Page is loading ...

Millerfi

October

1990

FORM:

OM-871

E

ffective

With

Style

No.

JD-23

MODEL:

RDC-IW-1

RDC-IW-2

OWNERS

MANUAL

IMPORTANT:

Read

and

understand

the

entire

contents

of

both

this

manual

and

the

power

source

manual

used

with

this

unit,

with

special

emphasis

on

the

safety

material

throughout

both

manuals,

before

installing,

operating,

or

maintaining

this

equipment.

This

unit

and

these

instructions

are

for

use

only

by

persons

trained

and

experienced

in

the

safe

operation

of

welding

equip

ment.

Do

not

allow

untrained

persons

to

install,

operate,

or

maintain

this

unit.

Contact

your

distributor

if

you

do

not

fully

understand

these

instructions.

MILLER

ELECTRIC

Mfg.

Co.

A

Miller

Group

U~.,

Company

P.O.

Box

1079

Appleton,

WI

54912

USA

Tel.

414-734.9821

SA-094

539

PRINTED

IN

U.S.A.

I

J

LIMITED

WARRANTY

EFFECTIVE:

AUGUST

6,

1990

This

warranty

supersedes

all

previous

MILLER

warranties

and

is

exclusive

with

no

other

guarantees

or

warranties

expressed

or

implied.

LIMITED

WARRANTY

Subject

to

the

terms

and

conditions

hereof.

MILLER

Electric

Mfg.

Co..

Appleton.

Wisconsin

war

rants

to

its

Distributor/Dealer

that

all

new

and

unused

Equipment

furnished

by

MILLER

is

free

from

detect

in

workmanship

and

material

as

of

the

time

and

place

of

delivery

by

MILLER.

No

warranty

is

made

by

MILLER

with

respect

to

engines,

trade

accessories

or

other

items

manufactured

by

others.

Such

engines,

trade

accessories

and

other

items

are

sold

subject

to

the

warranties

of

their

respective

manumacturers,

if

any.

All

engines

are

warrantied

by

their

manufacturer

for

two

years

from

date

of

original

purchase.

except

Deutz

engines

which

have

a

one

year.

2000

hour

warranty.

Except

as

specified

below.

MILLERs

warranty

does

not

apply

to

components

having

normal

useful

life

ot

less

man

one

II)

year.

such

as

spot

welder

tips,

relay

and

contactor

points,

MILLERMATIC

parts

that

come

in

contact

with

the

welding

wire

including

nozzles

and

nozzle

insulators

where

failure

does

not

result

from

defect

in

workmanship

or

material.

MILLER

shall

be

required

to

honor

warranty

claims

on

war

ranted

Equipment

in

the

event

of

failure

resulting

from

a

defect

within

the

following

periods

from

the

date

of

delivery

of

Equipment

to

the

original

user:

1.

Arc

welders,

power

sources.

robots,

and

1

year

components

2.

Load

banks

1

year

3.

Original

main

power

rectifiers

3

years

(labor

1

year

only)

4.

All

welding

guns.

feeder/guns

and

torches

.

.

90

days

5.

All

other

MILLERMATIC

Feeders

1

year

6.

Replacement

or

repair

parts.

exclusive

of

tabor

60

days

7.

Batteries

6

months

provided

that

MILLER

is

notified

in

writing

within

thirty

30)

days

at

the

date

of

such

failure.

As

a

matter

of

general

policy

only.

MILLER

may

honor

claims

submitted

by

the

original

user

within

the

foregoing

periods.

In

the

case

of

MILLERs

breach

of

warranty

or

any

other

duty

with

respect

to

the

quality

of

any

goods.

the

exclusive

remedies

therefore

shall

be.

at

MILLERs

option

li)

repair

or

12)

replace

ment

or.

where

authorized

in

writing

by

MILLER

in

appropriate

cases.

(3)

the

reasonable

cost

of

repair

or

replacement

at

an

authorized

MILLER

service

station

or

4)

payment

of

or

credit

for

the

purchase

price

(less

reasonable

depreciation

based

upon

actual

use)

upon

return

of

the

goods

at

Customers

risk

and

expense.

MILLERs

option

of

repair

or

replacement

will

be

FOB..

Factory

at

Appleton.

Wisconsin.

or

FOB.

at

a

MILLER

authorized

service

facility.

therefore.

no

compensation

for

transportation

costs

of

any

kind

will

be

allowed.

Upon

receipt

of

notice

of

apoarent

defect

or

?ajlure.

MILLER

shall

instruct

the

ciaimant

on

the

warranty

ciairn

oroceaures

to

oe

followed.

ANY

EXPRESS

WARRANTY

NOT

PROVIDED

HEREIN

AND

ANY

IMPLIED

WARRANTY.

GUARANTY

OR

REPRE

SENTATION

AS

TO

PERFORMANCE.

AND

ANY

REMEDY

FOR

BREACH

OF

CONTRACT

WHICH.

BUT

FOR

THIS

PROVISION.

MIGHT

ARISE

BY

IMPLICATION.

OPERATION

OF

LAW.

CUSTOM

OF

TRADE

OR

COURSE

OF

DEALING.

INCLUDING

ANY

IMPLIED

WARRANTY

OF

MERCHAN

TABILITY

OR

OF

FITNESS

FOR

PARTICULAR

PURPOSE.

WITH

RESPECT

TO

ANY

AND

ALL

EQUIPMENT

FURNISHED

BY

MILLER

IS

EXCLUDED

AND

DISCLAIMED

BY

MILLER.

EXCEPT

AS

EXPRESSLY

PROVIDED

BY

MILLER

IN

WRITING.

