GAS REQUIREMENTS

Use only Natural or LP (liquid propane) gases.

THE INSTALLATION MUST CONFORM WITH

LOCAL CODES, OR IN THE ABSENCE OF

LOCAL CODES, WITH THE NATIONAL FUEL

GAS CODE ANSI/Z223.1, LATEST REVISION

(FOR THE UNITED STATES), OR WITH THE

CAN/CGA-B149 INSTALLATION CODES (FOR

CANADA).

Gas dryers are equipped with a burner orifice for

operation on NATURAL gas. If the dryer is to be

operated on LP (liquid propane) gas, it must be

converted for safe and proper performance and

must be converted by a qualified service techni-

cian. Conversion kits from NATURAL to LP, or LP

to NATURAL are available through your local

Maytag dealer (see Accessories). If other conver-

sions are required, check with the local gas utility

for specific information concerning conversion

requirements.

A 1/2" gas supply line is recommended and must be

reduced to connect to the 3/8" gas line on the dryer.

The National Fuel Gas Code requires that an

accessible, approved manual gas shut off valve be

installed within 6 feet of the dryer.

Additionally, a 1/8" N.RT. (National Pipe Thread)

plugged tapping, accessible for test gauge

connection, must be installed immediately upstream

of the gas supply connection to the dryer.

The dryer must be disconnected from the gas supply

piping system during any pressure testing of the system.

DO NOT re-use old flexible metal gas line. Flexible

gas line must be design certified by American Gas

Association (CGA in Canada). NOTE: Any pipe

joint compound used must be resistant to the action

of any liquefied petroleum gas.

NOTE: As a courtesy, most local gas utilities will

inspect a gas appliance installation.

GAS IGNITION -

This dryer uses an automatic ignition system to ignite

the burner. There is no constant burning pilot.

ELECTRICAL REQUIREM ENTS

NOTE: Wiring diagram is located inside the control

console.

Export models (not U.S. or Canada): See

Additional Instructions for Export Models on the

other side of this sheet.

_-WARNING WARNING - To prevent unneces-

sary risk of fire, electrical shock or

personal injury, all wiring and

grounding must be done in

accordance with local codes, or

in the absence of local codes,

with the National Electrical Code,

ANSI/NFPA (for the United States) or the

Canadian Electrical Code CSA C22.1 (for

Canada).

GROUNDING

This dryer must be grounded. In the event of

malfunction or breakdown, the ground will reduce

the risk of electrical shock by providing a path of

least resistance for electrical current.

GAS MODELS

This appliance is equipped with a cord having an

equipment-grounding conductor and a grounding

plug. The plug must be plugged into an appropriate

outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

-_WARNING WARNING - Improper connection of

the equipment grounding conductor can

result in a risk of electric shock. Check

with a qualified electrician or serviceman

if you are in doubt as to whether the

appliance is properly grounded.

