Page is loading ...

Catalog Number 16116

8450 Residual Free Chlorine Monitor

INSTRUMENT MANUAL

© Hach Company, 2003. All rights reserved. Printed in the U.S.A.

ap/dk 07/03 2ed

Visit http: //www.hach.com

Page 3

16116TOC.fm Table of Contents

Table of Contents

Safety Precautions.................................................................................................................................................... 6

Specifications ............................................................................................................................................................ 7

Section 1 Introduction ........................................................................................................................................ 9

1.1 Introducing the Sigma Residual Chlorine Monitor Model 8450........................................................................... 9

1.2 Overview of Chlorine Characteristics.................................................................................................................. 9

1.2.1 Free Chlorine ............................................................................................................................................. 9

1.2.2 Probe Response and Effects of pH ........................................................................................................... 9

Section 2 Installation......................................................................................................................................... 11

2.1 Overview ........................................................................................................................................................... 11

2.2 Monitor Mounting .............................................................................................................................................. 11

2.2.1 Wall Mounting .......................................................................................................................................... 11

2.3 Panel Mounting the 8450 .................................................................................................................................. 12

2.3.1 Panel Mounting Considerations............................................................................................................... 12

2.3.2 Panel Mounting Sequence....................................................................................................................... 12

2.4 Rail-Mount Mounting......................................................................................................................................... 14

2.5 Probe Mounting................................................................................................................................................. 14

2.5.1 Submerged Probe Mounting.................................................................................................................... 14

2.5.2 Flow Cell Mounting .................................................................................................................................. 14

2.6 Electrical Connections ...................................................................................................................................... 16

2.6.1 ac Power.................................................................................................................................................. 16

2.6.2 Relay (Alarms) and Output Connections ................................................................................................. 17

2.6.3 Connecting the Probe.............................................................................................................................. 17

2.7 4-20 mA Surge Protector .................................................................................................................................. 18

2.7.1 Connections and Setup ........................................................................................................................... 19

2.7.2 Test and Check Procedure ...................................................................................................................... 20

2.7.3 4-20 mA Device Connection .................................................................................................................... 20

2.8 Data Communications....................................................................................................................................... 21

2.8.1 RS232 Communications.......................................................................................................................... 21

2.9 RS485 Communications ................................................................................................................................... 23

2.10 Probe Preparation ........................................................................................................................................... 24

2.11 New Membrane Pre-qualification Testing........................................................................................................ 24

2.12 Probe Preparation Procedure ......................................................................................................................... 25

Section 3 Operation........................................................................................................................................... 27

3.1 Overview ........................................................................................................................................................... 27

3.2 Front Panel Display and Controls...................................................................................................................... 27

3.3 Menus and Parameters..................................................................................................................................... 28

3.3.1 Main Screen ............................................................................................................................................ 28

3.3.2 Main Menu............................................................................................................................................... 28

3.4 Accessing and Changing System Parameters .................................................................................................. 28

3.4.1 Function Icon ........................................................................................................................................... 28

3.4.2 Arrow Icons.............................................................................................................................................. 29

3.4.3 Enter/Exit Icon ........................................................................................................................................ 29

3.5 Factory Default Parameters .............................................................................................................................. 30

3.6 Adjusting Display Screen’s Contrast ................................................................................................................. 30

Page 4

Table of Contents

16116TOC.fm

Table of Contents

3.7 Initial Power-Up and Self Test ........................................................................................................................... 31

3.7.1 *Check* Messages .................................................................................................................................. 31

3.7.2 Inhibiting Messages................................................................................................................................. 31

3.8 LCD Menu Descriptions .................................................................................................................................... 32

3.9 Setting Main Screen Time, Date, Temperature, and Concentration Units......................................................... 33

3.10 Setting Maximum Range................................................................................................................................. 33

3.11 System Calibration .......................................................................................................................................... 33

3.12 Frequency of Calibration ................................................................................................................................. 34

3.13 Considerations Before You Calibrate .............................................................................................................. 34

3.13.1 Probe Preparation and Setup ................................................................................................................ 34

