Page is loading ...

Foreword

8207A_002-824e-07.23 Page 1

Foreword

Thank you for choosing a Kistler quality product

characterized by technical innovation, precision and long

life.

Information in this document is subject to change without

notice. Kistler reserves the right to change or improve its

products and make changes in the content without

obligation to notify any person or organization of such

changes or improvements.

© 2018 … 2023 Kistler Group. Kistler Group products are

protected by various intellectual property rights. For more

details visit www.kistler.com. The Kistler Group includes

Kistler Holding AG and all its subsidiaries in Europe,

Asia, the Americas and Australia.

Kistler Group

Eulachstrasse 22

8408 Winterthur

Switzerland

Tel. +41 52 224 11 11

www.kistler.com

Uniaxial high temperature accelerometer Type 8207A…

2 8207A_002-824e-07.23

Content

1. Introduction .................................................................................................................................. 4

2. Important information ................................................................................................................. 5

2.1 Protection and standards .................................................................................................... 5

2.2 Precautions ......................................................................................................................... 6

2.3 Disposal instructions for electrical and electronic equipment ............................................. 6

2.4 Personal safety warnings .................................................................................................... 6

2.5 Ex-Approval – Versions for operation in hazardous areas ................................................. 7

2.5.1 ATEX- and IECEx-Approval ................................................................................... 8

3. Product description..................................................................................................................... 9

3.1 Technical data ..................................................................................................................... 9

3.2 Ordering key ........................................................................................................................ 9

4. Operation .................................................................................................................................... 10

4.1 General instructions for operation ..................................................................................... 10

4.1.1 Ground isolated measuring chain ........................................................................ 10

4.2 Application in non-hazardous areas .................................................................................. 10

4.2.1 Sensor execution .................................................................................................. 10

4.2.2 Ground isolated measuring chain ........................................................................ 11

4.2.3 Marking ................................................................................................................. 11

4.3 Application in hazardous areas ......................................................................................... 11

4.3.1 Instructions for application in hazardous areas .................................................... 11

4.3.2 Sensor executions ................................................................................................ 12

4.3.3 Ambient temperature range ................................................................................. 12

4.3.4 Specific conditions of use for the safe operation ................................................. 12

4.3.5 Marking on sensor ................................................................................................ 13

4.3.6 Labeling and packaging ....................................................................................... 13

4.3.7 Non-sparking equipment (Ex-nA) for use only in zone 2 ..................................... 14

4.3.7.1 Non sparking measuring chain (Ex-version) ......................................... 14

4.3.7.2 Maximum values for electrical connection ............................................ 14

4.3.8 Intrinsic safety equipment (Ex-ia) ......................................................................... 15

4.3.8.1 Intrinsic safety measuring chain (Ex-version) ....................................... 15

4.3.8.2 Entity parameter of the sensor .............................................................. 15

5. Installation .................................................................................................................................. 16

5.1 Mounting bore ................................................................................................................... 16

5.2 Sensor mounting and removal .......................................................................................... 17

5.2.1 Mounting of the sensor ......................................................................................... 18

5.2.2 Sensor removal .................................................................................................... 19

5.3 Cable handling and fixation ............................................................................................... 20

5.3.1 Mineral Insulated hardline cable .......................................................................... 20

5.3.2 Cable fixation ........................................................................................................ 20

5.4 Electrical connection ......................................................................................................... 21

5.4.1 Options ................................................................................................................. 21

5.4.2 2-pole Lemo connector ......................................................................................... 22

5.4.3 2-pole 7/16”-connector ......................................................................................... 22

5.4.4 Open leads ........................................................................................................... 23

5.5 Service and maintenance .................................................................................................. 23

5.6 Measuring chain compontents and accessories ............................................................... 23

6. Calibration and repair ............................................................................................................... 24

6.1 Calibration ......................................................................................................................... 24

6.2 Repair ................................................................................................................................ 24

Introduction

8207A_002-824e-07.23 Page 3

7. Declaration of Conformity ......................................................................................................... 25

Total pages: 25

Uniaxial high temperature accelerometer Type 8207A…

4 8207A_002-824e-07.23

1. Introduction

Please read through this manual thoroughly to enable

you to fully exploit the various features of your product.

To the extent permitted by law Kistler accepts no liability

if this instruction manual is not followed or products other

than those listed under Accessories are used.

These instructions describe the piezoelectric uniaxial

high temperature accelerometer Type 8207A.

Our thermoacoustics product and application brochures,

in addition to our detailed data sheets, will provide you

with an overview of our product range.

