Page is loading ...

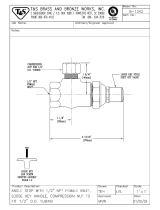

SERIES TBS

INSERTION TURBINE

INSTRUcTIONS

TBS-1XX

TBS-0XX

F-TBS

Rotor

Rugged cast aluminum housing

18 Foot Cable

Modular electronics (optional)

•rate/total/pulse/4-20mA

(Series RTI)

•blind4-20transmitter

(SeriesBAT)

Compression nut

for easy adjustment, secure locking

Adaptertting

with1-1/2”NPTthreads

Rotor housing

Removable jewel bearings

TBS-0XX

Adaptertting

with2”NPTthreads

Full-port2”ballvalve

for sensor removal

2”Adapter

removes to mount

hot-tapmachine

3/4”diametertubing

for low insertion force

TBS-1XX

Locking collar

TABLE OF CONTENTS

General Information

Features,Specications .......................................................................................................................................Page 1

Installation

Piping,Immersion,PositioningtheMeter ........................................................................................................... Page 2

StraightPipeRecommendations .........................................................................................................................

Page 3

FullPipeRecommendations ................................................................................................................................. Page 4

Fitting Installation, Meter Installation .................................................................................................................. Page 5

ProperDepthSetting,DimensionC,PipeWallThickness ..................................................................................Page 6

Set-Up

Connection,Calibration,K-Factors ......................................................................................................................Page 7

Operation

Flow Range, Flow Rates ........................................................................................................................................Page 8

Parts List

PartsExplodedView..............................................................................................................................................Page 9

Troubleshooting & Repair

Troubleshooting, Repair, Rotor Replacement ......................................................................................................... Back

TABLES AND DIAGRAMS

Features ................................................................................................................................................................ Page 1

Specifications ....................................................................................................................................................... Page 1

PositioningtheMeter ........................................................................................................................................... Page 2

Piping .................................................................................................................................................................... Page 2

StraightPipeRecommendations ........................................................................................................................

Page 3

FullPipeRecommendations ................................................................................................................................ Page 4

Meter Installation ................................................................................................................................................. Page 5

DepthSetting ....................................................................................................................................................... Page 6

PipeWallThickness ............................................................................................................................................. Page 6

ConnectionDiagram ............................................................................................................................................ Page 7

PartsExplodedView............................................................................................................................................. Page 9

PartsList ............................................................................................................................................................... Page 9

Rotor Replacement ..................................................................................................................................................Back

Page 1

GENERAL INFORMATION

The Series TBS is an adjustable depth insertion turbine that

comesinbrassor316stainlessmodelstot3”to40”pipe.

Installationttingsarestandard1-1/2"(TBS-XSXModels)or

2”(TBS-XLXModels)maleNPT.Fittingssuchassaddlesand

weldoletsmaybepurchasedeitherlocallyorfromDwyerInstru-

mentsInc.PleaseseeSeriesSDF.

Rubybearingsandanon-dragpickoffgivetheseadjustable

insertionturbineowsensorsawideowrangeandlonglife.

Asensordetectsthepassageofminiaturemagnetsinthero-

torblades.Theresultingsquare-wavesignalcanbesentfor

hundreds of feet without a transmitter, over unshielded cable.

ThissignalcanbeconnecteddirectlytomanyPLC’sandother

controls without any additional electronics.

If desired, a modular system of electronics can be installed

directlyontheowsensorormountedremotely.TheSeries

RTI (loop powered) provides digital rate and total display, as

well as programmable pulse. The Series RTI also provides a

4to20mAanalogoutput.TheBATisablindanalog(4to20

mA) transmitter. Programmablepulse for pumppacing is

availablewiththePWD.

The“hot-tap”modelscanbeinstalledorservicedwithoutshut-

tingdownthelinebymeansofa2”full-portisolationvalve

thatcomeswithanippleforinstallationonthepipetting.In

most circumstances, no special tool is required.

