Alto-Shaam CS-200 Installation Operation & Maintenance

- Category

- Food warmers

- Type

- Installation Operation & Maintenance

This manual is also suitable for

W164N9221WaterStreet•P.O.Box450

MenomoneeFalls,Wisconsin53052-0450U.S.A.

PHONE:262.251.3800•800.558.8744U.S.A./CANADA

FAX:

262.251.7067•800.329.8744U.S.A.ONLY

www.alto-shaam.com

Consultinstructions

foroperationanduse.

M N - 2 9 2 5 0 ( R e v . 3 ) • 11 / 1 5

p r i n t e d i n u . s . a .

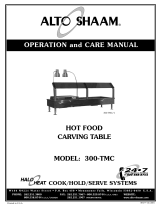

Carving Station

Models:

CS-100

CS-200

CS-100 with Breath Guard

CS-200 with Breath Guard

• INSTALLATION

• OPERATION

• MAINTENANCE

i

Delivery ..................................1

Unpacking ................................1

Safety Procedures and Precautions ............2

Installation

Installation Requirements .................. 4

Leveling ...............................4

Dimension Drawings, CS-100 ...............5

Dimension Drawings, CS-200 ...............6

Stacking ...............................7

Electrical Connection .....................8

Operation

User Safety .............................9

Start-Up ...............................9

Operating Procedures ....................9

General Holding Guidelines ............... 10

Care and Cleaning

Protecting Stainless Steel Surfaces ......... 11

Cleaning Agents ........................ 11

Cleaning Materials ......................11

Equipment Care ........................12

Clean Daily ............................ 12

Food Safety ........................... 13

Service

Service View, CS-100 .................... 14

Service View Parts List, CS-100 ............ 15

Service View, CS-200 .................... 16

Service View Parts List, CS-200 ............ 17

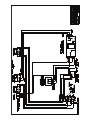

Wiring Diagrams

Always refer to the wire diagram(s) included with

the unit for most current version.

Warranty

Transportation Damage and Claims ..Back Cover

Limited Warranty ................Back Cover

MN-29250 (Rev. 3) 11/15 • CARVING STATIONS • 1

DELIVERY

ThisAlto-Shaamappliancehasbeenthoroughly

testedandinspectedtoensureonlythehighest

qualityunitisprovided.Uponreceipt,checkforany

possibleshippingdamageandreportitatoncetothe

deliveringcarrier.See Transportation Damage and

Claims section located in this manual.

Thisappliance,completewithunattacheditems

andaccessories,maybedeliveredinoneormore

packages.Ensureallstandarditemsandoptions

havebeenreceivedwitheachmodelasordered.

Savealltheinformationpackedwiththeappliance.

Registeronlineatwww.alto-shaam.comtoensure

promptserviceintheeventofawarrantypartsand

laborclaim.

Thismanualmustbereadandunderstoodbyall

peopleusingorinstallingtheequipmentmodel.

ContacttheAlto-ShaamTechTeamService

Departmentifyouhaveanyquestionsconcerning

installation,operation,ormaintenance.

1-800-558-8744;[email protected]

UNPACKING

• Carefullyremovetheappliance

fromthecartonorcrate.

NOTICE: Donotdiscardthe

cartonandother

packagingmaterial

untilyouhave

inspectedtheunit

forhiddendamage

andtesteditfor

properoperation.

• Readallinstructionsinthismanualcarefully

beforeinstallingthisappliance,usingtheappliance

orperformingroutinemaintenance.Following

proceduresotherthanthoseindicatedinthis

guidetouseandcleantheapplianceisconsidered

inappropriateandmaycausedamage,injuryor

fatalaccidents,inadditiontoinvalidatingthe

guaranteeandrelievingAlto-Shaamofallliability.

• DONOTDISCARDTHISMANUAL.

Thismanualisconsideredpartoftheappliance

andisprovidedfortheownerormanagerofthe

businessandfortrainingpersonnel.Additional

manuals are available from the Alto-Shaam

Tech Team Service Department.

• Removeallprotectiveplasticfilm,packaging

materials,andaccessoriesfromtheappliance

beforeconnectingelectricalpower.Storeany

accessoriesinaconvenientplaceforfutureuse.

®

®

WARNING

Appliance and accessories may be

heavy. To prevent serious injury,

ALWAYS use a sufficient number

of trained and experienced workers

when moving or leveling appliance

and handling accessories.

ENVIRONMENTAL CONDITIONS

•OperationalEnvironmentalConditions

•Unitmustacclimatetoroomtemperatureinthe

environmentitisplaced.24hoursisrecommended.

•Ambienttemperaturerangeof50°to110°F(10°to43°C).

•Relativehumidityoflessthan95%non-condensation.

•Atmosphericpressurerangeof50KPato106KPa.

Always include both model and serial numbers in your correspondence

regarding the unit.

Model: _____________________________________

Serial Number: _____________________________________

Purchased From: _____________________________________

Date Installed: ____________ Voltage: _______________

SERIAL NUMBER IS REQUIRED FOR ALL INQUIRIES

MN-29250 (Rev. 3) 11/15 • CARVING STATIONS • 2

CAUTION

Used to indicate the presence of a hazard that

can or will cause minor personal injury, property

damage, or a potential unsafe practice if the

warning included with this symbol is ignored.

CAUTION

Used to indicate the presence of a

hazard that can or will cause minor or

moderate personal injury or property

damage if the warning included with

this symbol is ignored.

DANGER

Used to indicate the presence of

a hazard that WILL cause severe

personal injury, death, or substantial

property damage if the warning

included with this symbol is ignored.

WARNING

Used to indicate the presence of

a hazard that CAN cause personal

injury, possible death, or major

property damage if the warning

included with this symbol is ignored.

•

Thisapplianceisintendedtocook,holdorprocess

foodsforthepurposeofhumanconsumption.No

otheruseforthisapplianceisauthorizedandis

thereforeconsidereddangerous.Theappliance

mustnotbeusedtocookfoodcontainingflammable

materials(suchasfoodwithalcohol).Substances

withalowflashpointcanignitespontaneouslyand

causeafire.

