Page is loading ...

These instructions include the Benchmark Commissioning Checklist and should be left with the

user for safe keeping. They must be read in conjunction with the Flue Installation Guide.

United Kingdom

en

24-28-35 / 18-24

Installation and Service Manual

Wall Mounted Gas Condensing Boiler

Baxi MainEco Combi and System

Dear customer,

Thank you for purchasing this appliance.

Please read this manual carefully before using the product and keep it in a safe place for future reference.

In order to ensure continued safe and efficient operation we recommend that the product is regularly maintained. Our Service

and After Sales organization can assist with this.

We hope you will receive many years of satisfactory service.

Contents

1.1 Building Regulations and the Benchmark

Commissioning Checklist ....................................6

1.2 The Benchmark Scheme ......................................6

1.3 Installer Notification Guidelines ..........................7

2 Introduction ................................................................................................8

2.1 Symbols used .......................................................8

2.2 Abbreviations ........................................................8

2.3 General ..................................................................8

2.3.1 Manufacturer’s liability

.............................................8

2.3.2 Installer’s liability .....................................................9

2.3.3 User’s liability ..........................................................9

2.4 Homologations ....................................................10

2.4.1 Certifications .........................................................10

2.4.2 Additional Directives ..............................................10

3 Safety instructions and recommendations ............................................11

3.1 Safety instructions .............................................11

3.2 Recommendations ..............................................11

4 Technical description ..............................................................................13

4.1 General description ............................................13

4.2 Main parts ............................................................13

4.3 Skeleton Diagrams .............................................14

4.4 Operating principle .............................................14

4.4.1 Gas/air setting .......................................................14

4.4.2 Combustion ...........................................................15

4.4.3 Heating and domestic hot water production ..........15

4.4.4 Control system ......................................................15

4.4.5 Adjustment ............................................................15

4.4.6 Regulation of the water temperature .....................16

4.4.7 Protection against low water or no

circulation ..............................................................16

4.4.8 Overheat temperature protection ..........................16

02092014 - 7619497-02

1

4.5 Circulating pump (Available pump head) .........16

4.6

Technical specifications ....................................17

5 Installation ................................................................................................19

5.1 Regulations governing installation ...................19

5.2 Choice of the location ........................................20

5.2.1 Type plate .............................................................20

5.2.2 Location of the boiler .............................................20

5.3 Main dimensions .................................................22

5.4 Positioning the boiler .........................................23

5.5 Hydraulic connections .......................................23

5.5.1 Flushing the system ..............................................24

5.5.2 Water flow rate ......................................................24

5.5.3 Connection of the heating circuit ...........................24

5.5.4 Connection of the water circuit for domestic

use ........................................................................25

5.5.5 Connecting the expansion vessel .........................25

5.5.6 Connecting the safety valve discharge pipe ..........26

5.5.7 Connecting the condensate discharge pipe ..........26

5.5.8 Automatic air bleed ...............................................28

5.6 Gas connection ...................................................29

5.7 Connections for the air and exhaust

pipes ....................................................................29

5.7.1 Classification .........................................................29

5.7.2 Outlets ...................................................................30

5.7.3 Lengths of the air/flue gas pipes ...........................31

5.7.4 Additional Directives ..............................................32

5.7.5 Connection of the combustion gas exhaust

pipe .......................................................................32

5.8 Electrical connections ........................................32

5.8.1 Control unit ............................................................32

5.8.2 Recommendations ................................................33

5.8.3 Access to the connector block / Boiler HMI ...........34

5.8.4 Connection options ...............................................34

5.9 Electrical diagram ...............................................38

5.10 Filling the system ...............................................38

5.10.1 Water treatment ....................................................38

5.10.2 Filling the condensate trap ....................................39

5.10.3 Filling the system ..................................................40

5.10.4 Venting the system ................................................41

Contents

02092014 - 7619497-02

2

6 Commissioning ........................................................................................42

6.1 Control panel .......................................................42