3.13.2 Stabilization Issues................................................................................................................................ 35

3.13.3 Probe Signal Stability and Amplitude .................................................................................................... 35

3.13.4 Probe Temperature Considerations ....................................................................................................... 35

3.13.5 Operational Considerations ................................................................................................................... 36

3.14 Zero Calibration............................................................................................................................................... 36

3.14.1 Preparation ............................................................................................................................................ 36

3.14.2 Optimizing Zero Calibration ................................................................................................................... 36

3.14.3 Zero Calibration Procedure ................................................................................................................... 37

3.15 Span Calibration.............................................................................................................................................. 37

3.15.1 Preparation ............................................................................................................................................ 38

3.15.2 Optimizing Span Calibration .................................................................................................................. 38

3.15.3 Span Calibration Procedure .................................................................................................................. 39

3.16 Relative Probe Sensitivity ............................................................................................................................... 39

3.17 Alarm Setup .................................................................................................................................................... 40

3.17.1 Set Point Adjustment ............................................................................................................................. 40

3.17.2 High Set Point Setup ............................................................................................................................. 40

3.17.3 Low Set Point Setup .............................................................................................................................. 40

3.17.4 Selecting Alarm Relay Options (lfit)....................................................................................................... 41

3.17.5 Check Alarm Relay Setup ..................................................................................................................... 41

3.17.6 Alarm Time Delays ................................................................................................................................ 42

3.18 VMA Output Setup ......................................................................................................................................... 42

3.19 System Security .............................................................................................................................................. 42

3.20 Changing Site Location Designation ............................................................................................................... 43

3.21 Changing Display Precision ............................................................................................................................ 43

3.22 Damping Adjustment....................................................................................................................................... 43

3.23 Optional Data Logger...................................................................................................................................... 44

3.23.1 SETTINGS Menu — Data Log Setup .................................................................................................... 45

3.23.2 Sampling Rate ....................................................................................................................................... 46

3.23.3 Control Parameters — On-Off-Reset..................................................................................................... 46

3.23.4 DATA Menu — Viewing Trend Data-Log Records On Screen................................................................ 46

3.23.5 REPORTs — Printing Trend Data.......................................................................................................... 47

3.23.6 Other Data Logger Considerations........................................................................................................ 48

3.24 SYS Menu ....................................................................................................................................................... 48

3.24.1 Gpot....................................................................................................................................................... 48

3.24.2 ADC ....................................................................................................................................................... 49

Section 4 Maintenance and Troubleshooting ............................................................................................. 51

4.1 Maintenance Overview...................................................................................................................................... 51

Table of Contents

Page 5

16116TOC.fm Table of Contents

4.2 Probe Maintenance and Poor Probe Output ..................................................................................................... 51

4.2.1 Membrane Troubleshooting and Maintenance......................................................................................... 51

4.2.2 Quick Membrane Replacement Procedure.............................................................................................. 51

4.2.3 Probe Electrode Maintenance ................................................................................................................. 52

4.2.4 Testing Thermistor Output ....................................................................................................................... 53

4.2.5 Testing for Electrical Isolation .................................................................................................................. 54

4.3 Resolving Calibration Problems ........................................................................................................................ 54

4.3.1 Timer Expires During Zero Calibration .................................................................................................... 55

4.3.2 Timer Expires During Span Calibration ................................................................................................... 56

4.4 Reading Drifts After Span Calibration ............................................................................................................... 57

4.5 Calibration Error Messages............................................................................................................................... 57

4.6 Calibrating with a Simulated Input..................................................................................................................... 57

4.6.1 Equipment Required................................................................................................................................ 57

4.7 *CHECK* Messages (Alphabetical Listing)....................................................................................................... 59

4.8 Resetting Factory Defaults................................................................................................................................ 60

Replacement Parts and Accessories ...................................................................................................................... 61

Contact Information for U.S.A. and Outside Europe ............................................................................................... 63

Contact Information for Europe............................................................................................................................... 64

Warranty ................................................................................................................................................................. 65

Page 6

Safety Precautions

16116Safety.fm

Safety Precautions

Please read this entire manual before unpacking, setting up, or operating this instrument.

