Page is loading ...

July

1980

FORM:

OM-825A

Effective

With

Serial

No.

HE810183

MODEL

AM

C-23A

RMC-23AG

RMC-23AW

R

RMC-23AWRG

RMC-23A

VS

RMC-23AVSG

RMC-23AWRVS

RMC-23AWR

VSG

OWNERS

MANUAL

IllullEul!

MILLER

ELECTRIC

MFG.

CO.

718

S.

BOUNDS

ST.

P.O.

Box

1079

APPLETON,

WI

54912

USA

PRINTED

IN

USA,

~IC~t~trtt~

~

LIMITED

WARRANTY

EFFECTIVE:

JUNE

1.

1979

This

warranty

supersedes

all

previous

MILLER

warranties

and

is

ex

elusive

with

no

other

guarantees

or

warranties

expressed

or

implied.

LIMITED

WARRANTY-

Subject

to

the

terms

and

conditions

As

a

matter

of

general

policy

only,

Miller

may

honor

claims

hereof,

Miller

Electric

Mfg.

Co.,

Appleton,

Wisconsin

warrants

submitted

by

the

original

user

within

the

foregoing

periods.

to

its

Distributor/Dealer

that

all

new

and

unused

Equipment

1

furnished

by

Miller

is

free

from

detect

in

workmanship

and

In

the

case

of

Millers

breach

of

warranty

or

any

other

duty

material

as

of

the

time

and

place

of

delivery

by

Miller.

No

war-

with

respect

to

the

quality

of

any

goods,

the

exclusive

remedies

ranty

is

made

by

Miller

with

respect

to

engines,

trade

ac-

therefore

shall

be,

at

Millers

option

(11

repair

or

121

replacement

cessories

or

other

items

marrufactured

by

others.

Such

or,

where

authorized

in

writing

hy

Miller

in

appropriate

cases,

131

(

ongines,

trade

accessories

arid

other

items

are

sold

sublect

to

the

reasonable

cost

of

repair

or

replacement

at

an

authorized

~.

the

warranties

of

their

respective

manufacturers,

if

any

.

All

Miller

service

station

or

141

payment

of

or

credit

for

the

purchase

engeres

are

warranted

by

their

manufacturer

for

one

year

from

price

(less

reasonable

depreciation

based

upon

actual

usel

upon

dale

of

original

purchase.

return

of

the

goods

at

Customers

risk

and

expense.

Upon

receipt

of

notice

of

apparent

defect

or

failure,

Miller

shall

instruct

the

clai-

r

Except

as

specified

below,

Millers

warranty

does

not

apply

mant

on

the

warranty

claim

procedures

to

be

followed.

S

to

components

having

normal

usetul

life

of

le~s

tlran

one

Ill

year,

such

as

spot

welder

tips,

relay

and

contactor

points,

ANY

EXPRESS

WARRANTY

NOT

PROVIDED

REREIN

ANU

~

MILLERMATIC

parts

that

come

in

contact

willi

the

welding

ANY

IMPLIED

WARRANTY,

GUARANTY

OR

REPRESENTA-

~

wire

including

nozzles

and

nozzle

insulators

where

failure

does

TION

AS

TO

PERFORMANCE,

AND

ANY

REMEDY

FOR

not

result

from

defect

in

workmanship

or

material.

BREACR

OF

CONTRACT

WHICH,

BUT

FOR

THIS

PROVISION.

k~

MIGHT

ARISE

BY

IMPLICATION,

OPERATION

OF

LAW,

Miller

shall

be

required

to

honor

warranty

claims

on

war-

CUSTOM

OF

TRADE

OR

COURSE

OF

DEALING,

INCLUDING

ranted

Equipmerrt

in

the

event

of

lailure

resulting

from

a

defect

ANY

IMPLIED

WARRANTY

OF

MERCRANTABILITY

OR

OF

~

within

the

following

periods

from

the

date

of

delivery

of

Equip-

FITNESS

FOR

PARTICULAR

PURPOSE,

WITH

RESPECT

TO

ment

to

the

original

user:

ANY

AND

ALL

EOUIPMENT

FURNISHED

BY

MILLER

IS

EX

CLUDED

AND

DISCLAIMED

BY

MILLER.