•

Thisapplianceisintendedforuseincommercial

establishmentswherealloperatorsarefamiliarwith

thepurpose,limitations,andassociatedhazardsof

thisappliance.Operatinginstructionsandwarnings

mustbereadandunderstoodbyalloperatorsand

users.Werecommendregulartrainingofyour

stafftoavoidtheriskofaccidentordamagetothe

unit.Operatorsmustalsoreceiveregularsafety

instructions.

•

Anytroubleshootingguides,componentviews,and

partslistsincludedinthismanualareforgeneral

referenceonlyandareintendedforusebyqualified

andtrainedtechnicians.

•

Thismanualshouldbeconsideredapermanent

partofthisappliance.Thismanualandallsupplied

instructions,diagrams,schematics,partslists,

notices,andlabelsmustremainwiththeappliance

iftheitemissoldormovedtoanotherlocation.

NOTICE: Used to notify personnel of

installation, operation, or

maintenance information that is

important but not hazard related.

SAFETY PROCEDURES

AND PRECAUTIONS

Knowledgeofproperproceduresisessentialtothe

safeoperationofelectricallyand/orgasenergized

equipment.Thefollowinghazardsignalwordsand

symbolsmaybeusedthroughoutthismanual.

Used to indicate that referral to

operating instructions is a mandatory

action. If not followed the operator

could suffer personal injury.

Used to indicate that referral to

operating instructions is recommended

to understand operation of equipment.

NOTICE: For equipment delivered for use in

any location regulated by the

following directive:

DO NOT dispose of electrical or

electronic equipment with other

municipal waste.

MN-29250 (Rev. 3) 11/15 • CARVING STATIONS • 3

• Topreventseriousinjury,deathorproperty

damage,yourapplianceshouldbeinspectedand

servicedatleasteverytwelve(12)monthsbyan

authorizedservicepartnerortrainedtechnician.

• ONLYallowanauthorizedservicepartneror

trainedtechniciantoserviceortorepairyour

appliance.Installationorrepairsthatarenot

performedbyanauthorizedservicepartneror

trainedtechnician,ortheuseofnon-factory

authorizedpartswillvoidthewarrantyandrelieve

Alto-Shaamofallliability.

• Whenworkingonthisappliance,observe

precautionsintheliterature,ontags,onlabels

attachedtoorshippedwiththeapplianceandother

safetyprecautionsthatmayapply.

• Iftheapplianceisinstalledoncastersfreedomof

movementoftheappliancemustberestrictedso

thatutilityconnections(includinggas,water,and

electricity)cannotbedamagedwhentheunitis

moved.Iftheapplianceismoved,makesurethatall

utilityconnectionsareproperlydisconnected.Ifthe

unitisreturnedtoitsoriginalposition,makesure

thatanyretentiondevicesandutilityconnections

areproperlyconnected.

• ONLYusetheappliancewhenitisstationary.

Mobileovenracks,mobileplateracks,transport

trolleys,andappliancesoncasterscantipover

whenbeingmovedoveranunevenflooror

thresholdandcauseseriousinjury.

• ALWAYSapplycasterbrakesonmobileappliances

oraccessorieswhenthesearenotbeingmoved.

Theseitemscouldmoveorrollonunevenfloors

andcausepropertydamageorseiousinjury.

• Beextremelycarefulwhenmovingappliances

becausethefoodtraysmaycontainhotfluidsthat

mayspill,causingseriousinjury.

• ALWAYSopentheappliancedoorveryslowly.

Escapinghotvaporsorsteamcancauseserious

injuryordeath.

ADDITIONAL SAFETY PROCEDURES

AND PRECAUTIONS

•

Ifyourgasapplianceisinstalledunderan

exhausthood,thehoodmustbeswitchedON

whentheovenisinusetoavoidthebuildupof

combustiongases.Failuretodosomayresultin

seriousinjury,deathorpropertydamage.

•

NEVERplaceobjectsneartheovenexhaustvents.

Thisareaishotandcouldbeapotentialignition

sourceforafire.

• Donotallowobjectstoblockorobstructthearea

belowtheovenbase.Thismayresultinfire,

damagetotheequipmentorseriousinjury.

• Donotusetheattachedhand-heldhosetospray

anythingotherthantheinterioroftheoven

compartment.

• Donotusetheattachedhand-heldhoseonthe

surfaceofahotcookingcompartment.The

suddentemperaturechangecandamagetheoven

interior.Allowtheoventocooltoaminimumof

150°F(66°C).Failuretoobservethisprecaution

canvoidthewarranty.

• Topreventseriousinjury,deathorproperty

damage,yourapplianceshouldbeinspectedand

servicedatleasteverytwelve(12)monthsbyan

authorizedservicepartnerortrainedtechnician.

• ONLYallowanauthorizedservicepartneror

trainedtechniciantoserviceortorepairyour

appliance.Installationorrepairsthatarenot

performedbyanauthorizedservicepartneror

trainedtechnician,ortheuseofnon-factory

authorizedpartswillvoidthewarrantyandrelieve

Alto-Shaamofallliability.

• Whenworkingonthisappliance,observe

precautionsintheliterature,ontags,onlabels

attachedtoorshippedwiththeapplianceandother

safetyprecautionsthatmayapply.

• Iftheapplianceisinstalledoncastersfreedomof

movementoftheappliancemustberestrictedso

thatutilityconnections(includinggas,water,and

electricity)cannotbedamagedwhentheunitis

moved.Iftheapplianceismoved,makesurethatall

utilityconnectionsareproperlydisconnected.Ifthe

unitisreturnedtoitsoriginalposition,makesure

thatanyretentiondevicesandutilityconnections

areproperlyconnected.

• ONLYusetheappliancewhenitisstationary.

Mobileovenracks,mobileplateracks,transport

trolleys,andappliancesoncasterscantipover

whenbeingmovedoveranunevenflooror

thresholdandcauseseriousinjury.

• ALWAYSapplycasterbrakesonmobileappliances

oraccessorieswhenthesearenotbeingmoved.

Theseitemscouldmoveorrollonunevenfloors

andcausepropertydamageorseiousinjury.

• Beextremelycarefulwhenmovingappliances

becausethefoodtraysmaycontainhotfluidsthat

mayspill,causingseriousinjury.

• ALWAYSopentheappliancedoorveryslowly.

Escapinghotvaporsorsteamcancauseserious

injuryordeath.