MILLER

PRODUCTS

ARE

INTENDED

FOR

ULTIMATE

PURCHASE

SY

COMMERCIAL

INDUSTRIAL

USERS

AND

FOR

OPERATION

BY

PERSONS

TRAINED

AND

EXPERIENCED

IN

THE

USE

AND

MAINTENANCE

OF

WELDING

EQUIPMENT

AND

NOT

FOR

CONSUMERS

OR

CONSUMER

USE.

MILLERS

WARRANTIES

DO

NOT

EXTEND

TO.

AND

NO

RESELLER

IS

AUTHORIZED

TO

EXTEND

MILLERS

WARRANTIES

TO.

ANY

CONSUMER.

UI:

ERRATA

SHEET

After

this

manual

was

printed,

refinements

In

equipment

design

occurred.

This

sheet

lists

exceptions

to

data

appearing

later

In

this

manual.

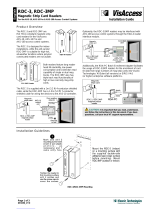

AMENDMENT

TO

SECTION

2-

INSTALLATION

Amend

Figure

2-2.

RDC-IW-1

Installation

With

Wire

Feeder

INTELLIWELD

POWER

SOURCE

TA-093

977-A

115

VAC/Contactor

RDC4W-1

Rear

View

Connected

To

Motor

Digital

Wire

Feeder

RDC-IW-1

Front

View

Figure

2-2.

RDC-IW-1

Installation

With

Wire

Feeder

Amend

Figure

2-3.

RDC-IW-2

Installation

With

Wire

Feeder

Figure

2-3.

RDC-IW-2

Installation

With

Wire

Feeder

Feeder

115

VAC

TA-093

978-A

Amend

heading

numbers

for

Figure

3-3

and

Figure

3-4

to

read

Figure

2-4

and

Figure

2-5.

AMENDMENT

TO

SECTION

4

SEQUENCE

OF

OPERATION

Add

the

following

WARNING

at

beginnings

of

Sections

4-1,

4-2,

4-3,

4-4,

and

4-5:

a

WARNING:

USING

BOTH

POSITIVE

(+)

WELD

OUTPUT

TERMINALS

at

same

time

can

cause

seri

ous

electric

shock

and

arcing

hazards.

Do

not

use

both

positive

(+)

weld

output

terminals

at

the

same

time.

Read

welding

power

source

Owners

Manual

for

additional

in

formation.

INTELLIWELD

POWER

SOURCE

115

VAC/Conlactor

Digital

Wire

Feeder

OM-871

Page

2

OU.871

.

l~l9O

RECEIVING-HANDLING

Before

unpacking

equipment,

check

carton

for

any

dam-

Use

the

following

spaces

to

record

the

Model

Designa

age

that

may

have

occurred

during

shipment.

File

any

tion

and

Serial

or

Style

Number

of

your

unit.

The

infor

claims

for

loss

or

damage

with

the

delivering

carrier.

mation

is

located

on

the

data

card

or

the

nameplate.

Assistance

for

filing

or

settling

claims

may

be

obtained

from

the

distributor

and/or

the

equipment

manufactur-

Model

________________________________________

ers

Transportation

Department.

Senal

or

Style

No.

____________________

When

requesting

information

about

this

equipment,

al

ways

provide

the

Model

Description

and

Serial

or

Style

Date

of

Purchase

_____________________

Number.

TABLE

OF

CONTENTS

Section

No.

Page

No.

SECTION

1

-

SAFETY

PRECAUTIONS

AND

SIGNAL

WORDS

1-1.

General

Information

And

Safety

1

1-2.

Safety

Alert

Symbol

And

Signal

Words

1

SECTION

2

SPECIFICATIONS

2-1.

Description

1

SECTION

3-INSTALLATiON

OR

RELOCATION

Diagram

3-1.

RDC-lW-1

Installation

With

Wire

Feeder

2

Diagram

3-2.

RDC-lW-2

Installation

With

Dual

Wire

Feeder

3

Diagram

3-3.

Output

Connections

For

Shielded

Metal

Arc

Welding

(SMAW)

(Reverse

Polarity)

Without

Wire

Feeder

3

Diagram

3-4.

Output

Connections

For

Gas

Tungsten

Arc

Welding

(GTAW)

(Straight

Polarity)

Without

Wire

Feeder

3

3-1.

Installation

Of

Remote

Control

4

3-2.

115

Volt

AC

Connection

To

The

Wire

Feeder

4

3-3.

Output

Control

Connection

4

3-4.

115

VAC

Contactor

Connection

To

Welding

Power

Source

4

3-5.

Switching

Relay

Connection

(RDC-IW-2

Models

Only)

4

3-6.

Remote

Control

Receptacles

4

SECTION

4-

OPERATOR

CONTROLS

4-1.

Volts

Control

5

4-2.

Amps

Control

5

4-3.

Volts/Amps

Display

Select

Switch

And

Indicating

Lights

5

4-4.

Remote

Control

Switch(es)

5

4-5.

CC/CP

Selector

Switch

5

4-6.

Arc

Control

5

4-7.

Contactor

Switch

6

4-8.

Digital

Display

6

Section

No.

Page

No.

SECTION

5-

SEQUENCE

OF

OPERATION

5-1.

Gas

Metal

Arc

And

Flux

Cored

Arc

Welding

(GMAW

And

FCAW)

6

5-2.

Shielded

Metal

Arc

Welding

(SMAW)

7

5-3.

Submerged

Arc

Welding

(SAW)

7

5-4.

Gas

Tungsten

Arc

Welding

(GTAW)

8

5-5.

Air

Carbon

Arc

Cutting

And

Gouging

(AAC)

8

5-6.

Shutting

Down

8

SECTION

6

MAINTENANCE

AND

TROUBLESHOOTING

6-1.

Routine

Maintenance

9

6-2.

