Pall Allegro™ XRS 25 Biocontainer Validation Guide

- Type

- Validation Guide

Pall Allegro™ XRS 25 Biocontainer is a single-use, gamma-irradiated biocontainer designed for use with the Allegro XRS 20 and 25 bioreactors. Constructed from low-density polyethylene (LDPE) film and high-density polyethylene (HDPE) ports, it is specifically designed to provide optimal growth conditions for mammalian cells, with a capacity of up to 25 liters.

The Allegro™ XRS 25 Biocontainer features a unique design that promotes efficient mixing of gases and liquids, fostering optimal cell growth and productivity. Its robust construction ensures reliability and durability, making it ideal for large-scale cell culture applications, including monoclonal antibody production and vaccine manufacturing.

Pall Allegro™ XRS 25 Biocontainer is a single-use, gamma-irradiated biocontainer designed for use with the Allegro XRS 20 and 25 bioreactors. Constructed from low-density polyethylene (LDPE) film and high-density polyethylene (HDPE) ports, it is specifically designed to provide optimal growth conditions for mammalian cells, with a capacity of up to 25 liters.

The Allegro™ XRS 25 Biocontainer features a unique design that promotes efficient mixing of gases and liquids, fostering optimal cell growth and productivity. Its robust construction ensures reliability and durability, making it ideal for large-scale cell culture applications, including monoclonal antibody production and vaccine manufacturing.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

Pall Allegro™ XRS 25 Biocontainer Validation Guide

- Type

- Validation Guide

Pall Allegro™ XRS 25 Biocontainer is a single-use, gamma-irradiated biocontainer designed for use with the Allegro XRS 20 and 25 bioreactors. Constructed from low-density polyethylene (LDPE) film and high-density polyethylene (HDPE) ports, it is specifically designed to provide optimal growth conditions for mammalian cells, with a capacity of up to 25 liters.

The Allegro™ XRS 25 Biocontainer features a unique design that promotes efficient mixing of gases and liquids, fostering optimal cell growth and productivity. Its robust construction ensures reliability and durability, making it ideal for large-scale cell culture applications, including monoclonal antibody production and vaccine manufacturing.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Pall Allegro™ STR 200 Biocontainer Validation Guide

Pall Allegro™ STR 200 Biocontainer Validation Guide

-

Pall Allegro™ 3D Biocontainers and Totes Validation Guide

Pall Allegro™ 3D Biocontainers and Totes Validation Guide

-

Pall Allegro™ 2D Biocontainers Validation Guide

Pall Allegro™ 2D Biocontainers Validation Guide

-

Pall Allegro™ 50 L Single-Use Mixer Biocontainers Validation Guide

Pall Allegro™ 50 L Single-Use Mixer Biocontainers Validation Guide

-

Pall Allegro™ TK8 Film Validation Guide

Pall Allegro™ TK8 Film Validation Guide

-

Pall Allegro™ 3D Biocontainers and Allegro Totes Step-by-Step Guide

Pall Allegro™ 3D Biocontainers and Allegro Totes Step-by-Step Guide

-

Pall Pneumatic Box Standard Step-by-Step Guide

Pall Pneumatic Box Standard Step-by-Step Guide

-

Pall Allegro™ Magnetic Mixer Drive Unit Step-by-Step Guide

Pall Allegro™ Magnetic Mixer Drive Unit Step-by-Step Guide

-

Pall Powder Handling Bags Validation Guide

Pall Powder Handling Bags Validation Guide

-

Pall HIT™ System Validation Guide

Pall HIT™ System Validation Guide

Other documents

-

Thermo Fisher Scientific Pierce Rapid Gel Clot User guide

Thermo Fisher Scientific Pierce Rapid Gel Clot User guide

-

Thermo Fisher Scientific Pierce Chromogenic User guide

Thermo Fisher Scientific Pierce Chromogenic User guide

-

Thermo Fisher Scientific Pierce LAL Chromogenic User guide

Thermo Fisher Scientific Pierce LAL Chromogenic User guide

-

Audibax FFN-5 Normal Fog Fluid 5L Owner's manual

Audibax FFN-5 Normal Fog Fluid 5L Owner's manual

-

Audibax FFH-5 Heavy Fog Fluid 5L Owner's manual

Audibax FFH-5 Heavy Fog Fluid 5L Owner's manual

-

Thermo Fisher Scientific Omni FTIR User manual

Thermo Fisher Scientific Omni FTIR User manual

-

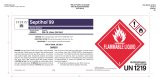

Steris Septihol 99 Alcohol Solution Operating instructions

Steris Septihol 99 Alcohol Solution Operating instructions

-

Thermo Fisher Scientific Zeocin Selection Reagent User guide

Thermo Fisher Scientific Zeocin Selection Reagent User guide

-

Thermo Fisher Scientific HyPerforma 2.1 Single-Use Bioreactor User guide

Thermo Fisher Scientific HyPerforma 2.1 Single-Use Bioreactor User guide

-

Thermo Fisher Scientific DR4 Mouse Embryonic Fibroblasts, Irradiated User guide

Thermo Fisher Scientific DR4 Mouse Embryonic Fibroblasts, Irradiated User guide