Page is loading ...

OPERATING INSTRUCTIONS

NAV210

2D LiDAR sensors

2

8024592/2019-08| SICKOPERATING INSTRUCTIONS | NAV210

Subject to change without notice

Described product

Product family: NAV210

Manufacturer

SICK AG

Erwin-Sick-Str. 1 · 79183 Waldkirch · Germany

Phone: +49 7641 469-0

Fax: +49 7641 469-1149

E-mail: [email protected]

Production location

SICK AG

Merkurring·20 22143 Hamburg · Germany

Legal information

This work is protected by copyright. The associated rights are reserved by SICK AG.

Reproduction of this document or parts of this document is only permissible within the

limits of the legal determination of copyright law.

Any modification, expurgation or translation of this document is prohibited without the

express written permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

CONTENTS

3

8024592/2019-08| SICK OPERATING INSTRUCTIONS | NAV210

Subject to change without notice

Contents

1 About this document................................................................................. 5

1.1 Purpose of this document...............................................................................5

1.2 Target group .................................................................................................... 5

1.3 Information depth ...........................................................................................5

1.4 Symbols used ..................................................................................................6

2 Safety information..................................................................................... 7

2.1 Authorized personnel......................................................................................7

2.2 Intended use ...................................................................................................7

2.3 General safety notes and protective measures.............................................8

2.3.1 Electrical installation work .............................................................8

2.3.2 Laser radiation from the 2D LiDAR sensor....................................9

2.4 Quick stop and quick restart ........................................................................10

2.4.1 Switching off the NAV210 ............................................................10

2.4.2 Switching on the NAV210 again...................................................10

2.5 Protection of the environment......................................................................10

2.5.1 Power consumption ......................................................................10

2.5.2 Disposal after final decommissioning .........................................10

3 Product description .................................................................................11

3.1 Scope of delivery...........................................................................................11

3.2 Structure of the NAV210 ..............................................................................12

3.3 Operating and status indicators ...................................................................13

3.3.1 Operator interface ........................................................................13

3.3.2 Status indicators...........................................................................13

3.4 Operating principle of the NAV210 ..............................................................15

3.4.1 Impact of objects on the measurement ......................................16

3.4.2 Sensing range of the NAV210......................................................17

3.4.3 Beam diameter and measuring point distance...........................18

3.4.4 Sensing range of the NAV210......................................................19

3.5 Measuring mode ...........................................................................................20

3.5.1 Contamination measurement ......................................................20

3.6 Output of measured values ..........................................................................21

3.7 Integrating the NAV210 into the control system of an automated guided

vehicle ...........................................................................................................21

3.7.1 Data interfaces .............................................................................21

3.7.2 Communicating data via telegrams .............................................21

3.7.3 Output of measured values of a second reflective pulse ...........23

3.7.4 Digital output ................................................................................25

3.7.5 Synchronizing the clock in the automated guided vehicle and the

NAV210 .........................................................................................25

3.7.6 Result Port ....................................................................................26

3.8 Digital switching outputs ..............................................................................27

CONTENTS

4

8024592/2019-08| SICKOP E RA TI N G I NS T RU C TI O N S | NAV210

Subject to change without notice

3.9 Project planning............................................................................................ 27

3.9.1 System requirements of the NAV210.......................................... 27

3.9.2 Mounting requirements ............................................................... 28

3.9.3 Distance between the NAV210 and the object/surface to be

measured...................................................................................... 28

