VI.KT.G7.02

6 | © Danfoss | 2018.05

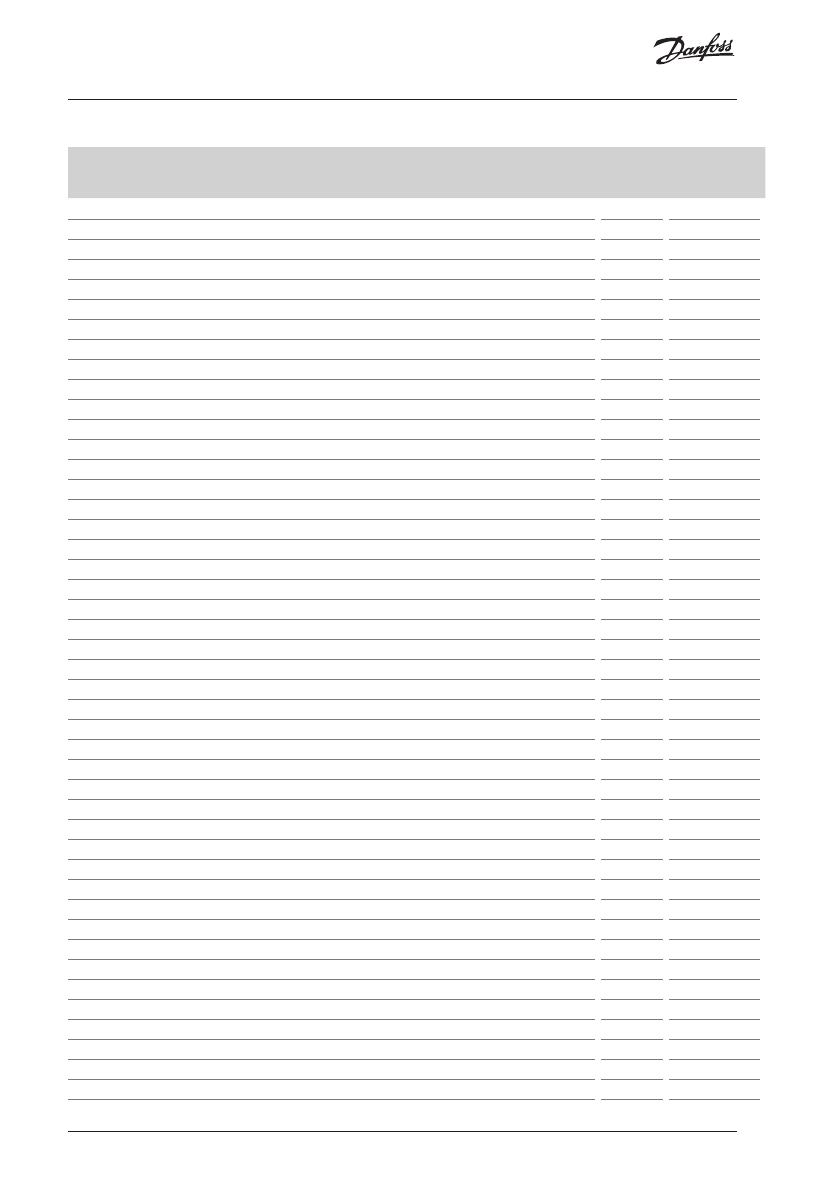

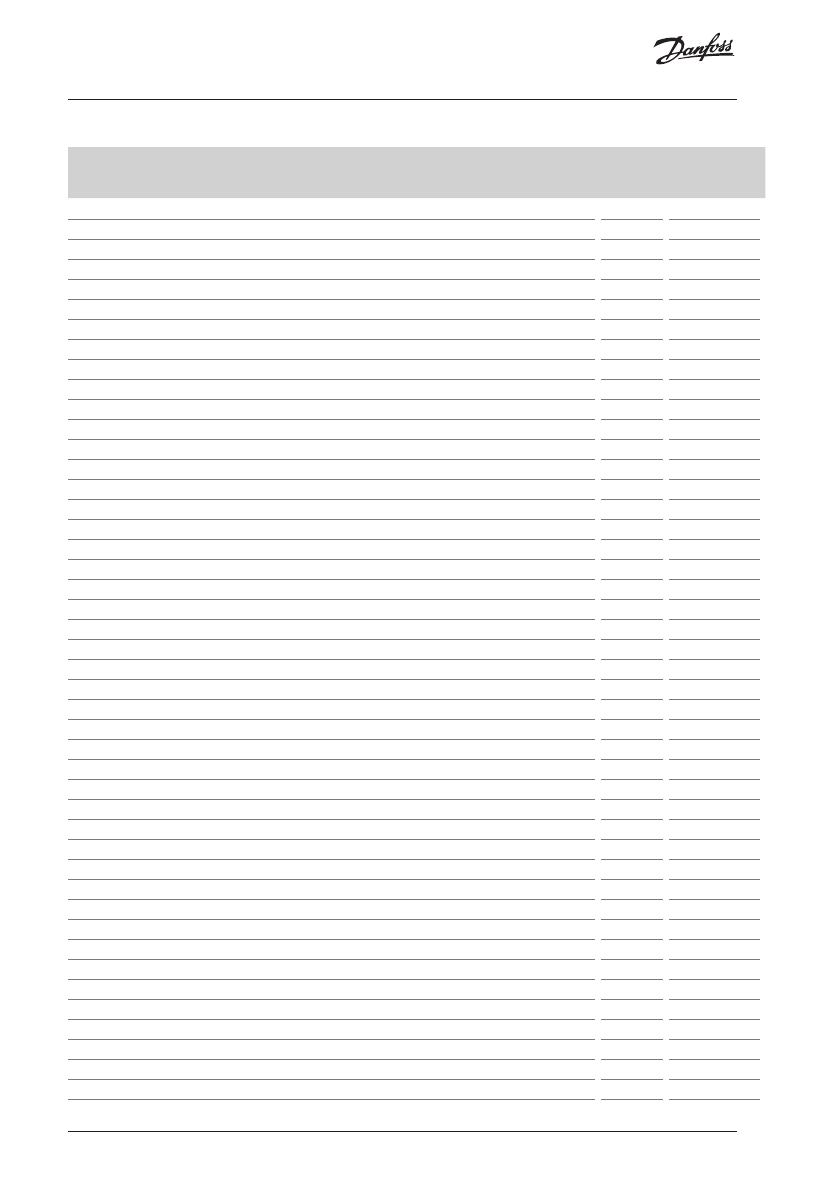

Settings overview

Line Page

Factory

setting

Your setting

Slope 2175 11

Displace (parallel displacement) 2176 13

Temp. min. (flow temp. limit, min.) 2177 13

Temp. max. (flow temp. limit, max.) 2178 13

Intgr. time (time constant for room temp.) 3015 16

Gain - max. (room temp. limitation, max.) 3182 16

Gain - min. (room temp. limitation, min.) 3183 16

Limit (return temp. limitation) 4030 17

Gain - max. (return temp. limitation - max. influence) 4035 18

Gain - min. (return temp. limitation - min. influence) 4036 18

Intgr. time (time constant for return temp. limitation) 4037 19

Priority (priority for return temp. limitation) 4085 19

Auto-reduct (setback temp. dependent on outdoor temp.) 5011 20

Boost 5012 20

Ramp (reference ramping) 5013 21

Optimizer (optimizing time constant) 5014 21

Based on (optimization based on room / outdoor temp.) 5020 22

Total stop 5021 23

S1 T filter (outdoor temp. filter) 5081 23

Cut-out (limit for heating cut-out) 5179 24

Motor prot. (motor protection) 6174 25