1.

Arcwelders,

power

sources

and

components

-

-

1

year

2.

Original

main

power

rectifiers

3

years,

EXCEPT

AS

EXPRESSLY

PROVIDED

BY

MILLER

IN

(labor

-

1

year

onlyl

WRITING,

MILLER

PRODUCTS

ARE

INTENDED

FOR

3.

All

welding

guns

and

feeder/guns

90

days

ULTIMATE

PURCHASE

BY

COMMERCIAL/INDUSTRIAL

r

4.

All

other

Millermatic

Feeders

1

year

USERS

AND

FOR

OPERATION

BY

PERSONS

TRAINED

AND

5.

Replacement

or

repair

parts,

exclusive

of

labor

-

60

days

EXPERIENCED

IN

THE

USE

-

AND

MAINTENANCE

OF

(

S

-

6.

Batteries

Smooths

-

WELDING

EOUIPMENT

AND

NOT

FOR

CONSUMERS

OR

~

-

-

CONSUMER

USE.

MILLER

WARRANTIES

DO

NOT

EXTEND

-

~

provided

that

Miller

is

notified

in

writing

witlrin

tlsrty

(301

days

TO.

AND

NO

RESELLER

IS

AUTHORIZED

TO

EXTEND

of

the

date

of

such

failure

MILLER

S

WARRANTIFS

10

ANY

CONSUMER

4rThC

,,,

~

.,,

~

--

~-g-

..~.

~

~.

~

~

~.

1-1.

GENERAL

This

manual

has

been

prepared

especially

for

use

in

familiar

izing

personnel

with

the

design,

installation,

operation,

main

tenance.

and

troubleshooting

of

this

equipment.

All

informa

tion

presented

herein

should

be

given

careful

consideration

to

assure

optimum

performance

of

this

equipment.

1-2.

RECEIVING-HANDLING

Prior

to

installing

this

equipment,

clean

all

packing

material

from

around

the

unit

and

carefully

inspect

for

any

damage

that

may

have

occurred

during

shipment.

Any

claims

for

loss

or

damage

that

may

have

occurred

in

transit

must

be

filed

by

the

purchaser

with

the

carrier.

A

copy

of

the

bill

of

lading

and

freight

bill

will

be

furnished

by

the

carrier

on

request

if

occasion

to

file

claim

arises.

When

requesting

information

concerning

this

equipment,

it

is

essential

that

Model

Description

and/or

Stock

Number

and

Serial

(or

Style)

Numbers

of

the

equipment

be

supplied.

1-3.

DESCRIPTION

The

remote

motor

control

is

a

means

for

crater

elimination,

low

current

start,

and

manual

remote

contactor

control.

The

remote

motor

controls

were

designed

to

be

used

with

any

welding

power

source

having

a

remote

amperage

control

receptacle.

The

RMC-23A(G)

and

RMC-23AV5(G)

alto

pro

vide

for

remote

contactor

control

for

those

welding

power

sources

equipped

with

a

remote

con

tactor

control

receptacle.

These

controls

have

a

115

volts

ac

revertible

motor

with

a

272

to

1

gear

reduction

coupled

to

the

amperage

control.

The

RMC-23AVS(G)

model

has

a

variable

speed

control

for

controlling

the

speed

of

the

motor.

The

RMC-23A(G),

and

RMC-23AWR

models

operate

from

minimum

to

maximum

within

approximately

4

to

6

seconds.

The

speed

at

which

the

RMC-23AVS(G)

operates

is

adjustable

within

a

range

of 3

to

60

seconds.

1-4.

SAFETY

Before

the

equipment

is

put

into

operation,

the

safety

sec

tion

at

the

front

of

the

welding

power

source

or

welding

generator

manual

should

be

ready

completely.

