Application Guide | Gas detection in refrigeration systems

© Danfoss | DCS (mwa) | 2018.08

14 | DKRCI.PA.S00.A2.02 | 520H12772

Two different methods are available for fulfilling

the calibration requirements.

• Replacing the sensor (sensor cartridge) with a

new factory pre-calibrated sensor.

• Performing a calibration to the sensor using

calibration gas (gas mixture with known target

gas concentration).

Calibration methods

Method I

Calibration by means of

replacing sensor heads

This method requires that the supplier offers

factory pre-calibrated sensor heads with

calibration certificate and traceability codes.

Additionally, an electrical simulation is required

to verify the output signals and alarm settings .

This method can be compared with the method

used for safety valves. The manufacturer

produces, tests, and certifies the product, which

can then be mounted in the system.

Danfoss offers the above-mentioned solution.

The sensor head, which is the essential measuring

element of the gas detector, is produced, tested,

calibrated, and certified by Danfoss.

After the gas detection unit has been tested

with the on-board test button function, which

simulates alarm signals and relay activation, to

ensure all electrical components are functional,

the new calibrated sensor head can be installed.

Danfoss recommends that the calibration is done

by means of pre-calibrated replacement sensors:

• As sensors have a limited lifetime, this method

basically ensures that the customer has a gas

detector as good as new after replacing the

sensor head.

• The method is typically more efficient and cost

effective compared to calibration carried out

on site.

Method II

Calibration of gas detectors by

means of calibration gas

The calibration of gas detectors by means of

calibration gas has traditionally been made

by using multimeters and adjustment of

potentiometers, which makes the process

relatively complicated, time consuming, and

expensive. However, the Danfoss gas detection

units have an integrated, digital calibration

function that makes the calibration process

easier, cheaper, and faster. Even though the

calibration is a simple procedure, it still requires

test equipment and basic competence in

calibration.

