Page is loading ...

INSTALLATION MANUAL

BX-246V

SLIDING

GATES OPERATORS

English

EN

119BF03EN

ENGLISH

p.

2

-

Manual code:

119BF03

119 B F03 ver.

2

04/2014

© 09/2010 © CAME cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.a. to notify said changes.

Foreword

• This product should only be used for the purpose for which it was

explicitly designed. Any other use is considered dangerous. CAME Cancelli

Automatici S.p.A. is not liable for any damage resulting from improper,

wrongful or unreasonable use • Keep these warnings with the installation

and use manuals issued with the automation system.

Before installing

(preliminary check: in case of a negative outcome, do not proceed until you

have complied with the safety requirements)

• Check that the part you intend to automate is in good mechanical

condition, balanced and aligned, and that it opens and closes properly.

Make sure that proper mechanical stops are already in place • If the

operator will be installed at a height of less than 2.5 m from the ground

or other access level, check whether you will need any protections and/

or warnings • Any leaves fi tted with pedestrian entrances onto which you

will install an operator must have a blocking mechanism when the leaf is

in motion • Make sure that the opening of the automated leaf is not an

entrapment hazard as regards any surrounding fi xed parts • Do not mount

the operator upside down or onto any elements that may fold under its

weight. If needed, add suitable reinforcements at the points where it is

secured • Do not install onto leaves not on level ground • Check that any

lawn watering devices will not wet the operator from the bottom up.

Installation

• Carefully section o the entire site to prevent unauthorised access,

especially by minors and children • Be careful when handling operators

that weigh more than 20 kg. In case, procure the tools required for safe

gate movement • All opening commands (buttons, key selectors, magnetic

readers etc.) must be installed at least 1.85 m from the perimeter of the

area of turnstile movement, or where they cannot be reached from outside

through the turnstile. In addition, direct controls (button, touch sensitive

keys, etc.) must be installed at a height of at least 1.5 m and must not

be accessible to the public • All ‘hold-to-run’ commands must be placed

where the moving gate leaves, transit areas and driveways are completely

visible • If missing, apply a permanent label that shows the position of the

release mechanism • Before delivering to the user, check that the system

is EN 12453 (impact test) standard compliant. Make sure that the operator

has been properly adjusted and that the safety and protection devices as

well as the manual release are working properly • Where necessary and in

plain sight, apply the Warning Signs (e.g. gate plate)

Special instructions and advice for users

• Keep the gate’s area of operation clean and clear of any obstacles. Check

that there is no vegetation in the area of operation of the photocells and

that there are no obstacles in the area of operation of the operator • Do

not allow children to play with the fi xed command devices, or in the gate’s

area of operation. Keep any remote control devices (i.e. transmitters) or any

control devices away from children as well, to prevent the operator from

being activated accidentally •The operator is not designed to be used by

persons (including children) whose physical, sensorial or mental capacities

are limited, or who are lacking in experience or knowledge, unless said

persons can be supervised or given instructions regarding using the

operator by a person responsible for their safety • Frequently check the

system, to see whether any anomalies or signs of wear and tear appear

on the moving parts, on the component parts, on the securing points, on

the cables and any accessible connections. Keep any joints (i.e. hinges)

lubricated and clean, and do the same where friction may occur (i.e. slide

rails) • Perform functional tests on photocells and sensitive edges every

six months. To check that the photocells work, pass an object in front of

them during closing. If the operator reverses the direction of movement or

comes to a halt, the photocells work correctly. This is the only maintenance

operation that must be carried out while the operator is live. Ensure that the

glass on the photocells is kept clean (use a cloth slightly moistened with

water; do not use solvents or any other chemicals as these could damage

the devices) • If the system requires repairs or modifi cations, release the

operator and do not use it until safety conditions have been restored • Cut

o the power supply before releasing the operator for manual openings

and before any other operation, to prevent dangerous situations. Read the

instructions • If the power cable is damaged, it must be replaced by the

manufacturer or the technical assistance service or by a person with a

similar qualifi cation so as to prevent any risks • It is STRICTLY FORBIDDEN

for users to perform OPERATIONS THEY ARE NOT EXPLICITLY REQUIRED

AND ASKED to do in the manuals. For repairs, adjustments and extraordinary

maintenance, CONTACT THE SPECIALIST TECHNICAL SERVICE CENTRE •

On the periodic maintenance log, note down the checks you have done.