This

will

help

avoid

possible

injury

due

to

misuse

or

improper

welding

applications.

1

-

Place

the

remote

control

unit

on

top

of

or

near

the

weld

ing

power

source.

2.

Insert

the

3

prong

twistlock

plug

into

the

remote

amper

age

control

receptacle

on

the

welding

power

source.

3.

Place

the

Standard-Remote

Amperage

Control

Switch

on

the

welding

power

source

in

the

REMOTE

position.

4.

Insert

the

twistlock

plug

into

the

Remote

Contactor

Con

trol

Receptacle.

5.

Place

the

Standard-Remote

Contactor

Control

Switch,

on

the

welding

power

source

in

the

REMOTE

position.

6.

Tape

the

Remote

Control

Switch

to

the

electrode

holder.

This

circuit

is

a

low

voltage

circuit.

7.

Insert

the 2

prong

straight

plug

into

a

115

volts

ac

exter

nal

power

supply

and

ground

the

green

lead.

If

the

weld

ng

power

source

incorporates

a

1/2

kva

transformer,

the

115

volts

ac

power

plug

may

be

connected

to

the

115

volts

ac

source

on

the

welding

power

source.

(See

circuit

diagram

for

the

welding

power

source).

SECTION

3

-

OPERATION

1.

Place

the

ON-OFF

Power

Switch

on

the

welding

power

source

in

she

ON

position.

2.

Select

the

proper

amperage

range

on

the

welding

power

source.

3.

Adjust

the

Fine

Current

Control

on

the

welding

power

source

to

the

maximum

amperage

desired

or

allowable

by

the

tungsten

or

electrode.

4.

Place

the

Power

Switch

on

the

remote

control

unit

in

the

ON

position.

The

pilot

light

will

indicate

power

being

supplied

to

the

remote

control

unit.

5.

Slide

the

switch

forward

to

increase

current.

The

contac

tor

will

close

and

the

welding

power

source

will

go

into

operation

as

the

switch

is

moved.

6.

Placing

she

switch

in

the

center

will

stop

the

control

at

any

desired

position.

7.

For

the

RMC-23AV5(G)

model,

set

the

speed

control

as

follows:

For

a

fast

change

of

current,

set

the

control

near

100.

For

a

slow

change

of

current,

set

the

control

near

zero.

The

control

may

be

adjusted

to

obtain

repeatable

speeds

within

a

range

of

3-60

seconds.

8.

Push

the

Remote

Control

Switch

backwards

to

reduce

current.

When

the

remote

control

reaches

minimum,

the

contactor

control

(if

used)

will

open

the

contactor

and

shut

down

the

welding

power

source.

SECTION

1

-

INTRODUCTION

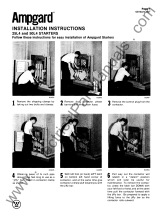

Figure

1-1.

RMC-23A(G)

TA.040

go3

SECTION

2

-

INSTALLATION

Figure

1-2.

RMC-23AV5(G)

TA.040

884

OM-B25

Page

1

TO

115V.

AC

RECEPTACLE

TO

REMOTE

CONTACTOR

CONTROL

RECEPTACLE

~

TO

115V.

AC

RECEPTACLE

Figure

3-1.

Circuit

Diagram

For

RMC-23A

&

RMC-23AWR

Figure

3-2.

Circuit

Diagram

For

RMC-23AVS

&

RMC-23AWRVS

Circuit

Diagram

No.

CA-040

903-1

Dl

TO

REMOTE

AMPERAGE

CONTROL

RECEPTACLE

PLG2

PRONG

VIEW

PLG1

PLG3

RI

A~

~C.

563

000

IT

Circuit

Diagram

No.

CA-040

884-1

Bi

Cl

IT

00000

7~

3

12

7

4

CR1

<

PLG~

PLG

a

PRONG

VIEW

Wfi1

LS3

8LK.

