Page is loading ...

OWNER'S OPERATOR AND

MAINTENANCE MANUAL

ORBIT SEAT OPTION

ON

POWER TIGER BASE

2

WARNING

W

A

R

N

I

N

G

SAVE THESE INSTRUCTIONS

WARNING

DO NOT OPERATE THIS EQUIPMENT WITHOUT FIRST

READING AND UNDERSTANDING THE INFORMATION IN THIS

SUPPLEMENTAL MANUAL AND THE OWNER’S MANUAL. IF YOU ARE

UNABLE TO UNDERSTAND THE WARNINGS, CAUTIONS, AND IN-

STRUCTIONS, CONTACT A HEALTHCARE PROFESSIONAL, DEALER OR

TECHNICAL PERSONNEL IF APPLICABLE BEFORE ATTEMPTING TO USE

THIS EQUIPMENT - OTHERWISE INJURY OR DAMAGE MAY RESULT.

ALL PROCEDURES IN THIS MANUAL SUPERCEDE ANY DUPLICATED

PROCEDURES FOUND IN THE POWER TIGER OWNER’S MANUAL,

PART NUMBER 1045938.

THE INITIAL SET UP OF THIS WHEELCHAIR MUST BE PERFORMED BY AN

AUTHORIZED INVACARE DEALER OR QUALIFIED TECHNICIAN.

SPECIAL NOTES

WARNING/CAUTION notices as used in this manual apply to hazards or unsafe practices which could

result in personal injury or property damage.

NOTICE

THE INFORMATION CONTAINED IN THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE.

WHEELCHAIR USER

As a manufacturer of wheelchairs, Invacare endeavors to supply a wide variety of Action wheelchairs to

meet many needs of the end user. However, final selection of the type of wheelchair to be used by an

individual rests solely with the user and his/her healthcare professional capable of making such a selection.

WHEELCHAIR TIE-DOWN RESTRAINTS AND SEAT POSITIONING STRAPS

Invacare recommends that Action wheelchair users NOT be transported in vehicles of any kind while

in wheelchairs. As of this date, the Department of Transportation has not approved any tie-down sys-

tems for transportation of a user while in a wheelchair, in a moving vehicle of any type.

It is Invacare’s position that users of Action wheelchairs should be transferred into appropriate seating

in vehicles for transportation and use be made of the restraints made available by the auto industry.

Invacare cannot and does not recommend any wheelchair transportation systems.

AS REGARDS RESTRAINTS - SEAT POSITIONING STRAPS - IT IS THE OBLIGATION OF THE DME DEALER, THERA-

PISTS AND OTHER HEALTHCARE PROFESSIONALS TO DETERMINE IF A SEATING POSITIONING STRAP IS

REQUIRED TO ENSURE THE SAFE OPERATION OF THIS EQUIPMENT BY THE USER. SERIOUS INJURY CAN

OCCUR IN THE EVENT OF A FALL FROM A WHEELCHAIR.

3

TABLE OF CONTENTS

T

A

B

L

E

O

F

C

O

N

T

E

N

T

S

SPECIAL NOTES .................................................................................................................................... 2

SPECIFICATIONS ................................................................................................................................... 4

PROCEDURE 1 - DISASSEMBLY/ASSEMBLY ........................................................................................ 5

DISASSEMBLING/ASSEMBLING THE SEAT FRAME TO/FROM THE BASE FRAME ............................... 5

PROCEDURE 2 - FRONT RIGGINGS ...................................................................................................... 7

INSTALLING FOOTRESTS .................................................................................................................... 7

ADJUSTING FOOTREST HEIGHT ......................................................................................................... 7

INSTALLING 3-INCH EXTENSION .......................................................................................................... 8

INSTALLING/ADJUSTING THE ADJUSTABLE ANGLE FLIP-UP FOOTPLATES ....................................... 8

REPLACING SECTOR BLOCK .............................................................................................................. 9

ADJUSTING THE TELESCOPING FRONT FRAME TUBES .................................................................. 10

HEEL LOOP REPLACEMENT .............................................................................................................. 10

PROCEDURE 3 - ARMS ....................................................................................................................... 11

INSTALLING THE T-ARM SOCKETS .................................................................................................... 11

INSTALLING/REMOVING THE T-ARMS ............................................................................................... 11

ADJUSTING THE T-ARMS ................................................................................................................... 12

ADJUSTING THE TRANSFER ASSISTS AND/OR SIDE GUARDS-T-ARMS ........................................... 13

REPLACING THE LOCKING LEVERS - T-ARMS .................................................................................. 13

REMOVING/INSTALLING JOYSTICK ................................................................................................... 14

PROCEDURE 4 - BACK/SEAT/WHEEL LOCKS ..................................................................................... 15

REPLACING THE LOCKING MECHANISM IN THE BACK CANE ........................................................... 15

INSTALLING/REMOVING STROLLER HANDLES ................................................................................. 15

FOLDING/UNFOLDING THE BACK CANES ......................................................................................... 16

REMOVING/INSTALLING THE SEAT PAN ............................................................................................ 16

ENGAGING/DISENGAGING WHEEL LOCKS ....................................................................................... 16

PROCEDURE 5 - CASTERS .................................................................................................................. 17

REMOVING/INSTALLING FRONT CASTERS ....................................................................................... 17

REPLACING FORKS ........................................................................................................................... 17

PROCEDURE 6 - TILTING ................................................................................................................... 18

ENGAGING THE TILT-IN-SPACE ......................................................................................................... 18

PROCEDURE 7 - DEALER ADJUSTMENTS - GENERAL ........................................................................... 19

REMOVING/INSTALLING THE SPREADER BAR .................................................................................. 19

CHANGING THE SEAT WIDTH ............................................................................................................ 20

REMOVING/INSTALLING/ADJUSTING THE CABLE ASSEMBLY ........................................................... 21

REMOVING/INSTALLING/THE CABLE ASSEMBLY FROM THE RELEASE PEDAL ................................ 22

REMOVING/INSTALLING THE TILT MECHANISMS .............................................................................. 22

PROCEDURE 8 - DEALER ADJUSTMENTS - STABILITY ........................................................................... 24