Special instructions and advice for all

• Avoid working near the hinges or moving mechanical parts • Stay clear

of the gate’s area of operation when in motion • Do not resist the direction

of movement of the gate; this may present a safety hazard • At all times

be extremely careful about dangerous points that must be indicated by

proper pictograms and/or black and yellow stripes • When using a selector

or command in ‘hold-to-run’ mode, keep checking that there are no people

in the area of operation of the moving parts. Do this until you release the

command • The gate may move at any time without warning • Always cut

the power when cleaning or performing maintenance.

CAUTION!

important personal safety instructions:

READ CAREFULLY!

Danger of hand crushing

Danger - live parts

No transit during the manoeuvre

Danger of crushing feet

#

#

p.

3

-

Manual code:

119BF03

119 B F03 ver.

2

04/2014

© 09/2010 © CAME cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.a. to notify said changes.

ENGLISH

This symbol shows parts which must be read with care.

This symbol means the parts which describe safety issues.

This symbol tells you what to tell the end-user.

The BX 246V operator is designed to operate sliding gates in residential and apartment-block settings.

Any installation and use other than that specified in this manual is forbidden.

"IMPORTANT INSTALLATION SAFETY INSTRUCTIONS"

“WARNING: IMPROPER INSTALLATION MAY RESULT IN SERIOUS HARM. PLEASE FOLLOW ALL INSTALLATION INSTRUCTIONS”

“THIS MANUAL IS INTENDED ONLY FOR PROFESSIONAL INSTALLERS OR OTHER COMPETENT INDIVIDUALS”

The operator is built partly with cast aluminium inside of which operates an irreversible, electro-mechanical gearmotor, and partly with an

ABS plastic coating inside of which there is an electronic card with a transformerand the two emergency-batteries housing bracket.

Came Cancelli Automatici employs an ISO 9001 certified quality-management system and an ISO 14001 environmental-management

system. Came engineers and manufactures entirely in Italy in compliance with the applicable safety regulations.

This product is compliant with: see statement of compliance.

For intensive use and apartment-blocks. maximum weight and length of the gate are 600 kg and 18 m respectively.

Power supply to control panel: 230 V AC 50/60 Hz

Motor power supply: 24 V DC

Maximum draw: A 10

Power: 400 W

Reduction ratio: 1/33

Thrust: 700=N

Maximum speed.: 18.5 m/min

Duty cycle: service intensive

Protection rating: IP54

Insulation class: I

Weight: 15 kg

Legend of symbols

Intended use

Intended use and limits to use

Technical data

Limits to use

Description

Automation

Legislative references

(mm)

9

3

4

2

5

6

7

10

11

1

2

8

ENGLISH

p.

4

-

Manual code:

119BF03

119 B F03 ver.

2

04/2014

© 09/2010 © CAME cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.a. to notify said changes.

Dimensions

Description of parts

1- Top cover

2 - Adjustments cover carter

3 - Electric card rack

4 - Endstop tabs

5 - Electronic card

6 - Front cover of the control panel

7 - - Access fl ap for reaching the release

8 - Anchoring plate

9 - Fastening bolts

10 - Plate for fastening bolts

11 - Fastening nut

Installation must be carried by skilled, qualified technicians in accordance with current regulations.

Preliminary checks

Before beginning to install, do the following:

• Make sure the gate is stable, and that the castor-wheels are properly greased and in good working order.

• The floor guide must be well-fastened to the ground, completely on the surface and free of any irregularities that may obstruct the

gate movement.

• The upper guide-sleds must not cause friction.

• Make sure there are opening and closing strike plates.