ADDITIONAL SAFETY PROCEDURES

AND PRECAUTIONS

•

Ifyourgasapplianceisinstalledunderan

exhausthood,thehoodmustbeswitchedON

whentheovenisinusetoavoidthebuildupof

combustiongases.Failuretodosomayresultin

seriousinjury,deathorpropertydamage.

• NEVERplaceobjectsneartheovenexhaustvents.

Thisareaishotandcouldbeapotentialignition

sourceforafire.

• Donotallowobjectstoblockorobstructthearea

belowtheovenbase.Thismayresultinfire,

damagetotheequipmentorseriousinjury.

• Donotusetheattachedhand-heldhosetospray

anythingotherthantheinterioroftheoven

compartment.

• Donotusetheattachedhand-heldhoseonthe

surfaceofahotcookingcompartment.The

suddentemperaturechangecandamagetheoven

interior.Allowtheoventocooltoaminimumof

150°F(66°C).Failuretoobservethisprecaution

canvoidthewarranty.

WARNING

This appliance is not intended for use

by persons (including children) with

reduced physical, sensory or mental

capabilities, or lack of experience and

knowledge, unless they have been

given supervision concerning use of

the appliance by person responsible for

their safety.

Children should be supervised to ensure

that they do not play with the appliance.

MN-29250 (Rev. 3) 11/15 • CARVING STATIONS • 4

SITE INSTALLATION

INSTALLATION

SITE INSTALLATION

1.Theappliance,completewithunattacheditems

andaccessories,maybedeliveredinoneormore

packages.Checktoensureallaccessoriesordered

havebeenreceived.

2.Thehotcarvingstationisdesignedtobemounted

directlyontopofaHaloHeatCook&Holdoven

orholdingcabinet.Theshelfcanalsobeusedasa

free-standingunit.

HEATED CABINET MOUNTED SHELVES:

Removethe1"(25mm)legspriortoplacingthe

carvingshelfontopoftheHaloHeatcook/

holdovenorholdingcabinet.Appliancemustbe

installedonastableandlevelsurface.

FREE-STANDING SHELVES:

Ensurethatthe1"(25mm)legsareinplacepriorto

placingthecarvingshelfonworksurface.Failure

tooperatewithoutthe1"(25mm)legspriorto

heatingtheshelfcouldresultindamagetothe

surfaceonwhichtheshelfisplaced,mayposea

potentialfirehazard,andnullifiesthevalidityof

theULlistingmark.Appliancemustbeinstalledon

astableandlevelsurface.

3. DO NOTinstallthisapplianceinanyareawhereit

maybeaffectedbyanyadverseconditionssuchas

steam,grease,drippingwater,hightemperatures,

oranyotherseverelyadverseconditions.

4. DO NOTinstallnearacoldairsourcesuchasa

freezer,airconditioningvents,orinanyareawhere

outsideairfluctuationcanaffectperformance.

5.Thisappliancemustbekeptfreeandclearofany

obstructionsblockingaccessformaintenanceor

service.

6.LiftBreathGuardupandslideintoplacein

bracketsfoundinthefrontoftheappliance.

Anumberofadjustmentsareassociatedwithinitial

installationandstart-up.Installationandstart-up

adjustmentsaretheresponsibilityofthedealeror

user.Theseadjustmentsincludebutarenotlimitedto

leveling,electricalhook-upandinstallationofbulbs.

LEVELING

Leveltheappliance

fromside-to-sideand

front-to-backwith

theuseofaspiritlevel.

NOTICE: Failuretoproperlylevelthisappliancecan

causeimproperfunction.

WARNING

Improper installation, alteration,

adjustment, service, cleaning, or

maintenance could result in property

damage, severe injury, or death.

READ and UNDERSTAND the

installation, operating and

maintenance instructions thoroughly

before installing, servicing, or

operating this equipment.

CAUTION

To prevent SEVERE PERSONAL

INJURY or PROPERTY DAMAGE:

ALWAYS use hand protection when

operating this appliance to avoid

burns. Metal parts of this equipment

become extremely hot when in

operation.

WARNING

Appliance and accessories may be

heavy. To prevent serious injury,

ALWAYS use a sufficient number

of trained and experienced workers

when moving or leveling appliance

and handling accessories.

CAUTION

The performance of this unit has been

optimized using the factory provided

bulbs. These bulbs should be replaced

with an exact replacement or with a

factory recommended replacement.

These bulbs have been treated to

resist breakage and must be replaced

with similarly treated bulbs in order

to maintain compliance with NSF

standards. DO NOT over-tighten bulbs

in their receptacles as this may cause

damage to the bulb fi lament.

MN-29250 (Rev. 3) 11/15 • CARVING STATIONS • 5

SITE INSTALLATION

INSTALLATION

HEATED PRODUCT CAPACITY

Weight (lbs) max. 40

Weight (kg) max. 18

Meat Size

small steamship round

CS-100

OPTIONS AND ACCESSORIES

Carving Board BA-28482

Carving Holder - Prime Rib HL-2635

Carving Holder - Steamship 4459

24-3/4" (629mm)

SWITCH TO BACK

7/8" (22mm)

CORD TO EDGE

7/16" (12mm)

SWITCH

31-1/4" (792mm)

17-1/2" (444mm)

25-1/2" (646mm)

25-15/16" (658mm)

16-3/4" (424mm)

HEAT SURFACE

14-13/16" (376mm)

HEAT SURFACE

18-3/16" (463mm)

WITHOUT BREATH GUARD

18-3/8" (466mm)

WITH BREATH GUARD

9-1/16" (230mm)

CORD

1-9/16"

(39mm)

FEET

MN-29250 (Rev. 3) 11/15 • CARVING STATIONS • 6

SITE INSTALLATION

INSTALLATION

21-3/4" (551mm)

HEAT AREA

21-5/8" (549mm)

CUTTING BOARD SURFACE

26" (660mm)

WITH BREATH GUARD

22-3/8" (568mm)

HEAT AREA

21-5/8" (549mm)

CUTTING BOARD SURFACE

1/2" (13mm)

SWITCH

12-7/8" (326mm)

1-9/16"

(39mm)

FEET

31-9/16" (801mm)

29-5/16" (744mm)

7/8" (22mm)

CORD POSITION

1-1/16" (27mm)

SNEEZE GUARD BRACKET

OPTIONS AND ACCESSORIES

Full-Size Carving Board BA-28066

Half-Size Carving Board BA-29244

Carving Holder - Prime Rib HL-2635

Carving Holder - Steamship 4459

HEATED PRODUCT CAPACITY

Weight (lbs) max. 70

Weight (kg) max. 31.7

Meat Size

large steamship round

CS-200

MN-29250 (Rev. 3) 11/15 • CARVING STATIONS • 7

STACKING

INSTALLATION

18-3/8" (466mm)

35-7/16" (900mm)

63-1/16" (1601mm)

35-1/2" (901mm)

65" (1650mm)

25-7/8" (657mm)

CS-100 OVER 500

CS-200 OVER 750

MN-29250 (Rev. 3) 11/15 • CARVING STATIONS • 8

ELECTRICAL CONNECTION

INSTALLATION

1. Anidentificationtagispermanentlymounted

onthecarvingstation.

