Omega DOH-10-Series_DO_Meter Owner's manual

- Category

- Measuring, testing & control

- Type

- Owner's manual

This manual is also suitable for

Omega DOH-10-Series_DO_Meter is a professional-looking portable meter with a large LCD display. It is designed with a BNC connector compatible with any DO galvanic electrode. The meter has a hold function, power capacity icon indicator, and automatic power-off in 15 minutes (which can be disabled). It also includes an RFS (Recover to Factory Setting) function. With built-in different temperature compensation selectable (Thermistor 30K, 10K ohm, and manual 25.

Omega DOH-10-Series_DO_Meter is a professional-looking portable meter with a large LCD display. It is designed with a BNC connector compatible with any DO galvanic electrode. The meter has a hold function, power capacity icon indicator, and automatic power-off in 15 minutes (which can be disabled). It also includes an RFS (Recover to Factory Setting) function. With built-in different temperature compensation selectable (Thermistor 30K, 10K ohm, and manual 25.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

Omega DOH-10-Series_DO_Meter Owner's manual

- Category

- Measuring, testing & control

- Type

- Owner's manual

- This manual is also suitable for

Omega DOH-10-Series_DO_Meter is a professional-looking portable meter with a large LCD display. It is designed with a BNC connector compatible with any DO galvanic electrode. The meter has a hold function, power capacity icon indicator, and automatic power-off in 15 minutes (which can be disabled). It also includes an RFS (Recover to Factory Setting) function. With built-in different temperature compensation selectable (Thermistor 30K, 10K ohm, and manual 25.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

Other documents

-

Bante Instruments 810 Benchtop Dissolved Oxygen Meter Owner's manual

Bante Instruments 810 Benchtop Dissolved Oxygen Meter Owner's manual

-

Apera Instruments SX716 User manual

-

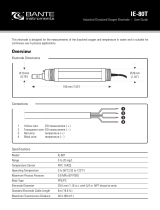

Bante Instruments IE-80T Industrial Dissolved Oxygen Electrode Owner's manual

Bante Instruments IE-80T Industrial Dissolved Oxygen Electrode Owner's manual

-

BANTE 820 User manual

-

Bante Instruments DOscan10 Pocket Dissolved Oxygen Tester Owner's manual

Bante Instruments DOscan10 Pocket Dissolved Oxygen Tester Owner's manual

-

CMA BT78i User guide

-

CMA ML66m User guide

-

Aquasol Digital AM-DO-01 User manual

Aquasol Digital AM-DO-01 User manual

-

FlePow 8541833494 User guide

-

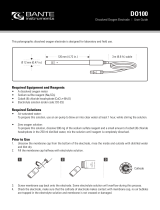

Bante Instruments Dissolved Oxygen Electrode Owner's manual

Bante Instruments Dissolved Oxygen Electrode Owner's manual