Pay particular attention to all danger and caution statements. Failure to do so could result in serious injury to the

operator or damage to the equipment. To ensure the protection provided by this equipment is not impaired, do not

use or install this equipment in any manner other than that which is specified in this manual.

Use of Hazard Information

If multiple hazards exist, this manual will use the signal word (Danger, Caution, Note) corresponding to the

greatest hazard.

DANGER: Indicates a potentially or imminently hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation that may result in minor or moderate injury.

Note: Information that requires special emphasis.

Precautionary Labels

Read all labels and tags attached to the instrument. Personal injury or damage to the instrument could occur if

not observed.

This symbol, if noted on the instrument, references the instruction manual for operation

and/or safety information.

This symbol, when noted on a product enclosure or barrier, indicates that a risk of electrical shock

and/or electrocution exists and indicates that only individuals qualified to work with hazardous voltages

should open the enclosure or remove the barrier.

This symbol, when noted on the product, identifies the location of a fuse or current limiting device.

This symbol, when noted on the product, indicates that the marked item can be hot and should not be

touched without care.

This symbol, when noted on the product, indicates the presence of devices sensitive to Electro-static

Discharge and indicates that care must be taken to prevent damage to them.

This symbol, when noted on the product, identifies a risk of chemical harm and indicates that only

individuals qualified and trained to work with chemicals should handle chemicals or perform

maintenance on chemical delivery systems associated with the equipment.

This symbol, if noted on the product, indicates the need for protective eye wear.

This symbol, when noted on the product, identifies the location of the connection for Protective Earth

(ground).

Page 7

16116Specs.fm Specifications

Specifications

Specifications are subject to change without notice.

Repeatability ±0.5%

Linearity ±0.5%

Output Range 0–20 ppm (selectable)

Displayed Precision 0.01, 0.1, 1

Damping Time Constant 0–300 seconds

Power 110/220 V ac (switchable)

Monitor Enclosure NEMA-4X (wall), NEMA-12(panel)

Monitor Temperature Limits -20 to 50 °C (-4 to 122°F)

Alarm LEDs 3 (red)

Analog Outputs

Concentration and temperature (°F and °C)

(2) 4-20 mA (or 20-4 mA) isolated into 800 ohm max.

(2) 0–1 or 0–5 V dc

Alarm Relays (2) 5A SPDT @ 110 V ac; (1) 5A SPDT @ 110 V ac

Alarm Relay Controls Latching, fail-safe, inhibit, and test

Security Features 3-digit entry w/confirmation

Probe type Temperature compensated (RTD), direct sensing membrane probe

Probe Temperature Limits 0 to 50 °C (32 to 122 °F)

Max pressure at probe 50 PSI

Probe Material PVC

System Shipping Weight 8 lbs.

Data Logger

Sampling Interval 1–90 minutes, selectable intervals

Max data points 13,000 @ 1 min. intervals

On Screen Report Daily high, low, avg. concentration. Individual.

Visit http: //www.hach.com

Page 9

16116Intro.fm Introduction

Section 1 Introduction

1.1 Introducing the Sigma Residual Chlorine Monitor Model 8450

Sigma Chlorine monitors are designed for on-line measurement of residual

chlorine concentrations in potable water, cooling towers, or wastewater. The

system consists of two main components: a programmable electronic monitor

housed within a NEMA-4X enclosure and an amperometric membrane probe.

The 8450 Monitor comes fully equipped with a variety of features. Monitor

operation and programming is accomplished via a magnet which, when

touched to the unit’s front panel icons, activates small internal switches and

permits adjustment of the various operation/set-up parameters. Each unit’s

alarm capabilities include two programmable high/low alarms and a fault

alarm. Four analog outputs are provided for operation of external alarm and

control devices. Chlorine levels from 0.00 to 20.0 ppm are displayed on an

auto-ranging LCD where concentrations may be viewed in either ppm or

mg/L. Other features include: password security, optional data logging, and an

optional RS232/RS485 communications port for remote monitoring and

system operation.