Troubleshooting

9

SECTION

7-

ELECTRICAL

DIAGRAMS

Diagram

7-1.

Circuit

Diagram

For

RDC-IW-1

Models

11

Diagram

7-2.

Circuit

Diagram

For

RDC-IW-2

Models

12

Diagram

7-3.

Wiring

Diagram

For

RDC-IW-1

Models

13

Diagram

7-4.

Wiring

Diagram

For

RDC-lW-2

Models

14

SECTION

8

PARTS

LIST

Figure

8-1.

Main

Assembly

16

Figure

8-2.

Circuit

Card,

Relay

18

LIST

OF

CHARTS

AND

TABLES

Table

6-1.

Maintenance

Schedule

9

Table

6-2.

Troubleshooting

10

SECTION

1

SAFETY

PRECAUTIONS

AND

SIGNAL

WORDS

1.1.

GENERAL

INFORMATION

AND

SAFETY

A.

General

Information

presented

in

this

manual

and

on

various

la

bels,

tags,

and

plates

on

the

unit

pertains

to

equipment

design,

installation,

operation,

maintenance,

and

troubleshooting

which

should

be

read,

understood,

and

followed

for

the

safe

and

effective

use

of

this

equipment.

The

nameplate

of

this

unit

uses

international

symbols

for

labeling

the

front

panel

controls.

The

symbols

also

ap

pear

at

the

appropriate

section

in

the

text.

B.

Safety

The

installation,

operation,

maintenance,

and

trouble

shooting

of

arc

welding

equipment

requires

practices

and

procedures

which

ensure

personal

safety

and

the

safety

of

others.

Therefore,

this

equipment

is

to

be

in

stalled,

operated,

and

maintained

only

by

qualified

per

sons

in

accordance

with

this

manual

and

all

applicable

codes

such

as,

but

not

limited

to,

those

listed

at

the

end

of

Section

1

Safety

Rules

For

Operation

Of

Arc

Weld-

ing

Power

Source

in

the

welding

power

sources

Owners

Manual.

1-2.

SAFETY ALERT

SYMBOL

AND

SIGNAL

WORDS

The

following

safety

alert

symbol

and

signal

words

are

used

throughout

this

manual

to

call

attention

to

and

iden

tify

different

levels

of

hazard

and

special

instructions.

This

safety

alert

symbol

is

used

with

the

signal

words

WARNING

and

CAUTION

to

call

atten

tion

to

the

safety

statements.

a

WARNING

statements

identify

procedures

or

practices

which

must

be

followed

to

avoid

seri

ous

personal

injury

or

loss

of

life.

a

CAUTION

statements

identify

procedures

or

practices

which

must

be

followed

to

avoid

minor

personal

injury

or

damage

to

this

equipment.

IMPORTANT

statements

identify

special

instructions

necessary

for

the

most

efficient

operation

of

this

equip

ment.

IMPORTANT:

RDC-IW-2

mode/illustrated.

Overall

dimen

sions

same

for

ROC-!

W-

I

models.

2-1.

DESCRIPTION

This

unit

is

a

remote

digital

control

for

the

INTELLI

WELD

welding

power

source.

When

properly

connected

to

the

welding

power

source,

this

unit

provides

arc

con

trol,

contactor

control,

voltage/amperage

control,

and

CC/CP

(constant

currentlconstant

potential

or

voltage)

selection.

The

RDC-IW-1

models

allow

presetting

of

voltage

or

current

parameters

for

a

single

digital

wire

feeder

or

one

side

of

a

dual

digital

wire

feeder.

RDC-lW-2

models

pro

vide

preset

voltage

or

current

parameters

for

both

sides

of

a

dual

wire

feeder.

The

RDC-lW

displays

the

actual

value

of

the

selected

parameter

upon

arc

initiation.

The

remote

digital

control

operates

on

115

VAC,

50/60

Hertz

and

draws

0.5

amps.

a

SECTION

2

SPECIFICATIONS

11-3/4

in.

(298

mm>

10-1/2

in.

(267

mm)

Figure

2-1.

Dimensions

SB.094

539

OM.871

Page

1

SECTION

3

INSTALLATION

OR

RELOCATION

*flDC.1w2

Models

Only.

115

VAClContactor

Receptacle

S0494

Connected

To

Motor

115

VAC/Contactor

Feeder

115

VAC

Diagram

3-1.

RDC-IW-1

Installation

With Wire

Feeder

~Feeder115VAC

Cord

*switching

Relay

Cord

Figure

3-1.

Rear

Panel

View

INTELLIWELD

POWER

SOURCE

Output

Control

Rear

View

Digital

Wire

Feeder

RDC-IW.1

El

0

Front

View

Digital

Wire

Feeder

S

0483

OM.871

Page

2

INTELLIWELD

POWER

SOURCE

Connected

Motor

Diagram

3-2.

RDC-IW-2

Installation

With

Dual

Wire

Feeder

115

VAC/Contactor

Feeder

115

VAC

Gun

Trigger

S-0484

S0485

Diagram

3-3.

Output

Connections

For

Shielded

Metal

Arc

Welding

(SMAW)

(Reverse

Polarity)

Without

Wire

Feeder

S

.0486

Diagram

3-4.

Output

Connections

For

Gas

Tungsten

Arc

Welding

(GTAW)

(Straight

Polarity)

Without

Wire

Feeder

Output

Control

Digital

Dual

Wire

Feeder

115

VAC/Contactor

INTELLIWELD

POWER

SOURCE

Output

Control

RDC.IW-1

Shown

(Connections

Same

For

RDC.IW.2)

115

VAC/Contactor

/

RDC-IW-1

Shown

(Connections

Same

For

RDC.IW.2)

OM.871

Page

3

a

WARNING:

ELECTRIC

SHOCK

can

kill.