STABILITY OVERVIEW ........................................................................................................................ 24

CHANGING THE CASTER POSITION .................................................................................................. 24

CHANGING THE BACK ANGLE ........................................................................................................... 24

CHANGING THE SEAT DEPTH ............................................................................................................ 25

ADJUSTING THE PIVOT POINT OF THE SEAT FRAME ....................................................................... 27

STABILITY ADJUSTMENTS WITHOUT A SEATING SYSTEM ............................................................... 29

STABILITY ADJUSTMENTS WITH A KSS SEATING SYSTEM .............................................................. 31

LIMITED WARRANTY ........................................................................................................................... 35

TABLE OF CONTENTS

4

SPECIFICATIONS

PHYSICAL SPECIFICATIONS

Overall Width:

Overall Depth

(w/o front riggings):

Overall Height:

Seat Width:

Seat Depth:

Seat-to-Floor Height:

Back Style and Height:

Arm Styles:

Footrest:

Rear Axle:

Rear Wheels:

Caster Size:

Wheel Locks:

Weight (Approx.)

W/O Batteries:

With Batteries:

Shipping Weight (Approx.):

ORBIT SEAT OPTION ON POWER TIGER BASE

*23-inches (including joystick)

*30-inches

*41-inches

10 to 16-inches (in one {1} inch increments)

10 to 16-inches (in one {1} inch increments)

19-3/4-inches (without seating system)

Adjustable Angle (80

o

to 110

o

), Fold Down

Fixed Height Anodized Cane W/Push Handles - 20-inch

Adjustable Height T - Arms

Swingaway Footrests

Fixed Rear Axle

12-Inch Pneumatic w/ flat free option

6 and 8-Inch Semi Pneumatic, 8-Inch Pneumatic

Push to Lock - Low Mounted

95 lbs.

173 lbs.

125 lbs

NOTE: All heights are approximate to

+1/4-inch due to tire wear and air pressure. The front seat-to-floor

heights are approximate to +1/4-inch.

SPECIFICATIONS

S

P

E

C

I

F

I

C

A

T

I

O

N

S

*Measurements taken using 16x16-inch Orbit Seat Frame.

5

PROCEDURE 1DISASSEMBLY/ASSEMBLY

This Procedure Includes the Following:

Disassembling/Assembly the Seat Frame From/To

the Base Frame

WARNING

After ANY adjustments, repair or service and

BEFORE use, make sure all attaching hardware

is tightened securely.

D

I

S

A

S

S

E

M

B

L

Y

A

S

S

E

M

B

L

Y

DISASSEMBLING/ASSEMBLING

THE SEAT FRAME FROM/TO THE

BASE FRAME (FIGURE 1)

Disassembling the Seat Frame from the Base

Frame (FIGURE 1)

WARNING

Invacare recommends that Action wheelchair

users NOT be transported in vehicles of any kind

while in wheelchairs. As of this date, the Depart-

ment of Transportation has not approved any tie-

down systems for transportation of a user while in

a wheelchair, in a moving vehicle of any type.

1. Return the wheelchair to 0

o

tilt. Refer to ENGAGING

THE TILT-IN-SPACE in PROCEDURE 6 of this

manual.

2. Remove occupant from wheelchair.

3. Remove the joystick from the mounting bracket. Re-

fer to REMOVING/INSTALLING JOYSTICK in PRO-

CEDURE 3 of this manual.

4. Remove the footrests. Refer to FRONT RIGGINGS

in PROCEDURE 2 of the manual.

NOTE: Tilting the wheelchair makes the plungers under

the seat plate more accessible.

5. Tilt the wheelchair. Refer to ENGAGING THE TILT-

IN-SPACE in PROCEDURE 6 of this manual.

6. Pull down and turn plungers located on underside of

base frame plate. See DETAIL "A".

7. Push in on the tip of the quick release pin located on

underside of base frame plate and pull out of seat/

base frame plate assembly. See DETAIL "A".

8. To disengage the seat frame from the base frame,

push/pull the seat frame forward.

9. If transporting is desired, perform the following steps:

NOTE: If a seating system is being used on the wheel-

chair, refer to the seating system Owner's Manual for

installation and removal of the seating system.

A. If so equipped, remove the existing seating sys-

tem from the seat frame.

B. Remove the T-arms. Refer to REMOVING/IN-

STALLING THE T-ARMS in PROCEDURE 3 of

this manual.

C. Fold down the back canes. Refer to FOLDING/

UNFOLDING THE BACK CANES in PROCE-

DURE 4 of this manual.

D. Remove the batteries from the base frame. Re-

fer to REMOVING BATTERIES on page 43 in

the Power Tiger Owners Manual, part number

1045938.

Assembling the Seat Frame to the Base Frame

(FIGURE 1)

1. Turn the plungers located on the underside of the

base frame plate until an audible click is heard. See

DETAIL "A".

2. Visually inspect the base frame plate to ensure the

locking buttons protrude all the way through the plate.

3. Place seat frame plate on base frame plate depress-

ing the locking buttons.

4. Slide seat frame rearward.

WARNING

Ensure both sides of seat frame plate are under-

neath the locking channels of the base frame

plate and the seat frame is securely locked in

place before using the wheelchair, otherwise in-

jury may result.

5. With both sides of seat frame plate underneath the

locking channels of the base frame plate, continue to

slide until an audible click from both locking buttons is

heard.

NOTE: If an audible click is not heard from both locking

buttons, wiggle seat frame plate back and forth until an

audible click is heard. This will ensure the seat frame is

locked into position.

WARNING

Make sure the locking pins of the quick-release

pin are fully released BEFORE operating the

wheelchair.

The locking pins MUST be protruding past the top

of the seat plate assembly for a positive lock.

Keep locking pin clean.

6. Push in on the tip of the quick-release pin and reinstall in

the seat/base frame plate assembly. See DETAIL "A".