6.2 Check points before commissioning ................43

6.2.1 Preparing the boiler for commissioning .................43

6.2.2

Hydraulic circuit .....................................................43

6.2.3 Electrical connections ...........................................43

6.3 Commissioning the boiler ..................................43

6.4 Gas settings ........................................................45

6.4.1 Gas circuit .............................................................45

6.4.2 Checking combustion ............................................45

6.4.3 Setting the air/gas ratio .........................................48

6.5 Finalizing work ....................................................49

6.6 Parameter descriptions ......................................50

7 Switching off the boiler ............................................................................52

7.1 Installation shutdown .........................................52

7.2 Antifreeze protection ..........................................52

8 Checking and maintenance .....................................................................53

8.1 General instructions ...........................................53

8.2 Standard inspection and maintenance

operations ...........................................................53

8.2.1 Open the boiler ......................................................53

8.2.2 Checking the hydraulic pressure ...........................54

8.2.3 Checking the expansion vessel .............................54

8.2.4 Checking the ionization current .............................54

8.2.5 Checking the DHW transfer capacity ....................55

8.2.6 Checking the flue gas discharge and the air

supply ....................................................................55

8.2.7 Checking combustion ............................................55

8.2.8 Checking the automatic air vent ............................55

8.2.9 Checking the condensate trap ..............................56

8.2.10 Checking the burner and cleaning the heat

exchanger .............................................................57

8.3 Specific maintenance operations ......................58

8.3.1 Replacing the ionization/ignition electrode ............58

8.3.2 Replacing the 3-way valve ....................................59

8.3.3 Cleaning the plate heat exchanger .......................59

8.3.4 Cleaning the domestic water cartridge ..................60

8.3.5 Replacement of the expansion vessel ..................60

8.3.6 Re-assembling the boiler ......................................61

02092014 - 7619497-02

3

9 Troubleshooting .......................................................................................63

9.1 Error codes ..........................................................63

9.2 Shutdowns and lock-outs ..................................63

9.2.1 Blocking .................................................................63

9.2.2

Lock out .................................................................65

10 Spare parts ................................................................................................70

10.1 General ................................................................70

10.2 Spare parts ..........................................................70

11 Appendix ...................................................................................................71

11.1 User instruction card ..........................................71

11.2 Gas boiler system commissioning

checklist ..............................................................72

11.3 Service record .....................................................73

Contents

02092014 - 7619497-02

4

02092014 - 7619497-02

5

EC declaration of conformity

The device complies with the standard type described in the EG

declaration of conformity. It was manufactured and commissioned in

accordance with European directives.

The original declaration of conformity is available from the

manufacturer.

1.1 Building Regulations and the Benchmark Commissioning Checklist

Building Regulations (England & Wales) require

notification of

the installation of a heating appliance to the

relevant Local Authority Building Control Department.

This can be achieved via a Competent Persons Self

Certification Scheme as an option to notifying the Local

Authority directly.

The Health & Safety Executive operates the ’Gas Safe

Register’, a selfcertification scheme for gas heating

appliances.

This company is a member of the Benchmark initiative

and fully supports the aims of the programme. Its aim is

to improve the standards of installation and

commissioning of central heating systems in the UK and

to encourage the regular servicing of all central heating

systems to ensure safety and efficiency.

Building Regulations require that installations should

comply with manufacturer’s instructions. It is therefore

important that the commissioning checklist is completed

by the installer. The relevant section of Building

Regulations only relates to dwellings. Therefore the

checklist only applies if the appliance is being installed in

a dwelling or some related structure.

The flowchart opposite gives guidance for installers on the

process necessary to ensure compliance with Building

Regulations.

1.2 The Benchmark Scheme

Benchmark places responsibilities on both manufacturers

and installers. The purpose is to ensure that customers

are provided with the correct equipment for their needs,

that it is installed, commissioned and serviced in

accordance with the manufacturer’s instructions by

competent persons and that it meets the requirements of

the appropriate Building Regulations.

The Benchmark

Checklist can be used to demonstrate compliance with

Building Regulations and should be provided to the

customer for future reference.

Installers are required to carry out installation,

commissioning

and servicing work in accordance with the

Benchmark Code of Practice which is available from the

Heating and Hotwater Industry Council who manage and

promote the Scheme. Visit www.centralheating.co.uk

for more information.