Do

not

touch

live

electrical

parts.

Shut

down

welding

power

source

and

wire

feeder,

and

disconnect

input

power

employ

ing

lockout/tagging

procedures

before

in

specting

or

installing.

Lockout/tagging

procedures

consist

of

pad

locking

line

disconnect

switch

in

open

position,

removing

fuses

from

fuse

box,

or

shutting

off

and

red-tagging

circuit

breaker

or

other

disconnect

ing

device.

3-1.

INSTALLATION

OF

REMOTE

CONTROL

The

remote

control

can

be

mounted

on

top

of

a

wire

feeder.

To

install

remote

control,

proceed

as

follows:

1.

Loosen

the

four

wrapper

screws

on

the

top

of

the

feeder

control

box.

2.

Place

remote

control

on

top

of

wire

feeder

control

box

with

front

panels

facing

in

the

same

direction.

3.

Position

control

so

that

wrapper

slots

correspond

to

feeder

control

box

screws.

4.

Slide

control

down

onto

screws.

5.

Tighten

wrapper

screws.

3-2.

115

VOLT

AC

CONNECTION

TO

THE

WIRE

FEEDER

(Figure

3-1

And

Diagrams

3-1

And

3-2)

Connect

four-socket

plug

from

rear

of

remote

control

to

four

pin

receptacle

on

rear

of

wire

feeder.

Rotate

collar

clockwise.

3-3.

OUTPUT

CONTROL

CONNECTION

(Figure

3-1

And

Diagrams

3-1

And

3-2)

Connect

ten-socket

plug

on

supplied

output

control

cord

to

ten-pin

receptacle

on

rear

of

the

remote

control.

Ro

tate

threaded

collar

fully

clockwise.

Connect

remaining

end

of

cord

to

REMOTE

10

recepta

cle

on

the

welding

power

source.

Rotate

threaded

collar

fully

clockwise.

3-4.

115

VAC

CONTACTOR

CONNECTION

TO

WELDING

POWER

SOURCE

(Figure

3-1

And

Diagrams

3-1

And

3-2)

Make

connections

between

remote

control,

wire

feeder,

and

welding

power

source

as

follows:

1.

Connect

ten-socket

plug

on

supplied

output

con

trol

cord

to

ten-pin

receptacle

on

rear

of

the

re

mote

control.

Rotate

threaded

collar

fully

clock

wise.

2.

Locate

115

volts/contactor

control

cable

supplied

with

wire

feeder.

3.

Connect

115

volts/contactor

cord

to

matching

re

ceptacle

on

rear

of

wire

feeder

as

follows:

align

keyways,

insert

plug,

and

roate

threaded

collar

fully

clockwise.

4.

Route

remaining

end

of

115

volts/contactor

cord

to

REMOTE

14

receptacle

on

welding

power

source.

Connect

plug

to

receptacle

as

follows:

align

keyways,

insert

plug,

and

roate

threaded

collar

fully

clockwise.

IMPORTANT:

If

the

supplied

cords

do

not

match

the

wire

feeder

and/or

welding

power

source

receptacles,

obtain

the

necessaiy

adapter

cord

from

your

welding

equipment

distributor.

3-5.

SWITCHING

RELAY

CONNECTION

(RDC

lW-2

Models

Only)

(Figure

3-1

And

Diagram

3-2)

Connect

four-contact

connector

from

rear

of

remote

control

to

four-contact

connector

on

rear

of

dual

wire

feeder.

3-6.

REMOTE

CONTROL

RECEPTACLES

(Figure

4-1)

The

remote

control

receptacle(s)

is

provided

on

the

re

mote

control

front

panel

for

connecting

an

optional

digi

tal

dual

schedule

control.

Use

an

interconnecting

cord

to

connect

six-socket

receptacle

on

front

of

the

remote

control

to

six-pin

receptacle

on

the

Digital

Dual

Schedule

Control.

IMPORTANT:

When

using

a

Digital

Dual

Schedule

Con

trol,

place

appropriate

STANDARD/REMOTE

switch

in

the

REMOTE

position.

OM.871

Page

4

SECTION

4-

OPERATOR

CONTROLS

Volts

Control

Digital

Display

Amps

Control

Remote

Control

Switch

Ret.

SA.094

539

Figure

4-1.

Front

Panel

View

(RDC-IW-2

Model

Illustrated)

4-1.

VOLTS

CONTROL

(Figure

4-1)

The

VOLTS

control

is

a

ten-turn

potentiometer

which

presets

weld

voltage

for

constant

voltage

applications.

Rotating

the

control

clockwise

increases

voltage.

This

control

is

disabled

when

the

CCICP

Selector

switch

is

in

the

CC

position.

IMPORTANT:

The

VOLTS

control

can

be

adjusted

while

welding.

4-2.

AMPS

CONTROL

(FIgure

4-1)

The

AMPS

control

is

a

ten-turn

potentiometer

which

pre

sets

weld

amperage

for

constant

current

applications.

Rotating

the

control

clockwise

increases

amperage.

This

control

is

disable

when

the

CC/CP

Selector

switch

is

in

the

CP

position.

IMPORTANT:

The

AMPS

control

can

be

adjusted

while

welding.

4-3.

VOLTS/AMPS

DISPLAY

SELECT

SWITCH

AND

INDICATING

LIGHTS

(Figure

4-1)

This

switch

is

used

to

select

either

volts

or

amps

to

be

shown

on

the

digital

display.

When

the

switch

is

in

the

VOLTS

(down)

position,

volts

are

displayed,

and

the

volts

indicating

light

comes

on.

When

the

switch

is

in

the

AMPS

position,

amps

are

displayed,

and

the

amps

indi

cating

light

comes

on.