2. Ifnecessary,aproperreceptacleoroutlet

configurationasrequiredforthisunit,mustbe

installedbyalicensedelectricianinaccordance

withapplicable,localelectricalcodes.

3. Plugcarvingstationintoaproperlygrounded

receptacleONLY,positioningtheunitsothe

powersupplycordiseasilyaccessibleincase

ofanemergency.Arcingwilloccurwhen

connectingordisconnectingtheunitunlessall

controlsareinthe“OFF”position.

WARNING

To prevent SERIOUS INJURY, DEATH

or PROPERTY DAMAGE:

All electrical connections must be

made by a qualified and trained

service technician in accordance with

applicable electrical codes.

DANGER

Ensure power source matches

voltage identified on appliance rating

tag. The rating tag provides essential

technical information required for any

appliance installation, maintenance

or repairs. Do not remove, damage or

modify the rating tag.

WARNING

To prevent SERIOUS INJURY,

DEATH, or PROPERTY DAMAGE:

All electrical connections must be

made by a qualified and trained

service technician in accordance

with applicable electrical codes.

This appliance MUST be adequately

grounded in accordance with local

electrical codes or, in the absence

of local codes, with the current

edition of the National Electrical

Code ANSI/NFPA No. 70. In Canada,

all electrical connections are to be

made in accordance with CSA C22.1,

Canadian Electrical Code Part 1 or

local codes.

WARNING

Improper installation, alteration,

adjustment, service, cleaning, or

maintenance could result in property

damage, severe injury, or death.

READ and UNDERSTAND the

installation, operating and

maintenance instructions thoroughly

before installing, servicing, or

operating this equipment.

Wire diagrams are located on the bottom outside of the unit.

For CE approved units:

To prevent an electrical

shock hazard between the appliance and other

appliances or metal parts in close vicinity,

an equalization-bonding stud is provided. An

equalization bonding lead must be connected to

this stud and the other appliances/metal parts

to provide sufficient protection against potential

difference. The terminal is marked with

the following symbol.

NOTICE: WherelocalcodesandCEregulatory

requirementsapply,appliancesmustbe

connectedtoanelectricalcircuitthatis

protectedbyanexternalGFCIoutlet.

ELECTRICAL - CS-100

VOLTAGE PHASE CYCLE /HZ AMPS

kW

CORD & PLUG

120 1 60 4.2 0.5

NEMA 5-15P

15A-120V

PLUG

230 1 50/60 2.2 0.5

PLUGS RATED

250V

CEE 7/7 CH2-16P BS 1363 AS/NZS 3112

ELECTRICAL - CS-200

VOLTAGE PHASE CYCLE /HZ AMPS

kW

CORD & PLUG

120 1 60 6.3 0.75

NEMA 5-15P

15A-120V

PLUG

230 1 50/60 3.26 0.75

PLUGS RATED

250V

CEE 7/7 CH2-16P BS 1363 AS/NZS 3112

MN-29250 (Rev. 3) 11/15 • CARVING STATIONS • 9

1. Set toggle switch.

Presstoggleswitchforheatedsurfaceto“ON”

position.Set3-waytoggleswitchtodesired

holdingtemperature(low/Med/high).

Presstoggleswitchforlampsto“ON”position.

2. Preheat.

Preheatforaminimumof30minutes.

3. Transfer hot foods to the carving station.

Theproductmustbeattheproperinternal

temperaturebeforetransferringfoodtothe

carvingstation.Useapocket-typemeat

thermometertochecktheinternaltemperature

oftheproductbeingheld.Adjusttheshelf

temperaturetogivethebestoverallsettingbased

ontheinternalproducttemperature.Ifanyfood

productisnotatproperservingtemperature,use

aHaloHeatCook&HoldOvenorCombitherm®

CombiOventobringtheproductwithinthe

correcttemperaturerange.

4. Check food temperature.

Sincepropertemperaturerangedependson

thetypeofproductsandthequantitiesbeing

held,itisnecessarytoperiodicallyuseapocket

thermometertocheckeachitemtomakecertain

thecorrecttemperaturesarebeingmaintained.

Localhealthregulationsmayvaryregarding

minimumservingtemperatures.Proper

temperaturerangeis140°to160°F(60°to71°C)

orhigher.

NOTICE: DoNOTuseknivesorutensilsonthehot

metalsurface.Acuttingboardissupplied.

USER SAFETY INFORMATION:

Thisapplianceisintendedforuseincommercial

establishmentsbyqualifiedpersonnelwhoare

familiarwiththepurpose,limitations,andassociated

hazardsofthisappliance.Operatinginstructions

andwarningsmustbereadandunderstoodbyall

operatorsandusers.

BEFORE INITIAL USE:

Cleanthemetalsurfaceexterioroftheappliancewith

adampclothandmildsoapsolution.Rinsewell.

Cleantheglassbreathguardwithsoapormild

detergentandwater.Drywithaclean,dampchamois.

Greaseandoilmayberemovedwithnaphthaor

hexane.DonotusecommercIalorhouseholdcleaners

containingammonia.Toavoidscratching,donotuse

dryclothsorscouringcompounds.

OPERATION

AVERAGE Heat Plate Temperature:

Setting Temperature

Low 127°F (53°C)

Med 160°F (71°C)

High 180°F (82°C)

OPERATING PROCEDURES

START UP

USER SAFETY INFORMATION

CAUTION

To prevent SEVERE PERSONAL

INJURY or PROPERTY DAMAGE:

ALWAYS use hand protection when

operating this appliance to avoid

burns. Metal parts of this equipment

become extremely hot when in

operation.

