Page is loading ...

2569 Kenworth Road, Suite C

Nanaimo, BC, V9T 3M4

CANADA

+1.250.729.8080

info@eddyfitechnologies.com

www.eddyfitechnologies.com

INUKTUN MAGGHD™

MaggHD™

Document: UMAU015088.docm

Revision: A08

Created by: KJB

Date: 26 Sep 2019

3080885-A08

Source Location: C:\ePDM\ISLEng\products\au-micromag\manuals\UMAU015088.docm

Page 2 of 29

User Manual

Table of Contents

About This Manual ........................................................................................................................................ 5

Description ................................................................................................................................................. 5

Specifications ............................................................................................................................................ 5

Precautions ............................................................................................................................................... 6

Certification and Directives ....................................................................................................................... 6

Safety ........................................................................................................................................................ 6

Intended Use............................................................................................................................................. 9

Laser Lines ............................................................................................................................................. 10

MaggHD™ Vehicle ................................................................................................................................. 11

Dimensions .......................................................................................................................................... 11

System Power ......................................................................................................................................... 12

Power Requirements ........................................................................................................................... 12

Generators / Inverters .......................................................................................................................... 12

Galvanic Corrosion Control ..................................................................................................................... 12

System Setup .............................................................................................................................................. 12

Personnel Requirements ........................................................................................................................ 12

Vehicle and Tether Connection .............................................................................................................. 13

Mini-Reel Setup ...................................................................................................................................... 13

Controller Connection ............................................................................................................................. 14

Configuration ............................................................................................................................................... 15

Camera Mounting ................................................................................................................................... 15

Standard Mounting ............................................................................................................................... 15

Pole Mounting ...................................................................................................................................... 16

Alternate Mounting ............................................................................................................................... 17

Operating MaggHD™ on Vertical or Inverted Surface ........................................................................... 17

Magnet Spacing ................................................................................................................................... 18

Fall Arrest ............................................................................................................................................. 19

MaggHD™

Document: UMAU015088.docm

Revision: A08

Created by: KJB

Date: 26 Sep 2019

3080885-A08

Source Location: C:\ePDM\ISLEng\products\au-micromag\manuals\UMAU015088.docm

Page 3 of 29

User Manual

Configuration Add-Ons .................................................................................. Error! Bookmark not defined.

MaggHD™ + Actuator for UT sensor ........................................................ Error! Bookmark not defined.

Probe Assembly ..................................................................................... Error! Bookmark not defined.

UT Probe Connection ............................................................................ Error! Bookmark not defined.

Couplant Pump Box Connection ............................................................ Error! Bookmark not defined.

Using the UT Probe .................................................................................. Error! Bookmark not defined.

Operation..................................................................................................................................................... 20

Tether Handling ...................................................................................................................................... 20

Connector Handling ................................................................................................................................ 20

SubConn Connector: Lubrication and Cleaning .................................................................................. 21

Impulse Connector: Lubrication and Cleaning ..................................................................................... 21

Pre-Operations Check ............................................................................................................................ 21

Post-Operations Check ........................................................................................................................... 22

ICON™ & ICON RPT™ .......................................................................................................................... 23

Driving the Vehicle .................................................................................................................................. 23

Maintenance ................................................................................................................................................ 24

Fuse Replacement .................................................................................................................................. 24

Microtrac™ Maintenance ........................................................................................................................ 24

Tether Re-termination ............................................................................................................................. 24

Troubleshooting .......................................................................................................................................... 25

Camera Control Problems ...................................................................................................................... 25

Video Issues ........................................................................................................................................... 25

Vehicle Issues ......................................................................................................................................... 25

Tether Reel Issues .................................................................................................................................. 26

Parts and Repairs ....................................................................................................................................... 27

Ordering Parts/Customer Service ........................................................................................................... 27

Warranty Repairs .................................................................................................................................... 27

Factory Returns to Canada ..................................................................................................................... 28

MaggHD™

Document: UMAU015088.docm

Revision: A08

Created by: KJB

Date: 26 Sep 2019

3080885-A08

Source Location: C:\ePDM\ISLEng\products\au-micromag\manuals\UMAU015088.docm

Page 4 of 29

User Manual

Product/System Drawing Package Availability ....................................................................................... 28

Limited Warranty Policy .............................................................................................................................. 28

MaggHD™

Document: UMAU015088.docm

Revision: A08

Created by: KJB

Date: 26 Sep 2019

3080885-A08

Source Location: C:\ePDM\ISLEng\products\au-micromag\manuals\UMAU015088.docm

Page 5 of 29

User Manual

About This Manual

This manual has been prepared to assist you in the operation and maintenance of your Eddyfi

Technologies Inuktun equipment. Correct and prudent operation rests with the operator who must

thoroughly understand the operation, maintenance, service and job requirements. The specifications and

information in this manual are current at the time of printing.