• Make sure that the point where the gearmotor is fastened is in an impact-free zone, and that the surface is solid;

Set up a suitable omnipolar cut-off device, with distances greater than 3 mm between contacts, wit sectioned power source;

• Check that any connections inside the container (made for continuity purposes of the protective circuit) be fitted with extra

insulation compared to other internal conductive parts;

• Set up proper conduits and electric cable raceways, making sure these are protected from any mechanical damage.

Installation

3

1

8

2

6

6

7

9

10

10

4

5

11

p.

5

-

Manual code:

119BF03

119 B F03 ver.

2

04/2014

© 09/2010 © CAME cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.a. to notify said changes.

ENGLISH

Make sure you have all the tools and materials needed to carry out the installation in total safety and in accordance with current

regulations. The figure shows some examples of the tools needed by installers.

N.B. If cables are of a different length than that shown in the table, determine the cable section based on the actual draw and the

number of connected devices and according the what is set forth in the CEI EN 60204-1 code of regulations.

For connections featuring several loads on the same line (i.e. sequential ones), the dimensions shown on the table must be reconsidered

according to the total draw and actual distances. When connecting products not featured in this manual, only refer to the literature

accompanying such products.

5.3 Cable types and minimum thickness

Connection for Cable type

Cable length

1 < 10 m

Cable length

10 < 20 m

Cable length

20 < 30 m

230 V power supply to control panel

FROR CEI

20-22

CEI EN

50267-2-1

3G x 1.5 mm

2

3G x 2.5 mm

2

3G x 4 mm

2

Flashing light 2 x 0.5 mm

2

2 x 1 mm

2

2 x 1.5 mm

2

Photocell transmitters 2 x 0.5 mm

2

2 x 0.5 mm

2

2 x 0.5 mm

2

Photocell receivers 4 x 0.5 mm

2

4 x 0.5 mm

2

4 x 0.5 mm

2

Accessories power source 2 x 0.5 mm

2

2 x 0.5 mm

2

2 x 1 mm

2

Safety and command devices 2 x 0,5 mm

2

2 x 0.5 mm

2

2 x 0.5 mm

2

Antenna connection RG58 max. 10 m

Tools and equipment

1) BX 246 Operator

2) Rack

3) Antenna

4) Flashing light

5) Key-switch selector

6) Photocell

7) Junction pit

8) Mechanical stop plates

9) Guide slide

10) Endpoint strip

11) Sensitive safety edge

Standard installation

ENGLISH

p.

6

-

Manual code:

119BF03

119 B F03 ver.

2

04/2014

© 09/2010 © CAME cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.a. to notify said changes.

- Dig a pit at the end of the gate (see measurement quotas in drawing).

Set up the necessary corrugated tubing for connections coming from the junction pit.

N.B. the number of tubes depends on the type of installation and accessories used.

The following illustrations are just examples, in that, the space for securing the operator and accessories varies depending on

the overall measurements. It is up to the installer to choose the most suited solution.

Junction pit-box

Fastening the plate and fi tting the operator

Tubes for electrical cables

to pass through

- Set up the anchoring plate, by threading the bolts and tightening them with the supplied nuts and washers. Extract the pre-shaped

brackets, using a screwdriver or pliers.

Position the plate above the grille. Warning! The tubes need to be threaded through the pre-set holes.

- Prepare a foundation box that is larger than the anchoring plate and fi t it into pit. The wooden form must protrude from the ground by

at least 50 cm.

Insert an iron grille into the wooden form to reinforce the concrete.

H

p.

7

-

Manual code:

119BF03

119 B F03 ver.

2

04/2014

© 09/2010 © CAME cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.a. to notify said changes.

ENGLISH

- For positioning the plate with respect to the rack, see and follow the instructions in the drawing.

Fill the wooden form with concrete and wait at least 24 hrs for it to solidify.

- Remove the wooden frame, use earth to fi ll the pit around the cement block.

- Unscrew the washers and nuts from the bolts. The anchoring plate must be free of any debris, perfectly level and with the bolt threads

completely emerged from the surface.

Insert the electrical cables into the tubes until they protrude by about 400 mm .