Sigma chlorine probes provide the means to directly measure chlorine. The

Model 8450 Monitor and its associated model 50 probes will respond to both

hypochlorous acid and the hypochlorite ion. Probes respond best in liquid

environments of up to a pH of 9; however, probes should be calibrated in the

pH at which measurements will be taken to obtain optimum accuracy. The

probe can be used in a constant-head flow assembly that provides better flow

control and enhances the operating environment for the probe.

1.2 Overview of Chlorine Characteristics

1.2.1 Free Chlorine

When chlorine (Cl

2

) is dissolved in water (H

2

O) it hydrolyzes (the reaction

between an ion and water in which the hydrogen–oxygen bond is broken) to

form hypochlorous acid or free chlorine:

Cl

2

+ H

2

O → HOCl + H

+

+ Cl

–

Hypochlorous acid is considered a “weak” acid and therefore tends to partially

dissociate and produce a hydrogen ion and a hypochlorite ion:

HOCl ↔ H

+

+ OCl

–

The combination of HOCl and OCl

–

is referred to as free chlorine. The extent

to which this dissociation occurs depends upon several factors, including the

temperature and pH of the solution. At pH levels between 6 and 9.5, the

dissociation of the hypochlorous acid is incomplete, thus both hypochlorous

acid and the hypochlorite ion will be present within the solution (see Figure 1).

The Model 8450 Free Chlorine Monitor has been designed to measure these

two species of dissolved chlorine.

1.2.2 Probe Response and Effects of pH

The pH of the water has a definite effect on the response of Model 8450 Free

Chlorine probes. In general, probes will begin to exhibit a reduced response

as pH levels increase above 7.5.

Page 10

Overview of Chlorine Characteristics

16116Intro.fm

Section 1

The effect of pH on the Sigma Free Chlorine probe is illustrated in Figure 1.

The Sigma Free Chlorine probe has a response that goes beyond the HOCl

species, and that it has a usable response to the hypochlorite ion (OCl

–

). This

enables the Sigma probe to be used at higher pH values than if it only

responded to hypochlorous acid. Depending upon expected pH swings, the

Free Chlorine probe response is not significantly affected below a pH of about

8. If the pH is constant, the probe can be calibrated and used at up to pH 9;

however, large pH swings centered at about pH 9 can cause errors. If the pH

is to be kept between 5 and 6 (i.e. 100% HOCl residual), a Sigma CO

2

Sparging system is recommended.

Figure 1 HOCl–OCl

–

Equilibrium and Sigma Free Chlorine Probe Outputs vs. pH

Sigma Standard Free Cl Sensor Response

2

Point (a) — Equal Parts HOCl and OCl

Point (b) — 80% HOCl and 20% OCl (example)

–

–

Greater

HOCl

Greater

OCl

Equal Parts

HOCl & OCl

–

a

b

-

-

Page 11

16116Install.fm Installation

Section 2 Installation

2.1 Overview

Installation of the residual chlorine monitor consists of mounting and wiring

the monitor, pipe-mounting the probe (for submersion applications), and

connecting sample and drain lines for applications requiring flow cell usage.

Connect the probe to the electronics module by plugging the probe multi-pin

plug into the receptacle at the bottom of the electronic module.

2.2 Monitor Mounting

The programmable electronic monitor is enclosed in a NEMA-4X enclosure

that can be mounted to a wall, through a panel, or onto a handrail or pole.

2.2.1 Wall Mounting

Two mounting brackets (one on each side) are attached to the monitor with

four screws (supplied). With the bracket tabs and mounting holes extending

beyond the monitor on each side, the monitor can be attached to a wall or flat

surface using four [need size] screws and appropriate mounting hardware.

