VL-Z700S-T

VL-Z800S-S/E-S/E-T/Z900H-S

VL-Z950S-S/E-A/E-S/E-T/E-W

9

5-2. Cautions in handling the mechanism

(1) Cut washers removed at the time of part replacement etc. should be

replaced with new ones without fail.

(2) Because no volume adjustment is available in this mechanism, cleaning or

part replacement should be performed if the setting is not satisfied.

(3) About oil

a) Be sure to use the specified oil. (If any oil other than the specified oil is

used, various troubles will occur.)

b) When lubricating the bearing, be sure to oil free from foreign particles

such as dust. (If oil in which foreign particles such as dust are mixed is

used, it will cause wear and seizure to the bearing.)

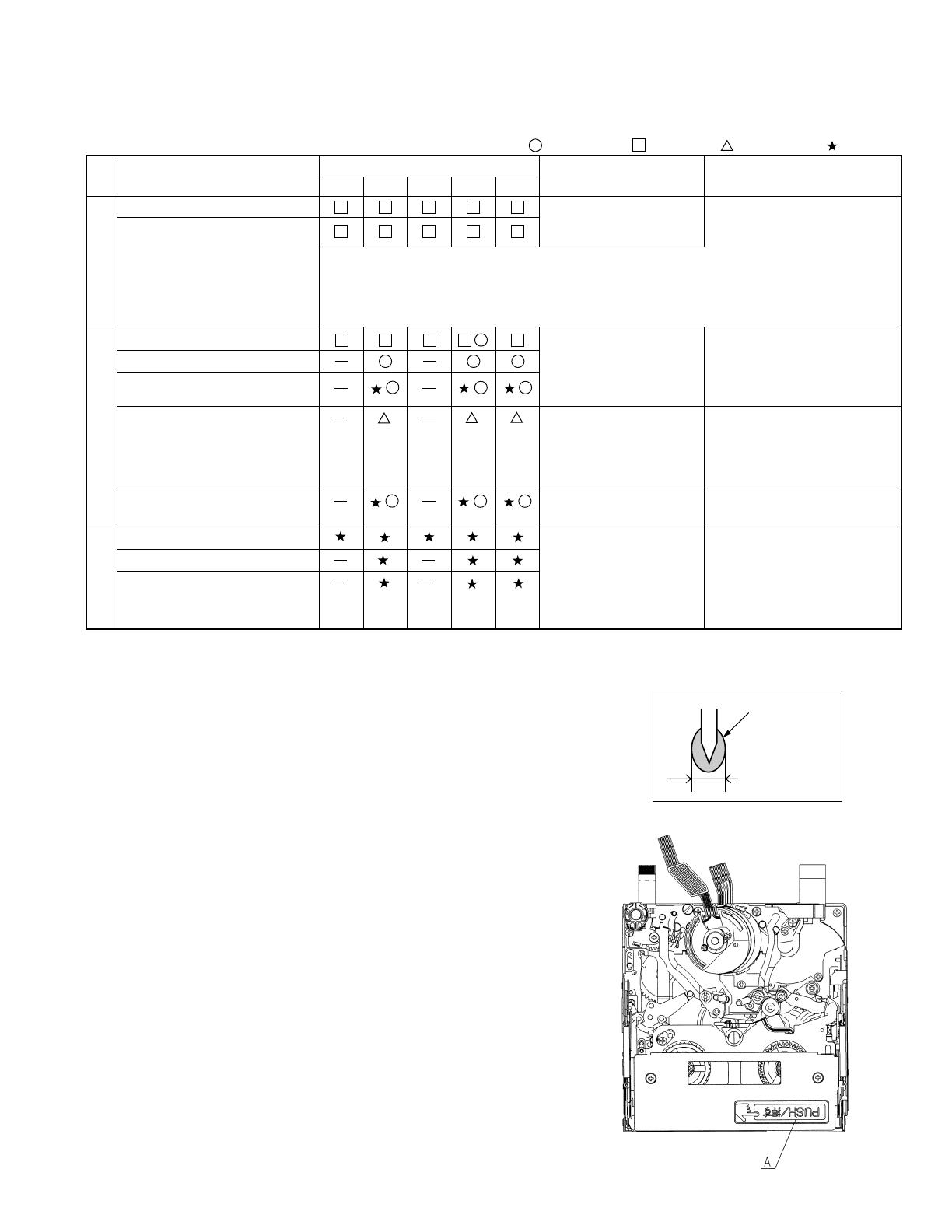

c) The term "One drop of oil" here means the amount of oil on the point of

a needle etc. shown in Fig.1.

(4) Repairing of circuits, final adjustment of running system, etc. should be

performed with the cassette controller assembly installed in the mechanism.

(5) When operating the mechanism singly, apply voltage to the loading motor

to drive it. The voltage between the terminals should be 3 to 4V DC. (Do

not apply external voltage to the loading motor with the mechanism

connected with the main circuit board. Doing so could cause a failure.)

(Turning the gears forcedly by hand may cause them to get damaged.)

When placing the mechanism singly, use an appropriate spacer so that the

capstan motor is not rubbed.

(6) When installing the cassette controller, push the portion indicated by "A" in

Fig.2. Do not push other portions.

(7) Take care not to deform the components of the mechanism.

