Page is loading ...

LAF 1000 valid for Serial NO 615 XXX--XXXX

LAF 1000M valid for Serial NO 845 XXX--XXX and for Serial NO 902 XXX--XXXX

0456 512 001 02--04--15

LAF 1000/ 1000M

DC

101103105107109111102021110025108024042106023061104022041100020040060001

Bruksanvisning

Brugsanvisning

Bruksanvisning

Käyttöohjeet

Instruction manual

Betriebsanweisung

Manuel d’instructions

Gebruiksaanwijzing

Instrucciones de uso

Istruzioni per l’uso

Manual de instruções

Ïäçãßåò ÷ñÞóåùò

-- 2 --

Rätt till ändring av specifikationer utan avisering förbehålles.

Ret til ændring af specifikationer uden varsel forbeholdes.

Rett til å endre spesifikasjoner uten varsel forbeholdes.

Oikeudet muutoksiin pidätetään.

Rights reserved to alter specifications without notice.

Änderungen vorbehalten.

Sous réserve de modifications sans avis préalable.

Recht op wijzigingen zonder voorafgaande mededeling voorbehouden.

Reservado el derecho de cambiar las especificaciones sin previo aviso.

Ci riserviamo il diritto di variare le specifiche senza preavviso.

Reservamo--nos o direito de alterar as especificações sem aviso prévio.

Äéáôçñåßôáé ôï äéêáßùìá ôñïðïðïßçóçò ðñïäéáãñáöþí ×ùñßò ðñïåéäïðïßçóç.

SVENSKA 3..............................................

DANSK 11................................................

NORSK 19................................................

SUOMI 27................................................

ENGLISH 35..............................................

DEUTSCH 44.............................................

FRANÇAIS 52.............................................

NEDERLANDS 60.........................................

ESPAÑOL 68..............................................

ITALIANO 76..............................................

PORTUGUÊS 84..........................................

ÅËËÇÍÉÊÁ 92.............................................

ENGLISH

-- 3 5 --

TOCe

1 DIRECTIVE 36........................................................

2SAFETY 37...........................................................

3 INTRODUCTION 39...................................................

3.1 Technical data 39............................................................

4 INSTALLATION 40....................................................

4.1 General 40..................................................................

4.2 Unpacking and erection 40....................................................

4.3 Mounting of the water protection cover 40.......................................

4.4 Connections 41..............................................................

4.5 PC board 42.................................................................

5 OPERATION 43.......................................................

5.1 Controls 43..................................................................

5.2 Start--up 43..................................................................

6 MAINTENANCE 43....................................................

6.1 Cleaning 43.................................................................

7 ORDERING OF SPARE PARTS 43......................................

DIAGRAM 100............................................................

LIST OF COMPONENTS 101...............................................

CONNECTION INSTRUCTION 102..........................................

SPARE PARTS LIST 105...................................................

-- 3 6 --

ba23d12e

1 DIRECTIVE

DECLARATION OF CONFORMITY

Esab Welding Equipment AB, S--695 81 Laxå, Sweden, gives its unreserved guaran-

tee that welding power source LAF 1000/ 1000M from serial number 615 / 845(M)

complies with standard EN 60974-- 1, in accordance with the requirements of direc -

tive (73/23/EEC) and addendum (93/68/EEC) and with standard EN 50199 in ac-

cordance with the requirements of directive (89/336/EEC) and addendum

(93/68/EEC).

-- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- -- --------

Anders Birgersson

Managing Director

Esab Welding Equipment AB

695 81 LAXÅ

SWEDEN Tel: + 46 584 81000 Fax: + 46 584 411924

Laxå 1999--01--07

GB

-- 3 7 --

ba23d12e

2SAFETY

In any arc welding or gouging operation, it is the responsibility of the user to observe certain safety rules

to ensure his personal safety and to protect those working near him. Read all safety articles relevant to

arc welding published by the WMA. Pay particular attention to any CAUTION or WARNING Notes in-

cluded in this manual. CAUTION indicates possible equipment damage. WARNING indicates possible

hazard to life.

1. Electrical

S Treat electricity with respect. Even the open circuit voltage of this equipment can be dangerous. Adjust-

ments to the torch or replacement of torch parts should be undertaken with the mains supply isolated from

the unit.

If damaged torch cables or torch components are found, the unit must be disconnected from the mains and

defective parts must be replaced using only Murex spare parts.

S Do not work on live circuits or cables. Disconnect the main power supply before checking the machine or

performing any maintenance operation.