IMPORTANT:

The

VOLTS/AMPS

Switch

can

be

changed

while

welding.

4-4.

REMOTE

CONTROL

SWITCH(es)

(Figure

4-1)

The

Remote

Control

switch(es)

is

provided

for

selecting

single

scheduling

via

the

RDC-IW

or

dual

scheduling

via

an

optional

Digital

Dual

Schedule

Control.

The

Remote

Control

switch

must

be

in

the

STANDARD

position

to

preset

welding

parameters

at

the

RDC-IW.

The

Remote

Control

switch

must

be

in

the

REMOTE

position

to

pre

set

welding

parameters

from

the

Digital

Dual

Schedule

control

and

to

dual

schedule

welding

conditions.

4-5.

CC/CP

SELECTOR

SWITCH

(Figure

4-1)

The

CC/CP

selector

switch

allows

selection

of

CC

(con

stant

current),

CP

(constant

potential

or

voltage)

output

from

the

welding

power

source.

The

CC

position

provides

a

constant

current

output

spe

cifically

designed

for

Shielded

Metal

Arc

(SMAW)

and

Gas

Tungsten

Arc

(GTAW)

Welding

processes.

The

CC

position

is

also

normally

used

for

Air

Carbon

Arc

Cutting

(AAC)

and

gouging

processes.

The

CP

position

provides

a

constant

voltage

output

de

signed

for

wire

feeding

applications

such

as

Gas

Metal

Arc

(GMAW),

Flux

Cored

Arc

(FCAW),

or

Submerged

Arc

(SAW)

Welding.

4-6.

ARC

CONTROL

(Figure

4-1)

IMPORTANT:

The

ARC

CONTROL

potentiometer

is

disabled

in

the

CP

(Constant

Potential)

and

pulsed

modes.

The

ARC

CONTROL

potentiometer

provides

variable

selection

of

short-circuit

current

to

suit

individual

welding

conditions.

Rotating

this

control

clockwise

causes

the

current

to

increase

as

the

short-circuit

condition

is

ap

proached.

When

this

control

is

set

at

some

value

above

0,

the

current

begins

to

increase

when

arc

voltage

drops

below

20

volts.

When

the

control

is

set

at

10,

the

short-circuit

current

is

considerably

higher

than

normal

welding

current

(see

welding

power

source

volt-ampere

curve

for

CC

mode).

Control

Arc

Control

Contactor

CC/C

P

Switch

Volts/Amps

5witch

Remote

Control

Receptacle

OM-871

Page

5

This

provides

extra

current

for

arc

starting

in

out-of-posi

tion

welds

as

well

as

for

certain

types

of

electrodes.

When

the

control

is

set

at

0,

short-circuit

current

is

the

same

as

normal

welding

current.

The

0

position

provides

current

characteristics

associated

with

the

Gas

Tung

sten

Arc

Welding

(GTAW)

process.

When

the

control

is

set

at

5,

short-circuit

current

is

ap

proximately

half

that

of

the

1

0

position

but

still

higher

than

normal

welding

current.

The

5

position

provides

a

moderate

current

increase

for

arc

starting

necessary

for

certain

types

of

electrodes

and

applications.

Select

a

setting

best

suited

for

the

application.

The

Arc

Control

indicating

light

turns

on

when

the

CC/

CP

Selector

switch

is

in

the

CC

position

indicating

that

the

ARC

CONTROL

is

active.

IMPORTANT:

The

ARC

CONTROL

can

be

adjusted

while

welding.

4-7.

CONTACTOR

SWITCH

(Figure

4.1)

a

WARNING:

ELECTRIC

SHOCK

can

kill.

Do

not

touch

live

electrical

parts.

Do

not

touch

the

weld

output

terminals

when

the

contactor

is

energized.

Do

not

touch

electrode

(or

gun

wire)

and

work

clamp

at

the

same

time.

If

the

Remote

Control

CONTACTOR

switch

is

in

the

ON

position,

open-circuit

voltage

will

be

present

at

the

out

put

terminals

whenever

the

welding

power

source

POWER

switch

ON

button

is

pressed.

IMPORTANT:

Although

the

term

CONTACTOR

is

used

on

the

nameplate

and

throughout

this

manual,

the

weld

output

is

not

switched

on

or

off

by

a

physical

secondary

contactor;

rather,

the

weld

output

is

controlled

by

solid-

state

circuitry

in

the

welding

power

source.

If

contactor

control

by

means

of

a

wire

feeder

is

desired,

place

the

Remote

Control

CONTACTOR

switch

in

the

OFF

position.

Open-circuit

voltage

will

be

present

at

the

weld

output

terminals

whenever

the

gun

switch

is

closed.

4-8.

DIGITAL

DISPLAY

(Figure

4-1)

When

functioning

as

a

voltmeter,

the

digital

display

indi

cates

voltage

to

the

nearest

tenth

of

a

volt

while

welding

and

preset

voltage

when

unit

is

idling.

When

functioning

as

an

ammeter,

the

digital

display

indi

cates

weld

amperage

to

the

nearest

ampere

while

weld

ing

and

preset

amperage

when

unit

is

idling.

SECTION

5

SEQUENCE

OF

OPERATION

f~

WARNING:

ELECTRIC

SHOCK

can

kill;

MOVING

PARTS

can

cause

serious

injury;

IMPROPER

AIR

FLOW

AND

EXPOSURE

TO

ENVIRONMENT

can

damage

internal

parts.

Keep

all

covers

and

panels

in

place

while

op

erating.

Warranty

is

void

if

the

unit

is

operated

with

any

portion

of

the

outer

enclosure

removed.

