Page is loading ...

ATTACHING PRESSURE REGULATOR TO CYLIN-

DER AND TIP.

1. Make sure the regulator valve knob is in the closed

position by turning knob in the clockwise direction. Do

NOT use excessive force which may cause the knob to

bind. Closing the knob prevents fuel gas from escaping

while attaching the regulator to the cylinder.

F-15-166

March, 1998

Instructions for

R-10-40-600

FUEL GAS REGULATOR

P/N 21504

These INSTRUCTIONS are for experienced operators. If you are not fully familiar with the principles of operation and safe practices

for air-fuel gas equipment, we urge you to read our booklet Precautions and Safe Practices, Form 2035. Do NOT permit untrained

persons to operate this equipment. Do NOT attempt to operate this equipment until you have read and fully understand these

instructions. If you do not fully understand these instructions, contact your supplier for further information.

The R-1 0-40-600 adjustable pressure regulator (0 - 40 psi) was designed for industrial use with FG-2 (propylene), propane, or Mapp

®

gas

supplied in disposable 14 - 16 oz. cylinders and PREST-0-LITE

®

Swirljet

®

LPG air/fuel tips sizes 3, 4, and 5.

Do NOT use the SJ-6LPG Swirljet

®

tip with the R-10-40-600.

2. Attach Swirljet

®

tip to the swivel nut part of the regula-

tor and then by holding tip in the desired position, hand

tighten the swivel nut to lock the tip in place.

3. Attach the regulator to the cylinder by turning cylinder

clockwise and tighten HAND TIGHT.

Do not use the SJ-6LPG tip with the regulator.

Be sure this information reaches the operator.

You can get extra copies through your supplier.

Use Swirljet Tips

SJ-2LPG

SJ-4LPG

SJ-5LPG

Disposable Cylinder

FG-2 16.0 Oz.

MAPP

®

16.0 Oz.

Propane 14.1 Oz.

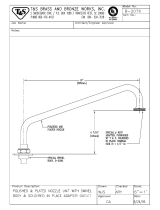

Swivel Nut

Pressure Adjusting Knob

Figure 1 - Hand Torch Indentification

RETAIN THESE INSTRUCTIONS

FOR FUTURE REFERENCE.

SAFETY PRECAUTIONS

Every worker should be familiar with the following personnel protection and fire prevention

measures:

1. Read and follow all precautions on the cylinder label.

2. Keep cylinder and appliances out of the reach of children.

3. ALWAYS disconnect regulator from cylinder when not in use. Be sure to close the valve knob when-

ever unit is not in actual operation.

4. This regulator is for use with FG-2 (propylene), propane and Mapp

®

gas only. NEVER use acetylene

or any other gas.

5. Fuel gas is extremely flammable when mixed with air and may form explosive mixtures with air.

Operate appliances ONLY in well-ventilated areas.

6. Always check for gas leaks. Light the torch and then (using a brush) apply soapy water around the

regulator cylinder connection, at the tip-to-regulator connection, and at all regulator joints. If leakage

is indicated, by bubbling at any of these points, shut off the torch and tighten the connections. Relight

and retest. Do NOT continue to use leaky equipment. Do NOT test for leaks with a flame.

7. Never store cylinders in areas of habitation such as inside home or office.

8. NEVER store or transport cylinders in car trunks, drawers, cabinets or other confined spaces, or in

any location where the temperature may exceed 120° F (49° C), or where sparks, flames, or combus-

tible material may be present.

9. Do NOT use lighted torch in any place where flammable or explosive gases, liquids, or other materi-

als may be accidentally ignited.

10. Do NOT leave lighted torch unattended. ALWAYS turn off torch when stopping work or when leaving

work area.

11. DO NOT solder or heat a container that contains or has contained flammable liquids or vapors, such

as gasoline, unless the container has been completely purged of all traces of flammable liquids and

vapors.

12. Do NOT attempt to force heat or warm the cylinder in any way to increase cylinder pressure or gas

flow. Move cylinder to a warm location if necessary.

13. When the cylinder is exhausted, ALWAYS discard it in a safe place. Do NOT puncture or incinerate.

NEVER attempt to refill it with any gas or liquid.

14. Do NOT alter equipment.

15. Fumes and gases can harm your health. Keep your head out of the fumes. Do not breathe fumes and

gases caused by the flame. Use enough ventilation. The type and amount of fumes and gases

depend on the equipment and supplies used. Air samples can be used to find out what respiratory

protection is needed.

