Page is loading ...

Series 5000 POSRV type 5046/5146/5066/5166

Installation and Maintenance Instructions

without notice ANGMC-6038-EN-1307

1.0 General valve description & start up

1.1 Operation

The AGCO Series 5000 valve is designed for modulating action. The main valve will open at

nameplate set, but only an amount proportional to the relieving capacity required. As process

pressure increases, the valve will open more and be in full lift at 110% of set.

The main valve uses the principle of pressurizing the larger area of a differential area piston with

line pressure to hold the piston closed up to set pressure. At set pressure, the pilot relieves,

depressurizing the volume on the larger area side of the piston. Line pressure acting on the smaller

area side causes it to lift, permitting discharge from the main valve. As capacity relief of the system

is satisfied, system pressure will begin to decrease. When it does, the pilot will actuate and direct

system pressure to the larger area side of the main valve piston to close it.

The set pressure range is 15 psig to 6170 psig for air, liquid and gas. For steam the set pressure

range is limited to a temperature 515°F.

1.2 Operation

Either or both inlet and outlet may be standard ANSI flanges or API flanges and are to be installed

in accordance with accepted piping practices.

1.3 Start-up

There must be pressure at the valve inlet or at the pilot inlet/sense port for valves with remote

sense to establish a differential force across the piston and “load” it in the closed position. Pressure

must pass through the pilot and exert force on the top of the piston. On normal plant start-up the

valve will close itself as pressure increases.

Block valves are often used under safety valves to isolate them when maintenance is required.

When putting the safety valve in service be sure the block valve is fully opened. If the block valve is

opened after system start-up, the safety valve may briefly vent before the volume on the larger area

side of the piston gets pressurized to close the main valve seat disk.

1.4 Maintenance

Anderson Greenwood Crosby recommended main valve and pilot maintenance procedures

including pilot set pressure adjustment and valve assembly testing are described in the following

paragraphs. Following these procedures in a regular pressure relief valve maintenance program

appropriate for the specific operating conditions will insure satisfactory valve performance and

provide optimum service life.

Should the pressure/media requirements of a pilot operated pressure relief valve be outside the

capabilities of the repair facility, contact Anderson Greenwood Crosby for specific instructions

before starting any maintenance activity.

This manual is provided as a general guide for the maintenance of the safety valves described

herein. It does not include procedures covering all valve configurations and variations

manufactured by Anderson Greenwood Crosby. The user is advised to contact Anderson

Greenwood Crosby or one of our authorized representatives for assistance with valve configurations

Table of contents

1.0 General valve description & start up 1

2.0 Main valve maintenance 2

3.0 Pilot maintenance procedure 5

4.0 Pilot set pressure adjustment 10

5.0 Valve assembly testing 12

6.0 Soft goods repair kits 12

ANDERSON GREENWOOD

Emerson.com/FinalControl © 2017 Emerson. All rights reserved.

Series 5000 POSRV type 5046/5146/5066/5166

Installation and Maintenance Instructions

Emerson reserves the right to change the contents without notice page 2

2.3 Assembly

2.3.1 Nozzle and nozzle seal installation

1. Place nozzle seal and nozzle in body.

2. Place nozzle retainer over nozzle and thread into body until it stops on nozzle shoulder. Do not

lubricate nozzle retainer threads or mating body threads.

3. Repeat steps 1 through 4 of disassembly procedure to compress nozzle seal. Thread nozzle

retainer into body as seal is compressed to keep nozzle retainer from binding against piston.

4. Use a punch or bar with a light hammer and tap on the nozzle retainer teeth to snug the nozzle

retainer threads.

5. Loosen cap bolts to remove load from spacer and remove spacer from valve.

Replace seat, piston and liner seal. Apply a light coat of Dow Corning #33 silicone lubricant on all

threads after cleaning. Do not use any lubricant on the soft goods.

When installing the cap, make sure it is seated squarely into body. Torque cap bolts uniformly so

as not to “cock” cap. See Table II for torque values. Such a condition may result in leakage at the

liner seal or cause the piston and liner to bind.

2.0 Main valve maintenance

2.1 Disassembly

Refer to Figure 1 for parts description and location.

Unscrew the bushing/siphon tube and remove the bushing seal. Remove the cap from the body.

Remove the piston and liner. A bolt may be threaded into hole in top of piston to aid in removal.