FEATURES

SPECIFICATIONS*

6-40Vdc

<2mA

Magnetoresistive

CurrentSinkingPulse

100mAmax

3to40Vdc

-S Model -L Model

3”-12”(50-300mm) 12”-40”(300-890mm)

Cast aluminum

Brass or 316 SS

PVDFstandard

Nickel-boundtungstencarbide/Ruby

TBS-0 TBS-1

None Bronze(316SSoptional)

1-1/2”NPT 2”NPT

0.5-30feet/sec(0.15-9.14meter/sec)

+/-1.5%offull-scale

200˚F(93˚C)

200psi(14bar)

0.44xpressureinpipe

#22AWG3-con,18’(6m);2,000’(650m)maximumcablerun

Power

Supply Voltage

Current

Sensor Type

Output

Sinking Current

External Pull-up Resistor

Pipe Size

Materials Housing

Sensor Body

Rotor

Shaft/Bearings

Isolation Valve

Fitting Size

Flow Range

Accuracy

Maximum Temperature

Maximum Pressure

Insertion Force

Cable

*Specications subject to change.

Note:ForlargerpipesizescontactDwyer

INSTALLATION

Page 2 Page 3

INSTALLATION

STRAIGHT PIPE RECOMMENDATIONS

(X = diameter)

5X

10X

5X10X

5X

20X

5X

20X

30X

50X

Reduced Pipe

Two Elbows In Plane

Two Elbows, Out Of Plane

Expanded Pipe

Swirling Flow

Propeller Meter

Partially Open

Buttery Valve

Spiral Flow

Fair (unacceptable if air is

present)

Fair (unacceptable if uid

contains sediment)

Best

mayexperienceoccasional temporary immersion, as in a

oodedvault,aunitmodiedforimmersionshouldbespeci-

ed(Option-IMM).

Aninsertionowsensormeasuresthevelocityofowatone

pointinthepipe;owrateandtotalcanbeinferredfromthis

onepoint.Accuracyisdecreasedbyanyfactorwhichmakes

theowatthemeasuredpointunrepresentativeoftheentire

owstream. Thisincludes distortedowpatternscaused

byupstreamttingstooclosetothesensor.Theworstof-

fendersarettingsthatincreasetheowononesideofthe

pipe,suchaspartially-openedgateorbutteryvalves.Fluid

movinginapipedoesnotowatthesamevelocity.Toward

thecenterofthepipe,uidmovesfasterthanatthewall,and

therelationshipbetweenthetwochangesasoverallowrate

increases.Thischangeinthe“velocityprole”canresultin

non-linearity,whichmeansthattheK-factorthatiscorrectfor

oneowratemaybeincorrectforanother.Recommended

depth settings (see page 6) have been carefully chosen to

minimizethissourceoferror,andshouldbefollowedcarefully,

especiallyinthesmallerpipesizes.

Piping. For best results, the TBS sensor should be

installed with at least ten diameters of straight pipe

upstreamandvedownstream.Certainextremesituations

suchaspartially-openedvalvesareparticularlydifcultand

may require more straight diameters upstream. See Straight

PipeandFullPiperecommendationsonfollowingpages.

Immersion. The Series TBS standard sensors are not de-

signed for continuous underwater operation. If your meter

Positioning the Meter. Horizontal is thepreferredinstal-

lation orientation, since it improveslow-ow performance

slightly and avoids problems with trapped air. Bottom, top,

and vertical pipe installations are all acceptable if required

by the piping layout.

CAUTION: These water meters are

not recommended for installation

downstream of the boiler feedwater

pump where installation fault may

expose the meter to boiler pressure

and temperature. Maximum recom-

mended temperature is 200ºF.

TBS

TBS

TBS

TBS

TBS

TBS

Page 4

INSTALLATIONINSTALLATION

FULL PIPE RECOMMENDATIONS

Allowsairpocketstoformatsensor

Ensuresfullpipe

Post-valvecavitationcancreateairpocket Keeps pipe full at sensor

Aircanbetrapped

Allowsairtobleedoff

Page 5

Better InstallationPossible Problem

Better InstallationPossible Problem

Better InstallationPossible Problem

TBS-0XX INSTALLATION

Fitting Installation.TBS-0XXsensorscomewitha1-1/2”maleNPTpipe

threadadaptertting.AnyttingthatprovidesthematchingNPTfemale

threadmaybeused.(ForcomparablesaddlettingpleaseseeSeries

SDF.)Installationprocedurecompensatesforttingheightdifferences.

