Page is loading ...

In staller/O w n er R espon sibility:

Ic o n ic F lo o rs, L L C striv e s to o e r its c u sto m e rs th e h ig h e st q u a lity e n g in e e re d h a rd w o o d o o rin g . C a re fu lly re v ie w

th is installation guide to ensure satisfactory results w ith your installation.

●

E x a m in e th e o o rin g u p o n re c e ip t a n d p rio r to in sta lla tio n . E x a m in e fo r g ra d e , c o lo r, n ish , q u a lity, a n d tra n sit

dam age. L ighting m ust be adequate for proper inspection. If ooring is deem ed unacceptable, contact S eller

im m e d ia te ly a n d a rra n g e fo r re p la c e m e n t. Ic o n ic F lo o rs, L L C c a n n o t a c c e p t re sp o n sib ility fo r in sta lla tio n o f

o o rin g w ith v isib le d e fe c ts.

●

P rio r to in sta lla tio n , th e in sta lle r m u st in su re th e jo b site a n d /o r su b o o r m e e t I c o n ic F lo o r's in sta lla tio n

in stru c tio n s re q u ire m e n ts. I c o n ic F lo o rs is n o t re sp o n sib le fo r o o rin g fa ilu re re su ltin g fro m u n a c c e p ta b le

jo b site a n d /o r o o rin g c o n d itio n s.

●

W h e n p u rc h a sin g Ic o n ic F lo o rs, L L C e n g in e e re d h a rd w o o d o o rin g , a d d 5 % to th e a c tu a l re q u ire d sq u a re

footage as a cutting allow ance.

Jobsite an d P re-In stallation R equ irem en ts:

H a rd w o o d o o rin g sh o u ld b e o n e o f th e la st ite m s in sta lle d fo r a n y c o n stru c tio n o r re n o v a tio n p ro je c t. W o rk

involving w ater or m oisture m u st be com pleted before ooring installation. R oom tem perature and hum idity in the

installation area should be consistent w ith norm al, year-round living conditions, and should achieve this for a t lea st

on e w eek prior to in stallation. R ecom m ended ranges are 60-70 (fahrenheit) degrees for tem perature, and 40-60%

fo r h u m id ity. I c o n ic F lo o rs m ay b e in sta lle d in w e ll- v e n tila te d b a th ro o m e n v iro n m e n ts, b u t th e o o r m u st b e d rie d

o f a n y sta n d in g w a te r a s it o c c u rs.

S to re Ic o n ic o o rin g in in sta lla tio n a re a fo r 2 4 - 7 2 h o u rs p rio r to in sta llin g . is w ill a llo w a c c lim a tiz a tio n o f th e

w o o d . D o n o t sto re d ire c tly o n c o n c re te o r n e a r o u tsid e w a lls.

In sta lla tio n T o o ls:

e fo llo w in g h a n d to o ls a r e r e co m m en d ed –

C arpenter's P en cil H am m er (16 – 20 oz) S p a c e r s ( w o o d / p la s tic ). O r c u t e n d s / p ie c e s o f

o o r in g . S e t o n e d g e .

C h a lk lin e H an d saw (C ro sscu t) T ape M easure

C r o w b a r / 'W o n d e r ' B a r N a il S e t T a p p in g B lo c k ( t r im m e d p ie c e o f o o r in g )

e fo llo w in g p o w er too ls w ill sp eed in sta lla tio n –

Bench Saw/T a b le S a w or M it e r S a w or C irc u la r S a w

e fo llo w in g a p p ly to in d iv id u a l in sta lla tio n m e th o d s–

N a il- d o w n : 1 / 2 ” P o w e r N a ile r 1 - 1 / 4 ” C le a t s or P in , B r a d o r F in is h N a ile r

G lu e - d o w n : F lo o rin g a d h e siv e T ro w el (16 ga., 18 ga., 1-1/4” or 1-1/2” brads/nails)

F lo a tin g : 6 - m il p o ly lm D u ct tap e/P o ly tap e F oam U nderlaym ent P V A C g lu e

A ccep ta b le S u b oors:

G en erally, su b oors m u st be–

Structurally Sound;

L e v e l . F lat to 3/16" per 10' radius;

C l e a n . oroughly sw ept and free of all debris. Free of w ax, grease, pain t, sealers, old adh esives and other substances; and

D r y a n d r e m a in d r y . Suboor m ust rem ain dry year-round. M o istu re c o n te n t m u st n o t e x c e e d 1 3 % fo r m o s t su rfa c e s, a n d

2 .5 % fo r c o n c re te . T e stin g fo r m o istu re m a y b e d o n e w ith a c o m m e rc ia lly a v a ila b le m oisture m eter. A n alternative m ethod

is listed under 'C oncrete Suboors'.

Prem ium H ardwood Flooring Installation Instructions

In staller/O w n er R espon sibility:

Ic o n ic F lo o rs, L L C striv e s to o e r its c u sto m e rs th e h ig h e st q u a lity e n g in e e re d h a rd w o o d o o rin g . C a re fu lly re v ie w

th is installation guide to ensure satisfactory results w ith your installation.

●

E x a m in e th e o o rin g u p o n re c e ip t a n d p rio r to in sta lla tio n . E x a m in e fo r g ra d e , c o lo r, n ish , q u a lity, a n d tra n sit

dam age. L ighting m ust be adequate for proper inspection. If ooring is deem ed unacceptable, contact S eller

im m e d ia te ly a n d a rra n g e fo r re p la c e m e n t. Ic o n ic F lo o rs, L L C c a n n o t a c c e p t re sp o n sib ility fo r in sta lla tio n o f

o o rin g w ith v isib le d e fe c ts.

●

P rio r to in sta lla tio n , th e in sta lle r m u st in su re th e jo b site a n d /o r su b o o r m e e t I c o n ic F lo o r's in sta lla tio n

in stru c tio n s re q u ire m e n ts. I c o n ic F lo o rs is n o t re sp o n sib le fo r o o rin g fa ilu re re su ltin g fro m u n a c c e p ta b le

jo b site a n d /o r o o rin g c o n d itio n s.

●

W h e n p u rc h a sin g Ic o n ic F lo o rs, L L C e n g in e e re d h a rd w o o d o o rin g , a d d 5 % to th e a c tu a l re q u ire d sq u a re

footage as a cutting allow ance.

Jobsite an d P re-In stallation R equ irem en ts:

H a rd w o o d o o rin g sh o u ld b e o n e o f th e la st ite m s in sta lle d fo r a n y c o n stru c tio n o r re n o v a tio n p ro je c t. W o rk

involving w ater or m oisture m u st be com pleted before ooring installation. R oom tem perature and hum idity in the

installation area should be consistent w ith norm al, year-round living conditions, and should achieve this for a t lea st

on e w eek prior to in stallation. R ecom m ended ranges are 60-70 (fahrenheit) degrees for tem perature, and 40-60%

fo r h u m id ity. I c o n ic F lo o rs m ay b e in sta lle d in w e ll- v e n tila te d b a th ro o m e n v iro n m e n ts, b u t th e o o r m u st b e d rie d

o f a n y sta n d in g w a te r a s it o c c u rs.

S to re Ic o n ic o o rin g in in sta lla tio n a re a fo r 2 4 - 7 2 h o u rs p rio r to in sta llin g . is w ill a llo w a c c lim a tiz a tio n o f th e

w o o d . D o n o t sto re d ire c tly o n c o n c re te o r n e a r o u tsid e w a lls.

In sta lla tio n T o o ls:

e fo llo w in g h a n d to o ls a r e r e co m m en d ed –

C arpenter's P en cil H am m er (16 – 20 oz) S p a c e r s ( w o o d / p la s t ic ). O r c u t e n d s / p ie c e s o f

o o r in g . S e t o n e d g e .

C h a lk lin e H an d saw (C ro sscu t) T ape M easure

C r o w b a r / 'W o n d e r ' B a r N a il S e t T a p p in g B lo c k ( t r im m e d p ie c e o f o o r in g )

e fo llo w in g p o w er too ls w ill sp eed in sta lla tio n –

Bench Saw/T a b le S a w or M it e r S a w or C ir c u la r S a w

e fo llo w in g a p p ly to in d iv id u a l in sta lla tio n m e th o d s–

N a il- d o w n : 1 / 2 ” P o w e r N a ile r 1 - 1 / 4 ” C le a t s or P in , B r a d o r F in is h N a ile r

G lu e - d o w n : F lo o rin g a d h e siv e T ro w el (16 ga., 18 ga., 1-1/4” or 1-1/2” brads/nails)

F lo a tin g : 6 - m il p o ly lm D u ct tap e/P o ly tap e F oam U n derlaym ent P V A C g lu e

A ccep ta b le S u b oors:

G en erally, su b oors m u st be–

Structurally Sound;

L e v e l . F lat to 3/16" per 10' radius;

C l e a n . oroughly sw ept and free of all debris. Free of w ax, grease, pain t, sealers, old adh esives and other substances; and

D r y a n d r e m a in d r y . Suboor m ust rem ain dry year-round. M o istu re c o n te n t m u st n o t e x c e e d 1 3 % fo r m o st s u r fa c e s, a n d

2 .5 % fo r c o n c re te . T e stin g fo r m o istu re m a y b e d o n e w ith a c o m m e rc ia lly a v a ila b le m oisture m eter. A n alternative m ethod

is listed under 'C oncrete Suboors'.