Fig. 2

Ø1.5 or less

Oil

Fig. 1

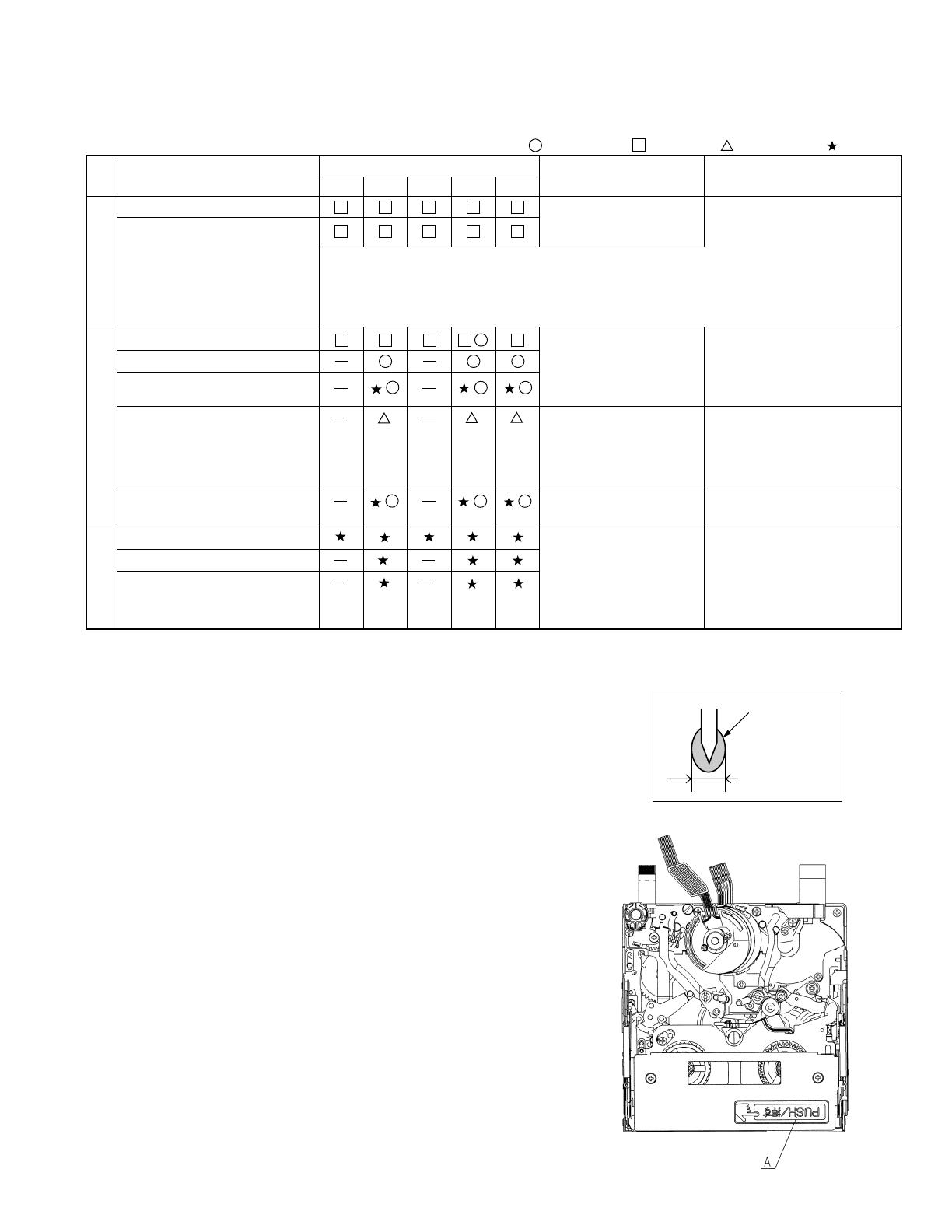

5. INSPECTION AND MAINTENANCE ITEMS AND INTERVALS

In order to maintain the quality of the mechanism section, perform the following maintenance and inspection. After repairing the

mechanism section, perform the following maintenance regardless of the number of hours of use by the user.

5-1. Maintenance and inspection list

Tape running section (See7-3.)

Swing arm

S reel table, Tu reel table

Running system

• • • Replace. • • • Clean. • • • Lubricate. • • • Check.

Note:

If no envelope output is obtained

in spite of the video head being

cleaned, replace the drum

component.

(If the envelope output is normal,

refer to "10. USEFUL TIPS".)

Performance check

[Oil] Cosmo Hydro HV22

[Grease] Molykote YM-103

Sankei Chemical CFD-409Z

Driving system

Number of hours of use (h)

500 1,000 1,500 2,000 3,000

Symptoms observed at the

time of maintenance

Notes and remarks

Inspection and

maintenance location

[Loctite adhesive] Three Bond 1401B

[Cleaning liquid] Industrial ethyl alcohol

• Tape not running

• Tape sagged

• Block noise

• Abnormal noise

• Replace if any abnormal

condition is found.

• Apply oil.

[Oil]

Cosmo Hydro HV22

Note:

Apply oil to the shaft and

lightly wipe it off with a cloth.

• Abnormal noise

• Ejecting cannot be made.

• Mode cannot be set.

• Replace if any abnormal

condition (noise etc.) is found.

• Tape not running

• Tape sagged

• Damage to tape

• Abnomaly in reproduced

picture

• If a part is out of spec, replace

it.

PB, VS/R and loading back tension

S reel table unloaded torque

PB and VS/R winding torque

Abnormal noise

Loading motor

Mode SW

Center gear boss

Relay pulley shaft

Capstan motor (Timing belt)

Pinch roller

Drum section, Video head

(See 7-3.)

<Rollers>

• Replace if abnormal rotation or swing (large) is found.

<Others>

• Cleans the portions that come in contact with the tape (the lower

drum helical portion in particular). Use the specified cleaning liquid.

• Block noise

• Clogging of head

• Damage to tape