This product is continually being updated and improved. Therefore, this manual is meant to explain and

define the functionality of the product. Furthermore, schematics or pictorials and detailed functionality

may differ slightly from what is described in this manual.

Eddyfi Technologies reserves the right to change and/or amend these specifications at any time without

notice.

Information in this manual does not necessarily replace specific regulations, codes, standards, or

requirements of others such as government regulations.

This manual copyright © 2019 by Inuktun Services Ltd. All rights reserved.

Description

The Inuktun MaggHD™ is a magnetic tracked crawler capable of driving vertically or inverted along

ferrous surfaces. Additionally, the magnet modules allow the vehicle to pull longer lengths of tether than

could normally be achieved without magnets, when travelling horizontally in steel pipes or on steel decks.

The crawler features a high definition camera with a full 360-degree continuous tilt range and minimal

viewing obstruction near the back of the vehicle. The vehicle uses two extended 4000 series Microtracs™

mounted underneath the main chassis plate and can be moved up or down to accommodate different

pipe sizes and configurations.

Specifications

Specifications

Details

Depth Rating

60 m (200 ft)

Weight

6.2 kg (14 Ib)

Front Facing Camera

Full HD, 10x Optical Zoom, 12x Digital, Continuous Tilt

Tracks

4000 Series Microtracs™

Light (Variable)

2x In-Camera LEDs

2x Optional External 801 Lights

Lasers

2x Optional Vertical Laser Lines, 635 nm, 70 mm (2.75 in) Spacing

Supported Software

ICON™ & ICON RPT™

Power Requirements

110-240VAC, 50/60Hz, 550W Minimum

Operating Temperature

0 ° – 50 °C (32 ° – 122 °F) *Dependent on operating conditions. Ask

your sales expert for more information.

Storage Temperature

-20 ° – 60 °C (0 ° – 140 °F)

MaggHD™

Document: UMAU015088.docm

Revision: A08

Created by: KJB

Date: 26 Sep 2019

3080885-A08

Source Location: C:\ePDM\ISLEng\products\au-micromag\manuals\UMAU015088.docm

Page 6 of 29

User Manual

Precautions

IMPORTANT: When configuring a 70V system, check to see if the tracks are

compatible. Older versions of 4000 series Microtracs™ are not 70V

compatible. Look for the Wide Input Voltage symbol \V/ located on the side

plate of the track indicating 70V compatibility.

Certification and Directives

This system is built in accordance with the Low Voltage Directive 2006/95/EC and Directive 2014/35/EU,

Machinery Directive 2006/42/EC, and Electromagnetic Compatibility Directive 2004/108/EC and Directive

2014/30/EU.

Safety

To use this product properly and safely, every user must first read these operating instructions and

observe the safety instructions contained therein. Take care of these operating instructions and keep

them in a place where they can be accessed by everyone. Untrained personnel should not handle or

operate this equipment.

CAUTION: Failure to follow these safety instructions may result in injury or

equipment damage.

WARNING: Hazardous Voltage 36-70 VDC. If the equipment is powered from a

source other than an Eddyfi Inuktun provided controller, the power supplied to the

product must have reinforced isolation from the mains with no reference to earth

ground.

WARNING: Magnetic Pinch Hazard – The magnetic

chassis is fitted with rare earth magnets. These magnets

are very strong and create an immanent pinch hazard.

Use caution when handling the magnets or vehicle near

steel objects and tools, they may snap together

unexpectedly.

Note: Rare earth materials are mechanically weak, and

magnetically very strong. They must therefore be

handled very carefully to avoid damage.

MaggHD™

Document: UMAU015088.docm

Revision: A08

Created by: KJB

Date: 26 Sep 2019

3080885-A08

Source Location: C:\ePDM\ISLEng\products\au-micromag\manuals\UMAU015088.docm

Page 7 of 29

User Manual

WARNING: Medical Hazard – Operators with magnetically sensitive medical implants should

be aware of and follow appropriate practices.

WARNING: Electronic Device Interference – Magnetically sensitive devices, including

computer hard drives, cell phones, watches and credit cards may be disrupted or damaged by

the magnetic field.