16. Heat rays (infrared radiation from the flame or hot metal) can injure eyes. Wear correct eye and body

protection.

17. For more information on safety and health, refer to the following publications: (1) ESAB Form 2035;

(2) OSHA Title 29 CFR 1910, Sub-part Q, available form U.S. Government Printing Office, Washing-

ton, D.C. 20402; (3) American National Standard Z49.1, available from the American Welding Soci-

ety, 550 N.W. LeJuene Rd. Miami, FL 33126.

MAINTENANCE

1. If the flame length cannot be maintained, resulting in

overheating the tip, the orifice nozzle P/N 21478 -

SJ-3LPG, P/N 21479 - SJ-4LPG, P/N 21480-SJ-5LPG

or filter screw (P/N 998311) in the back end of the tip

may be clogged. Use an 1/8 in. Allen wrench to re-

move filter screw, and then tap the tip lightly to dis-

lodge the nozzle. Blowing air through the front end of

the orifice nozzle may dislodge any dirt or grit that may

have lodged in the small orifice. Do not clean orifice

hole with a wire or similar object. The orifice hole can

LIGHTING TORCH AND FLAME ADJUSTMENT

1. Open the regulator knob one full turn (counter-clock-

wise), and immediately light flame at tip with a friction

lighter. Do NOT use a match. Use of a match can seri-

ously burn your hand.

2. After the tip has been lit, adjust regulator valve for the

proper flame setting. See Figure 2 Flame Settings

below.

3. As contents of the cylinder are withdrawn, pressure in

cylinder may drop slightly. Be sure to readjust the regu-

lator as necessary to maintain the correct flame set-

ting.

4. Shut off the regulator when work is completed. Always

remove regulator from cylinder when not in use.

INVERTED OPERATION

1. When using FG-2 (propylene) or propane, the cylinder

may be used in an inverted or horizontal position when

using Swirljet

®

tips size 3 and 4. However, prolong use

in this position may cause liquid fuel to enter the regu-

lator and cause the flame to flare. If this happens, turn

the cylinder upright or close the regulator knob until the

liquid evaporates permitting normal operation. Inverted

use with Swirljet tip size 5 is not recommended.

2. When using Mapp

®

gas, operating the cylinder in an

inverted or horizontal position is not recommended.

Correct Adjustment

Concentrated flame. Dark blue points extend from tip approx. 1-1/2 tip

diameters beyond end of tip. Tip operates cool when correctly adjusted.

Too Little Gas

Soft Flame - pressure too low. Tip will overheat. Dark blue portion of

flame barely visible from end of tip. Flame pink in color.

Too Much Gas

Dark blue portion of flame comes out from tip. Combustion taking

place beyond flame tube.

Figure 2 - Flame Settings

SWIRLJET

®

TIP DATA

TIP COPPER TUBING SIZE, IN. DIA. APPROX. WORK TIME

SIZE SOFT-SOLDER SILVER-SOLDER OF DISPOSABLE CYLINDER

3 1/4 TO 1 1/8 TO 3/8 6 HR.

4 3/8 TO 1- 1 /2 1/4 TO 5/8 3 HR.

5 1 TO 2-1/2 5/8 TO 1-3/8 1 HR.

easily become enlarged causing improper operation. If

orifice nozzle cannot be cleaned, replace both orifice

nozzle and filter screw.

2. Periodically, check for leakage by brushing soapy wa-

ter solution around all regulator valve joints and con-

nections after lighting the torch. If leakage is noted by

bubbling of the solution at any point and it cannot be

stopped by simply HAND tightening, then the regulator

should be replaced. Do NOT operate with regulator in

faulty condition. Do NOT attempt to repair the regula-

tor.

ACCESSORIES

Hose Adaptor, P/N 999315 - Connects to pressure regulat-

ing valve in place of tip permitting use of fuel gas hose with

A - size fitting.

PREST-O-LITE

®

and SWIRLJET

®

are registered trademarks of ESAB Welding & Cutting Products. Mapp

®

is a registered trademark of Airco, Inc.

Cobra Attachment, P/N 600533- No. 403 torch handle, 12 ft.

A-A fuel gas fitted hose assembly, and hose adaptor under

one part number permitting remote operation of tip from

disposable cylinder of FG-2, Mapp

®

or propane.

F-15-166 3/98 Printed in U.S.A.

/