3.9.4 Beam diameter and measuring point distance .......................... 29

3.9.5 Heating ......................................................................................... 30

4 Mounting...................................................................................................31

4.1 Overview of the mounting steps .................................................................. 31

4.2 Preparation for mounting ............................................................................. 31

4.2.1 Getting the components to be mounted ready ........................... 31

4.2.2 Getting the accessories and material ready ............................... 31

4.2.3 Getting the tools ready................................................................. 31

4.2.4 Selecting the mounting location.................................................. 32

4.3 Steps for mounting ....................................................................................... 32

4.3.1 Direct mounting............................................................................ 33

4.3.2 Mounting with mounting kit 1a.................................................... 33

4.3.3 Mounting with mounting kit 1b.................................................... 34

4.3.4 Mounting with mounting kit 2 and 3 ........................................... 35

4.4 Dismantling the NAV210.............................................................................. 35

5 Electrical installation...............................................................................36

5.1 Overview of the installation steps................................................................ 36

5.2 NAV210 connections.................................................................................... 36

5.3 Preparation for electrical installation .......................................................... 39

5.3.1 Supply voltage .............................................................................. 39

5.3.2 Wire cross-section ........................................................................ 39

5.3.3 General requirements of the data interfaces ............................. 39

5.4 Carrying out the electrical installation on the NAV210............................... 40

5.4.1 Auxiliary means ............................................................................ 40

5.4.2 Connecting to the auxiliary and Ethernet interface of the NAV210

40

5.4.3 Wiring the M12 round connector on the NAV210 ...................... 40

5.4.4 Wiring inputs and outputs on the NAV210 ................................. 42

6 Commissioning and configuration........................................................44

6.1 Overview of the commissioning steps ......................................................... 44

6.2 SOPAS ET configuration software ................................................................ 44

6.2.1 Installing SOPAS ET...................................................................... 44

6.2.2 SOPAS ET default settings ........................................................... 45

6.3 Establishing communication with the NAV210 ........................................... 45

6.3.1 Connecting data interfaces.......................................................... 45

6.3.2 Configuring the Ethernet connection........................................... 45

6.4 Initial commissioning.................................................................................... 46

6.4.1 NAV210 configuration.................................................................. 46

CONTENTS

5

8024592/2019-08| SICK OPERATING INSTRUCTIONS | NAV210

Subject to change without notice

6.5 Connecting and performing a test measurement........................................47

7 Maintenance.............................................................................................48

7.1 Maintenance during operation .....................................................................48

7.1.1 Cleaning the optical cover............................................................48

7.2 Replacing a NAV210 .....................................................................................48

8 Troubleshooting .......................................................................................49

8.1 Response to faults ........................................................................................49

8.2 Monitoring error and fault signals................................................................49

8.3 Troubleshooting ............................................................................................50

8.4 Detailed fault analysis ..................................................................................50

8.5 SICK support .................................................................................................51

9 Technical data..........................................................................................52

9.1 NAV210 data sheet.......................................................................................52

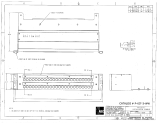

9.2 Dimensional drawings...................................................................................54

9.2.1 NAV210 dimensional drawing......................................................54

9.2.2 Mounting kit dimensional drawings.............................................55

9.3 Accessories ...................................................................................................57

10 Appendix ...................................................................................................58

10.1 Overview of the appendices .........................................................................58

10.2 Ordering information.....................................................................................58

10.2.1 Consumables ................................................................................58

10.3 Glossary.........................................................................................................58

10.4 EU declaration of conformity ........................................................................59

CONTENTS

6

8024592/2019-08| SICKOP E RA TI N G I NS T RU C TI O N S | NAV210

Subject to change without notice

7

8024592/2019-08| SICK OPERATING INSTRUCTIONS | NAV210

Subject to change without notice

ABOUT THIS DOCUMENT 1

1About this document

Please read this chapter carefully before you begin working with this documentation and

the NAV210 2D LiDAR sensor.

1.1 Purpose of this document

These operating instructions are intended to allow the technical personnel to perform

assembly, electrical installation work, configuration, commissioning, and maintenance on

the laser positioning system in the following variants:

Important For simplicity in this document, the variants are referred to as the “NAV210” for short,

unless a clear distinction needs to be made.