S Be sure the case of the welding machine is properly connected to a good electrical earth.

S Have the wiring for the welding machine installed by a qualified electrician. All connections must be made

according to specifications in force and to general safety standards.

S Do not stand in water or on damp floors while using an arc welder or cutter. Do not use in the rain.

S Do not operate with worn or poorly connected cables. Inspect all cables frequently for insulation failure,

exposed wires and loose connections.

S Do not overload cables or continue to operate with overheating cables. Cables which are too small for the

current carried will overheat, causing rapid deterioration of the insulation.

S Pay attention that live parts of the torch do not touch any metal which is connected to the earth cable. Fix

an insulated hook to hang the torch on when it is not in use.

2. Ventilation

S Do not weld or cut on containers which have held combustible or flammable materials, or materials which

give off flammable or toxic vapours when heated, without proper cleaning.

S Locate the welding/cutting operation far enough from any vapour--type degreaser using trichlorethylene or

other chlorinated hydrocarbons as solvents. The ultraviolet light from the arc can decompose these va-

pours into toxic gases at a considerable distance from the arc, even though the concentration of the gases

is low enough to be undetectable by smell.

S Be sure to provide adequate ventilation for removal and dilution of fume and gases. Fume exhaust facilities

near the arc, or a ventilated helmet should be used when cutting in confined spaces or on toxic material.

3. Glare

S Never look at the arc without wearing eye protection.

Always use the proper protective clothing, filter glasses, and gloves. Be careful to avoid exposed skin

areas. Do not use cracked or defective helmets or shields.

S Never s trike an arc when there is someone near who is not protected from the strong light of the arc.

S Warn bystanders who are not aware of the dangers of ultraviolet light.

4. General

S Take care when lifting the unit.

S Ensure that cylinders are secured by chains.

S Locate the unit so that there is adequate air flow to the ventilation louvres.

S Always dress correctly to protect against glare, radiation and spatter.

5. Fire

S Ensure that the correct type of fire extinguisher is available in the welding area.

S Do not weld near flammable materials or liquids, in or near explosive atmospheres, or on pipes carrying

explosive gases.

6. Vehicle electrics

S When working on motor vehicles, remove the battery and any circuitry which may be damaged by the arc.

S Whilst welding be aware of the possibility of ’hidden wires’ behind panels or bulkheads.

The ON/OFF switch on this equipment does not isolate the unit from the mains electrical supply.

AC POWER IS PRESENT ON THE ON/OFF SWITCH TERMINALS.

The ON/OFF lamp is an indication that the supply is switched on and does not imply that the unit is isolated from the supply.

BEFORE REMOVING THE COVERS FOR MAINTENANCE, ISOLATE THE UNIT FROM THE MAINS ELECTRICAL

SUPPLY.

WARNING

GB

-- 3 8 --

ba23d12e

WARNING

READ AND UNDERSTAND THE INSTRUCTION MANUAL BEFORE INSTALLING OR OPERAT ING.

ARC WELDING AND CUTTING CAN BE INJURIOUS TO YOURSELF AND OTHERS. TAKE PRECAU-

TIONS WHEN WELDING. ASK FOR YOUR EMPLOYER’S SAFETY PRACTICES WHICH SHOULD BE

BASED ON MANUFACTURERS’ HAZARD DATA.

ELECTRIC SHOCK -- Can kill

S Install and earth the welding unit in accordance with applicable standards.

S Do not touch live electrical parts or electrodes with bare skin, wet gloves or wet clothing.

S Insulate yourself from earth and the workpiece.

S Ensure your working stance is safe.

FUMES AND GASES -- Can be dangerous to health

S Keep your head out of the fumes.

S Use ventilation, extraction at the arc, or both, to keep fumes and gases from your breathing zone and

the general area.

ARC RAYS -- Can injure eyes and burn skin.

S Protect your eyes and body. Use the correct welding screen and filter lens and wear protective

clothing.

S Protect bystanders with suitable screens or curtains.

FIRE HAZARD

S Sparks (spatter) can cause fire. Make sure therefore that there are no inflammable materials nearby.

NOISE -- Excessive noise can damage hearing

S Protect your ears. Use ear defenders or other hearing protection.

S Warn bystanders of the risk.

MALFUNCTION -- Call for expert assistance in the event of malfunction.

PROTECT YOURSELF AND OTHERS!

WARNING

This product is intended for industrial use. In a domestic environment this prod -

uct may cause radio interference. It is the users responsibility to take adequate

precautions.