Prem ium H ardwood Flooring Installation Instructions

In staller/O w n er R espon sibility:

Ic o n ic F lo o rs, L L C striv e s to o e r its c u sto m e rs th e h ig h e st q u a lity e n g in e e re d h a rd w o o d o o rin g . C a re fu lly re v ie w

th is installation guide to ensure satisfactory results w ith your installation.

●

E x a m in e th e o o rin g u p o n re c e ip t a n d p rio r to in sta lla tio n . E x a m in e fo r g ra d e , c o lo r, n ish , q u a lity, a n d tra n sit

dam age. L ighting m ust be adequate for proper inspection. If ooring is deem ed unacceptable, contact S eller

im m e d ia te ly a n d a rra n g e fo r re p la c e m e n t. Ic o n ic F lo o rs, L L C c a n n o t a c c e p t re sp o n sib ility fo r in sta lla tio n o f

o o rin g w ith v isib le d e fe c ts.

●

P rio r to in sta lla tio n , th e in sta lle r m u st in su re th e jo b site a n d /o r su b o o r m e e t I c o n ic F lo o r's in sta lla tio n

in stru c tio n s re q u ire m e n ts. I c o n ic F lo o rs is n o t re sp o n sib le fo r o o rin g fa ilu re re su ltin g fro m u n a c c e p ta b le

jo b site a n d /o r o o rin g c o n d itio n s.

●

W h e n p u rc h a sin g Ic o n ic F lo o rs, L L C e n g in e e re d h a rd w o o d o o rin g , a d d 5 % to th e a c tu a l re q u ire d sq u a re

footage as a cutting allow ance.

Jobsite an d P re-In stallation R equ irem en ts:

H a rd w o o d o o rin g sh o u ld b e o n e o f th e la st ite m s in sta lle d fo r a n y c o n stru c tio n o r re n o v a tio n p ro je c t. W o rk

involving w ater or m oisture m u st be com pleted before ooring installation. R oom tem perature and hum idity in the

installation area should be consistent w ith norm al, year-round living conditions, and should achieve this for a t lea st

on e w eek prior to in stallation. R ecom m ended ranges are 60-70 (fahrenheit) degrees for tem perature, and 40-60%

fo r h u m id ity. I c o n ic F lo o rs m ay b e in sta lle d in w e ll- v e n tila te d b a th ro o m e n v iro n m e n ts, b u t th e o o r m u st b e d rie d

o f a n y sta n d in g w a te r a s it o c c u rs.

S to re Ic o n ic o o rin g in in sta lla tio n a re a fo r 2 4 - 7 2 h o u rs p rio r to in sta llin g . is w ill a llo w a c c lim a tiz a tio n o f th e

w o o d . D o n o t sto re d ire c tly o n c o n c re te o r n e a r o u tsid e w a lls.

In sta lla tio n T o o ls:

e fo llo w in g h a n d to o ls a r e r e co m m en d ed –

C arpenter's P en cil H am m er (16 – 20 oz) S p a c e r s ( w o o d / p la s t ic ). O r c u t e n d s / p ie c e s o f

o o r in g . S e t o n e d g e .

C h a lk lin e H an d saw (C ro sscu t) T ape M easure

C r o w b a r / 'W o n d e r ' B a r N a il S e t T a p p in g B lo c k ( t r im m e d p ie c e o f o o r in g )

e fo llo w in g p o w er too ls w ill sp eed in sta lla tio n –

Bench Saw/T a b le S a w or M it e r S a w or C ir c u la r S a w

e fo llo w in g a p p ly to in d iv id u a l in sta lla tio n m e th o d s–

N a il- d o w n : 1 / 2 ” P o w e r N a ile r 1 - 1 / 4 ” C le a t s or P in , B r a d o r F in is h N a ile r

G lu e - d o w n : F lo o rin g a d h e siv e T ro w el (16 ga., 18 ga., 1-1/4” or 1-1/2” brads/nails)

F lo a tin g : 6 - m il p o ly lm D u ct tap e/P o ly tap e F oam U n derlaym ent P V A C g lu e

A ccep ta b le S u b oors:

G en erally, su b oors m u st be–

Structurally Sound;

L e v e l . F lat to 3/16" per 10' radius;

C l e a n . oroughly sw ept and free of all debris. Free of w ax, grease, pain t, sealers, old adh esives and other substances; and

D r y a n d r e m a in d r y . Suboor m ust rem ain dry year-round. M o istu re c o n te n t m u st n o t e x c e e d 1 3 % fo r m o st s u r fa c e s, a n d

2 .5 % fo r c o n c re te . T e stin g fo r m o istu re m a y b e d o n e w ith a c o m m e rc ia lly a v a ila b le m oisture m eter. A n alternative m ethod

is listed under 'C oncrete Suboors'.

Prem ium H ardwood Flooring Installation Instructions

PGWood strives to oer its customers the highest quality engineered hardwood ooring. Carefully review this

installation guide to ensure satisfactory results with your installation.

• Examine the ooring upon receipt and prior to installation. Examine for grade, color, nish, quality, and transit

damage. Lighting must be adequate for proper inspection. If ooring is deemed unacceptable, contact Seller

immediately and arrange for replacement. PGWood cannot accept responsibility for installation of ooring

with visible defects.

• Prior to installation, the installer must insure the jobsite and/or suboor meet PGWood's installation

instructions/requirements. PGWood is not responsible for ooring failure resulting from unacceptable

jobsite and/or ooring conditions.

• When purchasing PGWood engineered hardwood ooring, add 5% to the actual required square footage as

a cutting allowance.

Hardwood ooring should be one of the last items installed for any construction or renovation project. Work

involving water or moisture must be completed before ooring installation. Room temperature and humidity in the

installation area should be consistent with normal, year-round living conditions for at least one week prior to

installation. Recommended ranges are 60-70 (fahrenheit) degrees, and 40-60% humidity. Flooring may be installed

in well-ventilated bathroom environments, but the oor must be dried of any standing water as it occurs.

Store ooring in installation area for 24-72 hours prior to installing. is will allow acclimatization of the wood.

In staller/O w n er R espon sibility:

Ic o n ic F lo o rs, L L C striv e s to o e r its c u sto m e rs th e h ig h e st q u a lity e n g in e e re d h a rd w o o d o o rin g . C a re fu lly re v ie w

th is installation guide to ensure satisfactory results w ith your installation.

●

E x a m in e th e o o rin g u p o n re c e ip t a n d p rio r to in sta lla tio n . E x a m in e fo r g ra d e , c o lo r, n ish , q u a lity, a n d tra n sit

dam age. L ighting m ust be adequate for proper inspection. If ooring is deem ed unacceptable, contact S eller

im m e d ia te ly a n d a rra n g e fo r re p la c e m e n t. Ic o n ic F lo o rs, L L C c a n n o t a c c e p t re sp o n sib ility fo r in sta lla tio n o f

o o rin g w ith v isib le d e fe c ts.

●

P rio r to in sta lla tio n , th e in sta lle r m u st in su re th e jo b site a n d /o r su b o o r m e e t I c o n ic F lo o r's in sta lla tio n

in stru c tio n s re q u ire m e n ts. I c o n ic F lo o rs is n o t re sp o n sib le fo r o o rin g fa ilu re re su ltin g fro m u n a c c e p ta b le

jo b site a n d /o r o o rin g c o n d itio n s.

●

W h e n p u rc h a sin g Ic o n ic F lo o rs, L L C e n g in e e re d h a rd w o o d o o rin g , a d d 5 % to th e a c tu a l re q u ire d sq u a re

footage as a cutting allow ance.

Jobsite an d P re-In stallation R equ irem en ts:

H a rd w o o d o o rin g sh o u ld b e o n e o f th e la st ite m s in sta lle d fo r a n y c o n stru c tio n o r re n o v a tio n p ro je c t. W o rk

involving w ater or m oisture m u st be com pleted before ooring installation. R oom tem perature and hum idity in the

installation area should be consistent w ith norm al, year-round living conditions, and should achieve this for a t lea st

on e w eek prior to in stallation. R ecom m ended ranges are 60-70 (fahrenheit) degrees for tem perature, and 40-60%

fo r h u m id ity. I c o n ic F lo o rs m ay b e in sta lle d in w e ll- v e n tila te d b a th ro o m e n v iro n m e n ts, b u t th e o o r m u st b e d rie d

o f a n y sta n d in g w a te r a s it o c c u rs.

S to re Ic o n ic o o rin g in in sta lla tio n a re a fo r 2 4 - 7 2 h o u rs p rio r to in sta llin g . is w ill a llo w a c c lim a tiz a tio n o f th e

w o o d . D o n o t sto re d ire c tly o n c o n c re te o r n e a r o u tsid e w a lls.