1.2 Target group

The target group for this document consists of people in the following roles:

Table 1: Target group

1.3 Information depth

These operating instructions contain the following information about the NAV210:

• Product description

• Mounting

• Electrical installation

• Commissioning and configuration

• Maintenance

• Troubleshooting

• Ordering information

• Conformity and approval

In addition, online support on operating the user interface and configuring the NAV210 is

included with the supplied SOPAS ET configuration software.

Additional information on the NAV210 is available from the SICK AG Identification &

Measuring Division and online at www.sick.com.

A detailed description of the different telegrams can be found in the document “Telegram

listing LMS1xx”, part no.: 8014631 with the accompanying “Supplement telegram listing

NAV210”, part no.: 8024593, English versions.

Activities Target group

Mounting, electrical

installation, maintenance,

replacement

Qualified personnel, such as service technicians or industrial

electricians

Commissioning,

configuration

Qualified personnel, such as technicians or engineers

8

8024592/2019-08| SICKOP E RA TI N G I NS T RU C TI O N S | NAV210

Subject to change without notice

1 ABOUT THIS DOCUMENT

1.4 Symbols used

Recommendation Recommendations are designed to assist you in the decision-making process with respect

to the use of a certain function or a technical measure.

Important Passages marked with “Important” inform you about special aspects of the device.

Explanation Explanations convey background knowledge about technical concepts.

Menu option

This font indicates a term in the SOPAS ET user interface.

Terminal output

This font indicates messages that the NAV210 outputs via its interfaces.

▸ Take action…

This indicates that action needs to be taken. This symbol indicates an instruction which only

contains one step, or steps in warnings where you do not have to adhere to a certain order.

Instructions which have several steps that follow on from one another are numbered.

This symbol includes a reference to additional documentation available.

Software notes show where you can make the appropriate settings in the SOPAS ET

configuration software.

NOTE:

A note refers to a potential risk of damage or functional impairment to the NAV210 or

other devices.

WARNING:

A warning indicates a specific or potential hazard. It is designed to protect you against

accidents.

The safety mark next to the warning refers to the type of accident risk, e.g., electricity-

related. The warning level (DANGER, WARNING, CAUTION) refers to the severity of the

danger.

▸ Carefully read and follow the warnings.

9

8024592/2019-08| SICK OPERATING INSTRUCTIONS | NAV210

Subject to change without notice

SAFETY INFORMATION 2

2 Safety information

This chapter concerns your own safety and the safety of the system operator.

▸ Please read this chapter carefully before you begin working with the NAV210.

2.1 Authorized personnel

The NAV210 2D LiDAR sensor must only be mounted, commissioned, and maintained by

adequately qualified personnel.

The following qualifications are necessary for the various tasks:

Table 2: Authorized personnel

2.2 Intended use

The NAV210 is used to determine reflector landmarks. The NAV210 is attached to the

automated guided vehicle and continuously measures the positions of identified reflectors

as well as the surrounding contour. Depending on the selected operating mode, the

NAV210 outputs the position of the reflectors as well as the distance, the angle, and the

reflectance of the visible surrounding contour on the automated guided vehicle's computer.

The vehicle computer can use this information to correct the course of the automated

guided vehicle accordingly to keep it on track.

NOTE:

Repair work on the NAV210 may only be performed by qualified and authorized service

personnel from SICK AG.

Activities Qualification

Mounting and maintenance

• Basic practical technical training

• Knowledge of the current safety regulations in the workplace

Electrical installation and

replacement

• Practical electrical training

• Knowledge of current electrical safety regulations

• Knowledge of the operation and control of the devices in their

particular application (e.g., crane, mounting system)

Commissioning, operation,

and configuration

• Knowledge of the operation and control of the devices in their

particular application (e.g., crane, mounting system)

• Knowledge of the software and hardware environment in their

particular application (e.g., crane, mounting system, forklift truck)

• Basic knowledge of the Windows operating system used

• Basic knowledge of data transmission

NOTE:

The NAV210 2D LiDAR sensor is intended for use in industrial environments. Radio

interference may result when used in residential areas.

