ATR243 - User manual - 3

Table of contents

1 Safety guide lines ......................................................................................................................................5

2 Model identification .................................................................................................................................5

3 Technical Data ...........................................................................................................................................5

3.1 General data .....................................................................................................................................5

3.2 Hardware data .................................................................................................................................6

3.3 Software data ................................................................................................................................... 6

4 Dimensions and Installation .................................................................................................................. 7

4.1 Panel Assembly ................................................................................................................................8

4.2 Electronics Removal ........................................................................................................................ 8

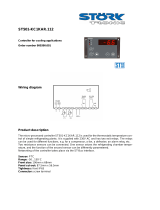

5 Electrical wirings .......................................................................................................................................9

5.1 Wiring diagram ................................................................................................................................9

6 Display and Key Functions .................................................................................................................... 15

6.1 Numeric Indicators (Display) ...................................................................................................... 15

6.2 Meaning of Status Lights (Led)...................................................................................................15

6.3 Keys ....................................................................................................................................................16

7 Controller Functions ............................................................................................................................... 16

7.1 Modifying Main Setpoint and Alarm Setpoint Values ......................................................... 16

7.2 Auto-Tuning ....................................................................................................................................16

7.3 Manual Tuning ...............................................................................................................................16

7.4 Automatic Tuning .......................................................................................................................... 17

7.5 Soft-Sta rt .......................................................................................................................................... 17

7.6 Automatic / Manual Regulation for % Output Control ....................................................... 17

7.7 Pre-Programmed Cycle ................................................................................................................18

7.8 CN-Config-Module (optional) ....................................................................................................19

7.9 Latch-on function......................................................................................................................... 20

7.10 Loop Break Alarm On Current Trasformer ............................................................................. 20

7.11 Digital Input Functions ............................................................................................................... 22

7.12 Dual Action Heating-Cooling ................................................................................................... 23

8 Serial Communication ...........................................................................................................................24

9 Enter configuration ................................................................................................................................ 29

9.1 Loading default values................................................................................................................ 29

10 Table of Configuration Parameters ................................................................................................... 30

11 Alarm Intervention Modes ....................................................................................................................42

12 Table of Anomaly Signals ......................................................................................................................45

13 Configuration EASY-UP ........................................................................................................................ 46