PLG

3

TO

REMOTE

CONTACTOR

CONTROL

RECEPTACLE

Page

2

TO

REMOTE

AMPERAGE

CONTROL

RECEPTACLE

PLG2

PRONG

VIEW

TO

115V.

AC

RECEPTACLE

TO

REMOTE

CONTACTOR

CONTROL

RECEPTACLE

R

MAX.

Figure

3-3.

Circuit

Diagram

For

RMC-23AG

&

RMC-23AWRG

TO

115V.

AC

RECEPTACLE

rQ~-O

WHT

L53

BLK.

PLO

z

PRONG

VIEW

-

REMOTE

AMPERAGE

CONTROL

RECEPTACLE

PLG3

TO

REMOTE

CONTACTOR

CONTROL

RECEPTACLE

Circuit

Diagram

No.

CA.041

163.1A1

Figure

3-4.

Circuit

Diagram

For

RMC-23AVSG

&

RMC-23AWRVSG

WHF

CPN

BL

K.

PLG1

INC.

BL

K

PLG3

563

WHI

~

~

IT

GRN.

I.

I.

Circuit

Diagram

No.

CA-041

162-1A1

IT

00000

71

3

12

7

4

CR1

PLGi

eLk.

I

II

OM-825

Page

3

July

1980

FORM:

OM-825A

PARTS

LIST

Effective

With

Serial

No.

HE810183

MODEL

RMC-23A

RMC-23AG

RMC-23AWR

RMC-23AWR

G

R

MC-23AVS

RMC-23AVSG

R

MC-23AWRVS

RMC-23AWR

VSG

a,

0

0

P

a

I-.

.0

E

a,

a

a

C

C

a,

LI~

N

I-

OM-825

Page

1

Quantity

Model

Item

Dia.

Factory

No.

Mkgs.

Part

No.

Figure

A

Description

C,,

c,J

o

C,,

a

C.,

C.J

a

Complete Assembly

a

U)

>

C,)

C.J

a

0

U,

>

C.,

a

C,)

>

C.)

a

0

U)

>

C.)

a

1

014923

WRAPPER

1

1 1

1

1

014928

WRAPPER

1

1

1

025217

WRAPPER

1

1

2

t

NAMEPLATE

1

1

1

1

1

1

1

ji

3

R2

030

152

RHEOSTAT,

WW

50

watt

300

ohm

1

1

1 1

4

Si

011

609

SWITCH,

toggle

SPDT

10

amp

125

volts

.

1

1

1

1

1

1

1

5

Ri

030

142

RHEOSTAT,WW

150

watt

15

ohm

1

1

1

1

5

Ri

030

143

RHEOSTAT,

WW

300

watt

36

ohm

1

5

Ri

028

502

RHEOSTAT,

WW

300

watt

36

ohm

1

1

6

7

010837

022529

PIN,spring3/32x5/8

BRACKET,

mtg

-

motor

&

rheostat

1

1

1

1

1

1

1

1

1

1

1

1

1

1

7

8

018

682

602

172

BRACKET,

mtg

-

rheostat

SCREW,

set

10.32

x

3/i6

3

3

3

3

1

3

1

3

3

3

9

024

663

CAM

ASSEMBLY

3

3

3

3

3

3

3

3

10

601

117

CLIP,

jiffy

1/2

inch

1

1

1

1

1

1

1

1

ii

025

186

BRACKET,

mtg

-

motor

1

1

12

M

032

676

MOTOR,

gear

115

volts

ac

1

1

1

1

12

M

032680

MOTOR,gearli5voltsdc

1

1

1

1

13

iT

038602

BLOCK,terminal

30amp3pole

1

1

1

1

13

iT

038622

BLOCK,terminal30amp5

pole

1

1

1

1

14

CR1,2

034613

RELAY,ii5voltsac3PDT

2

2

2

2

D1-4

026202

DIODE,

lamp

400

volts

4

4

4

4

15

+603

528

TUBING,

plastic

3/8

2

ft.

2

ft.

2

ft.