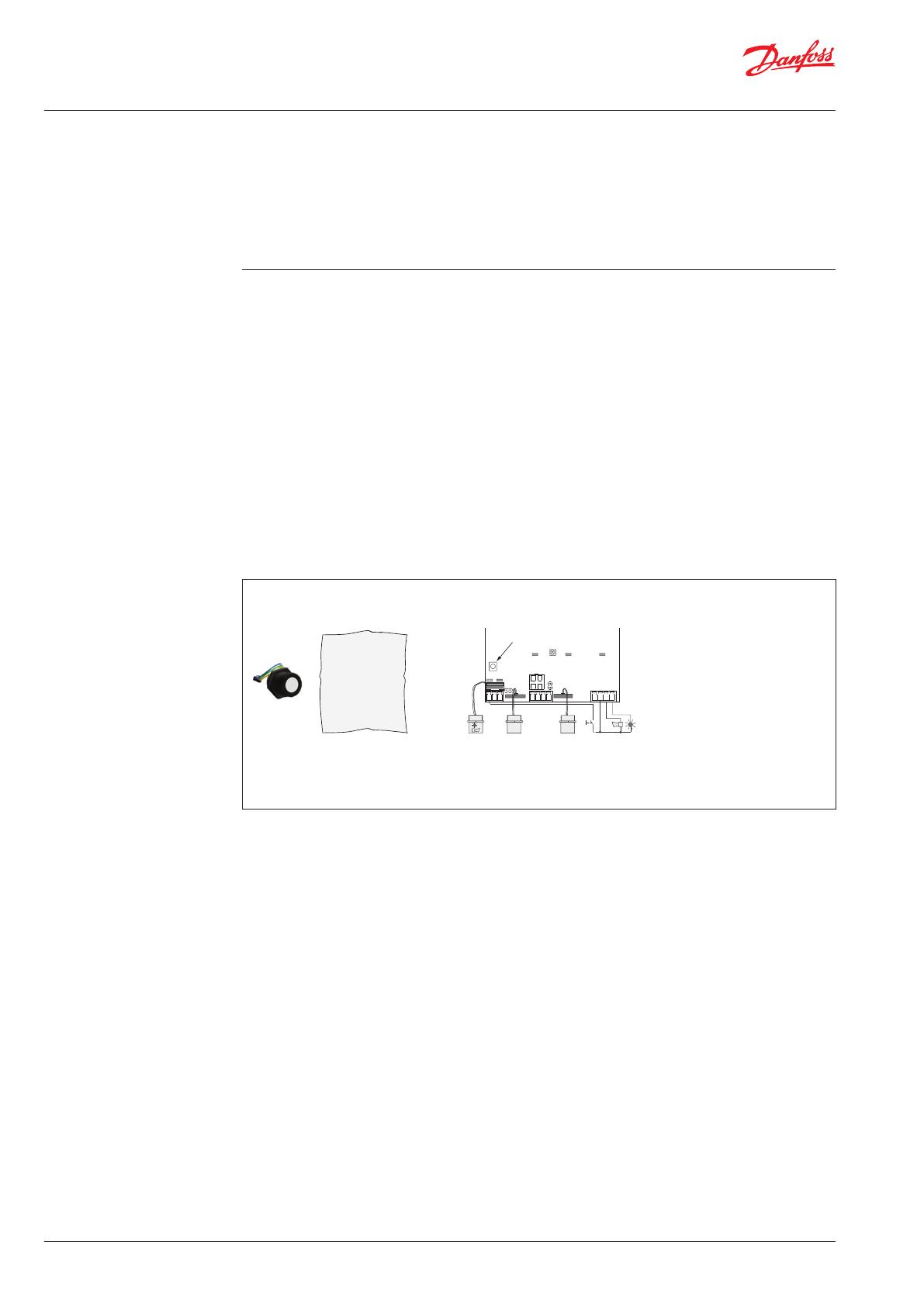

Calibration equipment for Gas Detection Units

(GDU) consists of:

• Valve/Flow regulator.

• Gas cylinder with the correct calibration gas for

each refrigerant and concentration (ppm).

• Calibration adapter.

• If the gas detector unit does not have a display,

the service tool or the PC tool is required.

In order to execute the calibration function, the

gas detector unit needs to be equipped with a

display or connection to either the service tool or

the PC tool.

Some calibration gas cylinders are treated as

dangerous substances, and therefore subject to

specific shipping requirements.