This welding equipment has been designed, manufactured and tested to the highest standards to ensure long

and trouble free life. However, regular maintenance is an essential part of keeping the machine operating in a

reliable and safe manner and your attention is drawn to any maintenance instructions that are contained in this

manual.

In general all welding equipment should be thoroughly inspected, tested and serviced at least annually. More

frequent checking will be required when the equipment is heavily used.

Wear and tear, particularly in electro-- mechanical and moving components, are gradual processes. Caught in

time, repair costs are small and the benefits in performance reliability and safety are significant. Left alone they

can put the equipment, and you, at risk.

Have this equipment regularly inspected and maintained by an approved service centre.

WARNING

GB

-- 3 9 --

ba23d12e

3 INTRODUCTION

LAF 1000/ 1000M are r emote--controlled 3--phase welding power sources designed

for high--efficiency mechanical gas metal arc welding (MIG/MAG) or sub arc welding

(SAW). It is always to be used in combination with ESAB‘s control box

A2--A6 Process Controller (PEH).

LAF is fan--cooled and monitored by a thermal overload protection. When the protec-

tion enters into action a yellow indicating lamp on the front panel goes on and is

reset automatically as soon as the temperature has gone down to an acceptable

level.

The welding power sources and the control unit are linked together over a 2--wire

bus enabling precision control of the welding process.

All welding parameter settings for the power source can be made by the operator on

the front panel of the control unit. The operation of the power source is completely

controlled and monitored by this unit. Even the start and stop qualities can be set by

way of the control unit. The preset welding current parameters can also be moni-

tored in the course of welding.

For more detailed information regarding the settings and the working mode of the

welding power source, please refer to the A2--A6 Process Controller (PEH) instruc-

tion manual.

3.1 Technical data

LAF 1000 LAF 1000M

Voltage 400/415/500 V, 3µ50 Hz

400/440/550 V, 3µ60 Hz

230/400/415/500 V, 3µ50 Hz

230/400/440/550 V, 3µ60 Hz

Permissible load at:

100 % duty cycle

60 % duty cycle

800 A/44 V

1000 A/44 V

800 A/44 V

1000 A/44 V

Setting range

MIG/MAG

SAW

50 A/17 V -- 1000 A/45 V

40 A/22 V -- 1000 A/45 V

50 A/17 V -- 1000 A/45 V

40 A/22 V -- 1000 A/45 V

No--load voltage 52 V 52 V

No--load power 145 W 145 W

Effiency 0,84 0,84

Power factor 0,95 0,95

Weight 330 kg 330 kg

Dimensions L x W x H 646 x 552 x 1090 646 x 552 x 1090

Class of enclosure IP 23 IP 23

DP, (CSA) drip proof is valid with water

protection cover, No. 458 186--001

Class of application

Enclosure class

The IP code indicates the enclosure class, i. e. the degree of protection against penetration by solid

objects or water . Equipment marked IP 23 is designed for indoor and outdoor use.

Application class

The symbol indicates that the power source is designed for use in areas with increased

electrical hazard.

GB

-- 4 0 --

ba23d12e

4 INSTALLATION

4.1 General

The installation shall be executed by a profession al.

4.2 Unpacking and erection

WARNING -- TIPPING RISK!

Fasten the equipment -- particularly if the ground is uneven or slanting.

S Place the welding power source on a level foundation.

S Make sure there is nothing to prevent the cooling.

Lifting instructions

4.3 Mounting of the water protection cover

To obtain the stated protection against water, Drip Proof, the water protection cover

shall be mounted.

Mount the water protection cover before use.

GB

-- 4 1 --

ba23d12e

4.4 Connections

S On delivery the welding power source is con-

nected for 400 V. For other supply voltage, switch

over to the desired voltage on the main trans-

former and the control transformer according to

the connection instructions on page 102.

S Make sure the mains cable has the right sectional

area and fuse it with an adequate fuse according

to applicable local directions (see table on page

41).

S Connect the earth cable to the screw marked .

S Tighten the cable support (1).

S Connect the mains cable to the main terminal

blocks L1, L2 and L3.

S Connect the control cable between the LAF

welding power source and the control unit to

the 12--pole contact (2) inside the welding

power source.

S Connect 1 pin socket measure cable (4).

S Connect a suitable welding and return cable to the contacts (3) m arked + and --

on the front of the power source.