ENGLISH

p.

8

-

Manual code:

119BF03

119 B F03 ver.

2

04/2014

© 09/2010 © CAME cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.a. to notify said changes.

- Remove the cover of the gearmotor by turning the lateral screws. Position the gearmotor onto the plate. Warning! The electrical cables

must pass through the inside of the gearmotor box.

- Lift the gearmotor from the anchoring base by between 5 and 10 mm by turning the threaded-steel feet to allow room any later

adjustments between pinion and rack.

- The following illustrations for fastening the rack, are just applicative examples. It is up to the installer to choose the most suitable

solution.

Release the gearmotor (see paragraph on manual release). Rest the rack onto the gearmotor pinion.

Either weld or fasten the rack along the entire length.

To assemble the rack modules, use a spare length of rack and rest it under the joining point and then lock it into place using two

clamps.

Note: If the rack is already installed, proceed directly with adjusting the joining pinion-rack distance.

p.

9

-

Manual code:

119BF03

119 B F03 ver.

2

04/2014

© 09/2010 © CAME cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.a. to notify said changes.

ENGLISH

- Manually open and close the gate and adjust the distance of the pinion-rack coupling by acting on the threaded-steel feet (vertical

adjustments) and the slots (horizontal adjustments). This helps prevent the weight of the gate from bearing down on the operator.

Once adjustments are complete, fasten the assembly with nuts an bolts. Add and fasten the cover after adjustments and electronic

settings on card are both complete.

Feet

Slot

Rack

Pinion

Vertical adjusting

Horizontal adjusting

Rack

Pinion

ENGLISH

p.

10

10 -

Manual code:

119BF03

119 B F03 ver.

2

04/2014

© 09/2010 © CAME cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.a. to notify said changes.

5.7 Manually releasing the gearmotor

- Insert the key into the lock and turn it clockwise, ....

Fastening the endstop strips

Position the endstop tabs onto the rack and fasten them with the 3 mm Allen wrench key. Their position, marks the limit of the gate

runs.

Note: avoid that the gate strikes the mechanical stop, whether when closing or opening.

Mechanical stop

WARNING: opening the

release door prevents the motor

from working.

Trilobed key

Release

handle

... open the inspection gate and turn the release handle counter-clockwise.

p.

11

11 -

Manual code:

119BF03

119 B F03 ver.

2

04/2014

© 09/2010 © CAME cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.a. to notify said changes.

ENGLISH

Power the electronic card with 230 V AC on terminals L-N, with a max frequency of 50/60 Hz.

the command devices and accessories are powered by 24 V. Warning! The accessories must not exceed 35 W overall.

The card is fi tted with an amperometric device which constantly controls motor thrust When the gate runs into an obstacle, the

amperometric sensor immediately detects a thrust overload and triggers and inversion of the gate direction.

- it reopens it when it is closing

(1)

;

- it recloses it when it is opening.

(1)

Warning: in this case, after 3 consecutive obstacle detections, the gate stops when opening and automatic closing is excluded;

for movement to resume press the command button or use the transmitter.

All connections are protected by quick fuses, see table.

The card handles the following functions:

- automatic closing after an opening command;

- obstacle detections when gate is not moving at any point;

- constantly checks proper photocell operation.

- opening/closing;

-opening/closing with maintained action;

- Partial opening;

- total stop.

After detecting and obstacle, the photocells trigger:

- the reopening of the closing gate;

- the partial stop of the gate if it is moving and then automatic closing (if this feature is selected).

After detecting an obstacle, the sensitive edges trigger:

- the reopening of the closing gate;

- the reclosing of the opening gate.

Specifi c trimmers regulate the:

- working time for automatic closing;

- partial opening;

- detection sensitivity of the amperometric device, for both normal gate-runs and slowdowns;

- speed for both normal gate-runs and slowdowns.