6

FIGURE 1 - DISASSEMBLING/ASSEMBLING THE SEAT FRAME FROM/TO THE BASE FRAME

SEAT FRAME AND BASE FRAME DISASSEMBLED

Locking

Channel

SEAT FRAME

BASE FRAME

PROCEDURE 1

SECTIONAL OF SEAT FRAME AND BASE FRAME

ASSEMBLED (WITHOUT SEATING SYSTEM)

Seat Frame

Plate

Base Frame

Plate

Locking Buttons

Locking Buttons

Engage Here

Seat Frame

Plate

Locking Buttons

Engaged

Locking

Channels

DETAIL "A" - SIDE VIEW

7. Pull down on quick-release pin to ensure positive lock.

8. Install the footrests. Refer to FRONT RIGGINGS in

PROCEDURE 2 of this manual.

9. Install joystick onto mounting bracket. Refer to RE-

MOVING/INSTALLING JOYSTICK in PROCE-

DURE 3 of this manual.

10. If necessary, perform the following:

A. Unfold the back canes. Refer to FOLDING/UN-

FOLDING THE BACK CANES in PROCEDURE

4 of this manual.

Crossmember

Crossmember

Seat Frame

Plate

Base Frame Plate

Plunger

Quick-Release

Pin

Locking

Pins

Quick-Release

Pin

Top of

Seat Frame

Plate

Base Frame

Plate

Tip

Locking

Button

B. Install the T-arms. Refer to REMOVING/IN-

STALLING THE T-ARMS in PROCEDURE 3 of

this manual.

NOTE: If a seating system is being used on the wheel-

chair, refer to the seating system Owner's Manual for in-

stallation and removal of the seating system.

C. Install the existing seating system onto the wheel-

chair, if so equipped.

D. Install the batteries. Refer to REMOVING BAT-

TERIES on page 43 in the Power Tiger Owners

Manual, part number 1045938.

DISASSEMBLY/ASSEMBLY

D

I

S

A

S

S

E

M

B

L

Y

A

S

S

E

M

B

L

Y

7

This Procedure Includes the Following:

Installing Footrests

Adjusting Footrest Height

Installing 3-inch Extension

Installing/Adjusting the Adjustable Angle Flip-up

Footplate

Replacing Sector Block

Adjusting the Telescoping Front Frame Tubes

Heel Loop Replacement

WARNING

After ANY adjustments, repair or service and

BEFORE use, make sure all attaching hardware

is tightened securely.

INSTALLING FOOTRESTS

(FIGURE 1)

NOTE: This procedure replaces FOOTREST ASSEM-

BLY on page 19 in the Power Tiger Owners Manual,

part number 1045938.

1. Turn the footrest to the side (open footplate is per-

pendicular to wheelchair).

2. Insert footrest mounting pin into mounting tube.

3. Push the footrest towards the inside of the wheel-

chair until it locks into place.

NOTE: The footplate will be on the inside of the wheel-

chair when locked in place.

4. Repeat this STEPS 1-3 for the opposite footrest.

FIGURE 1 - INSTALLING FOOTRESTS

NOTE: All swingaway style footrests are installed the same

way. Only one (1) style of footrest is shown for clarity.

Footrest

Footrest

Mounting

Pin

Footrest

Mounting

Tube

Footplate Height Adjustment (70

o

MFX

and 90

o

Footrests Only) (FIGURE 3)

1. Remove any accessories that are attached to the

footrests.

2. Remove the socket screw, coved washer and lock-

nut that secure the footplate to the footrest support.

3. Reposition the footplate to the desire height.

WARNING

DO NOT overtighten. Footrest must be able to ro-

tate upward from the horizontal to vertical position.

5. To release the footrest, push the footrest release le-

ver inward, rotate footrest outward.

ADJUSTING FOOTREST HEIGHT

NOTE: This procedure replaces ADJUSTMENT OF THE

FOOTREST HEIGHT on page 30 in the Power Tiger

Owners Manual, part number 1045938.

NOTE: Release the footrest locking mechanism and lift

the mounting pin out of the mounting tube. Lay the as-

sembly on a flat surface to simplify this procedure.

Pivot Slide Tube Height Adjustment

(FIGURE 2)

1. Remove any accessories that are attached to the

footrests.

2. Remove the hex screw and coved washer and posi-

tion the lower footrest assembly to the desired height.

3. Align the mounting hole in the footrest support, rein-

sert the hex screw and coved washer and securely

tighten.

4. Repeat STEPS 1-3 for the other footrest.

5. Reinstall any accessories that are attached to the

footrest.

PROCEDURE 2FRONT RIGGINGS

Hex Screw

Coved Washer

Lower Footrest

Assembly

FIGURE 2 - PIVOT SLIDE TUBE HEIGHT

ADJUSTMENT

F

R

O

N

T

R

I

G

G

I

N

G

S

8

INSTALLING/ADJUSTING THE

ADJUSTABLE ANGLE FLIP-UP

FOOTPLATES

NOTE: This procedure replaces ADJUSTING ARTICU-

LATING SWINGAWAY FOOTREST on page 32 in the

Power Tiger Owners Manual, part number 1045938.

WARNING

When determining the angle of the footplates,

make sure the rear of the footplates do not inter-

fere with the movement of the front casters.

Installing the Adjustable Angle Flip-up

Footplate(FIGURE 5)

1. Slide the half clamp over the footplate hinge.

2. Loosely tighten the two (2) flat screws that secure the

footplate to the half clamp.

3. Adjust the footplates to the desired angle and depth

for the user. Refer to the following sections of this

procedure.

Nylon

Adjustment

Screw

Footplate Hinge

Footplate

Hinge

Articulating

Footplate

Flat Screws

Half Clamp

Locknuts

Washers

Half

Clamp

90

o

Footrest

Support

FIGURE 5 - ADJUSTABLE ANGLE FLIP-UP

FOOTPLATES - INSTALLING/ DEPTH ADJUSTMENT

Footrest

Support

Hex Screw

(STEP 4)

Socket Screw,

Coved Washer

and Locknut

(STEPS 2,6)

3-inch

Extension

Locknut

(STEP 4)

Washer (STEP 4)

FIGURE 4 - INSTALLING 3-INCH EXTENSION

INSTALLING 3-INCH EXTENSION

(FIGURE 4)

NOTE: This procedure replaces ASSEMBLY OF THE

90

o

FOOTREST EXTENSION on page 31 in the Power

Tiger Owners Manual, part number 1045938.

NOTE: Note the position of the attaching hardware for

proper reassembly of the footrest.