Mains connectio n

LAF 1000

50 Hz 60 Hz

Voltage V 400 415 500 400 440 550

Current A

100%

60%

64

80

64

80

52

65

64

80

64

80

52

65

Cableareamm

2

4x16 4x16 4x16 4x16 4x16 4x16

Fuse, slow A 63 63 63 63 63 63

LAF 1000M 50 Hz 60 Hz

Voltage V 230 400 415 500 230 400 440 550

Current A

100%

60%

111

138

64

80

64

80

52

65

111

138

64

80

64

80

52

65

Cableareamm

2

4x50 4x16 4x16 4x16 4x50 4x16 4x16 4x16

Fuse, slow A 125 63 63 63 125 63 63 63

GB

1

2

3

4

-- 4 2 --

ba23d12e

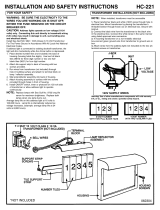

4.5 PC board

DIP switches

The PC board (AP1) has two DIP switches (SW1 and SW2) which are preset on de-

livery. The settings are not to be changed.

When spare parts are supplied the settings of the DIP switches must be checked

(and set, if necessary) before fitting the PC board into the welding power source.

S DIP switch SW1

To make the communication with the

A2--A6 Process Controller (PEH) work

DIP switch 1 (SW1) must be set.

S DIP switch SW2

DIP switch 2 (SW2) must be set in order to

inform the A2--A6 process controller (PEH)

about the rating of the power source that is

connected.

Setting of DIP switch SW1

S Set pole 6 to “ OF F “ position and all other

poles to “ON“.

Setting of DIP switch SW2

S Set pole 3 to “ OF F “ position and all other

poles to “ON“.

Welding power source program

The welding power source program is stored in the

flash memory

IC 6. The capsule is fitted in a holder and is replace-

able.

GB

-- 4 3 --

ba23d12e

5OPERATION

5.1 Controls

The front panel contains:

1. Main switch, breaking the incoming mains

voltage for the welding power source.

2. Indicating lamp (white), showing that the main

switch is activated.

3. Indicating lamp (yellow), showing that the

thermal protection has entered into action due to

overheating in the transformer. The lamp is reset

when the temperature has gone down to an

acceptable level.

4. Pushbutton, for the resetting of automatic fuse F U1 for 42 V supply voltage.

5. Emergency pushbutton. When the button is activated the main contactor in the

power source trips and the supply voltage for the control box is broken. (The

emergency button on the control unit has the same function).

5.2 Start--up

S Connect the return cable to the work piece.

S Set the main switch (1) to position “I“.

The white indicating lamp (2) goes on and the fan starts.

S Set the welding parameters and start welding by way of the control box

(see the A2--A6 Process Controller 0443 745 XXX instruction manual).

6 MAINTENANCE

6.1 Cleaning

S Clean the welding power source as necessary.

Dry compressed air is recommended for the purpose.

WARNING!

Blocked air inlets or outlets will lead to overheating.

7 ORDERING OF SPARE PARTS

Spare parts are ordered through your nearest ESAB representative, see back cover.

When ordering spare parts, please state machine type and number as well as desig-

nation and spare part number as shown in the spare parts list on page 105.

This will simplify dispatch and ensure you get th e right part.

GB

ESAB Welding Equipment AB

SE--695 81 LAXÅ

SWEDEN

Phone +46 584 81 000

Fax + 46 584 123 08

www.esab.com

001004

ESAB subsidiaries and representative offices

Europe

AUSTRIA

ESAB Ges.m.b.H

Vienna--Liesing

Tel: +43 1 888 25 11

Fax: +43 1 888 25 11 85

BELGIUM

S.A. ESAB N.V.

Brussels

Tel: +32 2 745 11 00

Fax: +32 2 726 80 05

THE CZECH REPUBLIC

ESAB V AMBERK s.r.o.

Prague

Tel: +420 2 819 40 885

Fax: +420 2 819 40 120

DENMARK

Aktieselskabet ESAB

Copenhagen--Valby

Tel:+4536300111

Fax:+4536304003

FINLAND

ESAB Oy

Helsinki

Tel: +358 9 547 761

Fax: +358 9 547 77 71

FRANCE

ESAB France S.A.