Figure 2 Monitor with Wall Mount Brackets

Figure 3 Wall Mount Brackets (Rear View)

9.75" (24.8 cm)

8.75" (22.2 cm) c-c

8.4" (21.3 cm)

4" (10.1 cm)

4.875" (12.4 cm)

6.4" (16.2 cm)

RESIDUAL CHLORINE MONITOR

Page 12

Panel Mounting the 8450

16116Install.fm

Section 2

Figure 4 Wall Mounted Monitor’s Depth

2.3 Panel Mounting the 8450

2.3.1 Panel Mounting Considerations

To install the panel-mount enclosure, remove the monitor’s four front panel

securing screws and the front-panel. Install the panel mount installation plate

(Cat. No. 16411). Note that the probe receptacle in a panel-mount application

may not be easily accessible behind the panel. For many panel-mount

applications, it may be advisable to wire the probe connections out to an

optional junction box near the probe location. The junction box contains a

receptacle for plugging in the probe (see Figure 11 on page 18). The junction

box should be no more than 200 feet from the monitor.

2.3.2 Panel Mounting Sequence

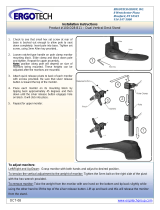

To attach the panel mount kit brackets, refer to Figure 5 and Figure 6 and

proceed as follows:

1. Attach the Z-brackets (Cat. No. x) using 1/4-20 x 0.25” L hex bolts at the

back of the meter. Do not completely tighten the bolts at this time.

2. Remove the front panel (4 screws) and position the Enclosure Plate.

3. Reattach the front panel with the Enclosure Plate sandwiched

underneath it.

4. Attach the Enclosure Plate to the Z-brackets with four screws and tighten

all screws to finish the assembly.

5.1" (13.0 cm)

Section 2

Page 13

16116Install.fm Panel Mounting the 8450

Figure 5 Panel Mounted Meter (Front View)

Figure 6 Panel Mount Attaching Parts (Side View)

1. Enclosure Plate 4. Panel

2. #10-32 x 0.75 stainless slotted hex washer-head

machine screw

5. 1/4-20 x 0.25 stainless steel machine screw

3. 1/4-20 x 0.75 stainless slotted hex wahser-head machine

screw

6. Z-bracket

RESIDUAL CHLORINE MONITOR

8.2” (20.8 cm)

10.7” (27.1 cm)

6

5

4

3

2

1

Page 14

Rail-Mount Mounting

16116Install.fm

Section 2

2.4 Rail-Mount Mounting

The Rail-Mount kit (Cat. No. 16088) allows the meter to be clamped to a hand

rail (that runs horizontally) or even to a pole (vertical pipe) if so desired (Figure

7). Brackets that attach to the back of the meter are in turn attached to the rail

or pole with U-bolt type pipe clamps. The brackets may be attached to the

sides (rail mount) or top and bottom (pole mount).

Figure 7 Rail or Pole Mount Brackets

2.5 Probe Mounting

The chlorine probe is suitable for either submersion or flow-cell use. In

general, the flow-cell system is preferable.

Note: In either case, it is essential that a flow velocity of at least 0.5 ft./sec., but not

greater than 2.5 ft./sec., is maintained at the probe.

2.5.1 Submerged Probe Mounting

For submerged applications, the chlorine probe is mounted at the end of a 1"

pipe using pipe mounting kit. Figure 8 shows the proper pipe mounting

assembly. Note that the pipe mounting kit does not include the pipe.

2.5.2 Flow Cell Mounting

Use a flow cell for free chlorine applications in situations where a uniform flow

across the membrane cannot be assured by other means.

The flow cell assembly contains a clear flow block into which the probe is

inserted and a constant head overflow that controls the flow through the cell.

The flow cell will operate with a minimum of 8 gph and a maximum of 25 gph.

If the supply for the flow-cell is variable in pressure, as is common in potable

water systems, place a pressure regulator with an outlet pressure of 10 to

15 psi ahead of the flow-cell.

Flow assemblies are wall mounted using the bolt holes in the four corners of

the assembly plates. Recommended sample piping is shown in Figure 9. The

probe is inserted into the flow-cells using a twist-lock arrangement. Align the

three pins in the probe with the slots in the flow-cell and press the probe down

until it can be turned slightly to engage the pins in the retaining slot. If

excessive force is required to press the probe past the sealing o-ring, remove

the o-ring and apply a small amount of silicone lubricant.