Cutaminimum1-3/4”holeinthepipe.Ifpossible,measurethewall

thickness and write it down for use in depth setting. Then install the

threadedtting(saddle,weldolet,etc.)onthepipe.

Meter Installation. Loosen the compression nut so that the adapter slides

freely.Pullthemeterfullyupwardandnger-tightenthecompression

nut.Usingathreadsealant,installtheadapterinthepipetting.Do

not overtighten. Loosen the compression nut and lower the meter to

the appropriate depth setting (see diagram and instructions that follow).

Caution:Donotallowthemetertofallintothepipeuncontrolled,asthis

maydamagethemeter.Besureowisinthedirectionofthearrowon

the housing. Tighten compression nut fully.

TBS-1XX INSTALLATION

‘Hot-tap’meters are designed to be installed and serviced without

depressurizingthepipe.

Fitting Installation. Thehot-tapsensorshavea2”maleNPTthreadfor

compatibilitywiththe2”isolationvalve.Anyttingthatprovidesmatching

NPTfemalethreadmaybeused.Theinstallationprocedurecompensates

fordifferencesinttingheight.

If initial installationis performedon anunpressurizedpipe, cuta

minimum1-3/4”holeinthepipe.Ifpossible,measurethewallthickness

andwriteitdownforuseindepthsetting.Theninstallthethreadedtting

(saddle,weldolet,etc.)onthepipe.(SuchastheSeriesSDF.)

If it is necessary to do the initial installation under pressure, any standard

hot-tapdrillingmachinewith2”NPTadapter,suchasaTransmateora

Mueller,canbeused.Ordinarily,itisnotnecessarytouseaninstallation

tool,sincethesmall-diametertubecanbecontrolledbyhandbutshould

be used for higher pressures.

Meter Installation. Remove the sensor unit from the valve assembly.

Usingathreadsealant,installthevalveassemblyonthepipetting.If

theinitialinstallationisapressure(“hot-tap"),removethe1-1/2”x2”

adapter bushing at the back of the valve. Thread the tapping machine

on,openthevalve,andtapusingaminimumof1-3/4”ormaximum

1-7/8”cutter.Afterretractingthemachineandclosingthevalve,reinstall

theowsensor.Whenthesensorissecure,openthevalveandadjust

depthsetting(seediagramandinstructionsthatfollow).Besureowis

in the direction of the arrow on the housing. Tighten locking collar and

compression nut fully.

Compression nut

Adaptertting

with

standard1-1/2"

NPTthreads

Compression nut

2”adapterremoves

tomounthot-tap

machine

Full-port2”ball

valve allows sensor

removal

Standard2”

NPTthreads

TBS-1XX Sensor

Removal

Locking collar

TBS-0XX

Proper Depth Setting. It is important for accuracy that

the sensor be inserted to the correct depth into the pipe.

1.InTable1,ndDimensionCforyoursensormodel

andpipesize.Subtractwallthicknessofyourpipe

(Table2)tocalculateDimensionD.

2. Measuringfromtheoutsideofthepipetothejoint

in the housing, as shown in the diagram on the left,

adjustthesensortoDimensionDandhand-tighten

compression nut.

3. Aligntheconduithousingwiththecenterlineofthe

pipe, as shown. Be sure the arrow on the housing

pointsinthedirectionofow.

4. CheckDimensionDonemoretime.

5. Tightenthecompressionnutfully.

strain

relief

FLOW

Page 6

INSTALLATION

Page 7

TABLE 2: PIPE WALL THICKNESS

PVC/Steel

Sch. 40

PVC/Steel

Sch. 80

Stainless

Steel (10S)

Stainless

Steel (40S)

Copper Tubing

(Type L)

Copper Tubing

(Type K)

Brass Pipe

Duct. Iron

(Class 52)

NOMINAL PIPE SIZE

3” 4” 6” 8” 10” 12” 14” 16” 18” 20” 24” 30” 36”

0.216 0.237 0.280 0.322 0.365 0.406 0.438 0.500 0.562 0.593 0.687

0.300 0.337 0.432 0.500 0.593 0.687 0.750 0.843 0.937 1.031 1.218

0.120 0.120 0.134 0.148 0.165 0.180 0.188 0.188 0.188 0.218 0.250 0.312 0.312

0.216 0.237 0.280 0.322 0.365 0.375 0.375 0.375 0.375 0.375 0.375 0.375 0.375

0.090 0.110 0.140 0.200 0.250 0.280

0.109 0.134 0.192 0.271 0.338 0.405

0.219 0.250 0.250 0.312 0.365 0.375

0.280 0.290 0.310 0.330 0.350 0.370 0.390 0.400 0.410 0.420 0.440 0.470 0.530

SET-UP

Connection. Sensors are supplied with 18 ft. of cable.