Through holes in seat retainers 2”, 3” & 4” sizes are threaded to assist in disassembly. Remove the

soft goods from the piston. If the piston is equipped with a wedge ring, clean and retain it for use

during assembly. The dipper tube is swaged in place and no attempt should be made to remove

it. Refer to Figure1 for parts description and location. The nozzle and nozzle seal should not be

removed unless the nozzle is damaged or the seal is leaking.

2.1.1 Nozzle and nozzle seal disassembly

Refer to Figure 2 for parts description and location.

1. Place liner in body and piston, without seat or seat retainer, into liner and on top of nozzle.

2. Place appropriate spacer (see Table I) on top of piston and then the cap over the spacer.

3. Thread the appropriate number of cap bolts (see Table I) into threaded holes on top of body.

If two bolts are used, they should be 180° apart. When using four bolts, they should be 90°

apart.

4. Tighten cap bolts evenly to the torque listed in Table I to compress nozzle seal.

5. Use a punch or bar with a light hammer and tap on the nozzle retainer teeth to loosen the

nozzle retainer. Unthread nozzle retainer approximately 1/2 turn.

6. Loosen cap bolts to remove load from nozzle. Remove components from main valve.

Valve size & type Min. nozzle

projection height (in)

1.5” Type 5046/5146 .045

2” Type 5046/5146 .055

3” Type 5046/5146 .055

4” Type 5046/5146 .055

6” Type 5046/5146 .070

8” Type 5046/5146 .070

1.5” Type 5066/5166 .055

2” Type 5066/5166 .055

3” Type 5066/5166 .055

4” Type 5066/5166 .070

6” Type 5066/5166 .070

8” Type 5066/5166 .070

2.2 Main valve nozzle rework

Should the main valve nozzle seating face become nicked or scratched such that the main valve

seat does not seal, the imperfections can be removed by polishing the nozzle face with 400

grit sandpaper on a flat surface plate. Certain critical nozzle dimensions and finishes must be

maintained and those are shown in the figure and table below.

Minimum

projection

32

32

.010

R.020

1/4 7

5/16 12

3/8 21

7/16 33

1/2 45

9/16 59

5/8 97

3/4 130

7/8 202

1 271

Series 5000 POSRV type 5046/5146/5066/5166

Installation and Maintenance Instructions

Emerson reserves the right to change the contents without notice page 3

Table I

Valve size & type Spacer P/N Cap bolt # Cap Cap bolt

thread bolts to torque

use (ft-lb)

1.5x2/3 Type 5046/5146 (G & H orifice) 06.5612.003 .500-20 UNF 2 41

1.5X2/3 Type 5046/5146 (G & H orifice) 06.5612.003 .625-18 UNF 2 51

2” Type 5046/5146 06.5612.005 .500-20 UNF 4 27

3” Type 5046/5146 06.5612.007 .500-20 UNF 4 35

4” Type 5046/5146 06.5612.008 .750-16 UNF 4 130

6” Type 5046/5146 06.5612.009 .750-16 UNF 2 82

6” Type 5046/5146 06.5612.009 .875-14 UNF 2 95

8” Type 5046/5146 06.5612.010 .875-14 UNF 4 123

8” Type 5046/5146 06.5612.010 1.000-14 UNS 4 140

1.5” Type 5066/5166 06.5612.005 .500-20 UNF 2 19

2” Type 5066/5166 06.5612.007 .500-20 UNF 2 31

3” Type 5066/5166 06.5612.008 .750-16 UNF 2 113

4” Type 5066/5166 06.5612.011 .625-18 UNF 2 63

6” Type 5066/5166 06.5612.012 .750-16 UNF 2 88

8x10 Type 5066/5166 06.5612.014 1.125-12 UNF 10 89

Table II

Bolt size Torque value

(FT-LBS)

6” and 8” size

1 1/2” thru 4” size

Siphon tube option

Figure 1

Item Part name Item Part name

1 Body

2 Piston

3 Liner

4 Nozzle (1)

5 Seat (2)

6 Retainer

7 Retainer bolt

8 Cap

9 Dipper tube

10 Piston seal (2)

Notes

(1) Not field replaceable.

(2) Recommended spare parts for repair.

(3) Used on 4” sizes and larger Type 5046,

5146 and 3” Type 5066, 5166.

See page 12 for soft goods repair kit part

number.