Section 2

Page 15

16116Install.fm Probe Mounting

Figure 8 Submerged Probe Using Pipe Mount Kit

1. Probe Cable to Monitor 5. 1” (2.54 cm) FNPT

2. 1.5” (3.8 cm) diam. Handrail 6. Probe Adapter Cone

3. 1” (2.54 cm) Schedule 80 PVC pipe (Customer-supplied,

length as required.)

7. Probe

4. Probe 8. Pipe Bracket

6

5

4

3

2

1

8

7

Page 16

Electrical Connections

16116Install.fm

Section 2

Figure 9 Flow Cell and Connections (Typical)

2.6 Electrical Connections

Electrical connections required for the residual chlorine monitor include probe

connection, ac power connection, and connection of analog outputs and

alarm relays, if they are being used. Figure 10 shows the terminals to which

connections are made for the various functions. If the unit being installed is a

1. Mounting Plate 5. Water Line

2. Flow Cell 6. Pressure Regulator (10–15 psi Output)

3. 0.5” Outlet 7. 0.25” Inlet (Inlet Flow = 8 to 25 gph)

4. Hand Valve

8.0” (20.3 cm)

7.5” (19.1 cm)

6.0” (15.2 cm)

5.5” (14.0 cm)

Mounting Plate

Flow Cell

0.5” Outlet

Hand Valve

Pressure Regulator

(10–15 PSI Output)

Water Line

0.25” Inlet

(Inlet Flow = 8 to 25 gph)

Section 2

Page 17

16116Install.fm Electrical Connections

panel-mount system, it is best to make all connections at the time of physical

installation.

2.6.1 ac Power

Wall mounted chlorine monitors are shipped with the power cord already

connected. If no outputs or alarms are to be used, all that is necessary is to

plug the probe cable into the receptacle at the bottom of the enclosure and

plug the power cord into a standard wall receptacle.

ac power can also be routed directly to the monitor in panel-mount

installations by connecting Line (L), Neutral (N), and ground (GND)

connections as shown in the Figure 10.

2.6.2 Relay (Alarms) and Output Connections

Warning: Remove ac power to the instrument before proceeding.

In order to access the terminal strip to make relay and output connections,

remove the four screws from the front panel and remove the front panel. Next,

remove the two screws on the right side of the display board (the display

board is hinged) and swing the display board out of the way. Make all

necessary connections in accordance with the Figure 10 and reassemble the

enclosure.

Connection mnemonics are V1 and V2 (voltage 1 and 2), I1 and I2 (current 1

and 2), AL1 (alarm 1), AL2 (alarm 2), and CHK (check relay).

Figure 10 Electrical Connections

2.6.3 Connecting the Probe

The two basic methods of connecting the probe are:

• Directly connecting the probe connector to monitor-connector P1 and,

• Connecting the probe connector to an intervening junction box.

The second method allows greater distance between the monitor and the

probe (up to 200 ft. between monitor and probe connector). It also is useful in

Page 18

4-20 mA Surge Protector

16116Install.fm

Section 2

those cases where this extended cable is to be routed through a conduit.

Figure 11 and Tabl e 1 depict the cable connections.

Figure 11 Probe Connection Options

2.7 4-20 mA Surge Protector

Required Materials

• Standard straight-slot screw driver

Direct Connection Connection Using Screw-Teminal Junction Box

Probe Connector (P1)

Junction Box Cable

Removable Face Plate

Probe Connector

Leads End

Connector

Junction Box

Table 1 Probe Conductor Identification

Probe Cable Color

Junction Box Bendix

Connector P2

Junction Box

Terminal Block

Junction Box Cable

Color

Monitor Bendix

Connector P1

Black D 4 Black D

Brown B 2 Brown B

White A 1 White A

Red C 3 Red C

Shield E 5 Shield Connector’s Shell

Section 2

Page 19

16116Install.fm 4-20 mA Surge Protector

• Small straight-slot screw driver

• Milliampmeter

• Color-coded connection wire, 10 in. (25.4 cm)/test leads

• 4-20 mA Surge Protector(s) (Cat. No. 16326)

2.7.1 Connections and Setup

Warning: Remove ac power to the instrument before proceeding.