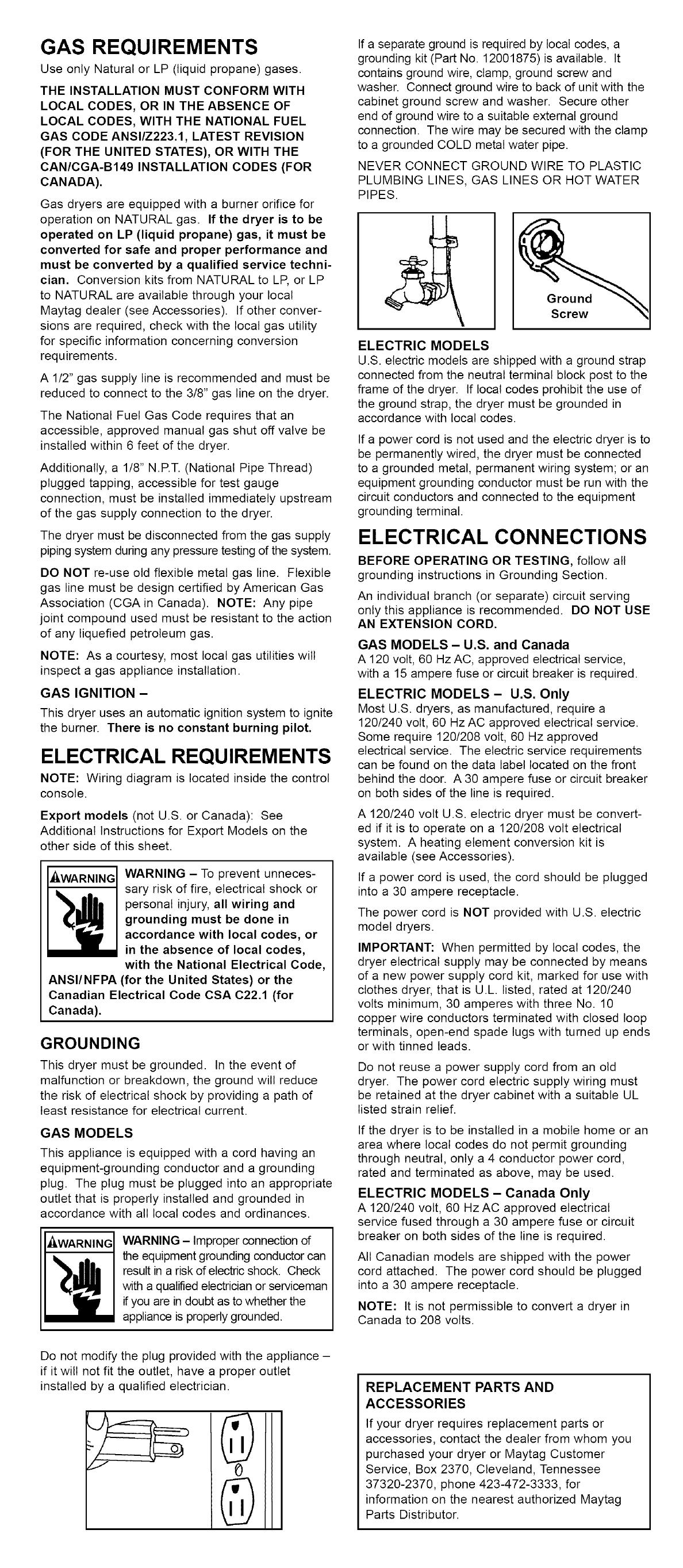

If a separate ground is required by local codes, a

grounding kit (Part No. 12001875) is available. It

contains ground wire, clamp, ground screw and

washer. Connect ground wire to back of unit with the

cabinet ground screw and washer. Secure other

end of ground wire to a suitable external ground

connection. The wire may be secured with the clamp

to a grounded COLD metal water pipe.

NEVER CONNECT GROUND WIRE TO PLASTIC

PLUMBING LINES, GAS LINES OR HOT WATER

PIPES.

Ground

Screw

ELECTRIC MODELS

U.S. electric models are shipped with a ground strap

connected from the neutral terminal block post to the

frame of the dryer. If local codes prohibit the use of

the ground strap, the dryer must be grounded in

accordance with local codes.

If a power cord is not used and the electric dryer is to

be permanently wired, the dryer must be connected

to a grounded metal, permanent wiring system; or an

equipment grounding conductor must be run with the

circuit conductors and connected to the equipment

grounding terminal.

ELECTRICAL CONNECTIONS

BEFORE OPERATING OR TESTING, follow all

grounding instructions in Grounding Section.

An individual branch (or separate) circuit serving

only this appliance is recommended. DO NOT USE

AN EXTENSION CORD.

GAS MODELS - U.S. and Canada

A 120 volt, 60 Hz AC, approved electrical service,

with a 15 ampere fuse or circuit breaker is required.

ELECTRIC MODELS - U.S. Only

Most U.S. dryers, as manufactured, require a

120/240 volt, 60 Hz AC approved electrical service.

Some require 120/208 volt, 60 Hz approved

electrical service. The electric service requirements

can be found on the data label located on the front

behind the door. A 30 ampere fuse or circuit breaker

on both sides of the line is required.

A 120/240 volt U.S. electric dryer must be convert-

ed if it is to operate on a 120/208 volt electrical

system. A heating element conversion kit is

available (see Accessories).

If a power cord is used, the cord should be plugged

into a 30 ampere receptacle.

The power cord is NOT provided with U.S. electric

model dryers.

IMPORTANT: When permitted by local codes, the

dryer electrical supply may be connected by means

of a new power supply cord kit, marked for use with

clothes dryer, that is U.L. listed, rated at 120/240

volts minimum, 30 amperes with three No. 10

copper wire conductors terminated with closed loop

terminals, open-end spade lugs with turned up ends

or with tinned leads.

Do not reuse a power supply cord from an old

dryer. The power cord electric supply wiring must

be retained at the dryer cabinet with a suitable UL

listed strain relief.

If the dryer is to be installed in a mobile home or an

area where local codes do not permit grounding

through neutral, only a 4 conductor power cord,

rated and terminated as above, may be used.

ELECTRIC MODELS - Canada Only

A 120/240 volt, 60 Hz AC approved electrical

service fused through a 30 ampere fuse or circuit

breaker on both sides of the line is required.

All Canadian models are shipped with the power

cord attached. The power cord should be plugged

into a 30 ampere receptacle.

NOTE: It is not permissible to convert a dryer in

Canada to 208 volts.

Do not modify the plug provided with the appliance -

if it will not fit the outlet, have a proper outlet

installed by a qualified electrician. REPLACEMENT PARTS AND

ACCESSORIES

If your dryer requires replacement parts or

accessories, contact the dealer from whom you

purchased your dryer or Maytag Customer

Service, Box 2370, Cleveland, Tennessee

37320-2370, phone 423-472-3333, for

information on the nearest authorized Maytag

Parts Distributor.