ARC

RAYS,

SPARKS,

AND

HOT

SURFACES

can

burn

eyes

and

skin;

NOISE

can

damage

hearing.

Wear

correct

eye,

ear,

and

body

protection.

FUMES

AND

GASES

can

seriously

harm

your

health.

Use

enough

ventilation

to

keep

fumes

and

gases

from

the

breathing

zone.

WELDING

WIRE

can

cause

puncture

wounds.

Do

not

point

gun

toward

any

part

of

the

body

or

other

personnel.

HOT

METAL,

SPATTER,

AND

SLAG

can

cause

fire

and

burns.

Watch

for

fire.

Have

a

fire

extinguisher

nearby

and

know

how

to

use

it.

MAGNETIC

FIELDS

FROM

HIGH

CURRENTS

can

affect

pacemaker

operation.

Wearers

should

consult

with

their

doctor

be

fore

going

near

arc

welding,

gouging,

or

spot

welding

operations.

See

Section

1

Safety

Rules

For

Operation

Of

Arc

Welding

Power

Source

in

the

welding

power

source

Owners

Manual.

5-1.

GAS

METAL

ARC

AND

FLUX

CORED

ARC

WELDING

(GMAW

AND

FCAW)

AA

WARNING:

Read

and

follow

safety

informa

tion

at

beginning

of

entire

Section

5

before

proceeding.

WARNING:

USING

BOTH

POSITIVE

(+)

WELD

OUTPUT

TERMINALS

at

same

time

can

cause

serious

electric

shock

and

arcing

hazards.

Do

not

use

both

positive

(+)

weld

output

termi

nals

at

the

same

time.

Read

welding

power

source

Owners

Manual

for

additional

information.

Install

and

connectwelding

power

source

accord

ing

to

its

Owners

Manual.

2.

Install

Remote

Control

as

instructed

in

Section

3.

a

OM.871

Page

6

3.

Install

and

connect

wire

feeder

according

to

its

Owners

Manual.

4.

Wear

dry

insulating

gloves

and

clothing.

5.

Connect

work

clamp

to

clean,

bare

metal

at

workpiece.

6.

Select

proper

welding

wire.

7.

Depress

welding

power

source

POWER

switch

ON

button.

8.

Place

Remote

Output

Control

switch

on

the

weld

ing

power

source

in

the

REMOTE

position.

9.

Place

remote

control

switch

on

the

A

DC-lW

con

trol

in

the

STANDARD

position.

10.

Place

CC/CP

Selector

switch

in

CP

position.

11.

Place

CONTACTOR

switch

in

OFF

position.

12.

Place

VOLTS/AMPS

switch

in

the

VOLTS

posi

tion.

13.

Preset

VOLTS

control

to

desired

weld

voltage

setting

(see

Section

4-1).

14.

Thread

welding

wire

as

instructed

in

wire

feeder

Owners

Manual.

15.

Make

ay

required

adjustments

to

wire

feeder.

IMPORTANT:

If

an

optional

Digital

Dual

Schedule

con

trol

is

used,

place

Remote

Control

switch

in

the

RE

MOTE

position

and

set

the

welding

parameters

for

the

second

schedule

on

the

Dual

Schedule

Control.

16.

Turn

on

shielding

gas

supply,

if

applicable.

17.

Wear

welding

helmet

with

proper

filter

lens

ac

cording

to

ANSI

Z49.1.

18.

Begin

welding.

5-2.

SHIELDED

METAL

ARC

WELDING

(SMAW)

a

WARNING:

Read

and

follow

safety

informa

tion

at

beginning

of

entire

Section

5

before

proceeding.

WARNING:

USING

BOTH

POSITIVE

(+)

WELD

OUTPUT

TERMINALS

at

same

time

can

cause

serious

electric

shock

and

arcing

hazards.

Do

not

use

both

positive

(.4.)

weld

output

termi

nals

at

the

same

time.

Read

we/ding

power

source

Owners

Manual

for

additional

information.

1.

Install

and

connect

welding

power

source

accord

ing

to

its

Owners

Manual.

2.

Install

Remote

Control

as

instructed

in

Section

3.

3.

Install

and

connect

wire

feeder

according

to

its

Owners

Manual.

4.

Wear

dry

insulating

gloves

and

clothing.

5.

Connect

work

clamp

to

clean,

bare

metal

at

workpiece.

6.

Select

proper

electrode.

7.

Depress

welding

power

source

POWER

switch

ON

button.

8.

Place

Remote

Output

Control

switch

on

the

weld

ing

power

source

in

the

REMOTE

position.

9.

Place

remote

control

switch

on

the

RDC-IW

con

trol

in

the

desired

position

(see

Section

4-4).

Place

CC/CP

Selector

switch

in

CC

position.

Place

CONTACTOR

switch

in

ON

position.

Place

VOLTS/AMPS

switch

in

the

AMPS

posi

tion.

13.

Preset

AMPS

Control

to

desired

weld

amperage

setting

(see

Section

4-2).

14.

Place

ARC

CONTROL

to

desired

position

(see

Section

4-6).

15.

Wear

welding

helmet

with

proper

filter

lens

ac

cording

to

ANSI

Z49.1.

16.

Insert

electrode

into

electrode

holder.

17.

Begin

welding.

5-3.

SUBMERGED

ARC

WELDING

(SAW)

a

WARNING:

Read

and

follow

safety

informa

tion

at

beginning

of

entire

Section

5

before

proceeding.

a

WARNING:

USING

BOTH

POSITIVE

(+)

WELD

OUTPUT

TERMINALS

at

same

time

can

cause

serious

electric

shock

and

arcing

hazards.

Do

not

use

both

positive

(+)

weld

output

termi

nals

at

the

same

time.

Read

welding

power

source

Owners

Manual

for

additional

in

formation.

1.