In sta lla tio n T o o ls:

e fo llo w in g h a n d to o ls a r e r e co m m en d ed –

C arpenter's P en cil H am m er (16 – 20 oz) S p a c e r s ( w o o d / p la s t ic ). O r c u t e n d s / p ie c e s o f

o o r in g . S e t o n e d g e .

C h a lk lin e H an d saw (C ro sscu t) T ape M easure

C r o w b a r / 'W o n d e r ' B a r N a il S e t T a p p in g B lo c k ( t r im m e d p ie c e o f o o r in g )

e fo llo w in g p o w er too ls w ill sp eed in sta lla tio n –

Bench Saw/T a b le S a w or M it e r S a w or C ir c u la r S a w

e fo llo w in g a p p ly to in d iv id u a l in sta lla tio n m e th o d s–

N a il- d o w n : 1 / 2 ” P o w e r N a ile r 1 - 1 / 4 ” C le a t s or P in , B r a d o r F in is h N a ile r

G lu e - d o w n : F lo o rin g a d h e siv e T ro w el (16 ga., 18 ga., 1-1/4” or 1-1/2” brads/nails)

F lo a tin g : 6 - m il p o ly lm D u ct tap e/P o ly tap e F oam U n derlaym ent P V A C g lu e

A ccep ta b le S u b oors:

G en erally, su b oors m u st be–

Structurally Sound;

L e v e l . F lat to 3/16" per 10' radius;

C l e a n . oroughly sw ept and free of all debris. Free of w ax, grease, pain t, sealers, old adh esives and other substances; and

D r y a n d r e m a in d r y . Suboor m ust rem ain dry year-round. M o istu re c o n te n t m u st n o t e x c e e d 1 3 % fo r m o st s u r fa c e s, a n d

2 .5 % fo r c o n c re te . T e stin g fo r m o istu re m a y b e d o n e w ith a c o m m e rc ia lly a v a ila b le m oisture m eter. A n alternative m ethod

is listed under 'C oncrete Suboors'.

Prem ium H ardwood Flooring Installation Instructions

In staller/O w n er R espon sibility:

Ic o n ic F lo o rs, L L C striv e s to o e r its c u sto m e rs th e h ig h e st q u a lity e n g in e e re d h a rd w o o d o o rin g . C a re fu lly re v ie w

th is installation guide to ensure satisfactory results w ith your installation.

●

E x a m in e th e o o rin g u p o n re c e ip t a n d p rio r to in sta lla tio n . E x a m in e fo r g ra d e , c o lo r, n ish , q u a lity, a n d tra n sit

dam age. L ighting m ust be adequate for proper inspection. If ooring is deem ed unacceptable, contact S eller

im m e d ia te ly a n d a rra n g e fo r re p la c e m e n t. Ic o n ic F lo o rs, L L C c a n n o t a c c e p t re sp o n sib ility fo r in sta lla tio n o f

o o rin g w ith v isib le d e fe c ts.

●

P rio r to in sta lla tio n , th e in sta lle r m u st in su re th e jo b site a n d /o r su b o o r m e e t I c o n ic F lo o r's in sta lla tio n

in stru c tio n s re q u ire m e n ts. I c o n ic F lo o rs is n o t re sp o n sib le fo r o o rin g fa ilu re re su ltin g fro m u n a c c e p ta b le

jo b site a n d /o r o o rin g c o n d itio n s.

●

W h e n p u rc h a sin g Ic o n ic F lo o rs, L L C e n g in e e re d h a rd w o o d o o rin g , a d d 5 % to th e a c tu a l re q u ire d sq u a re

footage as a cutting allow ance.

Jobsite an d P re-In stallation R equ irem en ts:

H a rd w o o d o o rin g sh o u ld b e o n e o f th e la st ite m s in sta lle d fo r a n y c o n stru c tio n o r re n o v a tio n p ro je c t. W o rk

involving w ater or m oisture m u st be com pleted before ooring installation. R oom tem perature and hum idity in the

installation area should be consistent w ith norm al, year-round living conditions, and should achieve this for a t lea st

on e w eek prior to in stallation. R ecom m ended ranges are 60-70 (fahrenheit) degrees for tem perature, and 40-60%

fo r h u m id ity. I c o n ic F lo o rs m ay b e in sta lle d in w e ll- v e n tila te d b a th ro o m e n v iro n m e n ts, b u t th e o o r m u st b e d rie d

o f a n y sta n d in g w a te r a s it o c c u rs.

S to re Ic o n ic o o rin g in in sta lla tio n a re a fo r 2 4 - 7 2 h o u rs p rio r to in sta llin g . is w ill a llo w a c c lim a tiz a tio n o f th e

w o o d . D o n o t sto re d ire c tly o n c o n c re te o r n e a r o u tsid e w a lls.

In sta lla tio n T o o ls:

e fo llo w in g h a n d to o ls a r e r e co m m en d ed –

C arpenter's P en cil H am m er (16 – 20 oz) S p a c e r s ( w o o d / p la s t ic ). O r c u t e n d s / p ie c e s o f

o o r in g . S e t o n e d g e .

C h a lk lin e H an d saw (C ro sscu t) T ape M easure

C r o w b a r / 'W o n d e r ' B a r N a il S e t T a p p in g B lo c k ( t r im m e d p ie c e o f o o r in g )

e fo llo w in g p o w er too ls w ill sp eed in sta lla tio n –

Bench Saw/T a b le S a w or M it e r S a w or C ir c u la r S a w

e fo llo w in g a p p ly to in d iv id u a l in sta lla tio n m e th o d s–

N a il- d o w n : 1 / 2 ” P o w e r N a ile r 1 - 1 / 4 ” C le a t s or P in , B r a d o r F in is h N a ile r

G lu e - d o w n : F lo o rin g a d h e siv e T ro w el (16 ga., 18 ga., 1-1/4” or 1-1/2” brads/nails)

F lo a tin g : 6 - m il p o ly lm D u ct tap e/P o ly tap e F oam U n derlaym ent P V A C g lu e

A ccep ta b le S u b oors:

G en erally, su b oors m u st be–

Structurally Sound;

L e v e l . F lat to 3/16" per 10' radius;

C l e a n . oroughly sw ept and free of all debris. Free of w ax, grease, pain t, sealers, old adh esives and other substances; and

D r y a n d r e m a in d r y . Suboor m ust rem ain dry year-round. M o istu re c o n te n t m u st n o t e x c e e d 1 3 % fo r m o st s u r fa c e s, a n d

2 .5 % fo r c o n c re te . T e stin g fo r m o istu re m a y b e d o n e w ith a c o m m e rc ia lly a v a ila b le m oisture m eter. A n alternative m ethod

is listed under 'C oncrete Suboors'.

Prem ium H ardwood Flooring Installation Instructions

e following hand tools are recommended—

Carpenter’s Pencil Hammer (16 – 20 oz) Spacers Or cut ends/pieces of ooring

(set on edge).

Chalkline Handsaw (Crosscut) Tape Measure

Crowbar/’Wonder’ Bar Nail Set Tapping Block (trimmed piece of ooring)

e following power tools will speed installation—

Bench Saw/Table Saw or Miter Saw or Chop Saw

e following apply to individual installation methods—

Nail-down: Pin, Brad or Finish Nailer (16 ga., 18 ga., 1-1/4” or 1-1/2” brads/nails)

Glue-down: Flooring adhesive Trowel

Floating: 6-mil poly lm Duct tape/Poly tape Underlayment PVAC glue

Generally,suboors must be—

Structurally Sound;

Level. Flat to 3/16” per 10’ radius;

Clean. oroughly swept & free of all debris. Free of wax, grease, paint, sealers, old adhesives & other substances; and

Dry and remain dry. Suboor must remain dry year round. Moisture content must not exceed 13% for most surfaces,

or 2.5% for concrete. Testing for moisture content may be done with a commercially available moisture meter. An

alternative method is listed under ‘Concrete Suboors’.

A ccep ta b le S u b oors, continued:

G eneral, continued...

S u b o o r T y p e s :

W ood:

M u st b e d ry a n d w e ll se c u re d . N a il o r sc re w e v e r y 6 " a lo n g jo ists to a v o id sq u e a k in g . If n o t le v e l, sa n d d o w n h ig h

sp o ts a n d ll lo w s p o ts w ith underlaym ent patch .

P rod u cts: P lyw ood (a t le a s t 1 /2 ”) U nderlaym ent-grade particleboard ( o a tin g o r g lu e - d o w n o n ly )

O SB (a t le a st 3 /4 ”) E xisting w ood oor

C o n crete: M u st b e fu lly c u re d (a t le a s t 6 0 d a y s o ld ) a n d s h o u ld h a v e m in im u m 6 - m il. p o ly lm b e tw e e n c o n c re te a n d

g r o u n d . Do n ot in sta ll o n c o n c re te u n le ss it sta y s d ry y e a r- ro u n d . C o n c re te m u st b e te ste d fo r m o istu re . If m o istu re m e ter

is unavailable, tape a 2' x 2' section of clear plastic to concrete slab, form ing an airtight seal. If condensation or discoloration

appears on plastic after 24-48 hours, m oisture content is too high for w ood ooring installation. P lease contact a professional

h a rd w o o d o o rin g in sta lle r to im p ro v e su b o o r to a c c e p ta b le le v e l.

