Page is loading ...

P C O R E E L E C T R I C 1 3 5 G I L B E R T S T R E E T L E R O Y N Y 1 4 4 8 2

5 8 5 . 7 6 8 . 1 2 0 0 W W W . H U B B E L L P O W E R S Y S T E M S . C O M

B-330756-A Rev. 4-15-16

Instructions for Installation and Use of PCORE

®

Seismically Enhanced Test (SET) Terminals

PCORE® SET Terminals are manufactured with the highest quality materials and are designed for

many years of reliable service. In order to obtain the highest performance, it is necessary to follow

these steps for installation and usage.

WARNING: The moveable side bars should be kept in the closed position at all times, except for

when tests (electrical and/or mechanical) are being performed upon the bushings and/or related

equipment on which each SET Terminal is installed.

STORAGE

PCORE SET Terminals must be stored in a clean and dry environment. DO NOT STORE OUTDOORS.

If the contact surfaces become corroded, the corrosion must be completely removed from the contact

surfaces before they are used.

APPLICATION REQUIREMENTS

PCORE SET Terminals must be connected properly to the equipment or overheating and damage may

result. The following requirements must be met to ensure proper operation:

1. All contact surfaces on both the PCORE SET Terminal and the connected equipment must be

properly cleaned with an abrasive pad or sandpaper and, for aluminum contacts, antioxidant

grease applied before installation.

2. If the PCORE SET Terminal utilizes a NEMA pad, then the cross section of the current carrying

bus must be equal or greater than the cross section of the pad.

3. Maximum cantilever loading of the PCORE SET Terminal is 2500 ft.-lbs. with the moveable side

bars in the open or closed position.

a. It is possible that the allowable loading of the PCORE SET Terminal exceeds that of the

apparatus on which it is mounted. In such a scenario, always design around the lower

maximum cantilever value to avoid possible damage to equipment.

INSTALLATION

PCORE SET Terminals are packaged ready for use. However, a few precautions must be taken before

installation:

1. The PCORE SET Terminal should be oriented so that the movable bars open in a downward

motion. See Figure 1 on reverse side.

a. For units with NEMA pads, the recommended loading direction is parallel to the flats of

the blade.

b. For units with female threaded connectors, the recommended loading is perpendicular to

the terminal clamp bolts.

2. Verify all fasteners are tight, recommended Torque Values:

a. Captive Bolts & Terminal Clamp Bolts (1/2-13), 40 ft.-lbs.

b. Corona Ring Bolts (3/8-16), 20 ft.-lbs.

3. For aluminum, clean all contact surfaces using an abrasive pad to remove any oxidation. Wipe

off all dirt and immediately (within 2 minutes) apply a thin coat of no-ox grease made specifically

for aluminum electrical contacts.

4. All connections should be bolted tight. The use of cone washers to prevent loosening of the

connection is highly recommended.

!

P C O R E E L E C T R I C 1 3 5 G I L B E R T S T R E E T L E R O Y N Y 1 4 4 8 2

5 8 5 . 7 6 8 . 1 2 0 0 W W W . H U B B E L L P O W E R S Y S T E M S . C O M

B-330756-A Rev. 4-15-16

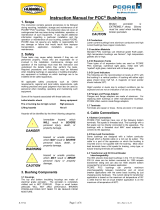

WARNING: This product utilizes captive bolts to prevent accidentally dropping the hardware

during use. Captive bolts are designed to remain in either the terminal caps or side bars, as

shown in Fig. 1. Do not forcibly remove any captive bolts or small (#10-32) locking screws.

OPERATION AND MAINTENANCE

PCORE SET Terminals will function properly for a long time with very little care. Performing the following

steps will ensure trouble-free operation:

1. Anytime the terminal is opened to perform testing, the contact surfaces of the side bars must be

inspected for corrosion. Any corrosion must be removed. If any surface has become dry or nearly

dry, you must clean and re-grease the contact surfaces.

2. Ensure that the insulator surface is clean and dry prior to performing any tests.

a. PCORE recommends cleaning the silicone insulator surface using a lint-free cloth soaked

with a mild cleaner. Do not apply heavy force, but rather rub the surface frequently with

light force. Abrasive materials are not recommended as they will mar the surface.

3. Always tighten the bolts to the proper torque values as indicated above.

4. Check the terminal and connections periodically with an infrared device to be sure that all

connections are functioning properly.

Figure 1

!

/