WARNING

To prevent SERIOUS INJURY,

DEATH, OR PROPERTY DAMAGE,

ALWAYS disconnect unit from power

source before cleaning or servicing.

MN-29250 (Rev. 3) 11/15 • CARVING STATIONS • 10

GENERAL HOLDING GUIDELINES

OPERATION

GENERAL HOLDING GUIDELINES

Chefs,cooksandotherspecializedfoodservice

personnelemployvariedmethodsofcooking.Proper

holdingtemperaturesforaspecificfoodproduct

mustbebasedonthemoisturecontentofthe

product,productdensity,volume,andproperserving

temperatures.Safeholdingtemperaturesmustalso

becorrelatedwithpalatabilityindeterminingthe

lengthofholdingtimeforaspecificproduct.

HaloHeatmaintainsthemaximumamountof

productmoisturecontentwithouttheadditionof

water,watervapor,orsteam.Maintainingmaximum

naturalproductmoisturepreservesthenatural

flavoroftheproductandprovidesamoregenuine

taste.Inadditiontoproductmoistureretention,the

gentlepropertiesofHaloHeatmaintainaconsistent

temperaturethroughoutthecabinetwithout

thenecessityofaheatdistributionfan,thereby

preventingfurthermoisturelossduetoevaporation

ordehydration.

Inanenclosedholdingenvironment,toomuch

moisturecontentisaconditionwhichcanberelieved.

Aproductachievingextremelyhightemperatures

inpreparationmustbeallowedtodecreasein

temperaturebeforebeingplacedinacontrolled

holdingatmosphere.Iftheproductisnotallowedto

decreaseintemperature,excessivecondensationwill

formincreasingthemoisturecontentontheoutside

oftheproduct.Topreservethesafetyandquality

offreshlycookedfoodshowever,amaximumof1

to2minutesmustbetheonlytimeperiodallowed

fortheinitialheattobereleasedfromtheproduct.

MostHaloHeatholdingequipmentisprovidedwith

athermostatcontrolbetween60°and200°F(16°

to93°C).Iftheunitisequippedwithvents,close

theventsformoistholdingandopentheventsfor

crispholding.

HOLDING TEMPERATURE RANGE

MEAT FAHRENHEIT CELSIUS

BEEF ROAST — Rare 130°F 54°C

BEEF ROAST — Med/Well Done 155°F 68°C

BEEF BRISKET 160°F — 175°F 71°C — 79°C

CORN BEEF 160°F — 175°F 71°C — 79°C

PASTRAMI 160°F — 175°F 71°C — 79°C

PRIME RIB — Rare 130°F 54°C

STEAKS — Broiled/Fried 140°F — 160°F 60°C — 71°C

RIBS — Beef or Pork 160°F 71°C

VEAL 160°F — 175°F 71°C — 79°C

HAM 160°F — 175°F 71°C — 79°C

PORK 160°F — 175°F 71°C — 79°C

LAMB 160°F — 175°F 71°C — 79°C

POULTRY

CHICKEN — Fried/Baked 160°F — 175°F 71°C — 79°C

DUCK 160°F — 175°F 71°C — 79°C

TURKEY 160°F — 175°F 71°C — 79°C

GENERAL 160°F — 175°F 71°C — 79°C

FISH/SEAFOOD

FISH — Baked/Fried 160°F — 175°F 71°C — 79°C

LOBSTER 160°F — 175°F 71°C — 79°C

SHRIMP — Fried 160°F — 175°F 71°C — 79°C

BAKED GOODS

BREADS/ROLLS 120°F — 140°F 49°C — 60°C

MISCELLANEOUS

CASSEROLES 160°F — 175°F 71°C — 79°C

DOUGH — Proofing 80°F — 100°F 27°C — 38°C

EGGS —Fried 150°F — 160°F 66°C — 71°C

FROZEN ENTREES 160°F — 175°F 71°C — 79°C

HORS D'OEUVRES 160°F — 180°F 71°C — 82°C

PASTA 160°F — 180°F 71°C — 82°C

PIZZA 160°F — 180°F 71°C — 82°C

POTATOES 180°F 82°C

PLATED MEALS 140°F — 165°F 60°C — 74°C

SAUCES 140°F — 200°F 60°C — 93°C

SOUP 140°F — 200°F 60°C — 93°C

VEGETABLES 160°F — 175°F 71°C — 79°C

THE HOLDING T E M PERATURES LIS T E D ARE SUGGEST E D GUIDELINES O N L Y. ALL

FOOD HOLDING S H OULD BE BASED O N INTERNAL PR O D UCT TEMPERATU R E S.

ALWAYS FOLLOW L OCAL HEALTH (H Y GIENE) REGULA T I ONS FOR ALL I N T ERNAL

TEMPERATURE R E Q UIREMENTS.

MN-29250 (Rev. 3) 11/15 • CARVING STATIONS • 11

CARE AND CLEANING

PROTECTING STAINLESS STEEL SURFACES

Itisimportanttoguardagainstcorrosion

inthecareofstainlesssteel

surfaces.Harsh,corrosive,

orinappropriatechemicals

cancompletelydestroythe

protectivesurfacelayer

ofstainlesssteel.Abrasive

pads,steelwool,ormetalimplementswillabrade

surfacescausingdamagetothisprotectivecoating

andwilleventuallyresultinareasofcorrosion.

Evenwater,particularlyhardwaterthatcontains

hightomoderateconcentrationsofchloride,will

causeoxidationandpittingthatresultinrust

andcorrosion.Inaddition,manyacidicfoods

spilledandlefttoremainonmetalsurfacesare

contributingfactorsthatwillcorrodesurfaces.

Propercleaningagents,materials,and

methodsarevitaltomaintainingtheappearance

andlifeofthisappliance.Spilledfoodsshouldbe

removedandtheareawipedassoonaspossible

butattheveryleast,aminimumofonceperday.

Alwaysthoroughlyrinsesurfacesafterusinga

cleaningagentandwipestandingwaterasquickly

aspossibleafterrinsing.