R000725-A

Baxi MainEco Combi and System 24 - 28 - 35 / 18 - 24

6

02092014 - 7619497-02

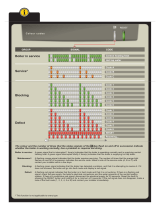

1.3 Installer Notification Guidelines

R000696-01

Choose Building

Regulations Notification

Route

Contact your relevant Local

Authority Building Control

(LABC) who will arrange

an inspection or contact

a government approved

inspector

LABC will record the data

and will issue a

cer

tificate of compliance

‘Gas Safe Register’ will issue a

Building Regulations Compliance

Certificate to the property owner

and inform the relevant LABC

Y

ou must ensure that the

certificate number issued by

the ‘Gas Safe Register’ is written

onto the Benchmark Checklist

Scheme Members only

Call ‘Gas Safe Register’ on:

0800 408 5577

or log onto:

www

.gassaferegister.co.uk

within 10 days

If you notify via the ‘Gas Safe

Register’, the register will issue

the Building Regulations

certificate on members’ behalf

Complete the

Benchmark Checklist

Install and Commission this

appliance to manufacturer's

instructions

Competent Person's

Self Certification Scheme

Building Control

Complete the

Benchmark Checklist

Install and Commission this

appliance to manufacturer's

instructions

Baxi MainEco Combi and System 24 - 28 - 35 / 18 - 24

02092014 - 7619497-02

7

2 Introduction

2.1 Symbols used

In these instructions, various danger levels are employed to draw the

user’s attention to particular information. In so doing, we wish to

safeguard

the user’s safety, highlight hazards and guarantee correct

operation of the appliance.

DANGER

Risk of a dangerous situation causing serious physical

injury.

WARNING

Risk of a dangerous situation causing slight physical

injury.

CAUTION

Risk of material damage.

Signals important information.

¼Signals a referral to other instructions or other pages in the

instructions.

2.2 Abbreviations

4 LTH: Low temperature heating

4 DHW: Domestic hot water

4 HRU: Heat Recovery Unit

4 PCU: Primary Control Unit - Electronic system to control burner

function

4 SCU: Secondary Control Unit - Additional electronic system

2.3

General

2.3.1. Manufacturer’s liability

Our products are manufactured in compliance with the requirements

of the various applicable European Directives. They are therefore

delivered with [ marking and all relevant documentation.

2. Introduction Baxi MainEco Combi and System 24 - 28 - 35 / 18 - 24

8

02092014 - 7619497-02

In the interest of customers, we are continuously endeavouring to

make improvements

in product quality. All the specifications stated in

this document are therefore subject to change without notice.

Our liability as the manufacturer may not be invoked in the following

cases:

4 Failure to abide by the instructions on using the appliance.

4 Faulty or insufficient maintenance of the appliance.

4 Failure to abide by the instructions on installing the appliance.

2.3.2. Installer’s liability

The installer is responsible for the installation and commissioning of

the appliance. The installer must respect the following instructions:

4 Read and follow the instructions given in the manuals provided

with the appliance.

4 Carry out installation in compliance with the prevailing legislation

and standards.

4 Perform the initial start up and carry out any checks necessary.

4 Explain the installation to the user.

4 If a maintenance is necessary, warn the user of the obligation to

check the appliance and maintain it in good working order.

4 Give all the instruction manuals to the user.

2.3.3.

User’s liability

To guarantee optimum operation of the appliance, the user must

respect the following instructions:

4 Read and follow the instructions given in the manuals provided

with the appliance.

4 Call on qualified professionals to carry out installation and initial

start up.

4 Get your installer to explain your installation to you.

4 Ensure the Appliance is serviced in accordance with the

manufacturer’s instructions by a suitable qualified person.

4 Keep the instruction manuals in good condition close to the

appliance.

This appliance is not intended to be used by persons (including

children) whose physcial, sensory or mental capacity is impaired or

persons with no experience or knowledge, unless they have the

benefit, through the intermediary of a person responsible for their

safety, of supervision or prior instructions regarding use of the

appliance. Care should be taken to ensure that children do not play

with the appliance.

If

the

mains power lead is damaged it must be replaced by the original

manufacturer, the manufacturer’s dealer or another competent

person to prevent hazardous situations.

Baxi MainEco Combi and System 24 - 28 - 35 / 18 - 24 2. Introduction

02092014 - 7619497-02

9

2.4 Homologations

2.4.1. Certifications

CE identification no

PIN 0063CM3019

NOx classification

5 (Standards EN)

Type of connection (Flue gas outlet) C

13

, C

33

, C

53

Gas Council number MainEco Combi 24: 47–075–93

MainEco Combi 28: 47–075–94

MainEco Combi 35: 47–075–95

MainEco System 18: 41–470–13

MainEco System 24: 41–470–14

2.4.2. Additional Directives

Apart from the legal provisions and Directives, the additional

Directives described in these instructions must also be observed.

For

all provisions and Directives referred to in these instructions, it is

agreed that all addenda or subsequent provisions will apply at the

time of installation.

