sensor measures forces as well as mo-

ments. Therefore it is possible to record a second process

value at the same time or successively.

The main areas of application are:

Calibration

Calibration of manual torque wrenches

Torque setting of pneumatic screwdrivers

Research and Development

Measurement of irregular motion and torsional

vibrations on small servo and stepper motors

Measurements of starting torques on electric motors

Measurements on fluid and slipping clutches

Viscosity measurements

Measuring the coefficient of friction of bearings

Designing torsion springs and damping elements

Development of locks and rotary switches

Lubricant development

Biomechanics and ergonomic measurements

Production Engineering

Monitoring automated screwing processes

Monitoring boring and cutting processes

Quality Control

Testing screw connections

Torsion testing of springs

Testing the torque characteristics of hinges

Testing rotary switches

Testing of screw caps

The hole pattern of the bilaterally integrated flange and the

optional accessories enable Kistler 2-component sensors to

be adapted to almost any task. Bilateral centering seats and

the included centering rings assist in the precise axial appli-

cation of torque. A centric bore can be used for shaft bush-

ing.

Kistler 2-component sensors are distinguished by high

rigidity and a high natural frequency. The effective useful

frequency range is, however, determined by the natural

frequency of the entire test arrangement. The high resolution

enables the tiniest dynamic changes to be measured, even

where large torques are involved.

Kistler 2-component sensors are calibrated prior to

delivery and can be used immediately.

2-Component Sensor Fz, Mz, Type 9345B, 9365B

Page 8 9345B_002-553e-03.23

3.2 Design and Functional Principle of the 2-Component Sensor Type

9345B and 9365B

The special patented design of Kistler 2-component sensors

is characterized in that the sensor is axially preloaded. Par-

ticularly in the case of small forces and moments, this pre-

loading of the sensor is a requirement for good linearity of

the output signal.

The 2-component sensor is rust-resistant, welded seal-tight

and the connection with a cable connected is protected

against the ingress of water spray (Condition: O-ring cor-

rectly located in the cable connector). In addition, the con-

nector is protected against mechanical damage by the con-

nector protector Art. No. 3.414.366 which is included.

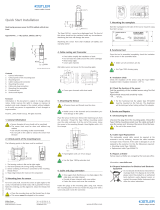

Fig. 1: Construction

1 Piezo element

2 Connection

3 Inner centering seat D2

4 Mounting thread K

5 Through-hole D3

The 2-component sensor contains a ring-shaped pair of

quartz crystal plates as an integrated sensor element sensitive

to pressure. The pressure-sensitive direction of the crystal

plates is arranged so that a charge signal proportional to the

magnitude of the compressive force is produced.

In addition there are quartz disks in a circular arrangement

built in. The shear-sensitive direction of the quartz disks is

tangential, so that a charge signal proportional to the

torque is fed out in a parallel circuit.

A negative charge produces a positive voltage at the out-

put of the charge amplifier and vice versa.

Measurement is made practically without displacement as a

result of the piezoelectric measuring principle and the high

rigidity of the 2-component sensor.

Installation and Startup

9345B_002-553e-03.23 Page 9

4. Installation and Startup

4.1 Important Information

The 2-component sensor Types 9345B and 9365B are pre-

cision instruments whose specifications are fully utilized on-

ly when they are correctly employed and only when they

are carefully handled. Please comply with the following:

Never let the 2-component sensor drop or expose it to

hard impacts! The peak force of such a shock can cause

irreparable damage.

Do not use a hammer to position the work pieces, as

impacts of this kind can also cause damage!

The following sections will provide you with information on

how to mount the 2-component sensor and on setting up a

measuring chain.

4.2 Installation of the 2-Component Sensor

Please comply with the following information con-

cerning the correct mounting of the 2-component sensor:

The 2-component sensor must be installed only by per-

sons who are familiar with it and are adequately quali-

fied for this work.

Angular seating will cause unwanted bending moments

which can overload and even destroy the sensor. The

contact surfaces of adapter flanges must be machined

perfectly flat. If the 2-component sensor is used as a

calibration element, the adjoining surfaces must have a

roughness of Ra ≤0,8 µm (N6), otherwise a roughness

of Ra ≤6,3 µm (N9) will suffice. Before mounting, the

contact surfaces must be thoroughly cleaned.

The 2-component sensor is designed for measuring forc-

es in the longitudinal axis as well as Moments on the ax-

is. Although additional bending moments, tensile, com-

pressive and shear forces can be tolerated by the

2-component sensor up to a certain extent, these should

be avoided if possible.

2-Component Sensor Fz, Mz, Type 9345B, 9365B

Page 10 9345B_002-553e-03.23

The force and moment must only be applied by the flange

surfaces at the top and bottom sides of the 2-component

sensor. The force is thereby transferred via the front-side

flanged-on adaptation parts (strength class at least 12.9) or

mounting parts with appropriate contact sur

faces. The

length of the screws must be selected so that the depth of

the blind hole in the 2-component sensor flange is fully

utilized. The screws must not, however, protrude against

the base of the blind hole.

Fig. 2: Mounting Fig. 3: Type 9345B, 9365B

Installation and Startup

9345B_002-553e-03.23 Page 11

When firmly tightening the screw connections, the fork

wrench must only be used to hold the flange on that

side where the screw connections are being tightened!

If the opposite side is held, there is a risk that the screw

connection in the 2-component sensor will loosen caus-

ing

the latter to turn within itself. This will alter the

internal preload resulting in the calibration being lost,

and possibly rendering the 2-component sensor unusa-

ble for precise torque measurement! In this event, the 2-

component sensor must again be properly preloaded and

recalibrated!