C eram ic tile, resilient tile and sheet vinyl: M u s t b e w e l l b o n d e d t o s u b o o r , i n g o o d c o n d i t i o n , c l e a n a n d l e v e l .

C a u tion : D o n o t sa n d e x istin g v in y l o o rs ; th e y m a y c o n ta in a s b e sto s.

R adian t h eat: U se o n ly oatin g installation over radiant heat. Suboor should n ev er exceed 85° F. C heck w ith

m anufacturer's suggested guidelines for correct w ater te m p e ra tu re in sid e h e a tin g p ip e s. S w itc h o h e a tin g u n it o n e o r

tw o d a y s b e fo re o o rin g in sta lla tio n . R o o m te m p e ra tu re sh o u ld n o t v a r y m o re th a n 1 5 ° F y e a r- a ro u n d . F o llo w o a tin g

in sta lla tio n in stru c tio n s fo r b e lo w - g ra d e .

P rep a rin g for in sta lla tion :

D o o r c a sin g s sh o u ld b e u n d e rc u t o r n o tc h e d o u t s o o o rin g w ill t u n d e rn e a th .

This can be don e easily by placing a piece of ooring on the suboor as a height

g u id e fo r y o u r sa w . B a se m o ld in g s a n d d o o r th re sh o ld s sh o u ld b e re m o v e d a n d

re p la c e d a fte r o o rin g in sta lla tio n . S ince w ood expands w ith any increase in

m oisture content, alw ays leave at least a 1/4"-1/2” expansion space betw een ooring

a n d a ll w a lls a n d v e rtic a l o b je c ts (p ip es, cab in ets). Th is w ill b e c o v e re d u p

once you reapply base m o ld in g s a ro u n d th e ro o m . U se w o o d o r p la stic s p a c e rs

d u rin g in sta lla tio n to m a in ta in th is e x p a n sio n sp a c e .

W hen laying ooring, stagger end joints from row to row by at least 18". W hen cutting the last plank in a row to t, you

can use the cut-o end to b e g in th e n e x t ro w . If c u t-o e n d is 8 " o r le ss, cu t a n e w p la n k a t a ra n d o m le n g th a n d u se it to

sta rt n ex t ro w . A lw a y s b e g in e a c h ro w fro m th e sa m e sid e o f th e ro o m .

T o p u ll p la n k s to g e th e r u se a ta p p in g b lo c k a n d h am m e r. W h en n e a r a w a ll, u se a c ro w o r p u ll b a r to c lo se e n d jo in ts. T a k e

care n o t to d am ag e ed g e o f o o rin g .

G ettin g sta rted :

F o r th e b e st a p p e a ra n c e , w o o d o o rin g is o fte n la id p a ra lle l to th e lo n g e st w a ll. Y o u sh o u ld m a k e th e n a l d e c is io n w h ic h

d ire c tio n th e p la n k s w ill ru n b a se d o n th e la y o u t o f th e ro o m a n d lo c a tio n s o f e n tra n c e s a n d w in d o w s. I c o n ic F lo o rs

re c o m m e n d s y o u b e g in in sta lla tio n n e x t to a n o u tsid e w a ll, w h ic h is u su a lly th e stra ig h te st, b e st re fe re n c e fo r e s ta b lis h in g a

stra ig h t w o rk in g lin e .

E sta b lish y o u r w o rk in g lin e b y m e a su rin g a n e q u a l d ista n c e fro m th e w a ll a t b o th e n d s a n d sn a p p in g a c h a lk lin e .

e d ista n c e y o u m e a su re fro m th e w a ll sh o u ld b e th e w id th o f a p la n k p lu s a b o u t 1 /4 ” fo r e x p a n sio n sp a c e .

Prem ium H ardwood Flooring Installation Instructions

p .2

A ccep ta b le S u b oors, continued:

G eneral, continued...

S u b o o r T y p e s :

W ood:

M u st b e d ry a n d w e ll se c u re d . N a il o r sc re w e v e r y 6 " a lo n g jo ists to a v o id sq u e a k in g . If n o t le v e l, sa n d d o w n h ig h

sp o ts a n d ll lo w s p o ts w ith underlaym ent patch .

P rod u cts: P lyw ood (a t le a s t 1 /2 ”) U nderlaym ent-grade particleboard ( o a tin g o r g lu e - d o w n o n ly )

O SB (a t le a st 3 /4 ”) E xisting w ood oor

C o n crete: M u st b e fu lly c u re d (a t le a s t 6 0 d a y s o ld ) a n d s h o u ld h a v e m in im u m 6 - m il. p o ly lm b e tw e e n c o n c re te a n d

g r o u n d . Do n ot in sta ll o n c o n c re te u n le ss it sta y s d ry y e a r- ro u n d . C o n c re te m u st b e te ste d fo r m o istu re . If m o istu re m e ter

is unavailable, tape a 2' x 2' section of clear plastic to concrete slab, form ing an airtight seal. If condensation or discoloration

appears on plastic after 24-48 hours, m oisture content is too high for w ood ooring installation. P lease contact a professional

h a rd w o o d o o rin g in sta lle r to im p ro v e su b o o r to a c c e p ta b le le v e l.

C eram ic tile, resilient tile and sheet vinyl: M u s t b e w e l l b o n d e d t o s u b o o r , i n g o o d c o n d i t i o n , c l e a n a n d l e v e l .

C a u tion : D o n o t sa n d e x istin g v in y l o o rs ; th e y m a y c o n ta in a s b e sto s.

R adian t h eat: U se o n ly oatin g installation over radiant heat. Suboor should n ev er exceed 85° F. C heck w ith

m anufacturer's suggested guidelines for correct w ater te m p e ra tu re in sid e h e a tin g p ip e s. S w itc h o h e a tin g u n it o n e o r

tw o d a y s b e fo re o o rin g in sta lla tio n . R o o m te m p e ra tu re sh o u ld n o t v a r y m o re th a n 1 5 ° F y e a r- a ro u n d . F o llo w o a tin g

in sta lla tio n in stru c tio n s fo r b e lo w - g ra d e .

P rep a rin g for in sta lla tion :

D o o r c a sin g s sh o u ld b e u n d e rc u t o r n o tc h e d o u t s o o o rin g w ill t u n d e rn e a th .

This can be don e easily by placing a piece of ooring on the suboor as a height

g u id e fo r y o u r sa w . B a se m o ld in g s a n d d o o r th re sh o ld s sh o u ld b e re m o v e d a n d

re p la c e d a fte r o o rin g in sta lla tio n . S ince w ood expands w ith any increase in

m oisture content, alw ays leave at least a 1/4"-1/2” expansion space betw een ooring

a n d a ll w a lls a n d v e rtic a l o b je c ts (p ip es, cab in ets). Th is w ill b e c o v e re d u p

once you reapply base m o ld in g s a ro u n d th e ro o m . U se w o o d o r p la stic s p a c e rs

d u rin g in sta lla tio n to m a in ta in th is e x p a n sio n sp a c e .

W hen laying ooring, stagger end joints from row to row by at least 18". W hen cutting the last plank in a row to t, you

can use the cut-o end to b e g in th e n e x t ro w . If c u t-o e n d is 8 " o r le ss, cu t a n e w p la n k a t a ra n d o m le n g th a n d u se it to

sta rt n ex t ro w . A lw a y s b e g in e a c h ro w fro m th e sa m e sid e o f th e ro o m .

T o p u ll p la n k s to g e th e r u se a ta p p in g b lo c k a n d h am m e r. W h en n e a r a w a ll, u se a c ro w o r p u ll b a r to c lo se e n d jo in ts. T a k e

care n o t to d am ag e ed g e o f o o rin g .

G ettin g sta rted :

F o r th e b e st a p p e a ra n c e , w o o d o o rin g is o fte n la id p a ra lle l to th e lo n g e st w a ll. Y o u sh o u ld m a k e th e n a l d e c is io n w h ic h

d ire c tio n th e p la n k s w ill ru n b a se d o n th e la y o u t o f th e ro o m a n d lo c a tio n s o f e n tra n c e s a n d w in d o w s. I c o n ic F lo o rs

re c o m m e n d s y o u b e g in in sta lla tio n n e x t to a n o u tsid e w a ll, w h ic h is u su a lly th e stra ig h te st, b e st re fe re n c e fo r e s ta b lis h in g a

stra ig h t w o rk in g lin e .

E sta b lish y o u r w o rk in g lin e b y m e a su rin g a n e q u a l d ista n c e fro m th e w a ll a t b o th e n d s a n d sn a p p in g a c h a lk lin e .

e d ista n c e y o u m e a su re fro m th e w a ll sh o u ld b e th e w id th o f a p la n k p lu s a b o u t 1 /4 ” fo r e x p a n sio n sp a c e .