If you require additional assistance beyond what can be

located online or in this manual, please contact Kistler‘s

extensive support organization or visit us online at

www.kistler.com/thermoacoustics

Important information

8207A_002-824e-07.23 Page 5

2. Important information

It is essential to review the following information, which is

intended to ensure your personal safety when working

with high temperature acceleration sensors and

contribute toward a long-fault-free service life.

To the extent permitted by law Kistler accepts no liability

if this instruction manual is not followed or products other

than those listed under Accessories are used.

2.1 Protection and standards

All equipment is tested and has left the factory in a

perfect, safe condition. In order to maintain this

condition and to ensure safe operation, it is essential

to follow strictly the instructions and warnings

contained in these operating instructions or printed on

the product itself.

Compliance with local safety regulations that apply to the

use of electrical and electronic equipment is to be

followed.

The sensor Type 8207A... is in compliance with CE and

complies with the following provisions of the directives:

• ISO 9001

• 2011/65/EU (ROHS)

• 2014/30/EU (EMC)

• 2014/34/EU (ATEX

Hazardous area:

The following harmonised standards were applied:

• EN 60079-0:2012+A11:2013/IEC 60079-0:2011

• EN 60079-11:2012/IEC 60079-11:2011

• EN 60079-15:2010/IEC 60079-15:2010

Uniaxial high temperature accelerometer Type 8207A…

6 8207A_002-824e-07.23

2.2 Precautions

Compliance with the following precautionary

measures is vital to ensure safe and reliable

operation:

The equipment should be used only under the

specified operating conditions.

If there is evidence that safe operation is no longer

possible, the instrument must be powered off and

rendered safe against accidental start-up.

Safe operation is no longer possible when the product

▪ shows visible signs of damage

▪ is no longer operating

▪ has been subjected to prolonged storage under

unsuitable conditions

2.3 Disposal instructions for electrical and electronic equipment

Do not discard old electronic instruments in municipal

trash. For disposal at end of life, please return this

product to an authorized local electronic waste

disposal service or contact your local Kistler Instrument

sales office for disposal instructions.

2.4 Personal safety warnings

Labels and markings are provided on the monitor to

guide the system integrator in the processes of choosing

appropriate interface equipment, determining safe use

conditions, and identifying recommended installation

procedures. The format of these markings are governed

by the standards that dictate safe use and environmental

compliance in a variety of regions and regulated settings.

Important information

8207A_002-824e-07.23 Page 7

2.5 Ex-Approval – Versions for operation in hazardous areas

Lesen und verstehen Sie das Handbuch vor

der Inbetriebnahme!

Read and understand manual before opera-

ting!

Lire et comprendre le manual avant d'utili-

ser!

WARNING: HAZARDOUS ENVIRONMENT

Risk of explosive atmosphere!

A potentially explosive atmosphere occurs where

there is a combination of flammable substances and

oxygen. Oxygen is usually present as a component in

the ambient air, which is why the warning of potential

explosion hazards must be considered very seriously.

Prevent corrosion and failure by checking that all

components are compatible as described in the

installation instructions.

Do not connect or disconnect the equipment when

energized unless the area is known to be non-

explosive.

Important:

▪ The sensor must not be modified in any way.

Otherwise the ATEX, IECEx and all other Ex

approvals will become invalid.

▪ Substitution of components may impair suitability for

hazardous area.

▪ Explosion Hazard. Do not connect or disconnect

when energized unless the area is free of ignitible

concentrations.

All Ex-relevant specifications have been adopted from

the EU type examination and Ex-certificates in these

operating instructions.

The special conditions for installation in hazardous

areas must be observed in particular!

If required, the Ex certificates can be ordered at the

manufacturer.

The IECEx certificate can be viewed online at

www.iecex.com

Uniaxial high temperature accelerometer Type 8207A…

8 8207A_002-824e-07.23

2.5.1 ATEX- and IECEx-Approval

All sensors of the 8207AE... series. are certified for use in

"potentially explosive atmospheres" according to the

ATEX directive and IECEx standards.

The sensors are certified as Ex-ia (intrinsically safe) and

Ex-nA (non-sparking).

Type of

protection

Ex-ia (intrinsically safe)

Ex-nA (non sparking)

ATEX

II 1G Ex ia IIC T6 … T710

SEV 17 ATEX0140X

II 3G Ex nA IIC T6 … T710

SEV 17 ATEX0140X

IECEX

Ex ia IIC T6 … T710 Ga

IECEx SEV 17.0012X

Ex nA IIC T6 … T710 Gc

IECEx SEV 17.0012X

Product description

8207A_002-824e-07.23 Page 9

3. Product description

Basic execution

Sensor Type 8207A… is a 2-wire, internally ground

isolated differential piezoelectric accelerometer. The

sensor is equipped with an integral mineral insulated

hardline cable and is available with different cable

terminations.