NOTE: If using ANY type of extension with the ADJUST-

ABLE ANGLE FOOTPLATE, refer to ADJUSTABLE

ANGLE FLIP UP FOOTPLATE PERPENDICULAR

AND/OR INVERSION/EVERSION ADJUSTMENT in

this procedure of the manual.

1. Remove any accessories that are attached to the

footrests.

2. Remove the socket screw, coved washer and lock-

nut that secure the footplate to the footrest support.

3. Insert the 3-inch extension into the footrest support

and align the mounting holes.

4. Secure the 3-inch extension to the footrest support

with NEW hex screw, washer and locknut. Securely

tighten.

5. Position the footplate at the desired height.

WARNING

DO NOT overtighten. Footrest must be able to ro-

tate upward from the horizontal to vertical position.

6. Reinstall the socket screw through the mounting holes

of the footplate and footrest support.

7. Secure the footplate to the footrest support with the

coved washer and locknut. Securely tighten.

Locknut

Socket Screw

and

Coved Washer

Height

Adjustment

Holes

FRONT RIGGINGSPROCEDURE 2

FIGURE 3 - FOOTPLATE HEIGHT ADJUSTMENT

(70

o

MFX AND 90

o

FOOTRESTS ONLY)

F

R

O

N

T

R

I

G

G

I

N

G

S

4. Reinstall the socket screw through the mounting holes

of the footplate and footrest support.

5. Secure the footplate to the footrest support with the

coved washer and locknut. Securely tighten.

Footrest

Support

Footplate

Footplate

9

PROCEDURE 2FRONT RIGGINGS

F

R

O

N

T

R

I

G

G

I

N

G

S

Adjustable Angle Flip-up Footplate Depth

Adjustment (FIGURE 5)

NOTE: Observe the angle of the articulating footplate for

reinstallation.

1. Remove the two (2) flat screws, washers and lock-

nuts that secure articulating footplate to the footplate

hinge.

2. Move the articulating footplate to one (1) of four (4)

mounting positions.

NOTE: If desired depth is still not obtained, rotate the half

clamp on the footplate hinge 180

o

.

3. Retighten the two (2) flat screws, washers and lock-

nuts.

NOTE: The settings for positioning the articulating

footplates on the half-clamps may vary for each footplate.

Adjustable Angle Flip-up Footplate Angle

Adjustment (FIGURES 5 AND 6)

1. Loosen, but do not remove the two (2) flat screws

and locknuts that secure the footplate to the footplate

hinge. (FIGURE 5)

2. Position the adjustable angle flip-up footplate to

the desired angle to accommodate the user.

3. Retighten the two (2) flat screws and locknuts. (FIG-

URE 5)

Footrest

Support

Footplate

FIGURE 6 - ADJUSTABLE ANGLE FLIP-UP

FOOTPLATE ANGLE ADJUSTMENT

Adjustable Angle Flip-up Footplate

Perpendicular and/or Inversion/

Eversion Adjustment (FIGURES 5 AND 7)

NOTE: It is not necessary to remove the footplate to per-

form this adjustment.

1. Insert a flathead screwdriver through the half clamp

on the adjustable angle footplate.

SIDE VIEW OF

FOOTPLATE

AND FOOTREST

Footplate

Footrest

Support

FRONT VIEW OF

FOOTPLATE

AND FOOTREST

SUPPORT.

FIGURE 7 - ADJUSTABLE ANGLE FLIP-UP

FOOTPLATE PERPENDICULAR AND/OR

INVERSION/EVERSION ADJUSTMENT

REPLACING SECTOR BLOCK

(FIGURE 8)

1. Remove the hex screw and washer that secure

the existing sector block to the wheelchair frame.

2. Position the NEW sector block on the wheel-

chair frame. Make sure the locking pin is facing

UP.

3. Secure the NEW sector block to the wheelchair

frame with the existing hex screw and washer.

Use Loctite

®

242 and securely tighten.

Wheelchair

Frame

Sector Block

Locking Pin

Hex Screw

Washer

FIGURE 8 - REPLACING SECTOR BLOCK

2. Slowly turn the nylon adjustment screw in or out until

the adjustable angle footplate is perpendicular to the

footrest assembly or the desired inversion or ever-

sion is obtained.

Loctite - Registered trademark of Loctite Corporation.

10

FRONT RIGGINGSPROCEDURE 2

F

R

O

N

T

R

I

G

G

I

N

G

S

ADJUSTING THE TELESCOPING

FRONT FRAME TUBES (FIGURE 9)

CAUTION

When determining the depth of the telescoping

front frame tubes, make sure the rear of the foot-

rests do not interfere with the movement of the

front casters. Otherwise damage to the wheel-

chair may result.

1. Remove the mounting screw and locknut that se-

cures the telescoping tube to the seat rail.

2. Adjust telescoping tube to IN or OUT to desired mount-

ing adjustment hole.

3. Reinsert mounting screw and install locknut. Securely

tighten.

4. Repeat STEPS 1-3 for opposite telescoping front

frame tube.

5. Rotate front casters to ensure there is no interfer-

ence between the footrests and front casters.

6. If interference occurs, repeat procedure and adjust

telescoping front frame tube accordingly.

2. Remove the lower footrest assembly.

3. Remove the phillips screws, spacers, and locknuts

that secure the heel loop to the footrest.

4. Slide heel loop over slide tube of footrest assembly.

5. Replace heel loop.

6. Reverse STEPS 1-5 to reassemble.

NOTE: When securing the heel loop to the footrest as-

sembly, tighten the phillips screw and locknut until the

spacer is secure.

Adjustable Footplate

1. Remove the four (4) phillips screws and washers that

secure the EXISTING heel loop to the footplate.

2. Position the mounting holes of the NEW heel loop

with the mounting holes in the adjustable footplate.

3. Secure the NEW heel loop to the footplate with the

four (4) phillips screws and washers. Securely tighten.