Note: To reduce risk of injury and damage to equipment, always store the

MaggHD™ vehicle in its magnetically shielded storage and shipping box

when not in use.

Note: Eddyfi strongly recommends using gloves when handling the vehicle to

reduce magnetic pinching hazard.

Warning: Avoid Magnetic Slamming. Extreme care must be taken when

handling the vehicle, particularly when placing it onto a wall or into its storage

box. Without taking heed of the sudden pull of the magnetic field onto surface,

the MaggHD™ can be slammed down hard causing damage to the vehicle.

Using a solid grip on the vehicle, we recommend touching down the vehicle by

one end first and then pivoting flat.

WARNING: Intense Optical Radiation - The MaggHD™ camera lights are

extremely bright. Never look directly at the lights. Use a welding filter (shade #8 or

higher) if inspecting the LEDs.

MaggHD™

Document: UMAU015088.docm

Revision: A08

Created by: KJB

Date: 26 Sep 2019

3080885-A08

Source Location: C:\ePDM\ISLEng\products\au-micromag\manuals\UMAU015088.docm

Page 8 of 29

User Manual

• CAUTION: Class II Laser: Do not intentionally stare into the

beam. Typically, Class II relies on the blink reflex to limit

exposure to no more than ¼-second. Intentionally staring into

the beam can cause eye injury.

• When performing maintenance or functional checks of the

lasers and camera lights, take precautions to protect nearby

personnel from unintended exposure which could be

temporarily blinding.

• Observe safe lifting practices. For storage and shipping, the MaggHD™ system is packed in three

parts: Controller, Vehicle and Tether. Each of the three components is either built or packed into

a Pelican case with carrying handle. The heaviest case containing the tether and mini-reel is

equipped with wheels and extending handle like a suitcase.

• Do not operate the system with damaged wires. A short circuit may damage the power system,

telemetry system, cameras, or attached equipment. Exposed wires may also create a shock

hazard.

• Disconnect the power source before servicing the product; otherwise, damage may result.

• Although designed for durability, the vehicle and its components or attached devices may suffer

structural damage if dropped or impacted. A lifeline or fall arrest system should be used at all time

when the vehicle is navigating on a vertical or inverted horizontal position. In addition, stepping on

the tether may pull the vehicle off the wall causing it to fall and sustain physical damage.

• All personnel operating or maintaining this equipment must be trained and competent.

• Our equipment is used in many varied environments from hot/dry to confined spaces to deep

underwater. Such diverse environment risks must be addressed by the operators who are trained

to work in such surroundings. As such, the operator is responsible to determine safe site setup

and appropriate personal protective equipment (PPE) for operation and maintenance of the

equipment.

WARNING: Spark Hazard - Under no circumstances should this equipment be

used in a potentially explosive atmosphere.

WARNING: Trip Hazard - Never stand on the tether. A snap load to the tether

may pull it out from underneath you and cause you to fall. Standing on the tether

may also damage its internal conductors, cause unnecessary wear, and decrease

its life.

WARNING: High Temperature - The camera head and auxiliary lights may

become extremely hot during operation. Allow a cool-down period before

handling.

MaggHD™

Document: UMAU015088.docm

Revision: A08

Created by: KJB

Date: 26 Sep 2019

3080885-A08

Source Location: C:\ePDM\ISLEng\products\au-micromag\manuals\UMAU015088.docm

Page 9 of 29

User Manual

WARNING: Falling Object - A lifeline or fall arrest system should be used at all

times when the vehicle is navigating on a vertical or inverted horizontal position.

When the vehicle is climbing, never stand below the vehicle operations area.

Intended Use

The MaggHD™ is an industrial inspection vehicle intended for crawling on steel walls, tanks and

structures and to provide close-up or zoom HD video of the inspection target, which could be a weld,

paint covering, etc. The MaggHD™ may be used above or below the waterline up to 60 m (200 ft) deep,

or in dry environments. It may also be used in non-magnetic environments with removal of the magnet

cups.

Typical applications include:

• Underwater weld and paint inspection

• Potable water system inspection

• Steel Tank inspection

• Large diameter pipe inspection

• Mobile robotics and remote sensing

• Reactor vessel inspection

Misuse of the system is deployment in a situation for which it is not rated, or incorrect handling.