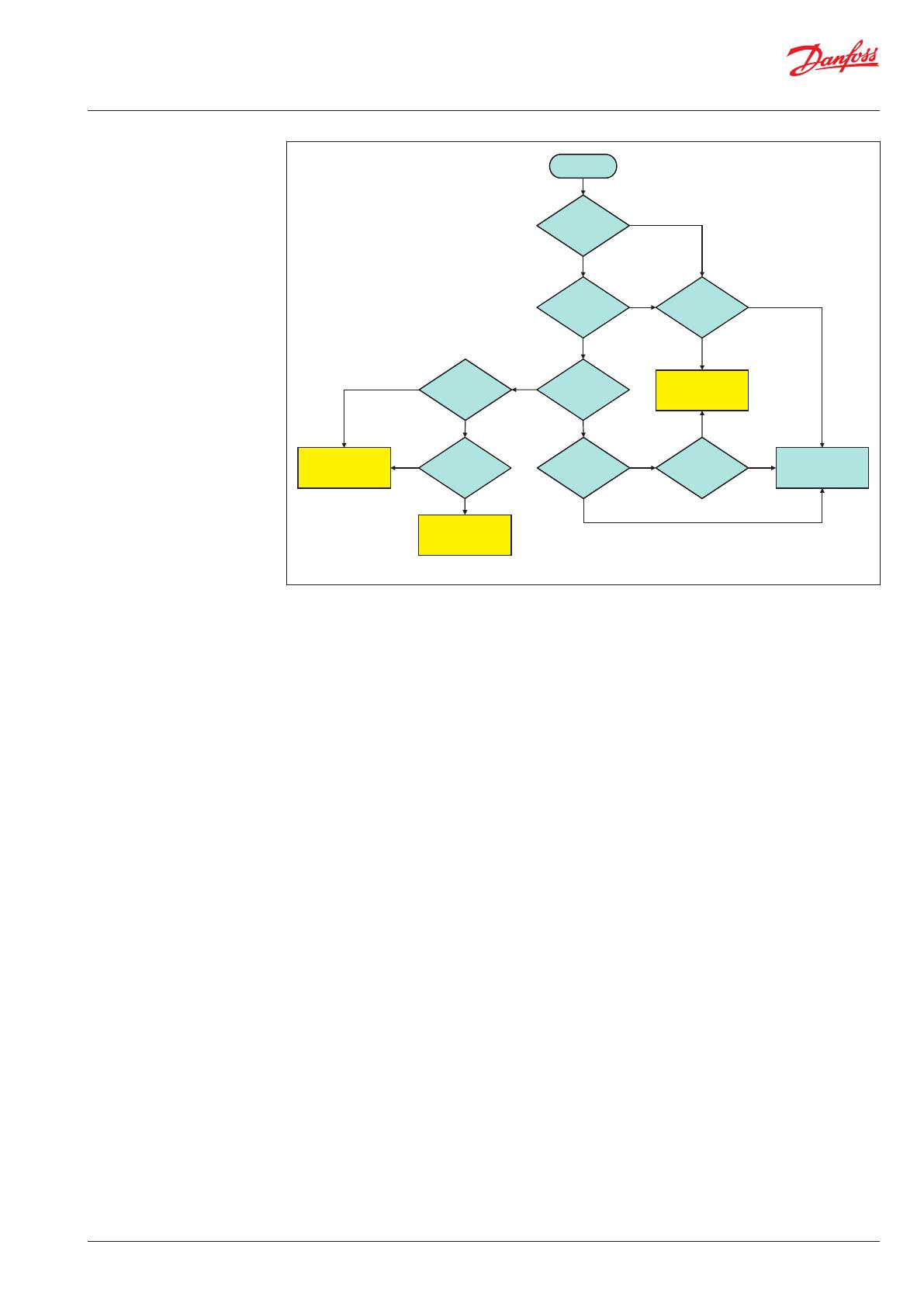

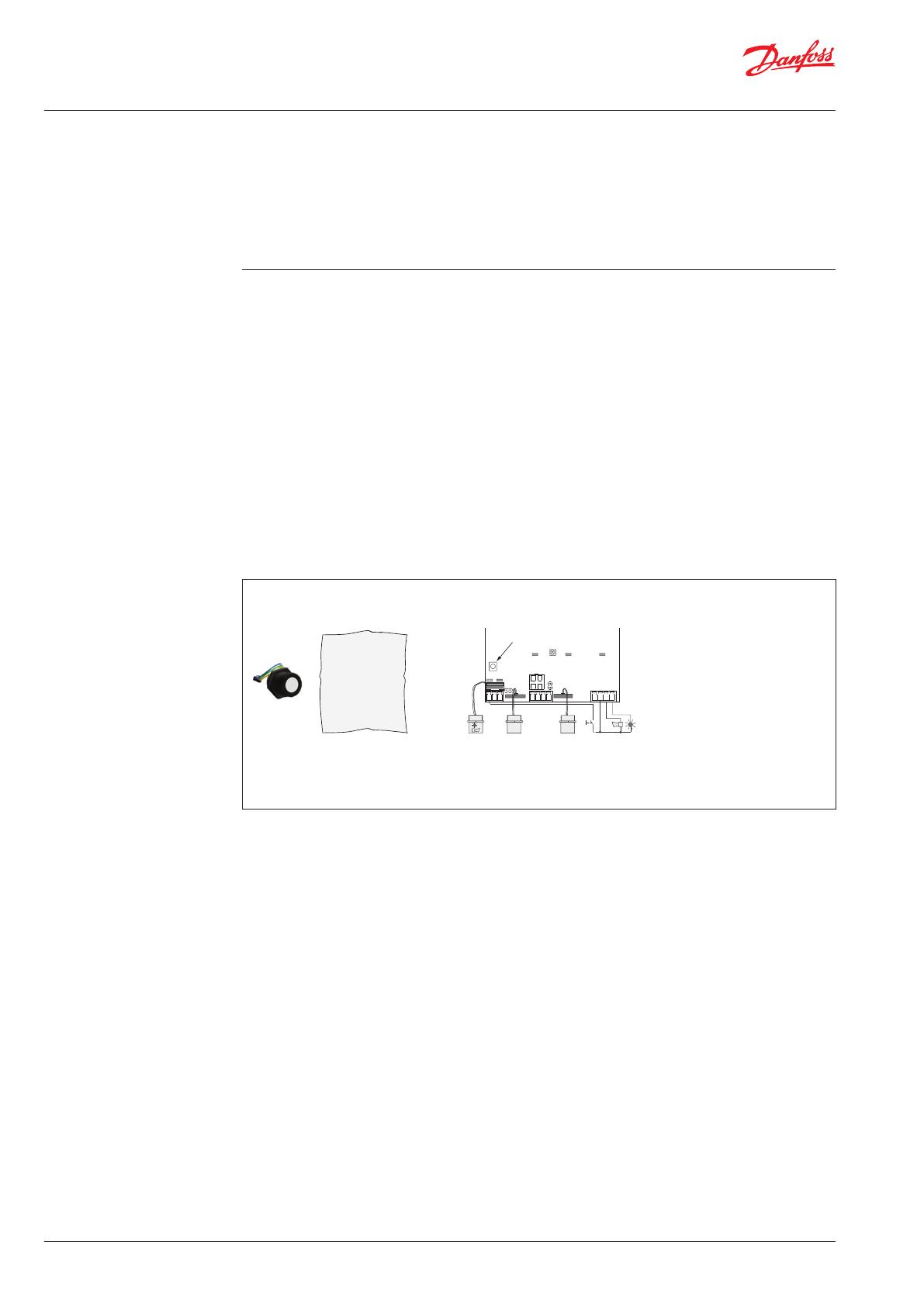

Fig. 9: Test and calibration of Danfoss gas detection unit (GDU) by the use of the on-board test function and

replacement of the sensor head.