11 Nozzle seal (1)

12 Liner seal (2)

13 Retaining ring

14 Cpa bolt

15 Lock washer

16 Dome spring

17 Inlet flange

18 Wedge ring (3)

19 Bushing/Siphon tube

20 Bushing seal

Series 5000 POSRV type 5046/5146/5066/5166

Installation and Maintenance Instructions

Emerson reserves the right to change the contents without notice page 4

Figure 2

Body

Nozzle seal

Nozzle

Nozzle retainer

Piston

Liner

Spacer

Cap

Cap bolt

Series 5000 POSRV type 5046/5146/5066/5166

Installation and Maintenance Instructions

Emerson reserves the right to change the contents without notice page 5

3.0 Pilot maintenance (see figures 3 & 4)

3.1 Disassembly

3.1.1 To facilitate assembly, place all parts removed in an orderly arrangement so that the

correct parts can be assembled in the proper sequence. Refer to Figures 3 & 4 for part

description.

3.1.2 (For lifting lever only) Remove cotter pin (42), lever pin (41) and remove lifting lever (40).

Remove the cap set screw (45) and cap (27). Remove cotter pin (44) from the spindle nut

(43) and remove the spindle nut.

3.1.3 Remove lock nut (26) and completely loosen the adjusting nut (25). Remove the bonnet

ring screw (21) and remove the bonnet ring (21) and bonnet. Remove bonnet ring by

using a 3/8-16 UNC-2A bolt and use as a handle or a spanner wrench. (Note: be careful

not to drop the spring (22) spring washers (23) and lifting rod (38) when removing the

bonnet).

3.1.4 (For lifting lever only) Slide the spindle bushing (39) and lifting rod (38) through the spring

washers (24) and spring (22).

3.1.5 Remove four piston plate screws (30) and remove the piston plate (11) with attached

sense piston (12), piston seal (17), piston connector (2), inlet seat (3), inlet nozzle (14),

exhaust seat retainer (4), exhaust seat (29), exhaust seat stem (5). Remove and discard

body/piston plate seal (32).

3.1.6 Remove bushing (13) using a 1/2” hex drive.

3.1.7 Place pilot on its side and remove the 1/4” pipe plug (34) from the bottom of the valve.

With a 3/8” flat end rod and hammer, gently tap through the bottom hole and push the

spool/body o-ring seal (31), dome spool (15), body/spool o-ring seal (31), exhaust nozzle

(6), exhaust washer (7), stem seal (28), body/spool o-ring seal (31) and stop washer (8)

out of body. Discard spool/body o-rings (31) and stem seal (28).

Note: If dome spool (15) and exhaust nozzle (6) are difficult to separate, place exhaust

nozzle into a soft jawed vice. Using a flat end brass bar hold it next to the dome spool

and gently tap using a hammer. Be careful not to scratch or damage the parts.

3.1.8 Unscrew the sense piston (12) from the piston connector (2) by placing an open end

wrench onto the flats on both parts (use soft jawed vice to hold sense piston if available).

Use an acetone base solution to remove the Loctite 242 solution from the threads. Slide

the piston connector through the piston plate (11). Holding the flats on the inlet nozzle (14)

and piston connector (2), unthread piston connector from inlet nozzle and remove inner

spring (10) and outer spring (9).

WARNING!

Carefully remove piston seal (17) from piston (12) to prevent scratching the sealing surface (I.D.) of

piston (12). Discard piston seal (17).

3.1.9 Insert a 1/8” hex drive into top of inlet seat (3) and with another 1/8” hex drive, insert

into the bottom of the exhaust seat stem (5) and unthread. Separate the exhaust seat

retainer (4) from the inlet seat (3). Remove exhaust seat (29) from exhaust seat retainer

(4) and discard exhaust seat (29). Use an acetone base solution to remove the Loctite 242

solution from the threads.

Series 5000 POSRV type 5046/5146/5066/5166

Installation and Maintenance Instructions

Emerson reserves the right to change the contents without notice page 6

3.2 Pilot assembly (Refer to Figure 3)

During assembly it shall be observed that all moving parts are free to move throughout their full

travel without any binding.

3.2.1 Inlet seat lapping

Place inlet seat (3) through inlet nozzle (14). Apply small amount of Hyprez 3L diamond

lapping compound or equal to the inlet seats conical surface. Hold the inlet nozzle in one

hand and lightly lap the inlet seat with the inlet nozzle by spinning the inlet seat onto the

inlet nozzles seating surface.