Examples of misuse include:

• In a vacuum

• Beyond its depth rating without factory approval

• Above or below its temperature rating

• Use in a potentially explosive atmosphere

• Use in incompatible chemical environments

• Very high radiation environments (Beta / Gamma)

• Prolonged overload (Payload or pulling load)

• Camera pointed at the Sun or at intense lighting

• Mechanical impacts & scraping during deployment / magnetic slamming / dropping

• In salt water without an anode

MaggHD™

Document: UMAU015088.docm

Revision: A08

Created by: KJB

Date: 26 Sep 2019

3080885-A08

Source Location: C:\ePDM\ISLEng\products\au-micromag\manuals\UMAU015088.docm

Page 10 of 29

User Manual

Laser Lines

The MaggHD™ may be optionally equipped with vertical laser lines (Class 2 lasers at 635 nm, 1.5 mW).

Laser line separation is 70 mm (2.75 in).

CAUTION: Class II Laser: Do not intentionally stare into the

beam. Typically, Class II relies on the blink reflex to limit

exposure to no more than ¼-second. Intentionally staring into

the beam can cause eye injury.

When performing maintenance or functional checks of the

lasers and camera lights, take precautions to protect nearby

personnel from unintended exposure which could be

temporarily blinding.

FIGURE 1 – LASER LINE SEPARATION

MaggHD™

Document: UMAU015088.docm

Revision: A08

Created by: KJB

Date: 26 Sep 2019

3080885-A08

Source Location: C:\ePDM\ISLEng\products\au-micromag\manuals\UMAU015088.docm

Page 11 of 29

User Manual

MaggHD™ Vehicle

FIGURE 2: VEHICLE

Dimensions

FIGURE 3: VEHICLE DIMENSIONS

MaggHD™

Document: UMAU015088.docm

Revision: A08

Created by: KJB

Date: 26 Sep 2019

3080885-A08

Source Location: C:\ePDM\ISLEng\products\au-micromag\manuals\UMAU015088.docm

Page 12 of 29

User Manual

System Power

Power Requirements

The MaggHD™ is operated through an ICON™ Portable Controller, or a Rackmount Interface Box. These

controllers provide power to the tether and vehicle.

Refer to the Controller User Manual for further details and power requirements.

Generators / Inverters

If powering the system from a generator or inverter, refer to that unit’s operating manual for

recommendations on continuous and peak load ratings. These power sources may apply a reduced

output rating based on electrical load and environmental temperature. Remember to include the power

needs of all other connected devices (external monitors, recording devices, lighting, etc.) when selecting

a generator or inverter.

Galvanic Corrosion Control

We strongly recommend cathodic protection whenever the vehicle is being deployed in a salt water

environment, either submerged or in salt spray. We recommend aluminum marine anodes exclusively for

use with the inspection system. Aluminum anodes are common in the marine industry and are replacing

zinc anodes in many areas. For inspection systems that are often pulled in and out of salt water,

aluminum anodes are especially important, as zinc anodes tend to scale over when exposed to air and

may not reactivate when submerged again. An aluminum anode will always reactivate.

For permanent installations, it is required that the structure to which the system is mounted also be

protected by aluminum anodes. If the structure is of a dissimilar metal, the system mount must be

isolated from the structure. Do not mix anode types (zinc and aluminum) on the assembly. There must be

only one anode type throughout the structure. Avoid use of Magnesium anodes altogether.

System Setup

Personnel Requirements

Basic deployment of the MaggHD™ system may be performed by one person. Operations at more

complex worksites may require two people, especially when the console location is removed from the

point of deployment.

• Console Operator: This person is responsible for driving the vehicle, watching the location of the

inspection and making comments about it and the surrounding conditions. It is also the operator’s

responsibility to assess whether the location of the inspection is in the appropriate condition for

safe passage of the vehicle or if there is a risk of getting stuck. The operator may also assist in

general site setup (cones, warning signs, etc.), vehicle maintenance and configuration.

• Deployment / Tether Handler / Field Maintenance: This person has several tasks including:

MaggHD™

Document: UMAU015088.docm

Revision: A08

Created by: KJB

Date: 26 Sep 2019

3080885-A08

Source Location: C:\ePDM\ISLEng\products\au-micromag\manuals\UMAU015088.docm

Page 13 of 29

User Manual

o Configuring the vehicle for the current inspection

o Placing and retrieving the vehicle to and from the inspection area

o Watching the tether as the vehicle enters and exits the inspection

o Operating the reel and winding the tether during recovery

Establish a good channel of communication between the operator and deployment personnel. Good

communication can avoid accidents, damage to the equipment, and promotes efficiency and productivity.