For sensors with no additional electronics, see diagram for

colorcoding.Forsensorswithon-boardelectronics,see

the manual accompanying the electronics module.

Calibration (“K-Factor”). In order to properly process pulses

fromtheowsensor,anumbermustbeenteredintothecontrol

towhichthesensorisconnected.Thisnumber,calledtheK-

factor, is the number of pulses the sensor puts out per unit of

uidpassingthroughthepipe.ItisnormallyprovidedforDwyer

sensors in pulses per gallon (see Table 3 below). These numbers

arebasedonextensivetesting,whichhasshowncloseagree-

ment between different TBS sensors in the same installation.

MostK-factorerrorcanbeattributedtoinstallationvariables,

suchasdepthsettingandttingconguration.

Itispossibletoeldcalibrateasensorbycatchingtheuidina

measured container and comparing with the number of pulses

recorded.(Torecordindividualpulses,settheK-factoronthe

controlto1.00.)Thisisespeciallydesirableiftheinstallation

has less than the recommended length of straight pipe up-

streamofthesensor.Fordetailedintructionsoneldcalibration,

pleasecontactDwyerInstrumentsInc.

RECORD YOUR SETTINGS

Onceyouhavethemetersetupandoperational,it

is important to record your meter setttings and save

them for future reference.

K-Factor

InsertionDepth(Dim.D)

NOMINAL PIPE SIZE

3” 4” 6” 8” 10” 12” 14” 16” 18” 20” 24” 30” 36”

9.16 9.08 8.99 8.82 8.48 8.14 7.80 7.46 6.78 - - - -

14.16 14.08 13.99 13.82 13.48 13.14 12.80 12.46 11.78 10.42 9.40 9.38 -

16.00 15.80 15.70 15.50 15.10 14.80 14.50 13.80 - - - - -

19.95 19.85 19.65 19.45 19.15 18.85 18.45 17.75 16.45 15.45 14.35 - -

TBS-0-S

TBS-0-L

TBS-1-S

TBS-1-L

TABLE 1: DIMENSION "C"

Nominal Pipe Size

3” 4” 6” 8” 10” 12” 14” 16” 18” 20” 24” 30” 36”

PVC/Steel

Sch. 40

12.067 7.049 2.949 1.690 1.033 0.694 0.575 0.465 0.391 0.326 0.220 - -

PVC/Steel

Sch. 40

13.506 7.917 3.293 1.845 1.150 0.772 0.631 0.498 0.419 0.354 0.419 - -

Stainless Steel

(10S)

10.688 6.160 2.663 1.551 0.944 0.642 0.538 0.439 0.364 0.303 0.199 0.127 0.088

Stainless Steel

(40S)

12.067 7.049 2.949 1.690 1.033 0.687 0.565 0.455 0.377 0.313 0.204 0.128 0.088

Copper Tubing

(Type K)

13.441 7.777 3.317 1.865 1.181 0.781 - - - - - - -

Copper Tubing

(Type L)

13.097 7.564 3.193 1.800 1.133 0.744 - - - - - - -

Copper Pipe

12.115 7.156 2.886 1.682 1.033 0.684 - - - - - - -

Duct Iron

(Class 52)

9.974 6.301 2.734 1.528 0.948 0.635 0.487 0.401 0.330 0.269 0.177 0.114 0.079

TABLE 3: TX100/200 K-factors (in Pulses/Gallon) for various pipe sizes

Page 8

Page 9

PARTS LIST

TBS-0XX Parts

1 Upper housing assembly

2 Housing Gasket

3 Lower housing

4 Housing screw assembly

5 Plug, steel

6 Strain relief

7 Sensor w/cable

8 Tube

9 Compression nut

10 Compression Ferrule

11 Adapter tting

12 Rotor housing O-ring

13 Rotor housing

14

Jewel bearing assembly

(for carbide shaft)