CLEANING AGENTS

Usenon-abrasivecleaningproductsdesignedfor

useonstainlesssteelsurfaces.Cleaningagents

mustbechloride-freecompoundsandmustnot

containquaternarysalts.Neverusehydrochloric

acid(muriaticacid)onstainlesssteelsurfaces.

Failuretoobservethisprecautionwillvoidthe

warranty.Alwaysusethepropercleaningagentat

themanufacturer'srecommendedstrength.

Contactyourlocalcleaningsupplierfor

productrecommendations.

CLEANING MATERIALS

Cleaningcanusuallybeaccomplishedwiththe

propercleaningagentandasoft,cleancloth.

Whenmoreaggressivemethodsareneeded,usea

non-abrasivescouringpadondifficultareasand

makecertaintoscrubwiththevisiblegrainof

surfacemetaltoavoidsurfacescratches.Never

usewirebrushes,metalscouringpads,orscrapers

toremovefoodresidue.Failuretoobservethis

precautionwillvoidthewarranty.

CLEANING AND PREVENTATIVE MAINTENANCE

CAUTION

To protect stainless steel surfaces,

completely avoid the use of

abrasive cleaning compounds,

chloride based cleaners, or

cleaners containing quaternary

salts. NEVER use hydrochloric acid

(muriatic acid) on stainless steel.

NEVER use wire brushes, metal

scouring pads or scrapers.

N

O

W

I

R

E

B

R

U

S

H

E

S

N

O

S

T

E

E

L

P

A

D

S

N

O

S

C

R

A

P

E

R

S

WARNING

To prevent SERIOUS INJURY,

DEATH, or PROPERTY DAMAGE:

The appliance must be cleaned

thoroughly to avoid deposits of

grease and or food residues inside

the appliance that may catch fi re. If

fat deposits and/or food waste inside

the appliance ignite, shut down the

appliance immediately and keep the

appliance door closed to extinguish

the fi re. If further extinguishing is

required, disconnect the appliance

from the main power and use a fi re

extinguisher (do not use water to

extinguish a grease fi re!). Failure

to clean the appliance properly

invalidates the warranty and relieves

Alto-Shaam of all liability.

MN-29250 (Rev. 3) 11/15 • CARVING STATIONS • 12

EQUIPMENT CARE

Thecleanlinessandappearance

ofthisequipmentwill

contributeconsiderablyto

operatingefficiencyand

savory,appetizingfood.Good

equipmentthatiskeptclean

worksbetterandlastslonger.

THOROUGHLY CLEAN THE APPLIANCE AFTER

EACH USE:

1. Removefoodfrom

carvingstation.

2. TurnON/OFFtoggleswitch

tothe“OFF”position.

Disconnectunitfrompower

source.Lettheunitcool.

3. Removecuttingboardaftereachuse.Cleanand

sanitizeseparatelyfollowingapplicablestateor

localhealthsanitationordinances.Airdrythe

boardonaclean,flatsurfacetopreventboard

fromwarping.Iftheboardbecomeswarped,

heatingwillrestoreflexibilitytofacilitate

flattening.Warpedboardsmaybeheated

onthecarvingshelfsurface,inapreheated

Combitherm®CombiOvenfor10minutesonthe

steamprogram,orinapreheatedHaloHeatCook

&HoldOvenfor15minutesat250°F(121°C).

4. Cleanmetalsurfacesoftheunitwithadamp,

cleanclothandanygoodcommercialdetergent

attherecommendedstrength.Useaplastic

scouringpadorovencleanerfordifficultareas.

Rinsesurfacesbywipingwithspongeandclean

warmwater.

NOTICE:Avoidtheuseofabrasivecleaning,

compounds,chloridebasedcleaners,

orcleanerscontainingquaternarysalts.

Neverusehydrochloricacid(muriatic

acid)onstainlesssteel.

5. Surfacescanbewipedwithasanitizingsolution

aftercleaningandrinsing.Thissolutionmust

beapprovedforuseonstainlesssteelfood

contactsurfaces.

6. Cleanbreathguardswithawindowcleaner.

7. DoNOTuseknivesorutensilsonthehotshelf

surface.Acuttingboardissupplied.

Alwaysfollowappropriatestateorlocalhealth

(hygiene)regulationsregardingallapplicable

cleaningandsanitationrequirementsfor

foodserviceequipment.

CARE AND CLEANING

WARNING

To prevent SERIOUS INJURY,

DEATH, OR PROPERTY DAMAGE,

ALWAYS disconnect unit from power

source before cleaning or servicing.

DANGER

To prevent SERIOUS PERSONAL

INJURY, DEATH, or PROPERTY

DAMAGE:

DO NOT steam clean, hose down

or flood the interior or exterior

with water or liquid solution of

any kind. DO NOT use water jet

to clean.

Failure to observe this precaution

will void the warranty.

MN-29250 (Rev. 3) 11/15 • CARVING STATIONS • 13

FOOD SAFETY

Food fl avor and aroma are usually so closely related that

it is diffi cult, if not impossible, to separate them. There

is also an important, inseparable relationship between

cleanliness and food fl avor. Cleanliness, top operating

effi ciency, and appearance of equipment contribute

considerably to savory, appetizing foods.

Most food imparts its own particular aroma and many

foods also absorb existing odors. Unfortunately, during

this absorption there is not a distinction between GOOD

and BAD odors. The majority of objectionable fl avors and

odors troubling food service operations are caused by

bacteria growth. Sourness, rancidity, mustiness, stale or

other OFF fl avors are usually the result of germ activity.

The easiest way to ensure full, natural food fl avor is

through comprehensive cleanliness. This means good

control of both visible soil (dirt) and invisible soil (germs).

A thorough approach to sanitation will provide essential

cleanliness. It will ensure an a ractive appearance of

equipment, along with maximum effi ciency and utility.

More importantly, a good sanitation program provides

one of the key elements in the prevention of food-

borne illnesses.

A comprehensive sanitation program should focus on

the training of staff in basic sanitation procedures. This

includes personal hygiene, proper handling of raw foods,

cooking to a safe internal product temperature, and

the routine monitoring of internal temperatures from

receiving through service.

A controlled holding environment for prepared foods is

just one of the important factors involved in the prevention

of food-borne illnesses. Temperature monitoring and

control during receiving, storage, preparation, and the

service of foods are of equal importance.