Ex-Versions

All sensors of the series 8207AE... are certified fo ruse in

„hazardous areas“.

The sensors have the following approvals for hazardous

areas:

▪ ATEX

▪ IECEx

3.1 Technical data

The sensors may only be used acc. to the technical

specifications made in the respective data sheet.

The technical specifications are given in data sheet

003-333.

3.2 Ordering key

Fig. 1: Ordering key

Uniaxial high temperature accelerometer Type 8207A…

10 8207A_002-824e-07.23

4. Operation

For proper operation it is necessary to first determine

whether the sensor is installed in a potentially explosive

atmosphere.

4.1 General instructions for operation

The following instructions regarding the installation

and operation must be followed:

▪ The sensor is hermetically sealed. The

integral cable meets ingress protection IP50

and must be protected against adverse

environmental effects where necessary.

▪ The sensor may only be used for its intended

purpose. Any violation will waive all

warranties and responsibilities of the

manufacturer.

▪ IP degree has to be maintained.

▪ The sensors may only be used within the

specifications listed in the sensor’s data sheet

and operating instructions.

4.1.1 Ground isolated measuring chain

For measurements of very small pressure fluctuations

and in environments with electromagnetic interference, it

is recommended to operate the measurement chain

completely ground isolated.

This requires a differential charge amplifier. Depending

on the required application, Kistler recommends the

differential charge amplifier Type 5183 (Ex ia) of Type

5185 (Ex nA).

Measuring chain examples are shown in Kistler

document No. 960-201.

4.2 Application in non-hazardous areas

4.2.1 Sensor execution

In non-hazardous areas the sensor without Ex certifica-

tion Type 8207A- … can be used

Operation

8207A_002-824e-07.23 Page 11

4.2.2 Ground isolated measuring chain

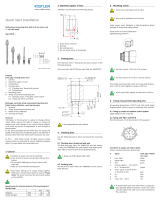

Fig. 2: Recommended measuring chain for operation in non-hazardous areas

4.2.3 Marking

The standard execution, “non Ex-Version” is marked as

follows on the package:

Kistler Instrumente AG

Winterthur Switzerland

Sensor Type: 8207A- …

SN: …

4.3 Application in hazardous areas

4.3.1 Instructions for application in hazardous areas

In addition to the general instructions for proper

operation under 4.1 and Ex approvals 2.5, the

following instructions must also be followed when

installing and commissioning in hazardous areas:

▪ The sensor may be used in constantly, long-

term or frequently hazardous locations. Prior

to installation, the installation site and its

potential explosion hazard must be assessed

and the suitability of the sensors determined.

▪ The provisions of EN 60079-10 / EN 60079-

14 or the corresponding local regulations

must be met during installation and commis-

sioning of the sensor in hazardous locations.

The operation of the sensor should be carried

out by specially trained personnel.

▪ Installation of intrinsic safety circuits must be

conducted by qualified and authorized

personnel only and in accordance with the

instructions of the contractor.

▪ All electrical connections must be properly

connected. The input ratings are safety limit

values which must not be exceeded.

▪ No modifications are permitted on any equip-

ment that is certified for use in hazardous

areas.

Uniaxial high temperature accelerometer Type 8207A…

12 8207A_002-824e-07.23

▪ Defective sensors must be returned to the

manufacturer.

▪ Correlation between temperature class and

permissible ambient temperature range have

to be taken into account according to table 1.

▪ The specific conditions of use have to be

taken into consideration.

4.3.2 Sensor executions

For applications in hazardous areas the sensor version

Type 8207AE… (certified ‚Ex-nA‘ and‚ Ex-ia‘) must be

used.

4.3.3 Ambient temperature range

Permissible ambient temperature at the location of use

(for appropriate use):

Type 8207

Type 8209 & 8211

Temperature class

Ambient temperature range

Ambient temperature range

T6

–55°C … +75°C

–55°C … +75°C

T5

–55°C … +90°C

–55°C … +90°C

T4

–55°C … +125°C

–55°C … +125°C

T3

–55°C … +190°C

–55°C … +190°C

T2

–55°C … +290°C

–55°C … +290°C

T1

–55°C … +440°C

–55°C … +440°C

T490°C

–55°C … +480°C

–55°C … +480°C

T710°C

–

–55°C … +700°C

Tab. 1: Temperature classes and corresponding ambient

temperature ranges

4.3.4 Specific conditions of use for the safe operation

Specific conditions of use for ATEX- and IECEx-

Approval:

1. See equipment description for ambient tempera-

ture restrictions or in the Instruction manual at

4.3.3.