Cergy Pontoise

Tel:+33130755500

Fax:+33130755524

GERMANY

ESAB GmbH

Solingen

Tel: +49 212 298 0

Fax: +49 212 298 204

GREAT BRITAIN

ESAB Group (UK) Ltd

Waltham Cross

Tel: +44 1992 76 85 15

Fax: +44 1992 71 58 03

ESAB Automation Ltd

Andover

Tel: +44 1264 33 22 33

Fax: +44 1264 33 20 74

HUNGARY

ESAB Kft

Budapest

Tel:+3612044182

Fax:+3612044186

ITALY

ESAB Saldatura S.p.A.

Mesero (Mi)

Tel:+3902979681

Fax:+390297289181

THE NE THERLANDS

ESAB Nederland B.V.

Utrecht

Tel: +31 30 248 59 22

Fax: +31 30 248 52 60

NORWAY

AS ESAB

Larvik

Tel:+4733121000

Fax:+4733115203

POLAND

ESAB Sp.z.o.o

Warszaw

Tel: +48 22 813 99 63

Fax: +48 22 813 98 81

PORTUGAL

ESAB Lda

Lisbon

Tel: +351 1 837 1527

Fax: +351 1 859 1277

SLOVAKIA

ESAB Slovakia s.r.o.

Bratislava

Tel:+421744882426

Fax:+421744888741

SPAIN

ESAB Ibérica S.A.

Alcobendas (Madrid)

Tel: +34 91 623 11 00

Fax: +34 91 661 51 83

SWEDEN

ESAB Sverige AB

Gothenburg

Tel:+4631509500

Fax:+4631509222

ESAB International AB

Gothenburg

Tel:+4631509000

Fax:+4631509360

SWITZERLAND

ESAB AG

Dietikon

Tel: +41 1 741 25 25

Fax: +41 1 740 30 55

North and South America

ARGENTINA

CONARCO

Buenos Aires

Tel: +54 11 4 753 4039

Fax: +54 11 4 753 6313

BRAZIL

ESAB S.A.

Contagem--MG

Tel: +55 31 333 43 33

Fax: +55 31 361 31 51

CANADA

ESAB Group Canada Inc.

Missisauga, Ontario

Tel: +1 905 670 02 20

Fax: +1 905 670 48 79

MEXICO

ESAB Mexico S.A.

Monterrey

Tel: +52 8 350 5959

Fax: +52 8 350 7554

USA

ESAB Welding & Cutting Products

Florence, SC

Tel: +1 843 669 44 11

Fax: +1 843 664 44 58

Asia/Pacific

AUSTRALIA

ESAB Australia Pty Ltd

Ermington

Tel: +61 2 9647 1232

Fax: +61 2 9748 1685

CHINA

Shanghai ESAB A/P

Shanghai

Tel: +86 21 6539 7124

Fax: +86 21 6543 6622

INDIA

ESAB India Ltd

Calcutta

Tel: +91 33 478 45 17

Fax: +91 33 468 18 80

INDONESIA

P.T. Esabindo Pratama

Jakarta

Tel: +62 21 460 01 88

Fax: +62 21 461 29 29

MALAYSIA

ESAB (Malaysia) Snd Bhd

Selangor

Tel: +60 3 703 36 15

Fax: +60 3 703 35 52

SINGAPORE

ESAB Singapore Pte Ltd

Singapore

Tel: +65 861 43 22

Fax: +65 861 31 95

ESAB Asia/Pacific Pte Ltd

Singapore

Tel: +65 861 74 42

Fax: +65 863 08 39

SOUTH KOREA

ESAB SeAH Corporation

Kyung --Nam

Tel: +82 551 289 81 11

Fax: +82 551 289 88 63

THAILAND

ESAB (Thailand) Ltd

Samutprakarn

Tel: +66 2 393 60 62

Fax: +66 2 748 71 11

UNITED ARAB EMIRATES

ESAB Middle East

Dubai

Tel: +971 4 338 88 29

Fax: +971 4 338 87 29

Representative offices

BULGARIA

ESAB Representative Office

Sofia

Tel/Fax: +359 2 974 42 88

EGYPT

ESAB Egypt

Dokki--Cairo

Tel: +20 2 390 96 69

Fax: +20 2 393 32 13

ROMANIA

ESAB Representative Office

Bucharest

Tel/Fax: +40 1 322 36 74

RUSSIA--CIS

ESAB Representative Office

Moscow

Tel: +7 095 937 98 20

Fax: +7 095 937 95 80

ESAB Representative Office

St Petersburg

Tel: +7 812 325 43 62

Fax: +7 812 325 66 85

Distributors

For addresses and phone

numbers to our distributors in

other countries, please visit our

home page

www.esab.com

/