Prem ium H ardwood Flooring Installation Instructions

p .2

p.2

For the best appearance, wood ooring is often laid parallel to the longest wall. You should make the nal

decision which direction the planks will run based on the layout of the room and locations of entrances and

windows. PGWood recommends you begin installation next to an outside wall, which is usually the straightest,

best reference for establishing a straight working line.

Establish your working line by measuring an equal distance from the wall at both ends and snapping a chalkline.

e distance you measure from the wall should be the width of a plank plus about 1/4” for expansion space.

A ccep ta b le S u b oors, continued:

G eneral, continued...

S u b o o r T y p e s :

W ood:

M u st b e d ry a n d w e ll se c u re d . N a il o r sc re w e v e r y 6 " a lo n g jo ists to a v o id sq u e a k in g . If n o t le v e l, sa n d d o w n h ig h

sp o ts a n d ll lo w s p o ts w ith underlaym ent patch .

P rod u cts: P lyw ood (a t le a s t 1 /2 ”) U nderlaym ent-grade particleboard ( o a tin g o r g lu e - d o w n o n ly )

O SB (a t le a st 3 /4 ”) E xisting w ood oor

C o n crete: M u st b e fu lly c u re d (a t le a s t 6 0 d a y s o ld ) a n d s h o u ld h a v e m in im u m 6 - m il. p o ly lm b e tw e e n c o n c re te a n d

g r o u n d . Do n ot in sta ll o n c o n c re te u n le ss it sta y s d ry y e a r- ro u n d . C o n c re te m u st b e te ste d fo r m o istu re . If m o istu re m e ter

is unavailable, tape a 2' x 2' section of clear plastic to concrete slab, form ing an airtight seal. If condensation or discoloration

appears on plastic after 24-48 hours, m oisture content is too high for w ood ooring installation. P lease contact a professional

h a rd w o o d o o rin g in sta lle r to im p ro v e su b o o r to a c c e p ta b le le v e l.

C eram ic tile, resilient tile and sheet vinyl: M u s t b e w e l l b o n d e d t o s u b o o r , i n g o o d c o n d i t i o n , c l e a n a n d l e v e l .

C a u tion : D o n o t sa n d e x istin g v in y l o o rs ; th e y m a y c o n ta in a s b e sto s.

R adian t h eat: U se o n ly oatin g installation over radiant heat. Suboor should n ev er exceed 85° F. C heck w ith

m anufacturer's suggested guidelines for correct w ater te m p e ra tu re in sid e h e a tin g p ip e s. S w itc h o h e a tin g u n it o n e o r

tw o d a y s b e fo re o o rin g in sta lla tio n . R o o m te m p e ra tu re sh o u ld n o t v a r y m o re th a n 1 5 ° F y e a r- a ro u n d . F o llo w o a tin g

in sta lla tio n in stru c tio n s fo r b e lo w - g ra d e .

P rep a rin g for in sta lla tion :

D o o r c a sin g s sh o u ld b e u n d e rc u t o r n o tc h e d o u t s o o o rin g w ill t u n d e rn e a th .

This can be don e easily by placing a piece of ooring on the suboor as a height

g u id e fo r y o u r sa w . B a se m o ld in g s a n d d o o r th re sh o ld s sh o u ld b e re m o v e d a n d

re p la c e d a fte r o o rin g in sta lla tio n . S ince w ood expands w ith any increase in

m oisture content, alw ays leave at least a 1/4"-1/2” expansion space betw een ooring

a n d a ll w a lls a n d v e rtic a l o b je c ts (p ip es, cab in ets). Th is w ill b e c o v e re d u p

once you reapply base m o ld in g s a ro u n d th e ro o m . U se w o o d o r p la stic s p a c e rs

d u rin g in sta lla tio n to m a in ta in th is e x p a n sio n sp a c e .

W hen laying ooring, stagger end joints from row to row by at least 18". W hen cutting the last plank in a row to t, you

can use the cut-o end to b e g in th e n e x t ro w . If c u t-o e n d is 8 " o r le ss, cu t a n e w p la n k a t a ra n d o m le n g th a n d u se it to

sta rt n ex t ro w . A lw a y s b e g in e a c h ro w fro m th e sa m e sid e o f th e ro o m .

T o p u ll p la n k s to g e th e r u se a ta p p in g b lo c k a n d h am m e r. W h en n e a r a w a ll, u se a c ro w o r p u ll b a r to c lo se e n d jo in ts. T a k e

care n o t to d am ag e ed g e o f o o rin g .

G ettin g sta rted :

F o r th e b e st a p p e a ra n c e , w o o d o o rin g is o fte n la id p a ra lle l to th e lo n g e st w a ll. Y o u sh o u ld m a k e th e n a l d e c is io n w h ic h

d ire c tio n th e p la n k s w ill ru n b a se d o n th e la y o u t o f th e ro o m a n d lo c a tio n s o f e n tra n c e s a n d w in d o w s. I c o n ic F lo o rs

re c o m m e n d s y o u b e g in in sta lla tio n n e x t to a n o u tsid e w a ll, w h ic h is u su a lly th e stra ig h te st, b e st re fe re n c e fo r e s ta b lis h in g a

stra ig h t w o rk in g lin e .

E sta b lish y o u r w o rk in g lin e b y m e a su rin g a n e q u a l d ista n c e fro m th e w a ll a t b o th e n d s a n d sn a p p in g a c h a lk lin e .

e d ista n c e y o u m e a su re fro m th e w a ll sh o u ld b e th e w id th o f a p la n k p lu s a b o u t 1 /4 ” fo r e x p a n sio n sp a c e .

Prem ium H ardwood Flooring Installation Instructions

p .2

Concrete: Must be fully cured (at least 60 days old) and should have minimum 6-mil. polylm between concrete and

ground. Do not install on concrete unless it stays dry year-round. Concrete must be tested for moisture. If moisture

meter is unavailable, tape a 2’ x 2’ section of clear plastic to concrete slab, forming an airtight seal. If condensation or

discoloration appears on plastic after 24-48 hours, moisture content is too high for wood ooring installation. Please

contact a professional hardwood ooring installer to improve suboor conditions to a acceptable level.

Products: Plywood (at least 1/2”) Underlayment-grade particleboard (oating or glue-down only)

Existing wood oor

• Lay subsequent rows by using ooring or nish nailer to blind nail top inside edge of tongue at 45° angle. Nail

each board every 8-12” and within 2” of each end. Remember to stagger the end joints from row to row, and use

a tapping block as needed to t boards together.

• It may be necessary to face-nail in doorways or tight areas where the nailer won’t t;

• e last row will need to be face-nailed as with the rst two rows.

G ettin g sta rted , con tin u ed

Y o u m a y w a n t to “d ry la y ” a fe w ro w s (n o g lu e o r n a ils) b e fo re sta rtin g in sta lla tio n to c o n rm y o u r la y o u t

d e c isio n s a n d w o rk in g lin e .

N ote: If o u tsid e w a ll is o u t o f sq u a re , a d ju st w o rk in g lin e to m a k e it stra ig h t fo r th e re st o f th e in sta lla tio n . Y o u

w ill n e e d to sc rib e th e rst ro w o f p la n k s to m a tc h th e w a ll a n d m a k e p o ssib le a stra ig h t w o rk in g lin e .

I n sta ll M e t h o d 1 – F lo a tin g

U nderlaym ent:

W e re c o m m e n d M P G lo b a l 'Q u ie tW a lk ' u n d e rla y m e n t. It re p la c e s th e n e e d fo r 6 - m il p o ly lm w h e n in sta llin g in

b e lo w - g ra d e c o n d itio n s. 'Q u ie tW a lk ' (a n d o th e r b ra n d s) h a s a 2 ' (5 c m ) to n g u e ru n n in g a lo n g its le n g th . is

should overlap the second course of underlaym ent and be fastened w ith eith er duct tape or poly tape.

ere is n o need to face-nail the perim eter. e advantage of a oating installation is that it allow s the building to

se e k its o w n c o n d itio n in g /e x p a n sio n /c o n tra c tio n rh y th m . A llo w 3 /1 6 ”p e rim e te r sp a c in g to a llo w th e o o r to re a c t

to se a so n a l e n v iro n m e n ta l c h a n g e . O u r h a rd w o o d p la n k is c o n d itio n e d to 6 - 8 % m o istu re c o n te n t, a n d a s su c h , is

lik e ly th e m o st sta b le c o m p o n e n t in th e b u ild in g a sse m b ly.

●

S ta rt th e rst ro w w ith th e g ro o v e sid e to n g u e - o u t; th a t is, fa c in g th e w a ll;

●

G lu e e n d jo in t o f rst ro w b y a p p ly in g a d h e siv e to th e bottom o f th e g ro o v e ;

●

A lw ays leave 1/4” expansion betw een ooring and all w alls and vertical objects

(pipes, cabinetry). U se w ood or plastic spacers to m aintain this expansion space;

●

L a y su b se q u e n t ro w s o f o o rin g b y a p p ly in g g lu e to sid e a n d e n d jo in ts, a n d

ttin g p la n k s w ith ta p p in g b lo c k . R e m e m b e r to sta g g e r e n d jo in ts fro m ro w

●

t o r o w .