Washer

ADJUSTABLE FOOTPLATES

Hex Screw/

Coved Washer

COMPOSITE FOOTPLATES

FIGURE 10 - HEEL LOOP REPLACEMENT

Phillips

Screws

Phillips

Screws

Locknut

Spacer

Phillips

Screw

HEEL LOOP REPLACEMENT

(FIGURE 10)

NOTE: This procedure replaces HEEL LOOP REPLACE-

MENT on page 32 in the Power Tiger Owners Manual,

part number 1045938.

Composite Footplates

1. Remove the hex screw and coved washer that se-

cures the lower footrest assembly to the swingaway

footrest assembly.

Lower

Footrest

Assembly

Slide

Tube

Swingaway Footrest

Assembly

Telescoping

Tube

Locknut

Mounting

Screw

Seat Rail

FIGURE 9 - ADJUSTING THE TELESCOPING

FRONT FRAME TUBES

Mounting

Adjustment

Holes

11

PROCEDURE 3ARMS

This Procedure Includes the Following:

Installing the T-arm Sockets

Installing/Removing the T-arms

Adjusting the T-arms

Adjusting the Transfer Assists and/or

Side Guards - T-arms

Replacing the Locking Lever - T-arms

Removing/Installing Joystick

FIGURE 1 - INSTALLING THE T-ARM SOCKETS

A

R

M

S

T-arm Socket

Inserts

Coved

Washers

Locknuts

Wheelchair Frame

T-arm Clamp

Hex Bolts

Hex Screws

Washers

T-arm

Socket

6. Adjust the T-arm socket. Refer to ADJUSTING THE

T-ARMS in this instruction sheet.

7. Repeat STEPS 2-6 for the opposite side of the wheel-

chair.

8. Install the T-arms into the T-arm sockets. Refer to

INSTALLING/REMOVING THE T-ARMS in this in-

struction sheet.

INSTALLING/REMOVING THE

T-ARMS (FIGURE 2)

Installing

1. Position the T-arm over the T-arm socket on the

wheelchair frame.

NOTE: Make sure the locking lever is towards the front of

the wheelchair.

2. Slide the T-arm into the T-arm socket until the lock-

ing lever is in the slot in the T-arm socket and an

audible "click" is heard.

3. Pull up on the T-arm to make sure the T-arm is locked

in place.

NOTE: If the T-arm does not slide in the T-arm socket as

desired, adjust the T-arm socket. Refer to ADJUSTING

THE T-ARMS in this procedure of the manual.

4. Adjust the T-arm for desired height, width and depth,

if necessary. Refer to ADJUSTING THE T-ARMS in

this procedure of the manual.

5. Repeat STEPS 1-4 for the opposite side of the wheel-

chair.

6. Install the joystick onto the right side T-Arm. Refer to

REMOVING/INSTALLING THE T-ARMS in this pro-

cedure of the manual.

Removing

NOTE: Remove the joystick before removing the right

side T-Arm. Refer to REMOVING/INSTALLING THE T-

ARMS in this procedure of the manual.

1. Press in on the locking lever and lift the T-arm straight

up and out of the T-arm socket.

NOTE: If the T-arm does not slide up and down in the T-

arm socket as desired, adjust the T-arm socket. Refer to

ADJUSTING THE T-ARMS in this procedure of this

manual.

2. Repeat STEP 1 for the opposite side of the wheel-

chair.

WARNING

After ANY adjustments, repair or service and BE-

FORE use, make sure all attaching hardware is

tightened securely.

INSTALLING THE T-ARM SOCKETS

(FIGURE 1)

1. Position the T-arm clamp on the wheelchair frame

as shown in FIGURE 1.

NOTE: The T-arm socket must be positioned on the

outside of the wheelchair frame.

2. Install the hex bolts through the T-arm clamp,

wheelchair frame and coved washers and tighten

securely with locknuts.

3. Position the T-arm socket inserts in the T-arm

socket as shown in FIGURE 1.

4. Line up the mounting holes in the T-arm socket

with the threaded holes in the T-arm clamp.

5. While holding the T-arm socket and the T-arm

clamp together, install the four (4) hex screws and

washers into mounting holes and tighten loosely.

12

ARMSPROCEDURE 3

FIGURE 2 - INSTALLING/REMOVING THE

T-ARMS

T-Arm Release

Lever - Unlocked

Position

Inside

T-Arm Post

Outside T-

Arm Post

T-Arm Release

Lever - Locked

Position

FIGURE 3 - ADJUSTING THE T-ARMS - HEIGHT

ADJUSTING THE T-ARMS

Height (FIGURE 3)

1. Unlock the T-arm by flipping the T-arm release lever

towards the inside of the wheelchair.

NOTE: If necessary, pull out on the T-arm release lever

and rotate 180

o

so it can be flipped towards the outside of

the wheelchair.

2. Slide the T-arm to one (1) of the eight (8) positions.

NOTE: If the inside T-arm post does not slide up and

down in the outside T-arm post as desired, perform one

(1) of the following:

A. Tighten - Tightening the set screws on the out-

side T-arm post will make it harder to move the

inside T-arm post up and down.

B. Loosen - Loosening the set screws on the out-

side T-arm post will make it easier to move the

inside T-arm post up and down.

3. Lock the T-arm by flipping the T-arm release lever

towards the front of the wheelchair.

Set

Screws

T-Arm

Socket

Slot

Locking Lever

(Towards the

front of the

wheelchair.)

T-Arm

Wheelchair

Frame

A

R

M

S

FIGURE 6 - ADJUSTING THE T-ARMS -

T-ARM SOCKETS

Hex Screws

and Washers

T-arm

Hex Screws

and Washers

T-arm Socket

T-Arm Sockets (FIGURE 6)

1. Loosen, but do not remove the four (4) hex screws

and washers that secure the T-arm socket to the T-

arm clamp.

NOTE: The T-arm socket will disassemble if the four (4)

hex screws and washers are removed.

2. Slide the T-arm into the T-arm socket until the lock-

ing lever is in the slot in the T-arm socket and an

audible "click" is heard.

3. Squeeze the T-arm socket the T-arm clamp together

until the socket is flush with the T-arm.

4. While holding the T-arm socket and the T-arm clamp

together, tighten the four (4) hex screws and wash-

ers securely.

5. Press in on the locking lever and lift the T-arm straight

up and out of the T-arm socket.