10

8024592/2019-08| SICKOP E RA TI N G I NS T RU C TI O N S | NAV210

Subject to change without notice

2 SAFETY INFORMATION

The NAV210 is a sensor designed for use in industrial environments and also for uses

within the permitted ambient temperature range in outdoor areas (also see “NAV210 data

sheet” on page 50).

Important In the event of any other usage or modification to the NAV210, e.g., due to opening the

housing during mounting and electrical installation, or to the SICK software, any claims

against SICK AG under the warranty will be rendered void.

2.3 General safety notes and protective measures

2.3.1 Electrical installation work

NOTE:

The NAV210 must only be operated in the permitted ambient temperature range

(see “NAV210 data sheet” on page 50).

WARNING:

Safety notes

Observe the following to ensure the safe use of the

NAV210 as intended.

• The notes in these operating instructions (e.g., regarding the use, mounting,

installation, or integration into the machine controller) must be observed.

• All official and statutory regulations governing operation of the NAV210 must be

complied with.

• The national and international legal specifications apply to the installation and use of

the 2D LiDAR sensor, to its commissioning, and to recurring technical inspections, in

particular:

– The accident prevention regulations and work safety regulations

– Any other relevant safety regulations

• The manufacturer and operator of the system in which the NAV210 is installed are

responsible for coordinating and complying with all applicable safety specifications

and regulations, in cooperation with the relevant authorities.

• Through checks must be carried out by qualified safety personnel or specially

authorized and instructed personnel and must be documented such that they can be

replicated and traced at any time.

• These operating instructions must be made available to the operator of the system in

which the NAV210 is used. The system operator must be instructed by qualified

safety personnel and must read the operating instructions.

• The NAV210 does not constitute personal protection equipment in accordance with

the respective applicable safety standards for machines.

NOTE:

• Only authorized personnel are allowed to perform electrical installation work.

• The power supply must be disconnected when attaching and detaching electrical

connections.

• Select and implement wire cross-sections and their correct fuse protection in

accordance with the applicable standards.

• An external fuse and an external switch to separate the supply voltage must be

provided for the electrical connection.

!▸

Do not open the housing.

▸ Observe the current safety regulations when working on electrical systems.

11

8024592/2019-08| SICK OPERATING INSTRUCTIONS | NAV210

Subject to change without notice

SAFETY INFORMATION 2

2.3.2 Laser radiation from the 2D LiDAR sensor

Important No maintenance is required to ensure compliance with laser class 1.

Laser output aperture

The laser output aperture is the window in the scanner head of the NAV210.

Laser power

The laser operates at a wavelength λ = 905 nm (invisible infrared light). The radiation

emitted in normal operation is harmless to human skin and eyes.

Fig. 1: Laser output aperture

WARNING:

Laser radiation!

The NAV210 corresponds to laser class 1 (eye-safe) according to

EN/IEC 60825-1:2014. Identical laser class for issue EN/IEC 60825-1:2007.

Complies with 21 CFR 1040.10 and 1040.11 except for deviations pursuant to

Laser Notice No. 50. The laser beam is not visible to the human eye.

• Improper use can lead to hazardous radiation exposure.

▸ Do not open the housing (opening the housing does not prevent the laser

from switching on).

▸ Pay attention to the laser safety regulations as per IEC 60825-1 (2007)

(valid version).

Window of the optical

cover

12

8024592/2019-08| SICKOP E RA TI N G I NS T RU C TI O N S | NAV210

Subject to change without notice

2 SAFETY INFORMATION

2.4 Quick stop and quick restart

2.4.1 Switching off the NAV210

▸ Switch off the power supply to the NAV210.

The NAV210 retains parameters permanently stored in the internal memory. Measured values

at the interface are lost.

2.4.2 Switching on the NAV210 again

▸ Switch on the power supply to the NAV210.

The NAV210 restarts operation with the last saved parameters.

