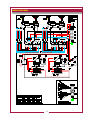

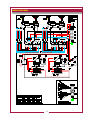

Wells Manufacturing F686 is a built-in electric auto-lift fryer that offers various features for efficient and safe food preparation. It comes with a 240V, 1ø power supply, 24.0A current draw, and 5.75KW power consumption. The fryer has a cord that is not supplied and requires a 208V/240V 3ø power supply. Wells Manufacturing F686 features a power switch for easy operation and an indicator light for power status. It also has a thermostat knob for precise temperature control and a timer knob for setting cooking time.

Wells Manufacturing F686 is a built-in electric auto-lift fryer that offers various features for efficient and safe food preparation. It comes with a 240V, 1ø power supply, 24.0A current draw, and 5.75KW power consumption. The fryer has a cord that is not supplied and requires a 208V/240V 3ø power supply. Wells Manufacturing F686 features a power switch for easy operation and an indicator light for power status. It also has a thermostat knob for precise temperature control and a timer knob for setting cooking time.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

Wells Manufacturing F686 Operating instructions

- Category

- Deep fryers

- Type

- Operating instructions

Wells Manufacturing F686 is a built-in electric auto-lift fryer that offers various features for efficient and safe food preparation. It comes with a 240V, 1ø power supply, 24.0A current draw, and 5.75KW power consumption. The fryer has a cord that is not supplied and requires a 208V/240V 3ø power supply. Wells Manufacturing F686 features a power switch for easy operation and an indicator light for power status. It also has a thermostat knob for precise temperature control and a timer knob for setting cooking time.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Wells Manufacturing F-58DJ Operating instructions

-

Wells Manufacturing F-886 Operating instructions

-

Wells Manufacturing F-886 Operating instructions

-

Wells Manufacturing F-58DJ Installation guide

-

Wells Manufacturing F58 Operating instructions

-

Wells Manufacturing F58 Operating instructions

-

Wells F-556 STS Operating instructions

-

Wells Manufacturing F-55 Operating instructions

-

Wells Manufacturing FLS-55 User manual

-

Wells F-856 Specification