15 Turbine Rotor assembly

16

Rotor repair kit

(consists of #14 & #15)

(0.5)

(1.0)

(2.0)

(5.0)

(10.0)

(20.0)

(30.0)

TABLE 4: Flow Rates converted from Feet/Sec to Gallons/Minute at various velocities: Schedule 40 pipe

Nominal pipe size

Feet / Sec

3" 4" 6" 8" 10" 12" 16" 24" 30" 36" 38" 40"

11.5 19.8 45 78 123 176 313 704 1100 1585 1770 1960

23 39.7 90 156 246 349 551 1250 2200 2910 3530 3915

46.1 79.4 180 312 492 698 1100 2510 4401 5830 7070 7825

115 198 450 780 1230 1740 2750 6270 11002 14570 17670 19560

230 397 900 1560 2460 3490 5510 12530 22005 29140 35350 39120

461 794 1800 3120 4920 6980 11020 25060 44010 58270 70700 78240

691 1190 2700 4680 7370 10470 16520 37600 66015 87410 106050 117500

Flow Range.Thesesensorsaredesignedtooperateatow

velocitiesof0.5to30feetpersecond(seeTable2,below).

If erratic readingsare encountered atlow ows, check the

charttoseeifowisbelowminimumforthepipesize.The

standard shaft and bearings should have a long life at continu-

oushighow.

TBS-1XX Parts (hot-tap)

All part numbers are the same except those

below

17 Locking Collar

18 Adapter tting O-ring

19 Adapter, hot tap

20

Valve assembly

(inlcudes Adapter, #20)

OPERATION

TX101/201

TX115/215

TBS-0XX

TBS-1XX

TROUBLESHOOTING and REPAIR

CAUTION! Never attempt to remove a

ow sensor when there is pressure in

the pipe. Loosen the compression nut

slowly to release any trapped pressure.

If uid sprays out when removing the

sensor, stop turning and depressurize the pipe. Fail-

ure to do so could result in the sensor being thrown

from the pipe, resulting in damage or serious injury.

WARRANTY/RETURN

Rotor Replacement.Rotorsareeasilyeld-replaced.Shaft

and rotor are a single unit, and are not replaced separately.

If replacement is due only to normal shaft wear, bearing re-

placement is probably not necessary. If the rotor has been

damaged by impact, the bearings should also be replaced.

Rotor and bearings can be ordered as a kit (see parts listing).

Followthesesteps:

1.Unscrewthethreadedbearinghousingstoexposethe

shaft ends. If bearings are being replaced, back them

completely out.

2.Removetherotor.Putthenewrotorinitsplace.

3. Thread in one bearing housing part way, then the

other. Take care to start the end of the shaft into

the bearing hole before tightening further.

4.Screwinbearinghousingsuntiltheybottom.

Note: Do not use excessive force.

5.Checkforfreespin.Blowinglightlyontherotor

should result in it spinning rapidly and coasting

to a smooth stop.

Shaft

Turbine Rotor

Bearing

Housing

Theowsensorhasonlyonemovingpart,therotor.Ifthis

isturningproperlyandthereisnosignal,theHall-effect

sensor is not operating properly. To check the signal, ap-

ply12VDCregulated*powertothered(+)andblack(-)

leads.Setamultimetertovoltagereading.Putthepositive

multimeter lead on the red wire and the negative lead on

thewhitewire.Slowlyturntherotor.Voltagereadingshould

swingbetween+12Voltsand0Voltsastherotorturns.If

it does not, the Hall effect sensor is not working properly.

Checking for continuity is not a useful test of these sensors.

*NOTE:Anunregulatedpowersupplycanexceedmaxvoltageof

micro powered sensor (gray cable) and damage sensor.

Referto"TermsandConditionsofSale"inourcatalogoron

our website. Contact customer service to receive a Returns

GoodsAuthorizationnumberbeforeshippingyourproduct

back for repair. Be sure to include a brief description of the

problem plus any relevant applciation notes.

Troubleshooting

PL-OM-65200391-091912

9/19/12

Dwyer Instruments, Inc. • 102 Indiana Highway 212 • Michigan City, IN 46360 • USA

(P) 219.879.8868 • (F) 219.872.9057 • 1.800.872.9141 • www.dwyer-inst.com

/