6. Repeat STEPS 3-6, if necessary until the T-arm slides

in the T-arm socket as desired.

13

PROCEDURE 3ARMS

ADJUSTING THE TRANSFER

ASSISTS AND/OR SIDE GUARDS -

T-ARMS (FIGURE 7)

1. Remove the T-arm from the wheelchair. Refer to IN-

STALLING/REMOVING THE T-ARMS in this pro-

cedure of the manual.

2. Remove the two (2) bottom socket screws that se-

cure the side guard to the bottom clamp.

3. Perform one (1) of the following:

Small Side Guards - Move the bottom clamp up

one (1) of two (2) mounting po-

sitions in the side guard.

Large Side Guards - Move the bottom clamp up

one (1) of three (3) mounting

positions in the side guard.

4. Re-secure the side guard to the bottom clamp with

the two (2) socket screws. Securely tighten.

5. Install the T-arm onto the wheelchair. Refer to IN-

STALLING/REMOVING THE T-ARMS in this pro-

cedure of the manual.

A

R

M

S

FIGURE 7 - ADJUSTING THE TRANSFER

ASSISTS AND/OR SIDE GUARDS-T-ARMS

Bottom

Socket

Screws

Bottom

Clamp

Transfer

Assist

Side

Guard

T-Arm

2. Remove the phillips bolt and locknut that secure the

EXISTING locking lever to the bottom bracket.

NOTE: The locking lever is spring loaded. Place your

free hand over the locking lever to prevent the parts from

springing off of the bottom bracket.

3. Remove the EXISTING locking lever and spring from

the bottom bracket.

NOTE: Inspect the spring for wear and damage. Replace

if necessary.

4. Position the spring on the bottom bracket as shown

in FIGURE 8.

5. Position the NEW locking lever onto the spring and

the bottom bracket.

NOTE: Make sure the two (2) extended ends of the spring

are inside the notch in the locking lever.

6. Line up the mounting holes in the NEW locking lever,

spring and bottom bracket.

WARNING

DO NOT over tighten the locknut that secures the

locking lever to the bottom bracket. Over tight-

ening this locknut will prevent the locking lever

from operating properly, possibly causing injury.

7. Install the phillips bolt and locknut. Tighten securely.

8. Install the T-arm onto the wheelchair. Refer to IN-

STALLING/REMOVING THE T-ARMS in this pro-

cedure of the manual.

DO NOT

REMOVE

THESE

MOUNTING

SCREWS

FIGURE 8 - REPLACING THE LOCKING LEVER -

T-ARMS

Bottom

Bracket

Phillips Bolt

Locking

Lever

Spring

Extended Ends

Locknut

Notch

REPLACING THE LOCKING LEVER -

T-ARMS (FIGURE 8)

1. Remove the T-arm from the wheelchair. Refer to

INSTALLING/REMOVING THE T-ARMS in this pro-

cedure of the manual.

14

PROCEDURE 3 ARMS

A

R

M

S

REMOVING/INSTALLING JOYSTICK

(FIGURE 9)

1. Disconnect (unplug) joystick from controller.

2. Cut plastic clips that secure cord to wheelchair frame.

3. Rotate release lever to COUNTERCLOCKWISE to

unlock the joystick mounting tube.

NOTE: Illustration depicts the locked position of the re-

lease lever facing forward and the unlocked position fac-

ing rearward. The unlocked and locked positions will not

always be as shown. Positions shown for reference only.

4. Remove joystick from T-arm mounting bracket.

5. To install, reverse STEPS 1-4.

NOTE: When installing, ensure joystick is facing front of

wheelchair.

FIGURE 9 - REMOVING/INSTALLING JOYSTICK

Unlocked

Locked

Mounting

Bracket

Joystick

Connects to

Controller

T-Arm

NOTE: T-Arm pad not shown for clarity.

Front of

Wheelchair

Release

Lever

Joystick Mounting

Tube

15

This Procedure Includes the Following:

Replacing the Locking Mechanism in the Back

Cane

Installing/Removing Stroller Handles

Folding/Unfolding the Back canes

Removing/Installing the Seat Pan

Engaging/Disengaging the Wheel Locks

PROCEDURE 4

FIGURE 1 - REPLACING THE LOCKING

MECHANISM IN THE BACK CANE

Locking

Mechanism

Back Cane

Actuator

Spring

Angled Portion

of Locking

Mechanism

WARNING

After ANY adjustments, repair or service and BE-

FORE use, make sure all attaching hardware is

tightened securely.

REPLACING THE LOCKING

MECHANISM IN THE BACK CANE

(FIGURE 1)

CAUTION

The locking mechanism in the back canes is

spring loaded. Slowly remove the back canes

from the wheelchair to prevent the springs from

being lost.

1. Fold back canes down. Refer to FOLDING AND

UNFOLDING THE BACK CANES in this procedure

of the manual.

2. Twist the actuator COUNTERCLOCKWISE to re-

move from the locking mechanism.

3. Slowly let the EXISTING locking mechanism and

spring slide out of the back cane.

NOTE: Inspect the spring for wear and damage. Replace

if necessary.

4. Slide the NEW locking mechanism and spring into

the back cane.

5. Make sure the angled end of the NEW locking mecha-

nism is facing down toward seat rails.

6. Use Loctite 242, on threads only, and securely tighten

the actuator into the locking mechanism.

7. Unfold back canes. Refer to FOLDING AND UN-

FOLDING THE BACK CANES in this procedure of

the manual.

FIGURE 2 - INSTALLING/REMOVING STROLLER

HANDLES

INSTALLING/REMOVING

STROLLER HANDLES (FIGURE 2)

1. Remove the back cane grips and plug buttons from

both back canes.

2. Slide the stroller handle into the back canes.

3. Align the mounting holes of the stroller handle and

the back canes.

4. Secure stroller handle to the back canes with the two

(2) mounting screws provided. Securely tighten.

5. To remove, reverse STEPS 1-4.

Quick-Release Pin

Back Cane

Stroller Handle

Button

B

A

C

K

S

E

A

T

W

H

E

E

L

L

O

C

K

S

BACK/SEAT/WHEELLOCKS

16

B

A

C

K

S

E

A

T

W

H

E

E

L

L

O

C

K

S

FIGURE 3 - FOLDING/UNFOLDING THE BACK

CANES

FOLDING/UNFOLDING THE BACK

CANES (FIGURE 3)

1. To fold back canes, lift up on actuator pins and fold

back canes forward.