1. Remove electrical power to the meter.

2. Unscrew the four cover face plate screws and remove the cover.

3. Unscrew the upper and lower right screws that hold the display circuit

board to the meter and swing the hinged display board back to access the

main circuit board inside the case.

4. As shown in Figure 12, insert the two pins of the Surge Protectors into

pins 7 and 8 (channel 1) and 5 and 6 (channel 2) on the terminal block.

5. Tighten the clamp screws on this connector.

Figure 12 Top View of Pins and Terminal Block

6. Connect the wires from the color-coded wire into surge protector terminal

screws. Route the wires through the bottom of the case (under the

display) and label the wires for channel 1 and 2 and + and –.

7. Temporarily tape the ends of channel 2 wires to avoid the possibility of

shorts. Connect a milliampmeter to the channel 1 extension leads.

8. Plug the screw-terminal block with attached surge protectors installed into

TB4 connector on the 8400 meter’s main circuit board (Figure 13.)

Note: The plug-in screw terminal connector is keyed to ensure that it plugs in correctly.

Note: The location of TB4 and its numbered terminals are marked on the main circuit

board.

Figure 13 Plug-in Connector in Place

9. Swing the display back into the closed position, using care to avoid

pinching or snagging wires (Figure 14).

Figure 14 Extension Leads and Milliampmeter Connections

10. Power the meter on again and proceed to section 2.7.2.

Page 20

4-20 mA Surge Protector

16116Install.fm

Section 2

2.7.2 Test and Check Procedure

2.7.3 4-20 mA Device Connection

This process contains three major steps:

• Hooking the 4-20 mA device in series with a milliampmeter and the 8400

meter.

• Performing the 4 mA and 20 mA adjustments for each device on each

channel.

• Removing the milliampmeter and connecting the 4-20 mA device directly

to the surge protectors on each channel.

Activate Result

F1.From the Main screen brings up the Main menu.

↑ 2. Several times to move to >VMA.

E3.Selection menu: CH1, CH2, ADJ.

↑ 4. Several times to move to >ADJ.

E5.Channel selection screen: >---NONE---.

E6.Enter channel selection. [---NONE--- blinks.]

↑ 7. “CH 1 4.00 mA” display blinks.

E8.Enters > CH1 4.00 mA [only (>) blinks].

9. Milliampmeter displays 4 mA ±2% (3.92 to 4.08 mA).

↓ 10. Adjust mA Output. To select > Adjust---.

E 11. Enters Adjust.

↑↓

12. Adjust output up or down as need until milliampmeter reads

4 mA ±2% (3.92 to 4.08) mA.

E 13. Enters (accepts the adjustment).

↑ 14. Return to channel selection. [Displays: >CH1 4.00 mA...]

E 15. Enter Channel selection.

↑ 16. “CH 1 20.0 mA” display blinks.

E 17. Enters >CH1 20.0 mA [only (>) blinks].

18. Milliampmeter displays 20 mA ±2% (19.6 to 2.04 mA).

↓ 19. Adjust 20 mA Output: To select >Adjust---.

E 20. Enters Adjust.

↑↓

21. Adjust output up or down as needed until milliampmeter reads

20 mA ±2% (19.6 to 2.04 mA).

E 22. Enters (accepts) the adjustment.

23. Continue On to Check Channel 2 in the same manner. Move

milliampmeter leads to channel 2 extension leads and tape

insulate the bare channel 1 leads to avoid the possibility of

shorting.

↑ 24. Moves to the channel line of the menu.

E 25. Channel menu line blinks.

↑ (5 times) 26. Displays CH2 4.00 mA.

E 27. Enters > CH2 4.00 mA [only (>) blinks].

28. Repeat steps 9 through 22 to check 4 mA and 20 mA outputs

of channel 2.

/