I n sta ll M e t h o d 2 – N a il D o w n

I n s ta llin g r s t a n d s e c o n d r o w s —

●

L a y o o rin g p e rp e n d ic u la r to o o r jo ists, u n le ss su b o o r is e x istin g h a rd w o o d a n d /o r h a s b e e n stre n g th e n e d to

prevent sagging;

●

L a y rst p la n k in sid e c h a lk lin e w ith g ro o v e d e d g e to w a rd w a ll (to n g u e o u t). P re - d rill 1 - 1 /2 ” fro m g ro o v e d e d g e

a n d a b o u t 8 ” a p a rt. S e c u re p la n k s w ith n ish n a ils;

●

U se n a il p u n c h to c o u n te rsin k n a ils, a n d ll w ith w o o d lle r. R e p e a t o n to n g u e e d g e o f p la n k ;

●

Install entire rst and second row in this m anner. A lw ays leave 1/4” expansion s pace betw een ooring and all

w alls and vertical objects (pipes, cabinetry). U se w ood or plastic spacers to m aintain this expansion space.

R em ainder of Installation —

●

L a y su b se q u e n t ro w s b y u sin g o o r n a ile r to b lin d n a il to p in sid e e d g e o f to n g u e a t 4 5 ° a n g le . N a il e a c h b o a rd

e v e r y 8 ” a n d w ith in 2 ” o f e a c h e n d . R e m e m b e r to sta g g e r th e e n d jo in ts fro m ro w to ro w , a n d u se a ta p p in g

b lo c k to t b o a rd s to g e th e r.

●

It m ay be necessary to face-nail in doorw ays or tight areas w h ere the nailer w on't t; and

●

e la st tw o ro w s w ill n e e d to b e fa c e - n a ile d a s w ith th e rst tw o ro w s.

Prem ium H ardwood Flooring Installation Instructions

p.3

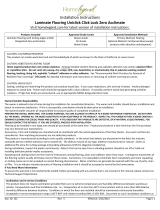

Example of Blind Nail

Example of Face Nail

G ettin g sta rted , con tin u ed

Y o u m a y w a n t to “d ry la y ” a fe w ro w s (n o g lu e o r n a ils) b e fo re sta rtin g in sta lla tio n to c o n rm y o u r la y o u t

d e c isio n s a n d w o rk in g lin e .

N ote: If o u tsid e w a ll is o u t o f sq u a re , a d ju st w o rk in g lin e to m a k e it stra ig h t fo r th e re st o f th e in sta lla tio n . Y o u

w ill n e e d to sc rib e th e rst ro w o f p la n k s to m a tc h th e w a ll a n d m a k e p o ssib le a stra ig h t w o rk in g lin e .

I n sta ll M e t h o d 1 – F lo a tin g

U nderlaym ent:

W e re c o m m e n d M P G lo b a l 'Q u ie tW a lk ' u n d e rla y m e n t. It re p la c e s th e n e e d fo r 6 - m il p o ly lm w h e n in sta llin g in

b e lo w - g ra d e c o n d itio n s. 'Q u ie tW a lk ' (a n d o th e r b ra n d s) h a s a 2 ' (5 c m ) to n g u e ru n n in g a lo n g its le n g th . is

should overlap the second course of underlaym ent and be fastened w ith eith er duct tape or poly tape.

ere is n o need to face-nail the perim eter. e advantage of a oating installation is that it allow s the building to

se e k its o w n c o n d itio n in g /e x p a n sio n /c o n tra c tio n rh y th m . A llo w 3 /1 6 ”p e rim e te r sp a c in g to a llo w th e o o r to re a c t

to se a so n a l e n v iro n m e n ta l c h a n g e . O u r h a rd w o o d p la n k is c o n d itio n e d to 6 - 8 % m o istu re c o n te n t, a n d a s su c h , is

lik e ly th e m o st sta b le c o m p o n e n t in th e b u ild in g a sse m b ly.

●

S ta rt th e rst ro w w ith th e g ro o v e sid e to n g u e - o u t; th a t is, fa c in g th e w a ll;

●

G lu e e n d jo in t o f rst ro w b y a p p ly in g a d h e siv e to th e bottom o f th e g ro o v e ;

●

A lw ays leave 1/4” expansion betw een ooring and all w alls and vertical objects

(pipes, cabinetry). U se w ood or plastic spacers to m aintain this expansion space;

●

L a y su b se q u e n t ro w s o f o o rin g b y a p p ly in g g lu e to sid e a n d e n d jo in ts, a n d

ttin g p la n k s w ith ta p p in g b lo c k . R e m e m b e r to sta g g e r e n d jo in ts fro m ro w

●

t o r o w .

I n sta ll M e t h o d 2 – N a il D o w n

I n s ta llin g r s t a n d s e c o n d r o w s —

●

L a y o o rin g p e rp e n d ic u la r to o o r jo ists, u n le ss su b o o r is e x istin g h a rd w o o d a n d /o r h a s b e e n stre n g th e n e d to

prevent sagging;

●

L a y rst p la n k in sid e c h a lk lin e w ith g ro o v e d e d g e to w a rd w a ll (to n g u e o u t). P re - d rill 1 - 1 /2 ” fro m g ro o v e d e d g e

a n d a b o u t 8 ” a p a rt. S e c u re p la n k s w ith n ish n a ils;

●

U se n a il p u n c h to c o u n te rsin k n a ils, a n d ll w ith w o o d lle r. R e p e a t o n to n g u e e d g e o f p la n k ;

●

Install entire rst and second row in this m anner. A lw ays leave 1/4” expansion s pace betw een ooring and all

w alls and vertical objects (pipes, cabinetry). U se w ood or plastic spacers to m aintain this expansion space.

R em ainder of Installation —

●

L a y su b se q u e n t ro w s b y u sin g o o r n a ile r to b lin d n a il to p in sid e e d g e o f to n g u e a t 4 5 ° a n g le . N a il e a c h b o a rd

e v e r y 8 ” a n d w ith in 2 ” o f e a c h e n d . R e m e m b e r to sta g g e r th e e n d jo in ts fro m ro w to ro w , a n d u se a ta p p in g

b lo c k to t b o a rd s to g e th e r.

●

It m ay be necessary to face-nail in doorw ays or tight areas w h ere the nailer w on't t; and

●

e la st tw o ro w s w ill n e e d to b e fa c e - n a ile d a s w ith th e rst tw o ro w s.

Prem ium H ardwood Flooring Installation Instructions

p.3

Example of Blind Nail

Example of Face Nail

G ettin g sta rted , con tin u ed

Y o u m a y w a n t to “d ry la y ” a fe w ro w s (n o g lu e o r n a ils) b e fo re sta rtin g in sta lla tio n to c o n rm y o u r la y o u t

d e c isio n s a n d w o rk in g lin e .

N ote: If o u tsid e w a ll is o u t o f sq u a re , a d ju st w o rk in g lin e to m a k e it stra ig h t fo r th e re st o f th e in sta lla tio n . Y o u

w ill n e e d to sc rib e th e rst ro w o f p la n k s to m a tc h th e w a ll a n d m a k e p o ssib le a stra ig h t w o rk in g lin e .

I n sta ll M e t h o d 1 – F lo a tin g

U nderlaym ent:

W e re c o m m e n d M P G lo b a l 'Q u ie tW a lk ' u n d e rla y m e n t. It re p la c e s th e n e e d fo r 6 - m il p o ly lm w h e n in sta llin g in

b e lo w - g ra d e c o n d itio n s. 'Q u ie tW a lk ' (a n d o th e r b ra n d s) h a s a 2 ' (5 c m ) to n g u e ru n n in g a lo n g its le n g th . is

should overlap the second course of underlaym ent and be fastened w ith eith er duct tape or poly tape.

ere is n o need to face-nail the perim eter. e advantage of a oating installation is that it allow s the building to

se e k its o w n c o n d itio n in g /e x p a n sio n /c o n tra c tio n rh y th m . A llo w 3 /1 6 ”p e rim e te r sp a c in g to a llo w th e o o r to re a c t

to se a so n a l e n v iro n m e n ta l c h a n g e . O u r h a rd w o o d p la n k is c o n d itio n e d to 6 - 8 % m o istu re c o n te n t, a n d a s su c h , is

lik e ly th e m o st sta b le c o m p o n e n t in th e b u ild in g a sse m b ly.

●

S ta rt th e rst ro w w ith th e g ro o v e sid e to n g u e - o u t; th a t is, fa c in g th e w a ll;

●

G lu e e n d jo in t o f rst ro w b y a p p ly in g a d h e siv e to th e bottom o f th e g ro o v e ;

●

A lw ays leave 1/4” expansion betw een ooring and all w alls and vertical objects

(pipes, cabinetry). U se w ood or plastic spacers to m aintain this expansion space;

●

L a y su b se q u e n t ro w s o f o o rin g b y a p p ly in g g lu e to sid e a n d e n d jo in ts, a n d

ttin g p la n k s w ith ta p p in g b lo c k . R e m e m b e r to sta g g e r e n d jo in ts fro m ro w

●

t o r o w .