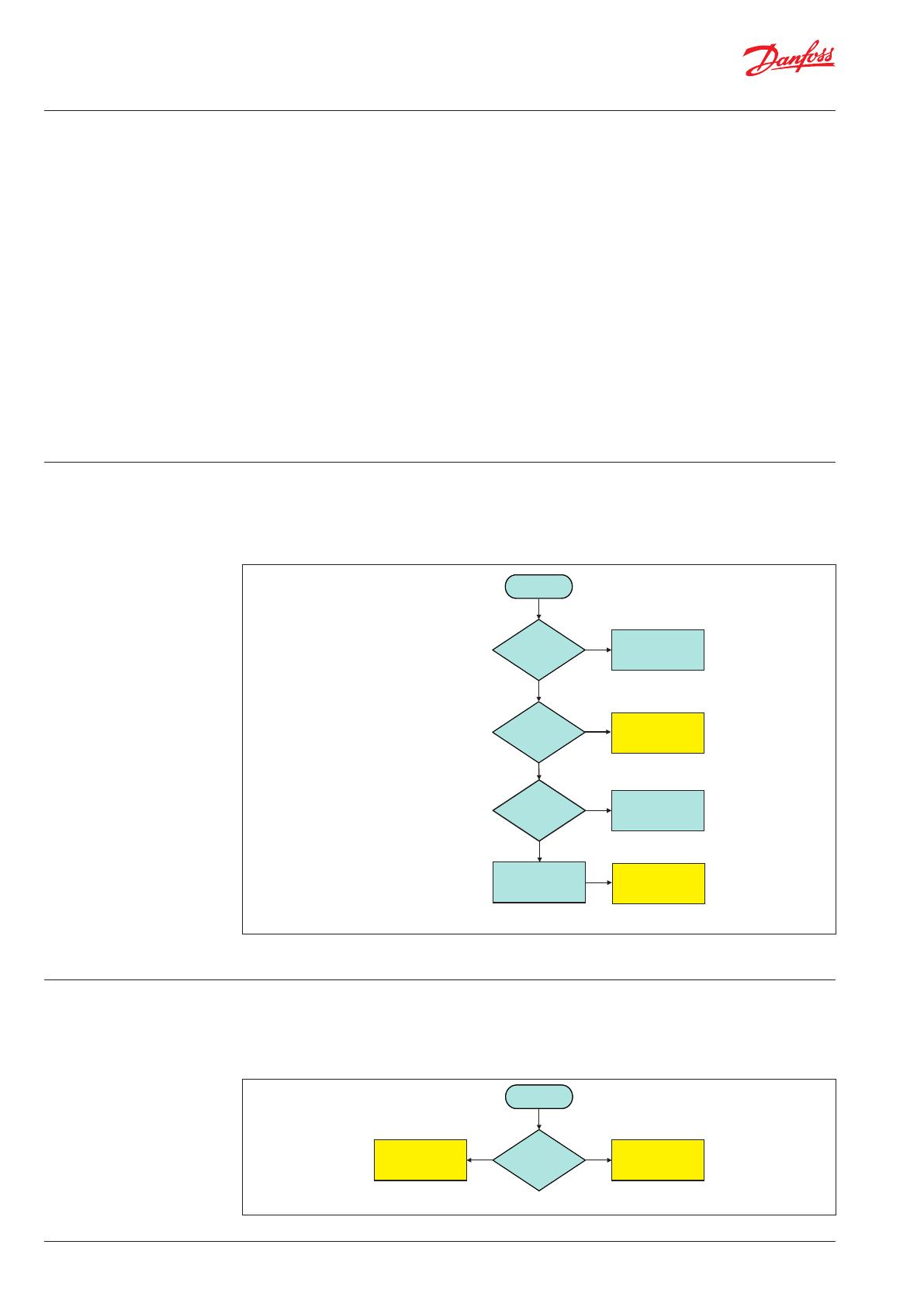

In addition to these calibration methods, a

“bump” test can be used, but only to test the

responsiveness and operation of the sensor. It is

important to highlight, that a bump test is not a

calibration.

Gas detection unit

tested and calibrated

Certificate

XXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXX

Gas/calibration levels etc.

Traceability

+

4

3

4

567

321

2

1

Sensor

Sensor

Test function button

On-board test functionExchange of sensor head