Install

and

connect

welding

power

source

accord

ing

to

its

Owners

Manual.

2.

Install

Remote

Control

as

instructed

in

Section

3.

3.

Install

and

connect

wire

feeder

according

to

its

Owners

Manual.

4.

Install

flux

system

according

to

its

Owners

Man

ual.

5.

Wear

dry

insulating

gloves

and

clothing.

6.

Connect

work

clamp

to

clean,

bare

metal

at

workpiece.

7.

Depress

welding

power

source

POWER

switch

ON

button.

8.

Place

remote

control

switch

on

the

RDC-IW

con

trol

in

the

desired

position

(see

Section

4-4).

9.

Place

CC/CP

Selector

switch

in

CP

position.

10.

Place

CONTACTOR

switch

in

OFF

position.

11.

Place

VOLTS/AMPS

switch

in

the

VOLTS

posi

tion.

12.

Preset

VOLTS

control

to

desired

weld

voltage

setting

(see

Section

4-1).

10.

11.

12.

a

OM-871

Page

7

13.

Wear

safety

goggles

with

correct

filter

shade

ac

cording

to

ANSI

Z49.1.

14.

Make

any

required

adjustments

to

wire

feeder.

15.

Turn

on

flux

system.

16.

Begin

welding.

5-4.

GAS

TUNGSTEN

ARC

WELDING

(GTAW)

a

WARNING:

Read

and

follow

safety

informa

tion

at

beginning

of

entire

Section

5

before

proceeding.

WARNING:

USING

BOTH

POSITIVE

(+)

WELD

OUTPUT

TERMINALS

at

same

time

can

cause

serious

electric

shock

and

arcing

hazards.

Do

not

use

both

positive

(.4.)

weld

output

termi

na/s

at

the

same

time.

Read

welding

power

source

Owners

Manual

for

additional

in

formation.

1.

Install

and

connect

welding

power

source

accord

ing

to

its

Owners

Manual.

2.

Install

Remote

Control

as

instructed

in

Section

3.

3.

Install

and

connect

wire

feeder

according

to

its

Owners

Manual.

4.

Install

and

connect

High-Frequency

unit

accord

ing

to

its

Owners

Manual,

if

applicable.

Scratch

start

GTAW

does

not

require

the

use

of

external

high

frequency.

5.

Wear

dry

insulating

gloves

and

clothing.

6.

Connect

work

clamp

to

clean,

bare

metal

at

workpiece.

7.

Select

proper

tungsten

electrode.

8.

Depress

welding

power

source

POWER

switch

ON

button.

9.

Place

remote

control

switch

on

the

RDC-IW

con

trol

in

the

desired

position

(see

Section

4-4).

10.

Place

CC/CF

Selector

switch

in

CC

position.

11.

Place

CONTACTOR

switch

in

ON

position.

12.

Place

VOLTS/AMPS

switch

in

the

AMPS

posi

tion.

13.

Preset

AMPS

control

to

desired

weld

amperage

setting

(see

Section

4-2).

14.

Set

ARC

CONTROL

toO

(zero).

15.

Prepare

tungsten

electrode

according

to

welding

power

source

Owners

Manual,

and

insert

into

torch.

16.

Turn

on

shielding

gas

and

water

supplies

as

appli

cable.

17.

Turn

on

and

adjust

High-Frequency

unit

if

appli

cable.

18.

Wear

welding

helmet

with

proper

filter

lens

ac

cording

to

ANSI

Z49.1.

19.

Begin

welding.

5-5.

AIR

CARBON

ARC

CUTTING

AND

GOUGING

(AAC)

a

WARNING:

Read

and

follow

safety

informa

tion

at

beginning

of

entire

Section

5

before

proceeding.

WARNING:

USING

BOTH

POSITIVE

(+)

WELD

OUTPUT

TERMINALS

at

same

time

can

cause

serious

electric

shock

and

arcing

hazards.

Do

not

use

both

positive

(..)

weld

output

termi

nals

at

the

same

time.

Read

welding

power

source

Owners

Manual

for

additional

information.

1.

Install

and

prepare

welding

power

source

accord

ing

to

its

Owners

Manual.

2.

Install

Remote

Control

as

instructed

in

Section

3.

3.

Connect

compressed

air

supply.

4.

Wear

dry

insulating

gloves

and

clothing.

5.

Connect

work

clamp

to

clean,

bare

metal

at

workpiece.

6.

Select

proper

carbon

electrode.

7.

Depress

welding

power

source

POWER

switch

ON

button.

8.

Place

CC/CP

Selector

switch

in

CC

position.

9.

Place

CONTACTOR

switch

in

ON

position.

10.

Place

VOLTS/AMPS

switch

in

the

AMPS

posi

tion.

11.

Preset

AM

PS

control

to

desired

amperage

setting

(see

Section

4-2).

12.

Set

ARC

CONTROL

to

desired

position

(see

Sec

tion

4-6).

13.

Insert

electrode

into

torch.

14.

Turn

on

air

supply.

15.

Wear

welding

helmet

with

proper

filter

lens

ac

cording

to

ANSI

Z49.1.

16.

Begin

cutting/gouging

process.

5-6.

SHUTTING

DOWN

1.

Stop

welding

or

cutting/gouging

process.

2.

Depress

the

welding

power

source

POWER

switch

OFF

button.

3.

Turn

off

the

shielding

gas

and

water

supplies

if

ap

plicable.

a

WARNING:

HIGH

CONCENTRATION

OF

SHIELDING

GASES

can

harm

health

or

kill.

Shut

off

gas

supply

when

not

in

use.

4.

Turn

off

flux

supply

and

compressed

air

supply

if

applicable.

a

a

OM-871

Page

8

SECTION

6

MAINTENANCE

AND

TROUBLESHOOTING

6-1.