I n sta ll M e t h o d 2 – N a il D o w n

I n s ta llin g r s t a n d s e c o n d r o w s —

●

L a y o o rin g p e rp e n d ic u la r to o o r jo ists, u n le ss su b o o r is e x istin g h a rd w o o d a n d /o r h a s b e e n stre n g th e n e d to

prevent sagging;

●

L a y rst p la n k in sid e c h a lk lin e w ith g ro o v e d e d g e to w a rd w a ll (to n g u e o u t). P re - d rill 1 - 1 /2 ” fro m g ro o v e d e d g e

a n d a b o u t 8 ” a p a rt. S e c u re p la n k s w ith n ish n a ils;

●

U se n a il p u n c h to c o u n te rsin k n a ils, a n d ll w ith w o o d lle r. R e p e a t o n to n g u e e d g e o f p la n k ;

●

Install entire rst and second row in this m anner. A lw ays leave 1/4” expansion s pace betw een ooring and all

w alls and vertical objects (pipes, cabinetry). U se w ood or plastic spacers to m aintain this expansion space.

R em ainder of Installation —

●

L a y su b se q u e n t ro w s b y u sin g o o r n a ile r to b lin d n a il to p in sid e e d g e o f to n g u e a t 4 5 ° a n g le . N a il e a c h b o a rd

e v e r y 8 ” a n d w ith in 2 ” o f e a c h e n d . R e m e m b e r to sta g g e r th e e n d jo in ts fro m ro w to ro w , a n d u se a ta p p in g

b lo c k to t b o a rd s to g e th e r.

●

It m ay be necessary to face-nail in doorw ays or tight areas w h ere the nailer w on't t; and

●

e la st tw o ro w s w ill n e e d to b e fa c e - n a ile d a s w ith th e rst tw o ro w s.

Prem ium H ardwood Flooring Installation Instructions

p.3

Example of Blind Nail

Example of Face Nail

G ettin g sta rted , con tin u ed

Y o u m a y w a n t to “d ry la y ” a fe w ro w s (n o g lu e o r n a ils) b e fo re sta rtin g in sta lla tio n to c o n rm y o u r la y o u t

d e c isio n s a n d w o rk in g lin e .

N ote: If o u tsid e w a ll is o u t o f sq u a re , a d ju st w o rk in g lin e to m a k e it stra ig h t fo r th e re st o f th e in sta lla tio n . Y o u

w ill n e e d to sc rib e th e rst ro w o f p la n k s to m a tc h th e w a ll a n d m a k e p o ssib le a stra ig h t w o rk in g lin e .

I n sta ll M e t h o d 1 – F lo a tin g

U nderlaym ent:

W e re c o m m e n d M P G lo b a l 'Q u ie tW a lk ' u n d e rla y m e n t. It re p la c e s th e n e e d fo r 6 - m il p o ly lm w h e n in sta llin g in

b e lo w - g ra d e c o n d itio n s. 'Q u ie tW a lk ' (a n d o th e r b ra n d s) h a s a 2 ' (5 c m ) to n g u e ru n n in g a lo n g its le n g th . is

should overlap the second course of underlaym ent and be fastened w ith eith er duct tape or poly tape.

ere is n o need to face-nail the perim eter. e advantage of a oating installation is that it allow s the building to

se e k its o w n c o n d itio n in g /e x p a n sio n /c o n tra c tio n rh y th m . A llo w 3 /1 6 ”p e rim e te r sp a c in g to a llo w th e o o r to re a c t

to se a so n a l e n v iro n m e n ta l c h a n g e . O u r h a rd w o o d p la n k is c o n d itio n e d to 6 - 8 % m o istu re c o n te n t, a n d a s su c h , is

lik e ly th e m o st sta b le c o m p o n e n t in th e b u ild in g a sse m b ly.

●

S ta rt th e rst ro w w ith th e g ro o v e sid e to n g u e - o u t; th a t is, fa c in g th e w a ll;

●

G lu e e n d jo in t o f rst ro w b y a p p ly in g a d h e siv e to th e bottom o f th e g ro o v e ;

●

A lw ays leave 1/4” expansion betw een ooring and all w alls and vertical objects

(pipes, cabinetry). U se w ood or plastic spacers to m aintain this expansion space;

●

L a y su b se q u e n t ro w s o f o o rin g b y a p p ly in g g lu e to sid e a n d e n d jo in ts, a n d

ttin g p la n k s w ith ta p p in g b lo c k . R e m e m b e r to sta g g e r e n d jo in ts fro m ro w

●

t o r o w .

I n sta ll M e t h o d 2 – N a il D o w n

I n s ta llin g r s t a n d s e c o n d r o w s —

●

L a y o o rin g p e rp e n d ic u la r to o o r jo ists, u n le ss su b o o r is e x istin g h a rd w o o d a n d /o r h a s b e e n stre n g th e n e d to

prevent sagging;

●

L a y rst p la n k in sid e c h a lk lin e w ith g ro o v e d e d g e to w a rd w a ll (to n g u e o u t). P re - d rill 1 - 1 /2 ” fro m g ro o v e d e d g e

a n d a b o u t 8 ” a p a rt. S e c u re p la n k s w ith n ish n a ils;

●

U se n a il p u n c h to c o u n te rsin k n a ils, a n d ll w ith w o o d lle r. R e p e a t o n to n g u e e d g e o f p la n k ;

●

Install entire rst and second row in this m anner. A lw ays leave 1/4” expansion s pace betw een ooring and all

w alls and vertical objects (pipes, cabinetry). U se w ood or plastic spacers to m aintain this expansion space.

R em ainder of Installation —

●

L a y su b se q u e n t ro w s b y u sin g o o r n a ile r to b lin d n a il to p in sid e e d g e o f to n g u e a t 4 5 ° a n g le . N a il e a c h b o a rd

e v e r y 8 ” a n d w ith in 2 ” o f e a c h e n d . R e m e m b e r to sta g g e r th e e n d jo in ts fro m ro w to ro w , a n d u se a ta p p in g

b lo c k to t b o a rd s to g e th e r.

●

It m ay be necessary to face-nail in doorw ays or tight areas w h ere the nailer w on't t; and

●

e la st tw o ro w s w ill n e e d to b e fa c e - n a ile d a s w ith th e rst tw o ro w s.

Prem ium H ardwood Flooring Installation Instructions

p.3

Example of Blind Nail

Example of Face Nail

p.3

• Start the rst row with the groove side tongue-out; that is, facing the wall;

• Glue end joint of rst row by applying PGWood approved adhesive to the bottom of

the groove;

• Always leave 1/4” expansion between ooring and all walls and vertical objects

(pipes, cabinetry). Use wood or plastic spacers to maintain this expansion space;

• Lay subsequent rows of ooring by applying glue to side and end joints, and tting

planks with tapping block. Remember to stagger end joints from row to row.

• Lay ooring perpendicular to oor joists, unless suboor is existing hardwood and/or has been strengthened to

prevent sagging;

• Lay rst plank inside chalkline with grooved edge toward wall (tongue out). Secure planks with nish nails.

• Use nail punch to countersink nails, and ll with wood ller.

• Install entire rst row in this manner. Always leave 1/4” expansion s pace between ooring and all

walls and vertical objects (pipes, cabinetry). Use wood or plastic spacers to maintain this expansion space.

Underlayment:

Use Suitable 6 mil rated ooring polylm for ooring installations when installing in below grade conditions.

Polylm should be overlapped at the seams and fastened with either duct tape or poly tape.

ere is no need to nail the perimeter. e advantage of a oating installation is that it allows the building to seek

its own conditioning/expansion/contraction rhythm. Allow 3/16” perimeter spacing to allow the oor to react to

seasonal environmental change. Our hardwood plank is conditioned to 6-8% moisture content, and as such, is

likely the most stable component in the building assembly.

Installing rst and second rows—

Remainder of Installation—

Install Method 2 – Nail Down

Example of Face Nail

Example of Blind Nail

6

I n sta ll M e t h o d 3 – G lu e D o w n

S preading A dhesive—

●

U se o n ly I c o n ic F lo o rs a p p ro v e d a d h e siv e s. Ic o n ic re c o m m e n d s B o stik 'B e st'. R e a d a d h e siv e in stru c tio n s

carefully for proper trow el size and adh esive set tim e.

W arning: N e v e r u se th e “ w e t la y ” o r “ lo o se la y ” m e th o d o f in sta llin g I c o n ic

F lo o rs h a rd w o o d o o rs. is is w h e n y o u in sta ll o o rin g im m e d ia te ly a fte r

spreading adhesive. is m ethod w ill trap m oisture under th e oor, and w ill

c a u se o o rin g to w a rp .