The most accurate method of measuring safe temperatures

of both hot and cold foods is by internal product

temperature. A quality thermometer is an eff ective tool for

this purpose, and should be routinely used on all products

that require holding at a specifi c temperature.

Hazard Analysis (at) Critical Control Points (HACCP), is a

quality control program of operating procedures to assure

food integrity, quality, and safety. Taking steps necessary

to augment food safety practices is both cost eff ective

and relatively simple. Additional HACCP information is

available by contacting:

Center for Food Safety and Applied Nutrition

Food and Drug Administration

PHONE: 1-888-SAFEFOOD

www.foodsafety.gov

INTERNAL FOOD PRODUCT TEMPERATURES

HOT FOODS

DANGER ZONE 40°F TO 140°F (4°C TO 60°C)

CRITICAL ZONE 70°F TO 120°F (21°C TO 49°C)

SAFE ZONE 140°F TO 165°F (60°C TO 74°C)

COLD FOODS

DANGER ZONE ABOVE 40°F (ABOVE 4°C)

SAFE ZONE 36°F TO 40°F (2°C TO 4°C)

FROZEN FOODS

DANGER ZONE ABOVE 32°F (ABOVE 0°C)

CRITICAL ZONE 0°F TO 32°F (-18°C TO 0°C)

SAFE ZONE 0°F or below (-18°C or below)

