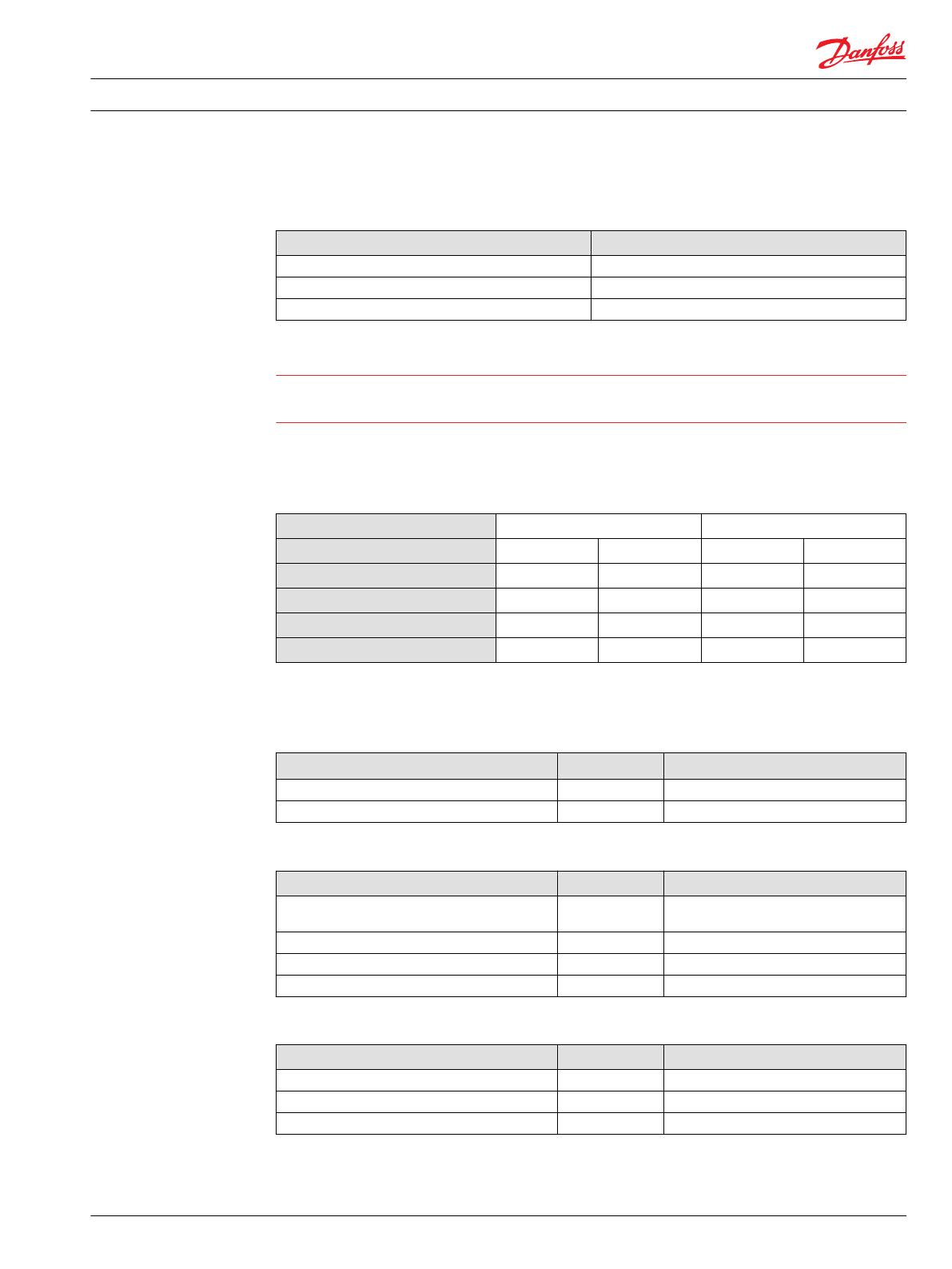

Pin compatibility

PLUS+1

®

module pin type

Pin Function

1, 4, A, D PWMOUT/DOUT/PVG Power supply

1, 4, A, D PWMOUT/DOUT/PVGOUT

2, 3, B, C Power ground -

Warning

Unintended vehicle or machine movement hazard. Verify the wiring harness to ensure the correct PLUS

+1

®

pin is properly connected to each control pin.