●

A lw ays allow for adequate ventilation w h en w orking w ith ooring adhesives!

●

R ead A dhesive instructions for proper set tim e before beginning installation. is is usually 30 m inutes.

●

S tarting at outside w all, spread as m uch adhesive as can be covered by ooring in one hour. O r, a s

recom m ended by your adhesive instructions. S pread w ith trow el at 45° angle.

In sta llin g th e F lo o r–

●

O n c e a d h e siv e h a s se t, la y th e rst ro w o f o o rin g w ith g ro o v e fa c in g th e w a ll. C o n tin u e la y in g o o r u n til

a d h e siv e is c o v e re d . A lw a y s c h e c k y o u r w o rk in g lin e s to b e su re th e o o r is still a lig n e d . U se ta p p in g b lo c k

to t planks togeth er. B e careful not to let installed oor m ove on the w et adhesive w hile you are w orking.

●

W h e n r s t s e c t i o n i s n i s h e d , c o n t i n u e t o s p r e a d a d h e s i v e a n d l a y o o r i n g s e c t i o n b y s e c t i o n u n t i l i n s t a l l

is c o m p le te . U se a d a m p c lo th to im m e d ia te ly re m o v e a n y a d h e siv e th a t g e ts o n o o rin g su rfa c e . R e m e m b e r

to sta g g e r e n d jo in ts fro m ro w to ro w .

●

A lw ays leave at least 1/4” expansion space betw een ooring and all w alls and vertical objects (pipes, cabinets.

U se w o o d o r p la stic sp a c e rs d u rin g in sta lla tio n to m a in ta in th is e x p a n sio n sp a c e .

●

W a lk e a c h se c tio n o f o o rin g fo o t- b y - fo o t w ith in th e a d h e siv e w o rk in g tim e to e n su re a so lid b o n d w ith th e

adhesive.

●

F lo o rin g p la n k s o n th e p e rim e te r o f th e ro o m m a y re q u ire w e ig h tin g u n til a d h e siv e c u re s su c ie n tly to h o ld

th e m d o w n .

F

inishing the Job—

●

R e m o v e e x p a n sio n sp a c e rs a n d in sta ll o r re in sta ll b a se m o u ld in g to c o v e r e x p a n sio n sp a c e .

●

In sta ll a n y tra n sitio n p ie c e s th a t m a y b e n e e d e d in c lu d in g re d u c e r strip s a n d T -m o ld in g s.

●

If G lu e -D o w n o r F lo a tin g , d o n o t a llo w fo o t tra c o r h e a v y fu rn itu re o n th e o o r fo r 2 4 h o u rs.

●

D u st m o p o r v a c u u m th e o o r to re m o v e a n y re sid u a l d irt/d eb ris.

Prem ium H ardwood Flooring Installation Instructions

p .4

p.4

Use only PGWood approved adhesives. PGWood recommends Bostik ‘Best’. Read adhesive instructions

carefully for proper trowel size and adhesive set time.

•

6

I n sta ll M e t h o d 3 – G lu e D o w n

S preading A dhesive—

●

U se o n ly I c o n ic F lo o rs a p p ro v e d a d h e siv e s. Ic o n ic re c o m m e n d s B o stik 'B e st'. R e a d a d h e siv e in stru c tio n s

carefully for proper trow el size and adh esive set tim e.

W arning: N e v e r u se th e “ w e t la y ” o r “ lo o se la y ” m e th o d o f in sta llin g I c o n ic

F lo o rs h a rd w o o d o o rs. is is w h e n y o u in sta ll o o rin g im m e d ia te ly a fte r

spreading adhesive. is m ethod w ill trap m oisture under th e oor, and w ill

c a u se o o rin g to w a rp .

●

A lw ays allow for adequate ventilation w h en w orking w ith ooring adhesives!

●

R ead A dhesive instructions for proper set tim e before beginning installation. is is usually 30 m inutes.

●

S tarting at outside w all, spread as m uch adhesive as can be covered by ooring in one hour. O r, a s

recom m ended by your adhesive instructions. S pread w ith trow el at 45° angle.

In sta llin g th e F lo o r–

●

O n c e a d h e siv e h a s se t, la y th e rst ro w o f o o rin g w ith g ro o v e fa c in g th e w a ll. C o n tin u e la y in g o o r u n til

a d h e siv e is c o v e re d . A lw a y s c h e c k y o u r w o rk in g lin e s to b e su re th e o o r is still a lig n e d . U se ta p p in g b lo c k

to t planks togeth er. B e careful not to let installed oor m ove on the w et adhesive w hile you are w orking.

●

W h e n r s t s e c t i o n i s n i s h e d , c o n t i n u e t o s p r e a d a d h e s i v e a n d l a y o o r i n g s e c t i o n b y s e c t i o n u n t i l i n s t a l l

is c o m p le te . U se a d a m p c lo th to im m e d ia te ly re m o v e a n y a d h e siv e th a t g e ts o n o o rin g su rfa c e . R e m e m b e r

to sta g g e r e n d jo in ts fro m ro w to ro w .

●

A lw ays leave at least 1/4” expansion space betw een ooring and all w alls and vertical objects (pipes, cabinets.

U se w o o d o r p la stic sp a c e rs d u rin g in sta lla tio n to m a in ta in th is e x p a n sio n sp a c e .

●

W a lk e a c h se c tio n o f o o rin g fo o t- b y - fo o t w ith in th e a d h e siv e w o rk in g tim e to e n su re a so lid b o n d w ith th e

adhesive.

●

F lo o rin g p la n k s o n th e p e rim e te r o f th e ro o m m a y re q u ire w e ig h tin g u n til a d h e siv e c u re s su c ie n tly to h o ld

th e m d o w n .

Finishing the Job—

●

R e m o v e e x p a n sio n sp a c e rs a n d in sta ll o r re in sta ll b a se m o u ld in g to c o v e r e x p a n sio n sp a c e .

●

In sta ll a n y tra n sitio n p ie c e s th a t m a y b e n e e d e d in c lu d in g re d u c e r strip s a n d T -m o ld in g s.

●

If G lu e -D o w n o r F lo a tin g , d o n o t a llo w fo o t tra c o r h e a v y fu rn itu re o n th e o o r fo r 2 4 h o u rs.

●

D u st m o p o r v a c u u m th e o o r to re m o v e a n y re sid u a l d irt/d eb ris.

Prem ium H ardwood Flooring Installation Instructions

p .4

Warning: Warning: Never use the “wet lay” or “loose lay” method of installing PGWood

hardwood oors, unless the adhesive says “suitable for wet lay or walk on method”. Only high

quality adhesives will say suitable for “wet lay” method, otherwise lower grade adhesives have

moisture that will be trapped under your new oor, and will cause the ooring to warp.

PGWood Floors / Attn: Claims

PO Box 68

Port Gamble, WA 98364

PGWood Floors warrants that the PGWood wood oors:

• Are free from defects in lamination, milling and assembly and will remain free from these defects for

a lifetime.

• Will remain structurally sound during normal moisture changes provided that the proper suboor

and installation requirements were met.

• Are protected by an enhanced nish that will not wear through for a lifetime (not to exceed 100

years) under normal residential use, if recommended maintenance steps are followed.

Warranty excludes impact damage or wear from heavy furniture or equipment used without proper protection. Warranty

excludes indentations, scratches or surface damage caused by lack of proper maintenance, misuse, negligence, spiked heel

shoes, water, erosion, pebbles, sand or other abrasives. No warranties apply to product designated as “closeouts”, or non

standard items. Such product is sold “as is”. Over time, normal exposure to sunlight will bring subtle changes in the shading of

any hardwood oor; these changes may vary in areas of the oor that are blocked from sunlight, such as under area rugs. This is

not a product defect. Any damage that occurs during shipping is the responsibility of the shipping company.

If PGWood accepts a claim under this warranty, it will repair or replace, at its option, the affected ooring material. This warranty

covers the repair or replacement of affected material only, it does not cover any labor cost. If ooring is purchased and installed

by PGWood certied Flooring Consultant and PGWood Certied Flooring Installer, the workmanship will be covered for a

“Lifetime”. All repair, replacement or substitute options will still apply if necessary (Lifetime is not to exceed 100 years from

date of purchase). If ooring product for which the claim is being made is no longer available, PGWood will replace the affected

ooring material with product of equal or greater value. Any claims for warranty must be made in writing within 30 days after it

has been detected and mailed to the following address.

PGWood Floors will refund, if requested, the purchase price for the portion on the oor that fails. PGWood reserves the right

to have a designated representative inspect the oor and remove samples for evaluation of claim. This warranty is transferable.

This warranty is limited to a one time repair or replacement of defective material and shall be the buyer’s exclusive remedy. No

other warranties, expressed or implied, are made and under no circumstances shall PGWood be liable for any loss or dam-

age arising from the purchase, use or inability to use this product or any special, indirect, incidental or consequential damages.

This warranty gives you specic legal rights, and you may also have other rights, which vary from state to state. This warranty is

“Non-Transferable”.

Lifetime Limited Warranty

Finish

Warranty

/