- 82 -

GB

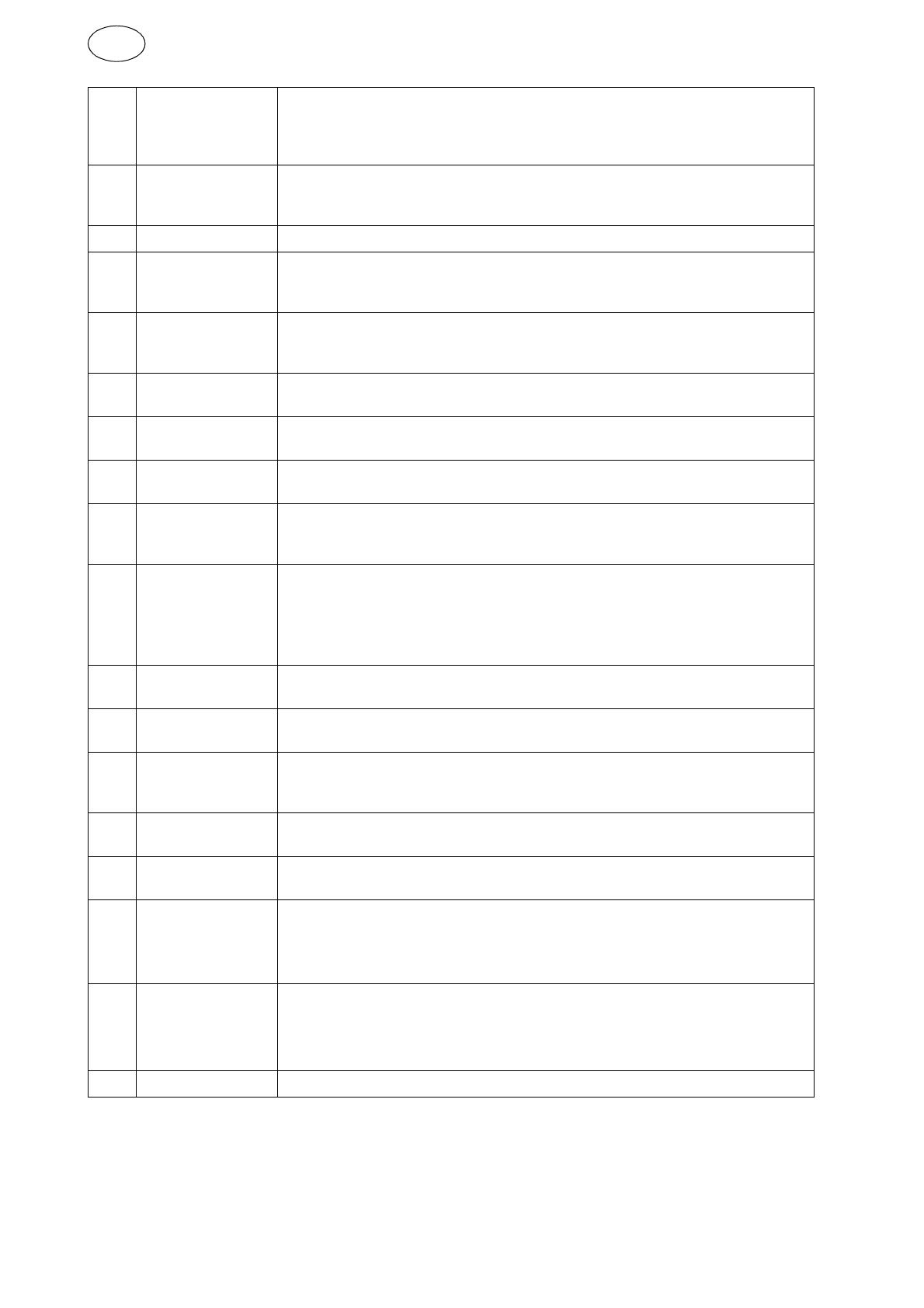

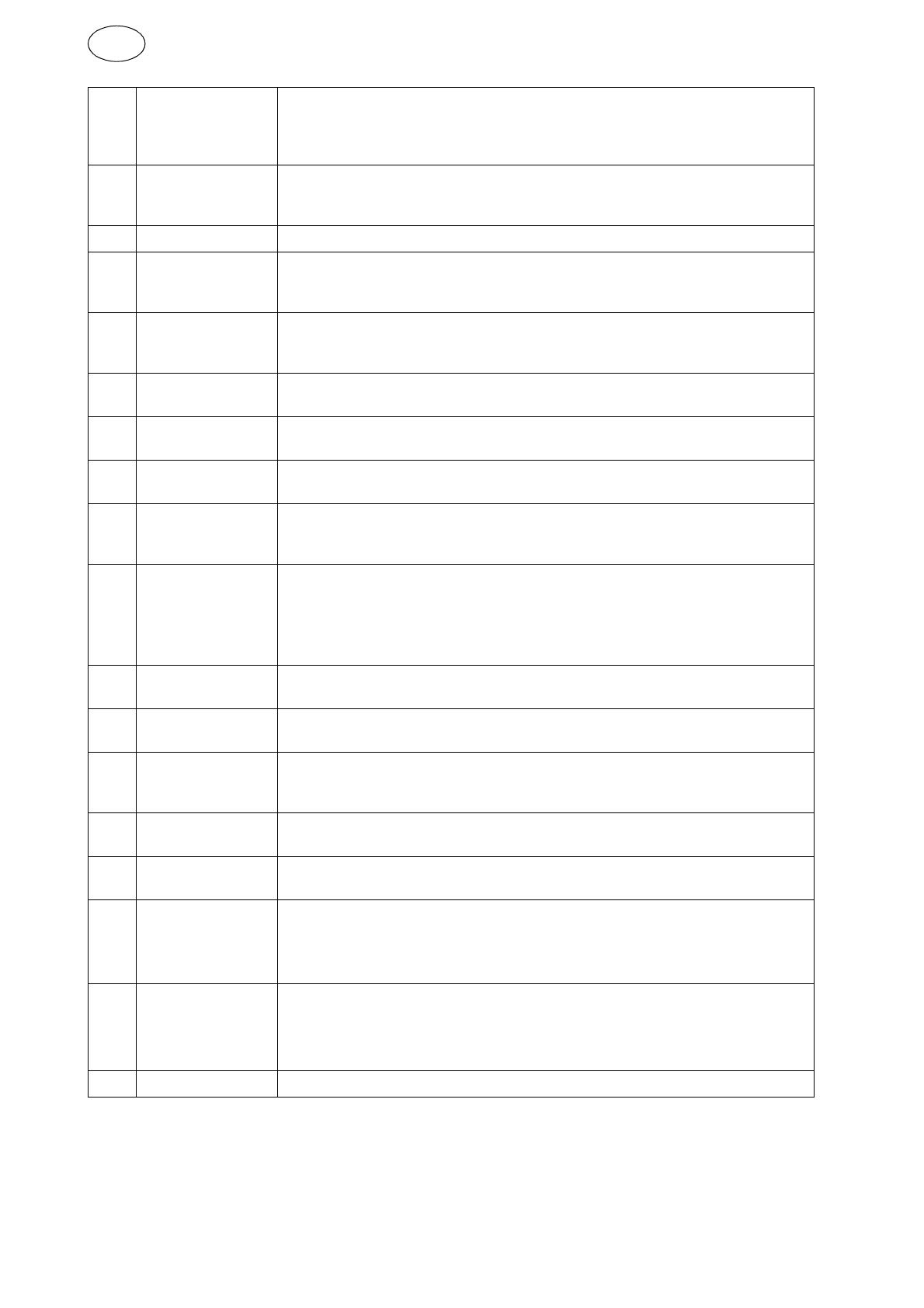

5 LED, welding LED illuminates when voltage is applied to the welding current socket.

In the TIG operation mode, after activating the torch button whereas in

the electrode operation mode, this occurs after selecting electrode

welding.

6LED,

protective gas

on

LED illuminates when the solenoid valve is open and the protective

gas can flow. After switching the device on, the hose bundle is

automatically purged with protective gas.

7 LED, ramp up LED lights in the ramp up phase (Up-Slope).

8 Rotary switch,

ramp up

Sets the rate at which the current ramps up from the ignition current I1

to the welding current I2. Turning direction anticlockwise decreases

the ramp rate.

9 Welding cur-

rent 7 segment

display

Displays the value of the welding current of the current function.

10 Rotary switch,

I4

Sets the current I4 during pulsed operation.

11 LED, I4 active I4 active. During pulsed operation: Toggles between the two displays

I4 and I2 with fixed pulse frequency.

12 LED,

ramp down

Displays the ramp down phase (Down-Slope).

13 Rotary switch,

ramp down

Sets the rate at which the welding current I2 ramps down to the

drop-off current I3 at the end of throat. The ramp down prevents

cratering.

14 Button, gas

test

In order to manually purge the hose bundle with protective gas.

Pressing this button opens the gas valve without applying a welding

voltage to the electrode.

During pulsed operation: When activating the button gas test, the

display (10) switches to the I4 value.

15 Display,error

code

Display of possible error messages.

16 LED, fault LED flashes if a fault condition occurs in the device. The error

message appears in the error display.

17 Rotary switch,

gas post-flow

time

Sets the gas post-flow time after finishing welding to protect the

weldpool. The time can be set from approximately 0.2 to 30s.

18 Rotary switch,

AC frequency

Continuous setting of the AC frequency from 50 Hz up to 200 Hz.

19 LED, final

current I3

LED illuminates when the final current I3 is active.

20 Rotary switch,

AC balance

If the rotary switch is set to the middle position, the positive and the

negative half cycles are equal for AC welding.

This rotary switch is deactivated, when welding using DC current (DC

operation).

21 Welding cur-

rent selector

• DC with lift arc ignition

• DC with HF ignition

• Square AC with HF ignition

• Sinusoidal AC with HF ignition

22 LED, I1 LED illuminates, when the ignition current I1 is active.