Input/output matrix

Pump output flow direction versus control signal

Shaft rotation

CW CCW

Positive current to terminal

A, C, 1, 3 B, D, 2, 4 A, C, 1, 3 B, D, 2, 4

Port A flow

Out In In Out

Port B flow

In Out Out In

High pressure servo gauge port

M4 M5 M4 M5

High pressure EDC pilot gauge

X2 X1 X2 X1

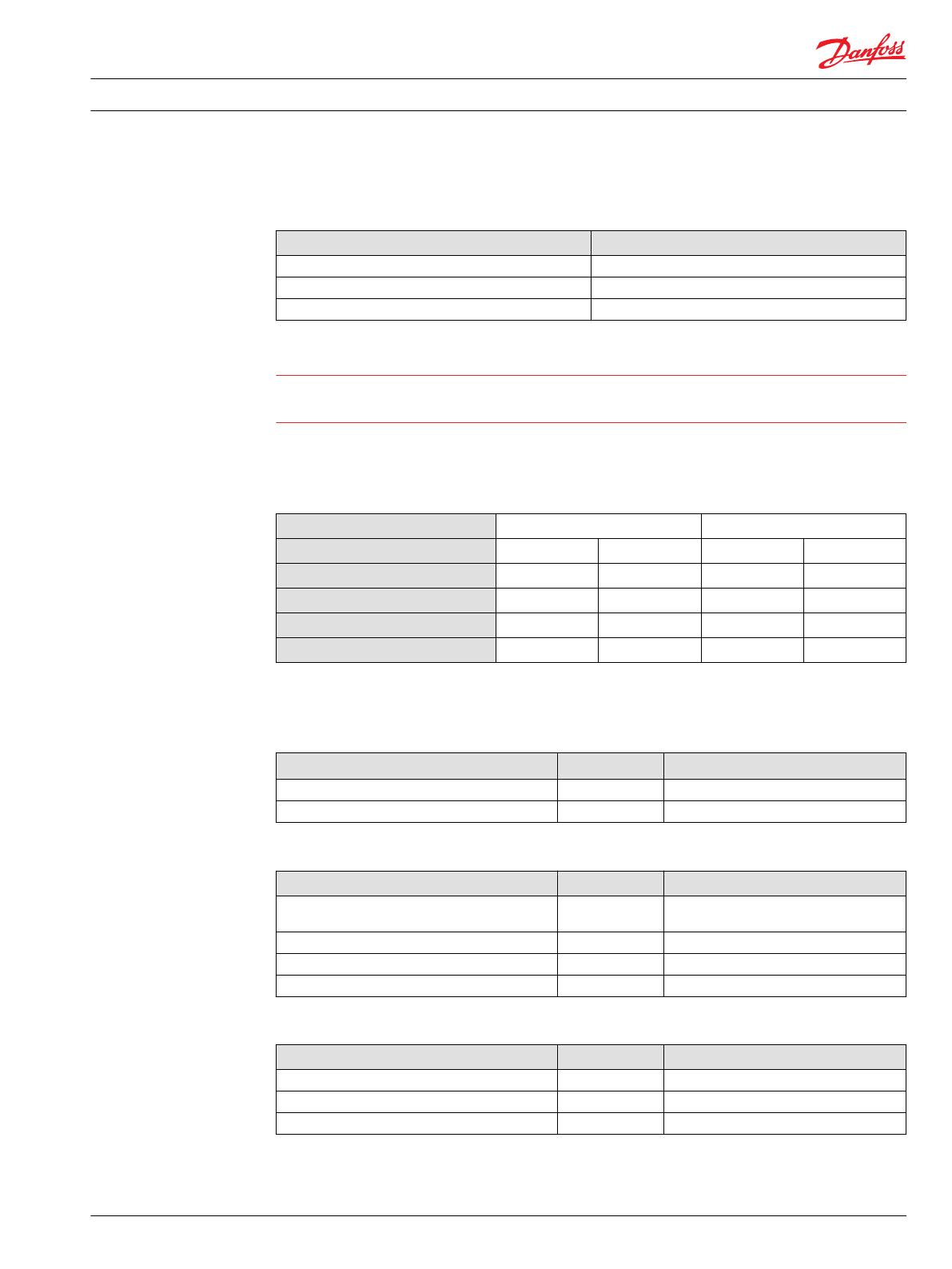

Mating connector

MS connector parts list

Description Quantity Ordering number

MS connector 1 SG3108E-14S-2S-SR

Mating connector kit 1 Danfoss K08106

Packard Weather-Pack connector parts list

Description Quantity Ordering number

4 way black Weather-Pack tower sealed female

connector assembly

1 12015797

Female terminals (18 to 20 AWG) 4 15408312

Cable seals (2.03 to 2.85 mm cable diameter) 4 12015323

Mating connector kit 1 Danfoss K03384

DEUTSCH connector parts list

Description Quantity Ordering number

4 way gray connector assembly 1 DEUTSCH DT06-4S-E003

Female nickel-plated terminals (16 to 18 AWG) 4 DEUTSCH 0462-201-16141

Mating connector kit 1 Danfoss K23511

Electrical Installation S42 EDC

Electrical installation

L1022027 • Rev CA • September 2015 9