FUSE TABLE

to protect: fuses for:

Motor 10 A-F

Electronic board (line) 1.6 A-F

Accessories 1.6 A-F

Command devices 1 A-F

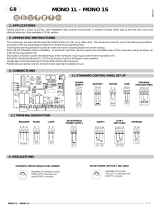

General description

Electronic card

COM

NC

NC

COM

COM

NC

NC

COM

MN

L2T

L1T

017

26

10 11 E1 1 2 3P 5 7 2 C1 C3 C7 C8

TS

+E

-

FC FA

F

LINE FUSE

230V=1.6A-F

120V=3.15A-F

MOTOR FUSE

BX243=8A-F

BX246=10A-F

ACCESSORIES

FUSE

1.6A-F

C. BOARD

FUSE

1A-F

+ RUN S. -+ SLOW S. -+ RUN V. -+ SLOW V. - + A.C.T. -+ PAR.OP. -

ZN5 M1

ZN5U

CONTROL BOARD

PWR

1

C1

C3

C7

C8

ON

2

1 345678910

PROG.

MN

L2T

L1T

LN

017

26

10 11 E1 1 2 3P 5 7 2 C1 C3 C7 C8

TS

+E

-

FC FA

F

2

10

7

9

5

12

17

13

15

16

1

14 43

6

8

11

ENGLISH

p.

12

12 -

Manual code:

119BF03

119 B F03 ver.

2

04/2014

© 09/2010 © CAME cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.a. to notify said changes.

Electrical connections

Gearmotor, endstop and encoder

1) Power source terminals

2) Endstop terminals

3) Motor terminals

4) Encoder terminals

5) Accessories fuse

6) Card fuse

7) radio-code memorisation button

8) Radio code notification LED light

9) 120V power supply LED warning-light

10) Control and notification LED warning-light

11) Features selector-switch

12) Radio-frequency card connector

13) Terminals for connecting the antenna

14) Terminals for connecting accessories and

command devices

15) Motor fuse

16) Line fuse

17) Adjustment Trimmer

Main component parts

Orange

Orange

White

White

Red

Red

Brown

Grey

Black

24 V (DC) motor

with encoder

Closing micro switch

To change installation side,

invert the gearmotor stages (M-N) and endstop ones (FA-FC)

Black

Black

Blue

Blue

Opening micro switch

Description of electrical connections which are already established for left-hand installation

,

.

+

-

%

0

#

#

#

#

43

p.

13

13 -

Manual code:

119BF03

119 B F03 ver.

2

04/2014

© 09/2010 © CAME cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.a. to notify said changes.

ENGLISH

Terminals for powering accessories:

- for 24 V AC at normal operation;

- when emergency batteries are operating;

Overall allowed power: 35 W

Accessories power source

230 V AC powered, 50 / 60 Hz

frequency

Eyelet terminal with screw and washer for ground connection

Stop button (N.C. contact.)

- Gate stop button. Excludes automatic closing. To resume movement press

the command button or transmitter key.

Key switch selector and/or command button (N.O. contact) - Gate

opening and closing command. Pressing the button or turning

the key-switch selector, the gate inverts its movement or stops

depending on selection made on the DIP-switches (see selecting

functions, DIP-switches 2-3)

Key-switch selector and/or opening button (N.O. contact.)

- Partial opening of the gate for pedestrian passage.

Command devices

Warning devices

Gate open warning light Contact rated for:

24 V - 3 W Max.) - Warns of open gate

position, turns o when gate is closed

Movement fl ashing light (Contact range:

24V – 25W max) - Flashes during the gate’s

opening and closing phases.

TX

RX

RX

TX

RX TX

./ # .#

TX

./

#.#

RX

ENGLISH

p.

14

14 -

Manual code:

119BF03

119 B F03 ver.

2

04/2014

© 09/2010 © CAME cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.a. to notify said changes.

Safety devices

"Reopening while closing" (N.C.) Contact

- Input for safety devices like photocells, compliant with

law EN 12978. While the gate is closing, opening the

contact will invert movement until it is fully opened.

(N.C.) "partial stop" contact

- Input for safety devices like photocells, compliant

with law EN 12978. Stops gate if it is moving and then

automatically closes it (if this function is selected).