Xp (proportional band) 6184 25

Tn (integration time constant) 6185 25

M1 run (running time of the motorized control valve) 6186 25

Nz (neutral zone) 6187 26

ECA address (choice of room panel / remote control) 7010 28

P1 exercise (pump exercise) 7022 28

M1 exercise (valve exercise) 7023 28

Actuator (gear motor / thermo actuator) 7024 28

DHW prior. (closed valve / normal operation) 7052 29

P1 frost T (frost protection) 7077 29

P1 heat T (heat demand) 7078 30

Standby T (standby temperature) 7093 30

Ext. (external override) 7141 30

Knee point 7162 31

Min. on time (min. activation time gear motor) 7189 31

Daylight (daylight saving time changeover) 7198 31

ECL address (master / slave address) 7199 31

Type 7600 32

Code no. 8300 33

Ver. (version no.) 8301 33

Backlight (display brightness) 8310 33

Contrast (display contrast) 8311 33

Language 8315 34

MOD address (MODBUS address) 8320 34

1.2

0

10 °C

90 °C

OFF

-4.0

0.0

50 °C

-2.0

0.0

25 s

OFF

-15 °C

OFF

OFF

OFF

OUT

OFF

100

18 °C

OFF

80 K

30 s

35 s

3 K

OFF

ON

OFF

GEAR

OFF

2 °C

20 °C

10 °C

OFF

40 °C

10

ON

15

130

XXXX

XXXX

16

10

English

5

!