3.2.2 Clean the inlet seat (3) and nozzle (14) by removing the lapping compound using Varsol

followed by Acetone. Afterwards, wipe with a clean lint-free cloth or towel. When dry,

the seating surface should be examined to verify if an acceptable sealing surface has

been achieved. A proper surface is one which exhibits a dark gray appearance with no

visible scratched across the entire lapping surface.

3.2.3 Inlet seat and exhaust seat sub assembly

Carefully examine the exhaust seat (29) to verify if one side is concave and the other side

is flat.

Place the inlet seat (3) through the inlet nozzle (14). Slide the exhaust seat retainer (4)

onto the inlet seat. Slide the exhaust seat (29) with the flat face down onto the exhaust

seat stem (5). Place a small amount of Loctite 242 on the threads of the inlet seat. Thread

the exhaust seat stem onto the inlet seat squeezing the exhaust seat into the exhaust

seat retainer. Using a 1/8” hex drive that is on top of the inlet seat and the exhaust stem,

tighten the inlet seat onto the exhaust stem. (Be careful not to over tighten, may cause

damage to the parts.)

3.2.4 Place the u-cup seal (28) with the opening of the cup facing outward into the exhaust

washer (7). Place stop washer (8) into body cavity with the raised face up. Place body/

spool o-ring seal (31) into body cavity on top of the stop washer. Place exhaust washer

into body cavity with the u-cup seals facing down into the cavity. Place exhaust spool (6)

into body cavity with the larger open end facing downward next to the exhaust washer.

Place another body/spool o-ring seal (31) into cavity.

3.2.5 Place back-up ring (16) into dome spool. Next place dome seal (18) on top of back up ring

with the opening of the dome seal facing up. Place dome spool into body cavity with

dome seal facing up. Place final body/spool o-ring seal (31) into body cavity. Apply a light

coating of Fluorolube LG-160 oil or equivalent on threads of bushing. Thread bushing (13)

into body and tighten until spool set is compressed fully metal to metal.

3.2.6 Place inner spool spring (10) onto the inlet seat (3). Place outer spool spring (9) over

the inner spool spring onto the inlet seat (3). Place a small amount of Loctite 242 on

the threads of the inlet nozzle (14). Thread on the piston connector (2) and tighten

compressing the springs.

3.2.7 Carefully install piston seal (17) into the groove of the piston (12) with the opening of

the seals facing outward. Carefully insert the piston (12) into the piston plate (11). Place

a small amount of Loctite 242 on the threads the piston connector. Thread the piston

connector onto the piston and tighten using the wrench flats on both parts.

3.2.8 Pilots without lift lever only. (Refer to Figure 3)

Place body/piston plate seal (32) between these parts and very carefully, guide the

exhaust seat stem (5) of the upper assembly through the bushing (13), dome spool seal

(18) and exhaust washer seal (28). (Be careful not to scratch or dent the exhaust nozzle

(6) seating surface). Also, be careful not to damage the dome seal (18). This assembly

will stop when the exhaust seat comes in contact with the exhaust nozzle. Using the

capscrews (30), tighten the piston plate onto the body (1). Place roll pin (33) into pin

locator hole located near the edge of the piston plate.

3.2.9 Pilots without lift lever only. (Refer to Figure 3)

3.2.9.1 Place spring (22) between the spring washers (23,24). Place a small amount of

Fluorolube LG-160 or equivalent on top of spring washer and place on top of

piston. Lower the bonnet (19) over the spring and spring washer stack until the

flange rests on the piston adapter with the pin engage in it’s respective hole in

the bonnet outer rim. Apply a light coating of Fluorolube LG-160 oil or equivalent

on the outer threads of the body.

Series 5000 POSRV type 5046/5146/5066/5166

Installation and Maintenance Instructions

Emerson reserves the right to change the contents without notice page 7

3.2.9.2 Slide the bonnet ring (20) over the bonnet and thread onto the body capturing

the bonnet. Thread appropriate bolts, .375-16UNC-2A x approximately 2.50

inches long, into the threaded hole in the bonnet ring (do not bottom). Use the

bolt as a handle to tighten the ring into place.

3.2.9.3 Place a small drop of Loctite 242 or equal on the threads of the set screw (21),

thread into the side of the bonnet ring, and tighten.