2

ft.

2

ft.

2

ft.

2

fti2

ft.

16

023

608

CORD,

portable

16/3

28

ft

1

1

1

1

1

1

1

1

17

011

757

SWITCH,

slide

(consisting

of)

1

1

1

1

1

1

1

1

18

010860

.CLAMP,hose

1

1

1

1

1

1

1

1

19

PLG3

039

618

CAP,

twistlock

2P2W

1

1

1

1

19

PLG3

035

494

CAP,

grounded

-

twistlock

3P3W

1

1

1

1

20

023

607

CORD,

portable

16/2

6

ft

1

20

+600

341

CORD,

portable

16/3

6

ft.

6

ft.

6

ft.

6

ft.

21

R3

025224

RESISTOR,fixed50wattl000hm

1

1

1

1

22

014

924

PANEL,

rear

1 1

1

1

I

22

025152

PANEL,rear

1

1

22

025811

PANEL,rear

1

1

23

PLG2

605

797

CAP,

twistlock

3P3W

1 1 1

1

1

1

-

1

24

023

621

CORD,

portable

16/3

5

ft

1

1 1

1

1

1

.1

25

26

PLG1

023618

010

916

CORD

SET,

ll5volts3/C

lOft

CONNECTOR,

clamp

-

cable

3/4

1

2

1

2

1

2

1

2

i

2

1

2

1

2

:1

2

27

600176

BUSHING,steel

4

4

4

4

28

019663

MOUNT,neophrene

4

4

4

4

29

021 195

LABEL,

terminal

marking

5

pole

1

1

1

1

30

SRi

035914

RECTIFIER,400volts25amp

1

1

1

1

31

014926

BASE

1

1 1

1

31

025145

BASE

1

1

31

025219

BASE

1

1

32

018

684

BRACKET,

mtg

-

switch

rear

1

1

33

LS1-3

011

628

SWITCH,limit

15

amp

125

volts

3 3

3

3

3

3

3

3

34

018

562

BRACKET,

mtg

-

switch

front

1

1

35

027664

PANEL,front

1

1

1 1

35

024150

PANEL,front

1

1

35

025810

PANEL,front

1

1

36

012

111

LABEL,on-off

Si

1 1 1

1

1

1

1

1

37

013

758

PLATE,

indicator

1 1

1

1

1

1

OM-825

Page

2

013

757

009

728

019

660

024

366

011

197

027

628

PL1

*027

629

027

631

Cl

031

741

022

534

C1-3

031

643

PLATE,

indicator

POINTER

&

SHAFT

INDICATOR

1

POINTER,

w/knob

KNOB,

pointer

-

rheostat

PLATE,

indicator

-

rheostat

LENS,

red

-

indicator

light

1

BULB,

slide

base

120

volts

1

HOUSING,

indicator

light

1

CAPACITOR,

paper

oil

4

uf

370

volts

...

1

CLAMP,

capacitor

1

CAPACITOR,

ceramic

.01

uf

500

volts...

Quantity

Mode

1

1

1

1

1

1

1

1

1

1

1

1

1

1

11

1

1

11

1 1

11

1

1

1

1

*Recommended

Spare

Parts.

+These

items

are

ordered

by

the

foot.

tOrder

nameplate

by

stock,

model,

and

serial

numbers.

BE

SURE

TO

PROVIDE

STOCK,

MODEL,

AND

SERIAL

NUMBERS

WHEN

ORDERING

REPLACEMENT

PARTS.

Item

Dia.

Factory

No.

Mkgs.

Part

No.

Figure

A

I

C,,

c-J

Description

I

(

S

C,,

(J

Complete

Assembly

(Continued)

Cl)

>

C,,

CS1

a

U)

>

C,,

C,.J

a

U)

>

C,,

a

0

U)

>

C,)

c.1

a

cc

37

38

38

39

40

41

42

43

1

1

1

1 1

1

1

1

1

1

1

1

1

1

1

1

1

3

3

3~

3

Page

3

/