ROUTINE

MAINTENANCE

IMPORTANT:

Every

six

months

inspect

the

labels

on

this

unit

for

legibility.

All

precautionary

labels

must

be

maintained

in

a

clearly

readable

state

and

replaced

when

necessary.

See

Parts

List

for

part

number

of

precautionary

labels.

a

WARNING:

ELECTRIC

SHOCK

can

kill.

Do

not

touch

live

electrical

parts.

Shutdown

welding

power

source,

and

discon

nect

input

power

employing

lockout/tagging

procedures

before

inspecting,

maintaining,

or

servicing.

Lockout/tagging

procedures

Consist

of

pad

locking

line

disconnect

switch

in

open

position,

removing

fuses

from

fuse

box,

or

shutting

off

and

red-tagging

circuit

breaker

or

other

disconnect

ing

device.

MOVING

PARTS

can

cause

serious

injury.

Keep

away

from

moving

parts.

HOT

SURFACES

can

cause

severe

burns.

Allow

cooling

period

before

servicing.

Table

6-1.

Maintenance

Schedule

Frequency*

Maintenance

Every

month.

Units

in

heavy

service

environ

ments:

Check

labels

and

interconnecting

cords.

Every

6

months.

Check

all

labels

(see

IMPORTAN1

block,

Section

6-1)

and

inter

connecting

cords.

*Frequency

of

service

is

based

on

units

operated

40

hours

per

week.

Increase

frequency

of

maintenance

if

usage

exceeds

40

hours

per

week.

Every

six

months,

inspect

all

interconnecting

cords

and

plugs

for

damage

to

the

insulation

jacket.

Repair

or

re

place

the

cord(s)

as

necessary.

6-2.

TROUBLESHOOTING

(Table

6-2)

a

WARNING:

ELECTRIC

SHOCK

can

kill.

Do

not

touch

live

electrical

parts.

Shutdown

welding

powersource,

and

discon

nect

input

power

employing

lockout/tagging

procedures

before

inspecting,

maintaining,

or

servicing.

Lockout/tagging

procedures

consist

of

pad

locking

line

disconnect

switch

in

open

position,

removing

fuses

from

fuse

box,

or

shutting

off

and

red-tagging

circuit

breaker

or

other

disconnect

ing

device.

MOVING

PARTS

can

cause

serious

injury.

Keep

away

from

moving

parts.

HOT

SURFACES

can

cause

severe

burns.

Allow

cooling

period

before

servicing.

Troubleshooting

to

be

performed

only

by

quali

fied

persons.

It

~

assumed

that

the

unit

was

properly

installed

accord

ing

to

Section

3

of

this

manual,

the

operator

is

familiar

with

the

function

of

controls,

the

unit

was

working

prop

erly,

and

that

the

trouble

is

not

related

to

the

welding

process.

The

following

table

is

designed

to

diagnose

and

provide

remedies

for

some

of

the

troubles

that

may

develop

in

this

unit.

Use

this

table

in

conjunction

with

the

circuit

dia

gram

while

performing

troubleshooting

procedures.

If

the

trouble

is

not

remedied

after

performing

these

proce

dures,

contact

the

nearest

Factory

Authorized

Service

Station.

In

all

cases

of

equipment

malfunction,

strictly

follow

the

manufacturers

procedures

and

instructions.

OM-871

Page

9

Table

6-2.

Troubleshooting

TROUBLE

CAUSE

REMEDY

No

display.

Wire

feeder

Power

switch

in

OFF

position.

Energize

wire

feeder.

Digital

meter.

Replace

meter.

Welding

power

source

does

not

deliver

preset

current

and

voltage.

Remote

Control

switch

on

RDC-IW-2

in

REMOTE

position

without

a

digital

Dual

Scheduling

Control

connected.

Place

Remote

Control

switch

in

STANDARD

position

or

connect

a

Digital

Dual

Scheduling

Control.

Remote

Control

switch

on

welding

power

source.

Make

sure

Remote

Control

switch

is

in

REMOTE

position.

Unable

to

preset

voltage;

current

adjustment

available.

VOLTS

control

Ri.

Replace

Ri.

~______________________________

VOLTS/AMPS

Switch

S2.

Replace

S2.

Relay

CR52.

Replace

CR52.

Switch

S5.

Replace

S5.

Unable

to

preset

current;

voltage

adlustment

available.

AMPS

control

R2

(or

R4).

Replace

R2

(or

R4).

VOLTS/AM

PS

switch

S2.

Replace

S2.

Relay

CR52.

Replace

CR52.

Switch

S5.

Replace

S5.

Does

not

display

actual

parameters

while

welding.

115

VAC

connection

to

feeder

improper

or

not

secure.

Check

connection.

Relays

CR50

or

CR54

(RDC-1W-1

models),

or

CR50

or

CR56

(RDC-1W-2

models).

Replace

relay(s).

OM.871

Page

10

SECTION

7-

ELECTRICAL

DIAGRAMS

AC

IN

B

AC

DA

B

C

E

H

C

D

I

Circuit

Diagram

No.

A-093

385

Diagram

7-1.

Circuit

Diagram

For

RDC-IW-1

Models

OM-871

Page

11

AC

IN~

AC

OUT

Diagram

7-2.

Circuit

Diagram

For

RDC-IW-2

Models

Circuit

Diagram

No.

B-093

419-A

A

~

C

CE

F

OM-871

Page

12

SI

PL2

P3

PLG5O

KEYWAY

PCJ

PLG

I

PLG2

248

Diagram

7-3.

Wiring

Diagram

For

RDC-IW-1

Models

PC

I

Wiring

Diagram

No.

SC-i

07

635

GPOUNO

1/26