2. For ignition protection type "nA":

▪ The connector or the flying leads of the integral

mineral insulated cable shall be installed in an

enclosure that provides a degree of protection

not less than IP 54 in accordance with lEC

60079-15.

▪ “Transient protection shall be provided that is set

at a level not exceeding 140% of the peak rated

voltage value at the supply terminals to the

equipment".

Operation

8207A_002-824e-07.23 Page 13

4.3.5 Marking on sensor

Marking on sensor top

Kistler

Type …

SN …

CE…

Minimal marking for ATEX / IECEx

Due to lack of space, the minimal Ex marking is engraved on

the sensor.

4.3.6 Labeling and packaging

The relevant declaration of conformance- and explosion pro-

tection symbols are shown on a label that is affixed to the

product package.

ATEX/ IECEX:

Uniaxial high temperature accelerometer Type 8207A…

14 8207A_002-824e-07.23

4.3.7 Non-sparking equipment (Ex-nA) for use only in zone 2

4.3.7.1 Non sparking measuring chain (Ex-version)

The sensor can be used in non-sparking measuring

chains in Ex-classified zone 2.

For application in hazardous areas the sensor must be

operated with an accordingly Ex-certified differential

charge amplifier.

Delivery includes the sensor only.

Appropriate apparatus such charge amplifier,

softline cable, junction box and galvanic

separation has to comply with the Ex-

certificate. For recommendations visit us on

www.kistler.com/thermoacoustics

Fig. 3: Example of a non-sparking measuring chain for zone 2

4.3.7.2 Maximum values for electrical connection

Maximum input voltage: 30 V

Maximum input current: 130 mA

Operation

8207A_002-824e-07.23 Page 15

4.3.8 Intrinsic safety equipment (Ex-ia)

4.3.8.1 Intrinsic safety measuring chain (Ex-version)

The sensor may be connected to intrinsically safe

measuring chain in Ex-classified zone 0, 1 and 2. To

ensure safe use, observe the electrical input ratings in

accordance with the temperature classes as specified

in the chapter "4.3.8.2 Entity parameter of the

sensor".

For operation in hazardous areas, the sensor must be

operated with an Ex-certified differential charge ampli-

fier and a corresponding Ex-certified barrier. The

entity parameters between the sensor and dif-

ferential charge amplifier respectively differential

charge amplifier and barrier must be appropriately

matched to each other.

Delivery includes the sensor only.

Appropriate apparatus such charge amplifier, softline

cable, junction box and galvanic separation has to

comply with the Ex-certificate. For recommendations

visit us on auf www.kistler.com/ thermoacoustics

Fig. 4: Example of an intrinsic safety measuring chain for zone 0, 1 or 2

4.3.8.2 Entity parameter of the sensor

Maximum values of electrical connection with

non-detachable cable:

Ui V ≤ 30

Li mA ≤ 130

Pi W ≤ 0,8

Ci pF ≤ 15 + 170 pF/m * cable length

Li μH ≤ 0 + 1.5 μH/m * cable length

Uniaxial high temperature accelerometer Type 8207A…

16 8207A_002-824e-07.23

5. Installation

The quality of the threaded holes as well as the

installation according to the instructions are essential to

assure proper performance of the sensor within the given

specification.

5.1 Mounting bore

An uneven contact surface significantly reduces the

accuracy of the frequency bandwith.

For the version with ARINC footprint (8207A_1C_J_)

prepare the mounting bores according to Figure 5.

For the version with the square footprint (8207A_2C_J_)

prepare the mounting bores according to Figure 6.

Fig. 5: Mounting bores for ARINC footprint sensor Type 8207A_1C_J_

Installation

8207A_002-824e-07.23 Page 17

Fig. 6: Mounting bores for square footprint sensor Type 8207A_2C_J_

5.2 Sensor mounting and removal

To remove the sensor do not pull on the cable but hold

the sensor body tightly and lift upwards.

Uniaxial high temperature accelerometer Type 8207A…

18 8207A_002-824e-07.23

5.2.1 Mounting of the sensor

Install the sensor with the according mounting screws,

see table 3.

High temperature screw paste Type 1059 must be

applied to the mounting srew.

The tightening torque must be observed.

Sensor

execution

Temperature

[°C]

Mounting screw

Tightening

torque

[Nm]

ARINC

footprint

8207A_1C_J_

<350

8445AS1

M4x12

2.9

>350

8445AS1HT

M4x12

2.9

Square

footprint

8207A_2C_J_

<350

8445AS2

M6x30

4

>350

8445AS2HT

M6x30

4

Table 3: Mounting screws depending on sensor footprint and operation

temperature

Fig. 7: Mounting of ARINC footprint sensor Type 8207A_1C_J_

/