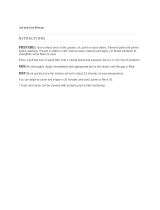

BODY CONSTRUCTION BC-3

1. Radiator support lower member

2. Radiator support upper member

3. Radiator support center member

4. Fender panel

5. Fender apron inner panel

6. Front shock absorber housing panel

7. Shock absorber cover

8. Shock absorber housing reinforcement

9. Fender apron upper outer panel

10. Fender apron upper inner panel

11. Fender apron front upper reinforcement

12. Fender apron front lower reinforcement

13. Transaxle side mounting bracket

14. Engine mounting support

15. Front side inner member

16. Front side member inner reinforcement

17. Front side outer member

18. Engine mounting rear bracket

19. Engine mounting front bracket

20. Front end module mounting reinforcement

21. Front end module mounting bracket

22. Front side member outer extension

23. Front side member outer front extension

24. Sub frame mounting front support

25. Front side rear lower member

26. Front side member rear lower reinforcement

27. Front side inner rear reinforcement

28. Front side rear upper reinforcement

29. Front side member rear lower extension

30. Side sill inner front extension

31. Sub frame rear mounting bracket

32. Sub frame rear mounting reinforcement

33. Sub frame rear mounting support

34. Side inner panel

35. Cowl cross member front bracket

36. Cowl cross member rear bracket

37. Front pillar upper extension

38. Front seatbelt reel mounting bracket

39. Center pillar inner reinforcement

40. Side outer panel

41. Front pillar outer lower reinforcement

42. Front pillar outer upper reinforcement

43. Center pillar outer reinforcement

44. Center pillar outer upper reinforcement

45. Side sill outer reinforcement

46. Roof side outer reinforcement

47. Roof side outer rail

48. Fuel filler mounting

49. Side outer rear extension

50. Rear combination lamp housing panel

51. Quarter inner lower panel

52. Quarter inner upper panel

53. Quarter panel reinforcement

54. Wheel house inner panel

55. Rear package tray side front panel

56. Rear package tray side rear panel

57. Cowl top upper reinforcement

58. Cowl top lower reinforcement

59. Shock absorber housing gusset assembly

60. Cowl top panel assembly

61. Dash panel assembly

62. Center floor panel assembly

63. Side sill inner panel

64. Roof panel

65. Roof front rail assembly

66. Roof center NO.1 rail

67. Roof center rail assembly

68. Roof center NO.3 rail

69. Roof rear rail assembly

70. Sun roof reinforcement ring

71. Hood panel assembly

72. Trunk lid panel assembly

73. Back panel

74. Rear transverse member

75. Trunk lid striker support

76. Rear transverse extension

77. Rear package tray center panel

78. Rear package tray front lower member

79. Rear window opening outer frame

80. Rear floor rear panel assembly

81. Rear floor side panel assembly

82. Rear floor front panel

83. Rear seat mounting bracket

84. Rear floor front extension

85. Rear floor front cross member assembly

86. Rear floor front cross reinforcement

87. Center floor side member rear extension

88. Rear floor front filler assembly

89. Center floor side member rear extension assembly

90. Rear floor center cross member assembly

91. Rear floor center cross center reinforcement

92. Rear door panel assembly

93. Rear floor center cross member extension

94. Rear suspension mounting upper bracket

95. Rear floor side member assembly

96. Rear floor side rear member assembly

97. Rear suspension spring sheet reinforcement

98. Trailing arm mounting upper bracket

99. Rear tie down reinforcement

100. Side sill inner rear panel

101. Trailing arm mounting upper bracket assembly

102. Side sill inner rear reinforcement

103. Trailing arm mounting lower bracket assembly

104. Front door panel assembly

mashinesoft.com

09120146259