Tightening Torques MA for Fillister-Head Screws

Type 9345B M5x12 MA = 4 N·m

Type 9365B M8x20 MA = 21 N·m

We recommend the use of screws from the strength class

12.9 upwards.

The connecting cable must be connected only after the

2-component sensor has been installed. Since contamina-

tion on the connector contacts can lead to sizeable measur-

ing errors (in particular drift), the plastic protective connector

covers on the sensor as well as on the cable should always

remain screwed in position during mounting! In particular,

the greatest care must be exercised in dirty environmental

conditions.

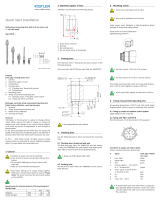

4.3 Overview of Adaptation Possibilities Type 9345B and 9365B

Fig. 4: Overview of mounting possibilities

Press

2-Component

Se

nsor

Fz

Ram

Punch

Table mo

unting

Mz

2-Component Sensor Fz, Mz, Type 9345B, 9365B

Page 12 9345B_002-553e-03.23

Mounting in Press Punch

A

Fig. 5: Mounting in press punch

Mounting in Press Ram

B C

Fig. 6: Mounting in press ram

Shaft Installation

Installation in shaft with

adapter for shaft journal

with pin

Instal

lation in shaft with

adapter flange

Ins

tallation in s

haft with

integrated flange

Adapter for straight

bore recess with pin

Installation and Startup

9345B_002-553e-03.23 Page 13

Table Mounting

D E F

G H I

Fig. 7: Table mounting

These mounting possibilities are described in the following

pages.

2-Component Sensor Fz, Mz, Type 9345B, 9365B

Page 14 9345B_002-553e-03.23

4.3.1 Adaptation A: Installation in Shaft with Adapter for Shaft Journal with Pin

Fig. 8: Mounting example A

Fz = Compressive force [N]

Mz = Torque [N·m]

Applied via shaft with tool shank or cylinder bore

and flange adapter with pin (pinned during installa-

tion).

Fs = Transverse force [N]

This "disturbance force" represents the shear forces

and bending moments acting on the reaction torque

sensor. The maximum permissible values are listed in

the table in the "Technical data" on page 48 (shear

force max. Fx,y).

MA

Fs

Installation

clearance

S

Adapter for shaft journal

with pin

Customized tool

adapter

Centering rings

(included access

ories)

Adapter for cylinder

bore recess with pin

Mz

Pinned during installation

Pinned during installation

Fz

MA

Installation and Startup

9345B_002-553e-03.23 Page 15

Centering rings (Art.-No. 3.420.180/181) on 2-compo-

nent sensor into the centering bores on the reaction

torque sensor up to the mechanical limit stop.

Tightening torques MA for socket head screws

Type 9345B M5x12 MA = 4 N·m

Type 9365B M8x20 MA = 21 N·m

We recommend using screws with at least property

class 12.9, see also Section 4.2.

Clearance S between the end of the mounting screw

and the base of the threaded blind bore in the flange of

the 2-component sensor. The installation clearance

should not be less than 0,5 mm or half a screw turn.

Similarly, the depth of the seating for the centering

rings recess in the adapter must also have a clearance of

at least approx. 0,5 mm.

2-Component Sensor Fz, Mz, Type 9345B, 9365B

Page 16 9345B_002-553e-03.23

4.3.2 Adaptation B: Installation in Shaft with Adapter Flange

Fig. 9: Mounting example B

Fz = Compression force [N]

Mz = Torque [N·m]

Applied via adapter flange for flat mounting in a

shaft.

Fs = Transverse force [N]

This "disturbance force" represents the shear forces

and bending moments acting on the reaction torque

sensor. The maximum permissible values are listed in

the table in the "Technical data" on page 48 (shear

force max. Fx,y).

Adapter flange for

flat m

ounting in

shaft

Customized centering

ring (g6)

Customized center-

ing ring (g6)

M

z

Installation

clearance S

Fs

M

A

Fz

M

A

Installation and Startup

9345B_002-553e-03.23 Page 17

Centering rings (customer specific, fit g6) press into the

centering bores on the 2-component sensor up to the me-

chanical limit stop.

Tightening torques MA for socket head screws

Type 9345B M5x12 MA = 4 N·m

Type 9365B M8x20 MA = 21 N·m

We recommend using screws with at least property

class 12.9, see also Section 4.2.

Clearance S between the end of the mounting screw

and the base of the threaded blind bore in the flange of

the 2-component sensor. The installation clearance

should not be less than 0,5 mm or half a screw turn.

Similarly, the depth of the seating for the centering

rings recess in the adapter must also have a clearance of

at least approx. 0,5 mm.

2-Component Sensor Fz, Mz, Type 9345B, 9365B

Page 18 9345B_002-553e-03.23

4.3.3 Adaptation C: Installation in Shaft with Integrated Flange

Fig. 10: Mounting example C

Fz = Compression force [N]

Mz = Torque [N·m]

Applied via shaft with integrated flange and center-

ing pin.

Fs = Transverse force [N]

This "disturbance force" represents the shear forces

and bending moments acting on the reaction torque

sensor. The maximum permissible values are listed in

the table in the "Technical data" on page 48 (shear

force max. Fx,y).

M

z

Installation

clearance S

Installation

clearance S

Fs

M

A

Centering pin g6 on

customized shaft

Fz

MA

/