3.2.9.4 Apply a light coating of Fluorolube LG-160 oil or equivalent on the internal

threads of the bonnet and the threads of the adjustment bolt (25). Screw the

adjustment bolt into the bonnet until it contacts the top spring washer. Thread

the adjustment bolt nut (26) down the adjustment bolt until the nut contacts the

bonnet and then secure hand tight. (See section 4 for pilot set pressure)

3.2.9.5 After pilot set pressure has been established, place cap (27) onto adjustment bolt

and tighten against nut (26). Install lock wire from the cap (27) to the bonnet ring

screw (21).

3.2.10 Pilots without lift lever only. (Refer to Figure 3)

3.2.10.1 Thread the lift rod bushing (39) onto the lift rod (38). Place a light coat of

Fluorolube LG-160 oil or equivalent to the contact surface of the bushing (28)

and top spring washer (23). Slide the lifting rod (38) with bushing through the

bottom spring washer (24).

3.2.10.2 Place the bottom washer, bushing and lifting rod assembly on top of sense

piston followed by stacking the spring (22) and the top of spring washer. Lower

the bonnet (19) over the spring and spring washer stack until the flange rests on

the piston plate with the pin engaged in it’s respective hole in the bonnet outer

rim. Apply a light coating of Fluorolube LG-160 oil or equivalent on the outer

threads of the body.

3.2.10.3 Slide the bonnet ring (20) over the bonnet and thread onto the body capturing

the bonnet. Thread appropriate bolt, .375-16UNC-2A x approximately 2.50

inches long, into the threaded hole in the bonnet ring (do not bottom). Use the

bolt as a handle to tighten the ring into place or a spanner wrench and tighten

using the unthreaded hole.

3.2.10.4 Place a small drop of Loctite 242 or equal on the threads of the set screw (21),

thread into the side of the bonnet ring, and tighten.

3.2.10.5 Apply a light coating of Fluorolube LG-160 oil or equivalent on the internal

threads of the bonnet and the threads of the adjustment bolt (25). Screw the

adjustment bolt into the bonnet until it contacts the top spring washer. Thread

the adjustment bolt nut (26) down the adjustment bolt until the nut contacts

the bonnet and then secure hand tight. (See section 4 for pilot set pressure)

3.2.10.6 After pilot set pressure has been established, screw the spindle nut (43) on

to the lifting rod (38). Place cap (27) on bonnet (19). Guide lifting lever (40)

through cap (27) under the spindle nut (43) and attach to cap (27) using the

lever pin (41). Adjust the spindle nut (43) until there is a 1/16 inch minimum

of play between the lifting lever (40) and the spindle nut (43). The spindle nut

(43) may be adjusted by removing the lifting lever pin (41) and lifting lever

(40).

3.2.10.7 Once the spindle nut has been set, remove cap (27) and place cotter pin (44)

into spindle nut. Replace cap (27) on bonnet (19) and position the lifting lever

(40) opposite of the valve outlet and install the cap set screws (45). Install

lockwire from lever pin screw (41) to cap screw (45) to bonnet ring screw (21).

3.3 Place pilot assembly on its side and install 1/4” pipe plug with Teflon tape into port on the

bottom of the pilot body.

3.4 During assembly it shall be observed that all moving parts are free to move throughout their

full travel without any binding.