2. To unfold back canes, pull back canes up until actua-

tor pins are locked in place.

NOTE: Actuator pins are locked in place when an au-

dible click is heard.

Actuator

Pin

Back Cane

PROCEDURE 4 BACK/SEAT/WHEELLOCKS

REMOVING/INSTALLING THE SEAT

PAN (FIGURE 4)

Removing

NOTE: If a seating system is being used on the wheel-

chair, refer to your particular seating system manufacturer's

Owner's Manual for installation and removal of the seat-

ing system.

1. If so equipped, remove seating system from wheel-

chair.

2. Remove the four (4) mounting screws that secure

the seat pan to the seat rails.

3. Remove existing seat pan and discard.

Installing

1. Position the NEW seat pan on crossmembers.

2. Secure with the existing four (4) mounting screws.

Securely tighten.

3. Reinstall seating system onto wheelchair.

FIGURE 4 -REMOVING/INSTALLING THE SEAT

PAN

Mounting

Screws

Seat Frame

Assembly

Mounting

Screws

Rigid Seat

Pan

ENGAGING/DISENGAGING THE

WHEEL LOCKS (FIGURE 5)

Engaging

1. Push handle forward away from tire to engage wheel

lock.

2. Repeat STEP 1 for opposite wheel.

Disengaging

1. Pull handle back toward tire to disengage wheel lock.

2. Repeat STEP 1 for opposite wheel.

FIGURE 5 - ENGAGING/DISENGAGING THE

WHEEL LOCKS

Wheellock

Handle

17

PROCEDURE 5CASTERS

C

A

S

T

E

R

S

This Procedure Includes the Following:

Removing/Installing Front Casters

Replacing Forks

WARNING

After ANY adjustments, repair or service and BE-

FORE use, make sure all attaching hardware is

tightened securely.

DO NOT use your power wheelchair unless it has

the proper tire pressure (p.s.i.). DO NOT over-inflate

the tires. Failure to follow these suggestions may

cause the tire to explode and cause bodily harm.

The recommended tire pressure is listed on the side

wall of the tire.

CAUTION

DO NOT overtighten hardware attaching to the

frame. Damage to components may occur.

REMOVING/INSTALLING FRONT

CASTERS (FIGURE 1)

NOTE: This procedure replaces FRONT TIRES - PNEU-

MATIC/SEMI-PNEUMATIC on page 38 in the Power Ti-

ger Owners Manual, part number 1045938.

Periodically, the tires will need to be replaced due to wear or

puncture.

Removing

1. Remove the mounting screw, spacers and locknut that

secure the EXISTING caster to the fork.

2. Remove the EXISTING caster from the fork.

Installing

1. Position the new/existing caster into the fork.

2. Reinstall the mounting screw, spacers and locknut.

Securely tighten.

Mounting

Screw

Locknut

Spacer

FIGURE 1 - REMOVING/INSTALLING FRONT

CASTERS

3. Torque locknut to 10-foot pounds (120-inch) pounds.

4. Loosen the locknut 1/8 of a turn.

5. Move the caster side to side.

NOTE: If the caster moves side to side, tighten the locknut

slightly. Repeat STEP 4 until there is no side to side move-

ment of the caster.

REPLACING FORKS (FIGURE 2)

NOTE: This procedure combined with REMOVING/IN-

STALLING FRONT CASTERS replaces SIX OR EIGHT

INCH CASTER INSTALLATION on page 36 in the Power

Tiger Owners Manual, part number 1045938.

1. Remove the caster from the existing fork. Refer to

REMOVING/INSTALLING FRONT CASTERS in this

procedure of the manual.

2. Remove the head tube cap.

3. Remove the locknut and nylon washer.

4. Drop the EXISTING fork out of the caster head tube.

5. Slide the new fork into the caster head tube.

NOTE: Check bearing assemblies. Replace if necessary.

6. Ensure NEW fork slides completely into caster

headtube.

7. Install nylon washer and secure with locknut.

WARNING

Improper positioning of the washer will prohibit the

free movement of the forks which may result in

injury to the occupant.

8. Install the caster onto the NEW fork. Refer to RE-

MOVING/INSTALLING CASTERS in this procedure

of the manual.

9. Install headtube cap.

FIGURE 2 - REPLACING FORKS

Headtube

Cap

Locknut

Nylon Washer

Caster Headtube

Fork

Spacer

Fork

Caster

18

This Procedure Includes the Following:

Engaging the Tilt-in-Space

FIGURE 1 - ENGAGING THE TILT-IN-SPACE

DETAIL "A"

Unlocked

Position

Locked

Position

Release

Pedal

Wheelchair

Frame

PROCEDURE 6

TILTING

T

I

L

T

I

N

G

6. SLOWLY, pull back on the back canes while step-

ping on the release pedal.

7. When the seat reaches the desired angle, SLOWLY

relieve the pressure on the release pedal.

8. Move the locking mechanism on the release pedal to

the locked position. See DETAIL "A".

9. Disengage wheel locks before attempting to move

occupant. ENGAGING/DISENGAGING THE

WHEEL LOCKS in PROCEDURE 4 of this manual.

Back

Cane

Locking

Mechanism

WARNING

After ANY adjustments, repair or service and BE-

FORE use, make sure all attaching hardware is

tightened securely.

ENGAGING THE TILT-IN-SPACE

(FIGURE 1)

WARNING

ALWAYS make sure that the wheelchair is stable

BEFORE using the tilt-in-space.

NEVER operate the wheelchair while in any tilt posi-

tion over 10

o

RELATIVE TO THE SEAT FRAME. If the

limit switch does not stop the wheelchair from op-

erating in a tilt position greater than 10

o

RELATIVE TO

THE SEAT FRAME, have the limit switch adjusted by

an authorized Invacare dealer or qualified techni-

cian.

Make sure the occupant of the wheelchair is

properly positioned.

Always engage both wheel locks.

DO NOT use the release pedal of the tilt mecha-

nism to gain leverage in tipping the wheelchair.