In particular, the person deploying the vehicle and watching the tether must be able to quickly tell the

operator to stop the vehicle if something goes wrong. The operator should never turn on power or initiate

movement without first communicating with the vehicle handler.

Vehicle and Tether Connection

The tether and vehicle are depth rated to 60 m (200 ft) of water. The tether connector and track

connectors are dry-mate types which must be dry when making a connection. Keep the tether connector

capped with a dummy plug when not connected to the vehicle to help keep out dirt.

It is important that the tether be properly connected to the vehicle.

1. Connect the vehicle end of the tether to the back of the harness block. Visually line up the key in

the connector before mating. Fully screw down and hand tighten the locking collar.

2. Verify the track and camera whips from the harness block to their respective components are

securely connected, and the whips are free from damage.

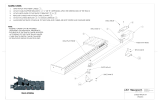

Mini-Reel Setup

If your system includes a Mini-Reel, follow these steps to operate:

1. Remove the Mini-Reel from the shipping case

2. Connect the deck cable from the reel to the controller

3. Connect the encoder deck cable from the reel to the Video Interface and Power Supply (if

provided with Mini-Reel)

4. Disengage the shipping brake

5. Make sure the friction brake is engaged – disengaging the friction brake can result in slack tether

resulting in potentially jamming the reel

6. Unwind some tether and connect the tether to the vehicle

MaggHD™

Document: UMAU015088.docm

Revision: A08

Created by: KJB

Date: 26 Sep 2019

3080885-A08

Source Location: C:\ePDM\ISLEng\products\au-micromag\manuals\UMAU015088.docm

Page 14 of 29

User Manual

FIGURE 4: MINI-REEL

Controller Connection

Refer to controller user manual for setup instruction and operation details.

MaggHD™

Document: UMAU015088.docm

Revision: A08

Created by: KJB

Date: 26 Sep 2019

3080885-A08

Source Location: C:\ePDM\ISLEng\products\au-micromag\manuals\UMAU015088.docm

Page 15 of 29

User Manual

Configuration

Camera Mounting

The MaggHD™ camera can be mounted in a standard configuration or can be removed from the vehicle

and mounted on an accessory pole. The camera can also be mounted in an alternate orientation option.

Standard Mounting

To install the camera onto the vehicle, do the following (removal is the reverse of installation):

1. Make sure the starboard axle screw is fully disengaged (tip should be slightly recessed in round

housing).

2. Slide the camera between the chassis fairings, make sure the connector is oriented as shown

and the washer is located with the locking nut on the outside of the fairing (see below).

3. Making sure the connector stem is seated all the way down in the port fairing slot, tighten the axle

screw; make sure it cleanly enters the bronze bushing in the camera head.

4. Tighten the port side locking nut.

5. Connect the camera whip to the bulkhead connector.

FIGURE 5: STANDARD MOUNTING

MaggHD™

Document: UMAU015088.docm

Revision: A08

Created by: KJB

Date: 26 Sep 2019

3080885-A08

Source Location: C:\ePDM\ISLEng\products\au-micromag\manuals\UMAU015088.docm

Page 16 of 29

User Manual

Pole Mounting

Mounting the camera onto the optional inspection pole is nearly identical to the standard installation (see

below).

FIGURE 6: POLE MOUNTING

MaggHD™

Document: UMAU015088.docm

Revision: A08

Created by: KJB

Date: 26 Sep 2019

3080885-A08

Source Location: C:\ePDM\ISLEng\products\au-micromag\manuals\UMAU015088.docm

Page 17 of 29

User Manual

Alternate Mounting

Mounting the camera onto the optional mount is as follows (removal is the reverse of installation):

1. Remove one magnet cup M5x30 SHCS from each side of the vehicle as shown below.

2. Install the optional mount with 2x M5x30 SHCS and 4x M4x12 SHCS as shown.

3. Install the camera onto the mount, making sure to fully seat the connector stem into its mounting

slot and tighten the lock nut.

FIGURE 7: ALTERNATE MOUNTING

Operating MaggHD™ on Vertical or Inverted Surface

The MaggHD™ vehicle comes equipped with magnet cups to enable the vehicle to maneuver on a

vertical or inverted magnetically attractive surface. The magnet cups utilize rare earth permanent magnets

and cannot be disabled (or turned off).

The inspection surface must be carbon steel or alloy steel that has good magnetic properties. Most

structural steels are strongly magnetic. 300 series stainless steels and some other alloys are not. The

client may be able to identify their metal and look up its properties or test it with a magnet.