Emerson reserves the right to change the contents without notice page 8

Series 5000 POSRV type 5046/5146/5066/5166

Installation and Maintenance Instructions

Item Description Material

1 Body - square SST 316

2 Connector - piston SST 316

3 Seat - inlet SST 316

4 Retainer - exhaust seat SST 316

5 Stem - exhaust seat SST 316

6 Nozzle - exhaust SST 316

7 Washer - exhaust SST 316

8 Washer - stop SST 316

9 Spring - outer-spool Inconel X750

10 Spring - inner-spool Inconel X750

11 Plate - piston SST 316

12 Piston SST 316

13 Bushing SST 316

14 Nozzle - inlet SST 316

15 Spool - dome SST 316

16 Bkup ring - dome seal PEEK

17 Seal - piston TFE/ELGILOY

18 Seal - dome TFE/ELGILOY

19 Bonnet - spring SST 316

See detail A

Figure 3

Detail A

20 Ring - HP bonnet SST 316

21 Screw - bonnet ring SST 18-8

22 Spring SST 316

23 Washer - spring SST 316

24 Washer - spring SST 316

25 Srew - pressure set SST 316

26 Locknut - adjusting screw SST SA316

27 Cap SST SA479-316

28 Seal - stem TFE/ELGILOY

29 Seat - exhaust Graphite/TFE

30 Screw - piston plate STL A193-B7

31 Seal - spool/body Teflon TFE

32 Seal - body/piston plate Teflon TFE

33 Pin - roll SST 420

34 Plug - pipe 1/4 NPT SST 316

35 Nameplate - pilot SST 18-8

36 Nameplate - patents SST 18-8

37 Pin - drive

Series 5000 POSRV type 5046/5146/5066/5166

Installation and Maintenance Instructions

Emerson reserves the right to change the contents without notice page 9

Item Description

2 Connector - piston

3 Seat - inlet

4 Retainer - exhaust seat

5 Stem - exhaust seat

6 Nozzle - exhaust

7 Washer - exhaust

8 Washer - stop

9 Spring - outer-spool

10 Spring - inner-spool

12 Piston - HP

13 Bushing - HP

14 Nozzle inlet - HP

15 Dome spool - HP

16 Bkup ring - dome seal HP

17 Seal - piston

18 Seal - dome

28 Seal - stem

29 Seat - exhaust

31 Seal - spool/body

32 Seal - body/piston plate

Item Description

1 Body - square

11 Piston plate HP

19 Bonnet - spring

20 Ring - HP bonnet

21 Screw - bonnet ring

22 Spring

23 Washer - spring

24 Washer - spring

25 Screw - pressure set

26 Lock nut - adjusting screw

27 Cap - LL

30 Screw - piston plate

33 Pin - roll

34 Plug - pipe 1/4 NPT

35 Nameplate - pilot

36 Nameplate - patents

37 Pin- drive

38 Lifting rod

39 Bushing spindle LL

40 Lever - LL

41 Lever pin - LL

42 Pin - cotter

43 Nut - spindle

44 Pin - cotter

45 Screw - LL cap

Figure 3A - Detail A

Figure 4

See detail A

Series 5000 POSRV type 5046/5146/5066/5166

Installation and Maintenance Instructions

Emerson reserves the right to change the contents without notice page 10

4.0 Pilot set pressure adjustment

4.1 Definitions

Set pressure is defined as the supply pressure on increasing pressure at which the dome pressure

is 70% of the supply pressure. This corresponds to the first steady stream of liquid from the main

valve.

Crack pressure is defined as the supply pressure on increasing pressure at which dome pressure

reduction first occurs.

Reseat pressure is defined as the supply pressure on decreasing pressure at which the dome

pressure increases to 75% of supply pressure. The pilot dome pressure may continue to increase

after reseat.

4.2 Set pressure, standard pilot

4.2.1 Initial adjustment on air

To adjust the set pressure, a test set-up similar to that shown in Figure 5 should be used.

The test media should be air. The adjustment screw should be turned IN most of the way.

Increase the supply pressure to nameplate setting and slowly back out the adjustment

screw until flow through the pilot exhaust begins. Continue to slowly back out the

adjustment screw until dome pressure is 70% of the supply pressure and the supply

pressure meets the required set pressure tolerance of paragraph 4.4. After adjustment is

completed, securely tighten the jam nut.

To determine reseat pressure, shut off the air supply and use the accumulator vent valve

to slowly reduce the supply pressure until the dome pressure is 75% of supply pressure.

Close the shut-off valve and slowly open the bleed valve. When the dome pressure gauge

reading is zero, the pilot may be removed from the test set-up.

4.2.2 Liquid service pilot

Note: An initial set pressure adjustment may be made with air as the supply pressure media using

a test set-up similar to that shown in Figure 5 and following the procedure described in paragraph

4.2.1 above. This initial set pressure may be lower than the set pressure observed when the pilot is

tested on liquid.

To adjust the set pressure, a test set-up similar to that shown in Figure 6 should be used. The

test media should be water. Some air volume must be maintained above the water surface in the

accumulator. The adjustment screw should be turned IN most of the way except when an initial

adjustment was made on air.

Increase the air supply pressure to nameplate setting and slowly back out the adjustment screw

until water flow through the pilot exhaust begins. Continue to slowly back out the adjustment

screw until dome pressure is 70% of the supply pressure and the supply pressure meets the

required set pressure tolerance of paragraph 4.4.