The release pedal was not designed to be used

in this manner and may cause injury to the assis-

tant and/or user or damage to the wheelchair.

1. Place the wheelchair on a level surface.

2. Engage both wheel locks. Refer to ENGAGING/DIS-

ENGAGING THE WHEEL LOCKS in PROCEDURE

4 of this manual.

3. Move the locking mechanism on the release pedal to

the unlocked position. See DETAIL "A".

4. Inform the occupant of the wheelchair that the wheel-

chair is about to be tilted and remind them to lean

back.

5. Stand behind the wheelchair and apply pressure to

the release pedal.

19

PROCEDURE 7DEALER ADJUSTMENTS - GENERAL

This Procedure Includes the Following:

Removing/Installing the Spreader Bar

Changing the Seat Width

Removing/Installing/Adjusting Cable Assembly

Removing/Installing the Cable Assembly from

the Release Pedal

Removing/Installing the Tilt Mechanism(s)

D

E

A

L

E

R

A

D

J

U

S

T

M

E

N

T

S

WARNING

After ANY adjustments, repair or service and BE-

FORE use, make sure all attaching hardware is

tightened securely.

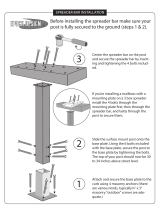

REMOVING/INSTALLING THE

SPREADER BAR (FIGURE 1)

NOTE: Make sure the spreader bar is ALWAYS attached

to the wheelchair.

NOTE: If a seating system is being used on the chair,

refer to the seating system Owner's Manual for installa-

tion and removal of the seating system.

1. Remove the EXISTING seating system from the

wheelchair, if so equipped.

2. Separate back assembly from the back angle brack-

ets by removing the mounting screws, coved spac-

ers, washers, and locknuts.

3. Remove the locking mechanisms in the back canes.

Refer to REPLACING THE LOCKING MECHANISM

IN THE BACK CANE in this procedure of the manual.

4. Loosen, but do not remove the two (2) set screws that

secure the EXISTING spreader bar to back canes.

5. Slide the EXISTING spreader bar off of the two (2)

back canes and slide NEW spreader bar on.

NOTE: Make sure the spreader bar is positioned on back

canes so not to interfere with the back angle brackets.

6. Securely tighten the two (2) set screws that secure

the new spreader bar to the back canes.

CAUTION

When reattaching back assembly, DO NOT

OVERTIGHTEN! Back will not fold down properly.

Tighten hardware until snug.

8. Reattach back assembly to the back angle brackets

with the EXISTING mounting screws, coved spac-

ers, washers, and locknuts. DO NOT OVER-

TIGHTEN! Wheelchair will not fold properly. Tighten

until a snug fit is provided.

9. Reinstall the locking mechanisms in the back canes.

Refer to REPLACING THE LOCKING MECHANISM

IN THE BACK CANE in PROCEDURE 4 of this

manual.

FIGURE 1 - REMOVING/INSTALLING THE

SPREADER BAR

Back

Assembly

(STEPS 2,8)

Mounting

Screw

(STEPS 2,8)

Coved Spacer

(STEPS 2,8)

Spreader Bar

(STEP 4-7)

Set

Screw

(STEP 4,7)

Back Angle

Bracket

(STEPS 2,8)

Locknut

(STEPS

2,8)

Washer

(STEPS 2,8)

Locking

Mechanism

(STEPS 3,9)

G

E

N

E

R

A

L

20

CHANGING THE SEAT WIDTH

(FIGURE 2)

NOTE: This procedure replaces 12-INCH TO 13-INCH

SEAT WIDTH ADJUSTMENT, 12-INCH OR 13-INCH

TO 14-INCH SEAT WIDTH ADJUSTMENT, SEAT

WIDTH ADJUSTMENT 12-INCH, 13-INCH OR 14-INCH

TO 15-INCH OR 16-INCH on page 51-57 in the Power

Tiger Owners Manual, part number 1045938.

1. Remove the seat frame from the base frame. Refer

to DISASSEMBLY/ASSEMBLY in PROCEDURE 1

of this manual.

NOTE: Note the orientation of the seat plate in relation to

the seat rails for proper reinstallation.

WARNING

Before removing the crossmembers, note the

mounting hole position of the crossmembers to

the seat rails for proper reinstallation. Otherwise

injury to the occupant and/or user and damage

to the wheelchair may occur.

NOTE: If a change in the position of the crossmembers is

desired, refer to ADJUSTING THE PIVOT POINT in this

procedure of the manual.

FIGURE 2 - CHANGING THE SEAT WIDTH

2. Remove the four (4) mounting screws and four (4)

washers that secure the crossmembers to the seat

rails.

3. Replace existing spreader bar with NEW spreader

bar. Refer to REMOVING/INSTALLING THE

SPREADER BAR in this procedure of the manual.

4. Remove the four (4) mounting screws and four (4)

locknuts that secure the seat plate to the

crossmembers.

5. Secure the seat plate to the NEW crossmembers

with the existing four (4) mounting screws and lock-

nuts. Securely tighten.

6. Secure the crossmembers to the seat rails with the

four (4) mounting screws and washers. Securely

tighten.

7. Reinstall the seat frame onto the base frame. Refer

to DISASSEMBLY/ASSEMBLY in PROCEDURE 1

of this manual.

PROCEDURE 7 DEALER ADJUSTMENTS - GENERAL

D

E

A

L

E

R

A

D

J

U

S

T

M

E

N

T

S

G

E

N

E

R

A

L

Mounting

Screws

(STEP 2, 6)

Washer

(STEP 2, 6)

Crossmember

(STEPS 2, 6)

Locknuts

(STEP 4, 5)

Washer

(STEP 2, 6)

Seat Rail

(STEP 2, 6)

Mounting

Screws

(STEPS 4, 5)

Seat Plate

(STEPS 4, 5)

Washer

(STEP 2, 6)

Crossmember

(STEPS 2, 6)

Mounting

Screws

(STEP 2, 6)

NOTE: The back angle plates

are not shown for clarity

Seat Rail

(STEP 2, 6)

Mounting

Screws

(STEP 4, 5)

/