DIR / DELTAS photocells

DIR / DELTAS photocells

"Reopen when closing" (N.C.) Contact

(N.C.) "partial stop" contact

DELTA photocells

DELTA photocells

DF

#./.#

6 6 .#./#6

DF

6

6

.#

./

#

6

#./.#

#

./

.##

./

.#

./

.#

#

&53)"),%M!

48

48

48

#

.#

DELTA DIR / DELTAS

p.

15

15 -

Manual code:

119BF03

119 B F03 ver.

2

04/2014

© 09/2010 © CAME cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.a. to notify said changes.

ENGLISH

"Reopening when closing" (N.C.) Contact

- Input for safety devices like sensitive

edges, compliant with EN 12978 law.

While the gate is closing, opening the

contact will invert movement until it is

fully opened; if unused,

short-circuit contact 2-C7.

(N.C.) "reclose while opening" contact

- Input for safety devices like sensitive

edges, compliant with EN 12978 law.

While the gate is opening, opening the

contact will invert movement until it is fully

closed; if unused, short-circuit contact

2-C8.

DF with control

card for DFI con-

nections

With each opening and closing command, the card checks the e ciency of the

photocells. Any anomalies in the photocells are notifi ed by the fl ashing PROG LED

on the control panel, and cancels any other command

from the radio transmitter or button.

Electrical connection to work the photocells safety test:

- the transmitter and receiver, must connected as shown in the diagram:

Set Dip-switch 7 to ON to activate the test.

IMPORTANT:

When the safety test feature is activated, the NC contacts - if unused - are excluded on the relative DIP-switches (see chapter on

"selecting features"

Electrical connection to work the photocells safety test

DF with control

card for DFI con-

nections

+ RUN S. -+ SLOW S. -+ RUN V. -+ SLOW V. - + A.C.T. -+ PAR.OP. -

2

1 345678910

ZN5U

PWR

1

C1

C3

C7

C8

+

RUN S. - + A.C.T. -+ PAR.OP. -

ENGLISH

p.

16

16 -

Manual code:

119BF03

119 B F03 ver.

2

04/2014

© 09/2010 © CAME cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.a. to notify said changes.

ADJUSTMENT TRIMMER LIST :

- «A.C.T.» Adjusts opening waiting time. The gate closes automatically once this time-frame has elapsed. The waiting time

may be adjusted from 1 second to 150 seconds.

- «PAR.OP.» Adjusts partial opening of the gate. Pressing the partial opening button connected to 2-3P, the gate opens depending

on the length of the gate

- «SLOW S.» Adjusts the amperometric sensitivity which controls the force generated by the motor during slowdowns; if the

force exceeds the adjusted level, the system intervenes and inverts the direction of travel.

- «RUN S.» Adjusters the amperometric sensitivity which controls the force developed by the motor during movement; if the force

exceeds the adjusted level, the system intervenes and inverts the direction of travel.

- «SLOW V.» Adjusts the gate's endpoint slowdown speed when closing and opening.

- «RUN V.» Adjusts the gate's moving speed when opening and closing.

Function of the LED control warning-light and command and safety devices. :

- «1» Red LED. Normally not lit up.

Warns that the TOTAL STOP button has been engaged.

- «C1» Yellow LED warning-light. Normally not lit up.

Warns of any obstacles between the photocells (these are connected to work

in the REOPEN WHILE CLOSING mode).

- «C3» Yellow LED warning-light. Normally not lit up.

Warns of any obstacles between the photocells (these are connected to work

in the PARTIAL STOP mode).

- «C6» Yellow LED warning-light. Normally not lit up.

Warns of any obstacles detected by the sensitive edges (these are connected

to work in the REOPEN WHILE CLOSING mode).

- «C7» Yellow LED warning-light. Normally not lit up.

Warns of any obstacles detected by the sensitive edges (these are connected

to work in the RECLOSE WHILE OPENING mode).

- «PWR» Green LED. Normally lit up.

Notifi es that the card is working properly.

- «PROG ON» Red LED. Normally not lit up.