To determine reseat pressure, shut off the air supply and use the accumulator vent valve to slowly

reduce supply pressure until the dome pressure is 75% of supply pressure.

Close the shut-off valve in the water line to the pilot inlet port and slowly open the bleed valve.

When the dome pressure gauge reading is zero, the pilot may be removed from the test set-up.

The optional indicator assembly shown in Figure 5 may be used for set pressure above 70 psig. If

an indicator assembly is used, slowly increase the supply pressure until the indicator pin pulls into

the indicator assembly and is approximately flush with the end of the indicator body. The pressure

when the pin pulls in is the set pressure. Loosen the jam nut, adjust the adjustment screw, and

retighten the jam nut as required to meet the set pressure tolerance of paragraph 4.4.

Shut off the air supply and use the accumulator vent valve to slowly bleed down supply

pressure until the indicator pin “pops” out of the indicator assembly (full extension of the pin is

approximately 7/16”). The pressure when the pin “pops” out is the reseat pressure.

Close the shut-off valve in the water line to the pilot inlet port and slowly open the bleed valve.

When the dome pressure gauge reading is zero, the pilot may be removed from the test set-up.

4.3 Range of adjustment

All pilots can be adjusted +/- 5% beyond the nameplate setting. If a set pressure change is made

that requires a new spring, consult Factory for information contained in spring chart.

4.4 Performance requirements

All pilots can be adjusted +/- 5% beyond the nameplate setting. If a set pressure change is made

that requires a new spring, consult Factory for information contained in spring chart.

Set pressure (psig) Tolerance Crack pressure Reseat pressure

as % of set as % of set

15 to 70 +/- 2 psig Min 96 0 to 3 psig below set

Above 70 to 6170 inclusive +/- 3% Min 96 96 to 100

Series 5000 POSRV type 5046/5146/5066/5166

Installation and Maintenance Instructions

Emerson reserves the right to change the contents without notice page 11

Dome pressure gauge

Dome pressure gauge

Set pressure adjustment

(turn in to increase set pressure)

(turn out to decrease set pressure)

Set pressure adjustment

(turn in to increase set pressure)

(turn out to decrease set pressure)

Accumulator

(approx.

1

/4 cu ft)

Accumulator

(approx.

1

/4 cu ft)

Vent valve

Vent

valve

Flexible hose

(to inlet port)

Flexible hose

(to inlet port)

Optional indicator

assembly installation

Shut-off valve

Shut-off valve

Shut-off valve

Shut-off valve (optional)

Shut-off valve

(optional isolation valve)

Indicator assembly (optional)

Air supply

Air supply

Supply pressure gauge

Bleed valve

Bleed valve

Indicator

Solid bar with threaded ends

Supply pressure gauge

Block valve

Block valve

Block valve

Pilot exhaust port

Pilot exhaust

port

Mounting stub

Figure 5 - Pilot adjustment air test set-up

Figure 6 - Pilot adjustment liquid test set-up

Series 5000 POSRV type 5046/5146/5066/5166

Installation and Maintenance Instructions

Emerson reserves the right to change the contents without notice page 12

Ported blind flange

Inlet pressure

Supply

1

/4” O.D. X .028 wall tube

Figure 7

5.0 Valve assembly testing

5.1 General

The complete valve assembly should be tested for internal and external leakage and to verify main

valve function using a test set-up similar to that shown in Figure 7. The test media should be air.

Note: Actuate valve a minimum of two (2) times before testing for pilot seat leakage.

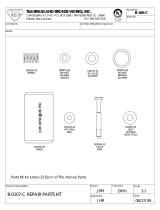

6.0 Soft goods repair kit

See manufacturer.

CAUTION

Do not test liquid service valves using water or other liquid test media. Liquid service valves

should be tested using air as the test media in accordance with the procedures described below.

Testing fully assembled liquid service valves using air insures that no water or other liquid will

remain in the main valve dome after final valve testing.

5.2 High pressure leakage check

Apply pressure to the inlet equal to 90% of the set pressure. Check for leakage at the main valve

outlet. Using a suitable gas or air leak detector solution, check for leakage at the cap seal and other

pressure connections. No leakage shall occur at the valve outlet and no visible leakage shall be

detected at the cap seal or other pressure connections in one minute.

/