Table of Contents RT /...

wc_bo0154652012enTOC.fm 4

4. Maintenance 42

4.1 Transporting Machine ..........................................................................42

4.2 Lifting Machine ....................................................................................42

4.3 Job Site Storage ..................................................................................43

4.4 Storage ................................................................................................44

4.5 New Machines .....................................................................................44

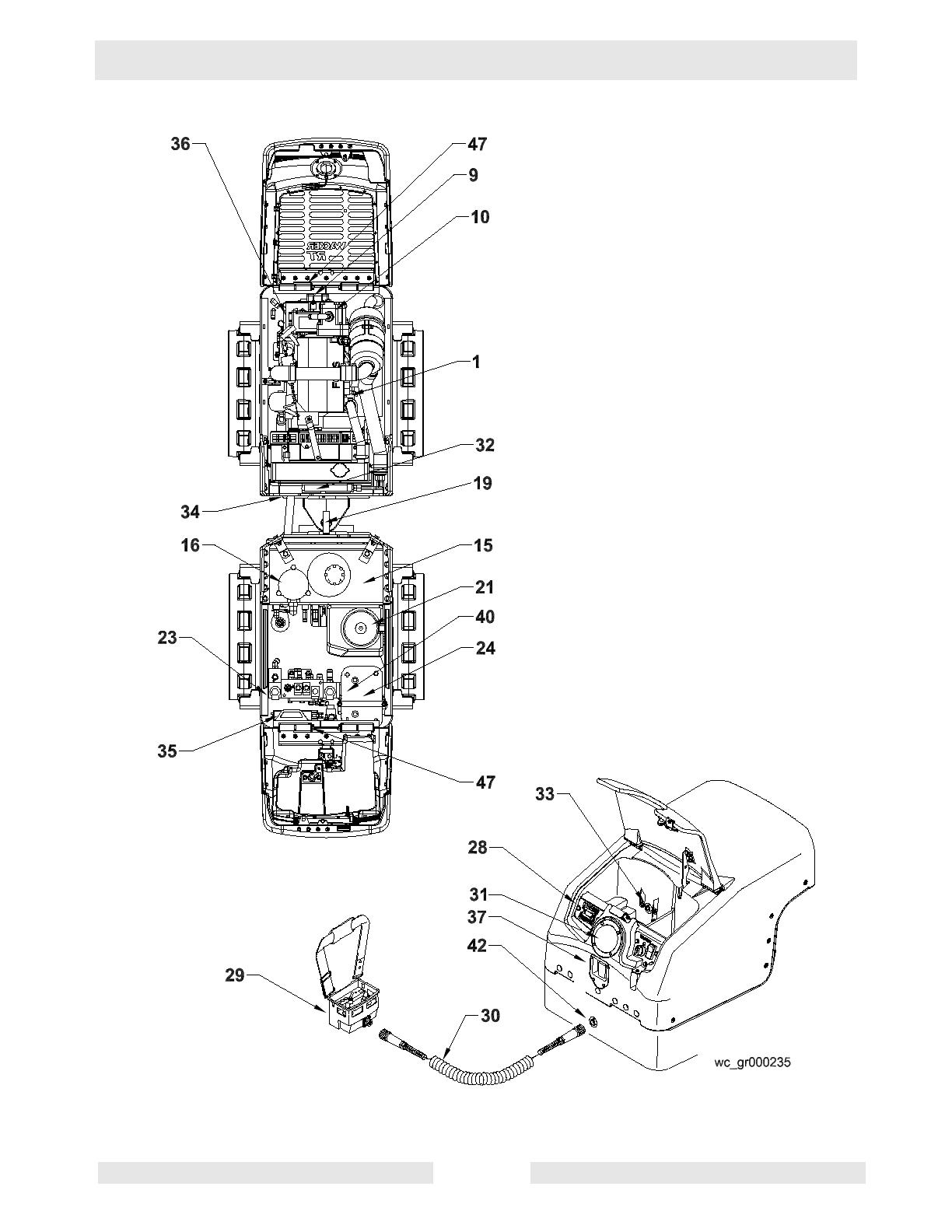

4.6 Periodic Maintenance Schedules ........................................................45

4.7 Hydraulic Oil Requirements .................................................................46

4.8 Hydraulic Oil Level ..............................................................................46

4.9 Changing Hydraulic Oil & Filter ...........................................................47

4.10 Articulated Joint, Steering Cylinder, and Hood Hinges .......................48

4.11 Cleaning SmartControl™ Transmitter .................................................48

4.12 Drive Gearcase ...................................................................................49

4.13 Exciter Lubrication ...............................................................................50

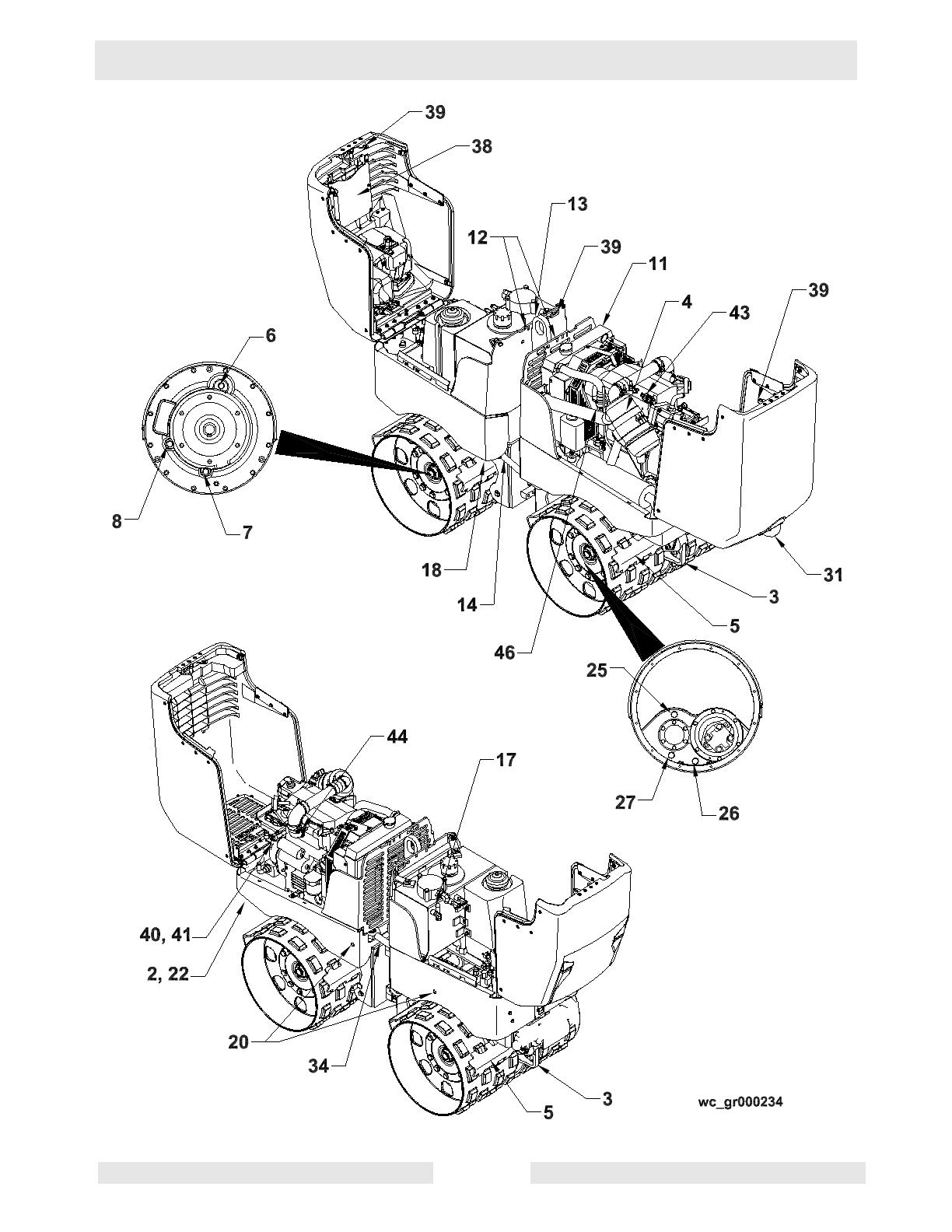

4.14 Scrapers ..............................................................................................51

4.15 Shockmounts .......................................................................................51

4.16 Changing Drums .................................................................................52

4.17 Battery .................................................................................................53

4.18 Engine Oil System ...............................................................................54

4.19 Engine Oil and Filter ............................................................................55

4.20 Air Cleaner ..........................................................................................56

4.21 Engine Fuel Delivery System Maintenance .........................................57

4.22 Fuel Filter ............................................................................................57

4.23 Priming the Fuel System .....................................................................58

4.24 Engine Coolant ....................................................................................58

4.25 Valve Clearances ................................................................................59

4.26 Adjusting Engine Fan Belt ...................................................................60

4.27 Basic Troubleshooting .........................................................................62

5. Technical Data 64

5.1 Engine .................................................................................................64

5.2 Roller ...................................................................................................65

5.3 Lubrication ...........................................................................................66

5.4 Sound and Vibration Measurements ...................................................66

5.5 Dimensions—0009025, 0009026, 0620365, 0620366, 0620397 ........67

5.6 Dimensions—0620324 ........................................................................67

5.7 Wiring Schematic—Machine Rev. 121 and lower ...............................68

5.8 Wiring Schematic—Machine Rev. 122 and higher ..............................70