During the transmitter activation procedure, it lights up or fl ashes.

LED signal lights

Adjustments

ON

OFF

/.

ON

2

1 345678910

ORIES

E

F

+ RUN S. -+ SLOW S. -+ RUN V. -+ SLOW V. - + A.C.T. -+ PAR.OP. -

ZN

ON

2

1 345678910

+ RUN S. -+ SLOW S. -V. - + A.C.T. -+ PAR.OP. -

2

345678910

PROG.

RIES

E

F

C. BOARD

FUSE

1A-F

ZN

CONTROL BO

ON

2

1 345678910

PROG

p.

17

17 -

Manual code:

119BF03

119 B F03 ver.

2

04/2014

© 09/2010 © CAME cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.a. to notify said changes.

ENGLISH

1 ON - Automatic closing - The automatic closing timer activates at the closing endpoint. The pre-set time is adjustable, but it's in

any case subject to any safety device intervention and does not activate after a total "stop" or in case of power failure.

2 ON - "Open-stop-close-stop"feature with (2-7) button and radio transmitter (fi tted with radio frequency card).

2 OFF - "Open-close"feature with (2-7) button and radio transmitter (fi tted with radio frequency card).

3 ON - "Open-only" feature with (2-7) button and radio transmitter (fi tted with radio frequency card activated).

4 OFF - Unused. Leave on OFF. .

5 OFF - With theBX-243 motor .

5 ON - With BX-246 motor.

6 ON - Maintained action - The gate works by keeping the button pressed(a 2-3 button for opening, a 2-7 button for closing).

7 ON - Photocells safety-test operation - Allows the card to check the efficiency of safety devices (i.e. photocells) after every

opening or closing command .

8 OFF - Total stop - - This feature stops the gate and then excludes any automatic closing cycle; use either the buttons or transmitter

to resume movement. Insert safety device on [1-C2]; if unused, set DIP switch to ON.

9 OFF - Reopening while closing - The gate inverts its direction of movement, if the photocells detect an obstacle when gate is

closing, until it is fully opened; connect the safety device to terminals [2-C1] ; if unused, set DIP switch to ON.

10 OFF - Partial stop - Gate stops if the safety device detects any obstacle; once the obstacle is removed, the gate stays still or

closes if the automatic closing feature is activated. if unused, set DIP switch to ON [2-C3]; if unused, set the Dip-switch to

.

Default setting

Calibrate the gate run by commanding a full opening and closing cycle.

The electronic card automatically logs the gate run calibration along

with the opening and closing slowdowns.

Memorise the adjustment by switching Dip-switch 6 to ONand press the PROG button until the LED warning light stays on.

Switch the Dip-switch back to OFF.

LED on

Dip-switch 6 on ON

Dip-switch 6 on OFF

Selecting functions

Programming for memorising gate-run and slowdown adjustments

MN 10 11 E1 1 2 3P 5 7 2 C1 C3 C7 C8

TS

+E

-

FC FA

F

C. BOARD

FUSE

1A-F

M1

U

L

BOARD

1

C1

C3

C7

MN

10 11 E1 1 2 3P 5 7 2 C1 C3 C7 C8

TS

+E

-

FC FA

F

MN

L2T

L1T

017

26

10 11 E1 1 2 3P 5 7 2 C1 C3 C7 C8

TS

+E

-

FC FA

F

LINE FUSE

230V=1.6A-F

120V=3.15A-F

MOTOR FUSE

BX243=8A-F

BX246=10A-F

ACCESSORIES

FUSE

1.6A-F

C. BOARD

FUSE

1A-F

ZN5 M1

ZN5U

CONTROL BOARD

PWR

1

C1

C3

C7

C8

ON

2

1 345678910

PROG.

MN

L2T

L1T

LN

017

26

10 11 E1 1 2 3P 5 7 2 C1 C3 C7 C8

TS

+E

-

FC FA

F

C

A

M

E

C

A

M

E

CAM

E

CAM

E

TOP

TOP-432NA • TOP-434NA

TOP-432S

TOP

TOP-302A • TOP-304A

TOP

TOP-432A • TOP-434A

TAM

T432 • T434 • T438

TAM-432SA

CAME

CAME

CAME

TOUCH

TCH 4024 • TCH 4048

TWIN

TWIN2 • TWIN4

ENGLISH

p.