2.5 Protection of the environment

The NAV210 has been designed to minimize its impact on the environment. It consumes

only a minimum of energy.

Always act in an environmentally responsible manner at work. For this reason, please note

the following information regarding disposal.

2.5.1 Power consumption

• The NAV210 consumes a maximum of 20 W in operation.

• The NAV210 also consumes a maximum of 40 W cyclically for heating.

2.5.2 Disposal after final decommissioning

▸ Always dispose of unusable or irreparable devices in accordance with the applicable

waste disposal regulations specific to your country.

▸ Dispose of all electronic assemblies as hazardous waste. The electronic assemblies are

easy to dismantle.

Important SICK AG does not currently take back devices that are unusable or irreparable.

13

8024592/2019-08| SICK OPERATING INSTRUCTIONS | NAV210

Subject to change without notice

PRODUCT DESCRIPTION 3

3 Product description

This chapter provides information on the special properties of the NAV210 2D LiDAR

sensor. It describes the construction and operating principle of the device, in particular the

various operating modes.

Always read this chapter before you mount, install and commission the device.

3.1 Scope of delivery

The NAV210 delivery includes the following components:

Table 3: Scope of delivery

Sources for obtaining more information

Additional information about the NAV210 and its optional accessories can be found in the

following places:

Product web page for the NAV210

(www.sick.com/NAV2xx)

• Detailed technical specifications (online data sheet)

• Technical information (additional information, e.g. for telegrams)

• These operating instructions are available in German, English, and other languages

if required.

• Dimensional drawing and 3D CAD dimension models in various electronic formats

• EU declaration of conformity

Updates for the SOPAS configuration software: Support is also available from your

sales partner: www.sick.com/worldwide.

Piece Component

1 NAV210 2D LiDAR sensor

1

Safety note with electrical connection

diagram for initial information

1Lens cloth

14

8024592/2019-08| SICKOP E RA TI N G I NS T RU C TI O N S | NAV210

Subject to change without notice

3 PRODUCT DESCRIPTION

3.2 Structure of the NAV210

Fig. 2: View of the NAV210

LEDs and 7-segment display

M12 round connector

15

8024592/2019-08| SICK OPERATING INSTRUCTIONS | NAV210

Subject to change without notice

PRODUCT DESCRIPTION 3

3.3 Operating and status indicators

3.3.1 Operator interface

The 2D LiDAR sensor is fully automatic in normal operation and requires no operator

intervention.

The SOPAS ET configuration software supplied makes interactive configuration possible.

For this, the software runs on a PC which is connected to one of the interfaces with the

NAV210.

Use the graphic scan view in SOPAS ET to verify the generated measured values and the

measuring range online. Please note that the field evaluation monitor cannot display the

data in real time and therefore not all measured values are visualized.

3.3.2 Status indicators

The LEDs and 7-segment display signal the operational status of the NAV210.

Fig. 3: Status indicators

Important As well as the standard indicators described below, the indicator functions of the LEDs and

the 7-segment display can be configured in SOPAS ET for the NAV210.

Project tree, NAV210, Parameters, Network/Interfaces/IOs, Indicator.

16

8024592/2019-08| SICKOP E RA TI N G I NS T RU C TI O N S | NAV210

Subject to change without notice

3 PRODUCT DESCRIPTION

LEDs

Table 4: Meaning of the LEDs

7-segment display

Table 5: Indicators in the 7-segment display

Indicator Possible cause

NAV210 in operation, no evaluation cases report an event

Red: Motor failure, configuration error

Off: OK, measurement

Optical cover is dirty

Switching output is on

Not assigned

OK

STOP

Q1

Q2

Display Possible cause Rectification of the error

,, …

Device in measurement mode No error

IDLE mode: Tthe outputs are in

the OFF state, the laser is

switched off.

No error. If the criteria for the IDLE mode are

withdrawn, readiness for operation is re-

established.