MN-29250 (Rev. 3) 11/15 • CARVING STATIONS • 14

A

C

31

20

21

19

25

24

9

6

23

40

39

41

14

22

38

11

33

7

13

16

27

45

44

32

22

30

30

28

10

35

15

1

12

30

12

30

30

1

18

2

4

1

43

42

36

26

37

15

34

29

17

12

3

1

40

39

41

4

33

SERVICE VIEW CS-100

201401

MN-29250 (Rev. 3) 11/15 • CARVING STATIONS • 15

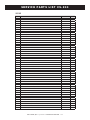

ITEM DESCRIPTION PART NO. QTY

1 L-BRACKET 1008529 2

2 LAMP LOCK DOWN WASHER 1011278 1

3 RELAY ATTACHMENT L-BRACKET 1011286 1

4 SNEEZE GUARD BRACKET 1011870 2

5 TOP COVER 500-S 1011946 1

6 TOP BASE PANEL SPOT 5008801 1

7 BASE HOUSING COVER PANEL 5008802 1

8 CORDSET, CH2-16P, FERRULE ASSEMBLY 5020353 1

9 CUTTING BOARD BA-28482 1

10 CONNECTION BLOCK, 4 CONDUCTOR, TOP SCREW, 5-POLE BK-34711 1

11 BUMPER, 3/8-16 MALE THREAD BM-22606 4

12 3/4" WHITE SNAP BUSHING BU-3008 2

13 BUSHING, STRAIN RELIEF, 90°, BLACK BU-34898 1

14 HEAT PAD, CS-100 CB-34630 1

15 230V, CONTROL BOARD, PRESETS CC-35016 1

16 CORDSET, CEE 7/7, 16A, 250V CD-3922 1

CORDSET, UK BS1363 8' CD-33925 1

CORDSET, CH2-16P, 16A-250V, 2-POLE CD-36321 1

CORDSET, NEMA 5-15P CD-3232 1

CORDSET, AS/NZS 3112, 15A, 250V CD-38149 1

17 CONNECTOR, DUAL SPADE, 1/4" CR-3849 5

18 CONNECTOR-5 CONDUCTOR CR-34646 2

19 SNEEZE GUARD FRAME FR-28484 1

20 GLASS, 5mm THICK, TEMPERED, UPPER GL-29240 1

21 GLASS, 5mm THICK, TEMPERED, LOWER GL-29241 1

22 INSULATION, 1.000" THICK, YELLOW IN-22265 1

23 WHITE PILOT LIGHT 250V LI-3951 1

24 LAMP, INFARED HEAT, COATED, 250W, 230V LP-33781 1

SOCKET, REPLACEMENT, 120V SK-35370 1

SOCKET, REPLACEMENT, 208-240V LAMP SK-35028 1

25 LAMP, HEATED, SINGLE, 120V, 250W LP-34896 1

26 NUT, 1/4-20 HEX S/S NU-2437 4

27 NUT, THREADED INSERT, M6 NU-22770 1

28 RELAY, SPST 30A, 277 VAC 12VDC RL-33558 1

29 SCREW, 10-32 x 1/4 PAN HD GROUND SCREW SC-2190 1

30 SCREW, 8-32 x 1/4" PHIL SCREW SC-2459 9

31 SCREW, 8-32 x 0.375" FLAT SC-2816 8

32 SCREW, HHCS, M6 x 20, WITH NO MARKING SC-22924 1

33 SCREW 8-32 x 1/4" HEX HEAD SC-24751 22

34 SCREW, 6-32 x 1/4" PHILLIPS PAN SC-28384 4

35 SCREW, M3 x 22mm, 0.5mm PITCH, PAN HEAD PHILLIPS SC-28846 2

36 SCREW, SET, HEX #1/4-20 x 1.00" LG SC-29222 4

37 SPACER, SCREW MOUNT SUPPORT, NYLON SP-28159 4

38 SPACER, NYLON, 1.300" DIA SP-38054 4

39 SWITCH, ROCKER, SEALED, 3-WAY SW-34653 1

40 SWITCH, ROCKER, SEALED, DOUBLE-POLE SW-34654 1

41 SWITCH, ROCKER, TUNGSTEN, 6 AMP, SEALED, DOUBLE POLE SW-34924 1

42 LOCK WASHER 1/4" WS-2294 4

43 WASHER, 1/4", FLAT, 5.8 OD 18-8 S/S WS-22094 4

44 WASHER, FLAT WS-22297 2

45 WASHER, SPLIT LOCK WS-22302 2

SERVICE PARTS LIST CS-100

201401

*NOT SHOWN

MN-29250 (Rev. 3) 11/15 • CARVING STATIONS • 16

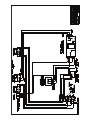

SERVICE VIEW CS-200

201301

A

19

30

18

23

32

32

22

4

21

39

38

40

17

16

37

10

14

15

13

31

5

8

32

26

4

3

2

29

9

29

33

35

42

24

41

3

16

17

7

27

26 34

28

12

36

MN-29250 (Rev. 3) 11/15 • CARVING STATIONS • 17

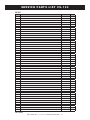

ITEM DESCRIPTION PART NO. QTY

1*

L-BRACKET 1008529

2

2

LAMP LOCK DOWN WASHER 1009413

1

3 SNEEZE GUARD BRACKET 1011870 2

4 TOP BASE PANEL SPOT 5007406 1

5 BOTTOM COVER PANEL HEX INSERT 5007447 1

6 CUTTING BOARD BA-28066 1

7 CONNECTION BLOCK, 4-CONDUCTOR, TOP SCREW, 5-POLE BK-34711 1

8 BUMPER 3/8-16 MALE THREAD BM-22606 4

9 BUSHING, 3/4" WHITE, SNAP BU-3008 2

10 BUSHING, STRAIN RELIEF, 90°, BLACK BU-34898 1

11* HEAT PAD, CS-200 CB-34544 1

12 CONTROL BOARD, 120V, PRESETS CC-34657 1

13 CORDSET, CEE 7/7, 16A, 250V CD-3922 1

CORDSET, UK BS1363 8' CD-33925 1

CORDSET, 16A-250V CH2-16P 2 POLE CD-36321 1

CORDSET, NEMA 5-15P CD-3232 1

CORDSET, AS/NZS 3112, 15A, 250V CD-38149 1

14 WASHER, SPLIT LOCK WS-22302 2

15 WASHER, FLAT WS-22297 2

16 CONNECTOR, DUAL SPADE, 1/4" CR-3849 5

17 CONNECTOR-5 CONDUCTOR CR-34646 2

18 FRAME, WELD, SNEEZE GUARD FR-28944 1

19 GLASS, 5mm THICK, TEMPERED GL-28416 1

GLASS, 5mm THICK, TEMPERED GL-28604 1

20* HEATSINK, THERMALLY CONDUCTIVE PAD HE-33926 1

21 WHITE PILOT LIGHT 250V LI-3951 1

22 LAMP, INFARED HEAT, COATED, 250W, 230V LP-33781 2

SOCKET, REPLACEMENT, 120V SK-35370 1

SOCKET, REPLACEMENT, 208-240V LAMP SK-35028 1

23 LAMP, HEATED, SINGLE, 120V LP-34896 1

24 NUT, 1/4-20 HEX S/S NU-2437 4

25* NUT, THREADED INSERT, M6 NU-22770 1

26 NUT, #8-32 UNC KEPS ZP NU-26526 2

27 RELAY, SPST 30A, 277 VAC 12VDC RL-33558 1

28 SCREW, 10-32 x 1/4 PAN HD GROUND SCREW SC-2190 1

29 SCREW, 8-32 x 1/4" PHIL SCREW SC-2459 8

30 SCREW, 8-32 x 0.375", FLAT SC-2816 8

31 SCREW, HHCS, M6 x 20, WITH NO MARKS SC-22924 1

32 SCREW 8-32 x 1/4" HEX HEAD SC-24751 22

33 SCREW, 6-32 x 1/4" PHILLIPS PAN SC-28384 4

34 SCREW, M3 x 22mm, 0.5mm PITCH, PAN HEAD PHILLIPS SC-28846 2

35 SCREW, SEST, HEX, #1/4-20 x 1.00" LG SC-29222 4

36 SPACER, SCREW MOUNT SUPPORT, NYLON SP-28159 4

37 SPACER, NYLON, 1.300" DIA SP-38054 4

38 SWITCH, ROCKER, SEALED, 3-WAY SW-34653 1

39 SWITCH, ROCKER, SEALED, DOUBLE-POLE SW-34654 1

40 SWITCH, ROCKER, TUNGSTEN, 6 AMP, SEALED, DOUBLE POLE SW-34924 1

41 LOCK WASHER 1/4" WS-2294 4

42 WASHER, 1/4", FLAT, 5/8 OD 18-8 S/S WS-22094 4

SERVICE PARTS LIST CS-200

201301

*NOT SHOWN

MN-29250 (Rev. 3) 11/15 • CARVING STATIONS • 18

Page is loading ...

Page is loading ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

Alto-Shaam CS-200 Installation Operation & Maintenance

- Category

- Food warmers

- Type

- Installation Operation & Maintenance

- This manual is also suitable for

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Alto-Shaam CS-100 Installation Operation & Maintenance

Alto-Shaam CS-100 Installation Operation & Maintenance

-

Alto-Shaam TY2-96 Quick start guide

-

Alto-Shaam Drawer Warmers 500-1DN Quick start guide

-

Alto-Shaam 600-LVD Installation Operation & Maintenance

-

Alto Shaam 300-TMC/1 Operating instructions

Alto Shaam 300-TMC/1 Operating instructions

-

Alto-Shaam HSM-38/3S Specification

-

Alto-Shaam HSM-38/3S Installation, Operation and Maintenance Manual

-

Alto-Shaam HSM-38/3S Installation, Operation and Maintenance Manual

-

Alto-Shaam 100-HSL/BCS-2 User manual

-

Alto Shaam 100-HSL/BCS-2 Operating instructions

Other documents

-

Alto Shaam 300-HST Operating instructions

Alto Shaam 300-HST Operating instructions

-

APW Wyott SG-30PX Operating instructions

APW Wyott SG-30PX Operating instructions

-

Alto Shaam 100-HSL/TM Operating instructions

Alto Shaam 100-HSL/TM Operating instructions

-

Alto Shaam 100-HSL/TM Operating instructions

Alto Shaam 100-HSL/TM Operating instructions

-

Alto Shaam 100-HSL/BCS-2 Operating instructions

Alto Shaam 100-HSL/BCS-2 Operating instructions

-

Zephyr AK7000AS Heat Lamp Manual (pdf)

-

3M Round Conductor Flat Cable, 3849 Series Important information

-

Alto Shaam 750-TH-II MARINE 230V Operating instructions

Alto Shaam 750-TH-II MARINE 230V Operating instructions

-

Alto Shaam 750-TH-II MARINE 230V Operating instructions

Alto Shaam 750-TH-II MARINE 230V Operating instructions

-

Alto Shaam 1000-TH-I Operating instructions

Alto Shaam 1000-TH-I Operating instructions