It is important to note that the magnet cups lose magnetic adhesion as they move away from the

attractive surface. The operator needs to pay attention to distance between the magnet cups and the

surface. If the magnets are too close to the surface, the Microtracs™ may not be able to overcome the

added friction for skid steering. If the magnets are too far away the vehicle may lose magnetic adhesion.

The distance from the magnet cups to the inspection surface can be adjusted by the operator by adding

or removing the magnet spacers. The thickness of the steel surface also affects the amount of magnetic

adhesion provided by the magnets.

MaggHD™

Document: UMAU015088.docm

Revision: A08

Created by: KJB

Date: 26 Sep 2019

3080885-A08

Source Location: C:\ePDM\ISLEng\products\au-micromag\manuals\UMAU015088.docm

Page 18 of 29

User Manual

Some considerations when determining magnet spacing:

• Thickness of stainless, plastic, or concrete cladding over the carbon steel surface

• Uneven surfaces such as large welds

• Thickness of magnetically attractive surface (0.20in minimum is ideal)

• Curvature of inspection surface

Magnet Spacing

The MaggHD™ vehicle comes with the tracks spaced down from the main chassis plate using four

groups of 8mm and 4.5mm spacers (two groups per track). The vehicle comes with a kit of spacers to

accommodate a wide range of track spacing.

Use the following mounting hardware depending on the track spacers used:

• When spacing the tracks between 6-12 mm (0.25-0.5 in), use M5x20 SHCS outboard and M5x25

SHCS inboard.

• For spacing less than 6 mm (0.25 in), use M5x14 SHCS outboard and M5x18 SHCS inboard.

• When spacing the tracks more than 12 mm (0.50 in), use M5x25 SHCS outboard and M5x30

SHCS inboard.

When remounting the tracks, make sure the whips are securely connected and the locking collars are

fully engaged. Be careful to not pinch the track whips, and route them upwards towards the top of the rear

crossbar.

FIGURE 8: MAGNET SPACING

MaggHD™

Document: UMAU015088.docm

Revision: A08

Created by: KJB

Date: 26 Sep 2019

3080885-A08

Source Location: C:\ePDM\ISLEng\products\au-micromag\manuals\UMAU015088.docm

Page 19 of 29

User Manual

Fall Arrest

IMPORTANT: A lifeline or fall arrest system should always be used when vehicle detachment

from the working surface threatens injury to personnel or damage to equipment. A fall arrest

system can be attached to the vehicle on either or both chassis handles.

Additionally, one of the handles may be relocated using the two mounting holes located behind

the camera.

FIGURE 9 - FALL ARREST

MaggHD™

Document: UMAU015088.docm

Revision: A08

Created by: KJB

Date: 26 Sep 2019

3080885-A08

Source Location: C:\ePDM\ISLEng\products\au-micromag\manuals\UMAU015088.docm

Page 20 of 29

User Manual

Operation

Tether Handling

The tether is one of the most important parts of the system. It feeds power and control signals to the

system and returns data to the controller. If the tether is damaged from improper use, poor handling or an

accident, the system may become inoperable. This could lead to significant downtime, loss of production,

and avoidable costly repairs. It is encouraged to stress the importance of the tether and its use to anyone

operating or maintaining the system. For maximum tether life and reliability, we recommend the following

tether handling tips.

• Do not step on the tether

• Do not drive over the tether

• Do not bend the tether beyond its minimum bend radius

• Do not kink the tether

• Do not snap load the tether

• Avoid loading the tether whenever possible

• Always use the cable grip strain relief if applicable to your system

• Regularly inspect the tether for damage

• Regularly clean the tether

Note:

Protecting the conductors inside the tether is critical to the life and operation of the tether.

Proper tether handling and care will result in extended tether life and system reliability.

Connector Handling

Connectors are an essential part of system reliability. They should be properly maintained and cared for

to ensure long life and reliability. It is recommended to follow these steps to help prevent damage and

increase the life of connectors.

• Always put the cap back on the tether bulkhead when the tether is disconnected

• Always inspect the end of the connector prior to engaging

• Never plug in a dirty or damaged connector

• Visually align key-ways or locating pins prior to engaging the connector

• Always fully engage or tighten the connector

• Secure locking collars finger tight

• Install dummy plugs on unused connectors

• Disconnect by pulling straight, not on an angle

• Do not pull on the cable to disengage the connector

IMPORTANT: Never “Hot Plug” any connector, this will result in internal damage to the

electronics. Power down the system prior to connecting the inspection system tether.

/