Motor starts No error

Device faulty Send the device to the manufacturer for

repair.

17

8024592/2019-08| SICK OPERATING INSTRUCTIONS | NAV210

Subject to change without notice

PRODUCT DESCRIPTION 3

3.4 Operating principle of the NAV210

The NAV210 has an opto-electronic laser scanner that uses laser beams to scan the

outline of its surroundings on a plane without contact. The NAV210 measures its

surroundings in two-dimensional polar coordinates. If a measuring beam strikes an object,

the position of that object is determined in terms of distance, direction, and remission.

Fig. 4: Measurement principle of the NAV210

The NAV210 calculates the distance from the object using the elapsed time that the light

requires between sending and receiving the reflection in the sensor.

The scanning sector is 270°. The scanner head rotates with a frequency of 25 Hz.

A laser pulse and thus a distance measurement is triggered continuously after each angle

increment of 0.25°.

18

8024592/2019-08| SICKOP E RA TI N G I NS T RU C TI O N S | NAV210

Subject to change without notice

3 PRODUCT DESCRIPTION

3.4.1 Impact of objects on the measurement

Most surfaces produce a diffuse reflection of the laser beam in all directions. The structure

and color of the surface determine how well the laser beam is reflected. Bright surfaces

reflect the laser beam better than dark surfaces and can be detected by the NAV210 over

greater distances. Brilliant white plaster reflects approx. 100 % of the light, while black

foam rubber reflects approx. 2.4 %. On very rough surfaces, part of the energy is lost due

to shadowing. The sensing range of the NAV210 is therefore reduced.

Fig. 5: Diffuse reflection of objects

The angle of reflection corresponds to the angle of incidence. If the laser beam hits a

surface at right angles, the energy is optimally reflected (left). If the laser beam hits a

surface at an oblique angle, energy, and range are lost accordingly (right).

19

8024592/2019-08| SICK OPERATING INSTRUCTIONS | NAV210

Subject to change without notice

PRODUCT DESCRIPTION 3

Possible sources of error

Fig. 6: Possible sources of error when measuring

The laser beam is almost completely deflected on reflective surfaces (fig. 9, left). This means

that an object hit by the deflected beam may be detected instead of the reflective surface.

Objects that are smaller than the diameter of the laser beam (fig. 9, right) cannot reflect

the laser light's full energy. The energy of the non-reflected part of the laser light is lost. This

means the range is less than would theoretically be possible due to the reflective property

of the object's surface.

3.4.2 Sensing range of the NAV210

The sensing range of the NAV210 depends on the remission of the object to be detected.

The better a surface reflects the beams it is hit by, the greater the range of the NAV210 is.

Table 6: Typical remissions

Material Remission

Black car paint, matte 5 %

Black photo mounting board, matte 10 %

Gray concrete 18 %

White cardboard 90 %

White plaster 100 %

Reflective tape 3000 %

20

8024592/2019-08| SICKOP E RA TI N G I NS T RU C TI O N S | NAV210

Subject to change without notice

3 PRODUCT DESCRIPTION

3.4.3 Beam diameter and measuring point distance

As the distance from the NAV210 increases, its laser beam expands. As a result, the beam

diameter increases on the surface of the object.

The range-dependent beam diameter corresponds to the distance (mm) × 0.015 rad + 8 mm.

As the distance from the NAV210 increases, the individual measuring points also grow

further apart from one another. The graph in fig. 10 shows the beam diameter and the

measuring point distance depending on the distance from the NAV210.

Fig. 7: Beam diameter and measuring point distance at 0 to 50 m

For an object to be detected reliably, it must be completely hit by the beam once. If it is only

partially hit, less energy will be reflected from the object than is required in some cases

(see “Possible sources of error when measuring”, page 19).

0

Distance [m]

Size [mm]

30 50

0

200

400

Measuring point distance

2010

600

800

40

Beam diameter

0.25° angular

resolution

Beam diameter

/