18

18 -

Manual code:

119BF03

119 B F03 ver.

2

04/2014

© 09/2010 © CAME cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.a. to notify said changes.

Connect the RG58 antenna cable to the apposite terminals.

Antenna

Radio frequency card

Transmitters

AF radio frequency card

Electronic card

Plug in the radio-frequency card onto the electronic board AFTER CUTTING OFF THE MAIN POWER SUPPLY (or disconnecting the

emergency batteries).

N.B.: The electronic card recognises the radio-frequency card only when it is powered up.

see instructions on box

Activating the radio command

MN

L2T

L1T

017

26

10 11 E1 1 2 3P 5 7 2 C1 C3 C7 C8

TS

+E

-

FC FA

F

LINE FUSE

230V=1.6A-F

120V=3.15A-F

MOTOR FUSE

BX243=8A-F

BX246=10A-F

ACCESSORIES

FUSE

1.6A-F

C. BOARD

FUSE

1A-F

+

RUN S.

-+

SLOW S.

-+

RUN V.

-+

SLOW V.

- +

A.C.T.

-+

PAR.OP.

-

ZN5

CONTROL BOARD

PWR

1

C1

C3

C6

C7

ON

2

1 345678910

PROG.

MN

L2T

L1T

LN

017

26

10 11 E1 1 2 3P 5 7 2 C1 C3 C7 C8

TS

+E

-

FC FA

F

MN

L2T

L1T

017

26

10 11 E1 1 2 3P 5 7 2 C1 C3 C7 C8

TS

+E

-

FC FA

F

LINE FUSE

230V=1.6A-F

120V=3.15A-F

MOTOR FUSE

BX243=8A-F

BX246=10A-F

ACCESSORIES

FUSE

1.6A-F

C. BOARD

FUSE

1A-F

+

RUN S.

-+

SLOW S.

-+

RUN V.

-+

SLOW V.

- +

A.C.T.

-+

PAR.OP.

-

ZN5

CONTROL BOARD

PWR

1

C1

C3

C6

C7

ON

2

1345678910

PROG.

MN

L2T

L1T

LN

017

26

10 11 E1 1 2 3P 5 7 2 C1 C3 C7 C8

TS

+E

-

FC FA

F

PROG

ATOMO

AT01 • AT02

AT04

CAME

CAME

CAME

p.

19

19 -

Manual code:

119BF03

119 B F03 ver.

2

04/2014

© 09/2010 © CAME cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.a. to notify said changes.

ENGLISH

Keep the PROGbutton pressed on the electronic card. The LED fl ashes ON and OFF.

Press the button on the transmitter to be memorised. The LED will stay ON to confi rm memorisation is OK.

Flashing LED

LED on

Memorisation

see instruction sheet in the packaging

of the AF43SR radio-frequency card

ON

2

1345678910

ENGLISH

p.

20

20 -

Manual code:

119BF03

119 B F03 ver.

2

04/2014

© 09/2010 © CAME cancelli Automatici S.p.A. - The data and information in this manual may be changed at any time and without obligation on the part of Came Cancelli Automatici S.p.a. to notify said changes.

With two coupled gearmotors, you can command only the opening (by button and/or radio control): the gate will close only in automatic

closing mode.

• Coordinate the direction of travel of the two gearmotors and , by modifying the motor's rotation (invert the cables on

terminals FA-FC and M-N).

• Make the electrical connections only on

the motor's control board .

Connecting two coupled gearmotors having a single control

• Whereas, the adjustments and features, must be made on both boards.

• Connect the two boards together, as illustrated.

• Set DIP 2 and 1 to ON on both boards.

For opening with a radio control, connect an external receiver (RExxx/RBExxx with relay in MONOSTABLE mode) on terminals 2-7 of

the motor .

/