2. Introduction Baxi MainEco Combi and System 24 - 28 - 35 / 18 - 24

10

02092014 - 7619497-02

3 Safety instructions and

recommendations

3.1 Safety instructions

DANGER

If you smell gas:

1. Do not use a naked flame, do not smoke, do not

operate electrical contacts or switches ( doorbell,

light, motor, lift, etc..).

2.

Shut off the gas supply.

3. Open the windows.

4. Report any leaks immediately.

5. Trace possible leaks and seal them immediately.

6. If the gas leak is before the gas meter, contact the

gas supplier.

DANGER

If you smell flue gases:

1.

Switch the appliance off.

2.

Open the windows.

3. Report any leaks immediately.

4. Trace possible leaks and seal them immediately.

3.2 Recommendations

WARNING

4 Installation and maintenance of the boiler must be

carried out by a qualified professional in compliance

with prevailing local and national regulations.

4 When working on the boiler, always disconnect the

boiler from the mains and close the main gas inlet

valve.

4 After maintenance or repair work, check all

installations to ensure that there are no leaks.

CAUTION

The boiler must be installed in a frost-free environment.

Keep this document close to the place where the boiler is

installed.

Baxi MainEco Combi and System 24 - 28 - 35 / 18 - 24 3. Safety instructions and recommendations

02092014 - 7619497-02

11

Casing components

Only remove the casing for maintenance and repair operations. Put

the casing back in place after maintenance and repair operations.

Instructions stickers

The instructions and warnings affixed to the appliance must never be

removed or covered and must remain legible during the entire lifespan

of the appliance. Immediately replace damaged or illegible

instructions and warning stickers.

Modifications

Modifications may only be made to the boiler after the written

permission of BAXI to do so.

3. Safety instructions and recommendations Baxi MainEco Combi and System 24 - 28 - 35 / 18 - 24

12

02092014 - 7619497-02

4 Technical description

4.1 General description

Wall-hung gas condensing boilers

4 High efficiency heating.

4 Low pollutant emissions.

4 Installation and connection facilitated by the mounting frame

delivered with the appliance.

4 Flue gas discharge via a forced flue or chimney type connection.

4 Baxi MainEco Combi 24 - 28 - 35: Heating and domestic hot

water production.

4 Baxi MainEco System 18 - 24: Heating only.

4.2

Main parts

1

Flue gas outlet/Air intake (Combustion air/flue gas

adapter 60/100)

2

Casing/air box

3

Outlet for measuring combustion gases

4

Ignition/ionization electrode

5

Flue gas discharge pipe

6

Gas/air

system with a fan, gas block and automatic burner

unit

7

Air intake silencer

8

Plate heat exchanger (DHW) (Only for Combi models)

9

Connection box

10

Condensate trap

11

Circulation pump

12

3-way valve

13

Primary heat exchanger

14

Expansion vessel

15

Automatic air vent

T004783-A

3

5

6

7

9

8

13

12

14

15

11

10

1

2

4

Baxi MainEco Combi and System 24 - 28 - 35 / 18 - 24 4. Technical description

02092014 - 7619497-02

13

4.3 Skeleton Diagrams

Combi 24 - 28 - 35

1

Primary heat exchanger

2

Hydroblock

3

Plate heat exchanger (DHW)

4

Safety valve

5

Heating flow

6

Domestic hot water outlet (DHW)

7

Domestic cold water inlet

8

Heating return

9

Circulation pump (Central heating)

10

3-way valve

System 18 - 24

1

Primary heat exchanger

2

Safety valve

3

Heating flow

4

Heating return

5

Circulation pump (Central heating)

4.4 Operating principle

4.4.1. Gas/air setting

The casing fitted to the boiler is also used as an air box. Air is sucked

in by the fan and gas injected into the venturi by the fan intake. The

fan rotation speed is set according to the settings parameters, the

thermal energy requirement and the temperatures measured by the

temperature sensors. The gas and air are mixed in the venturi.

The

gas/air ratio ensures that the quantities of gas and air are adjusted to

each other. This provides optimum combustion on the entire output

range. The gas/air mixture is fed into the burner on top of the

exchanger.

T003393-D

5 6 7 8

1

2

3

4

10

9

T003807-A

3 4

1

2

5

4. Technical description Baxi MainEco Combi and System 24 - 28 - 35 / 18 - 24

14

02092014 - 7619497-02

4.4.2. Combustion

The burner heats the heating water circulating in the heat

exchanger. At a

return temperature lower than around 55°C, the flue

gases cool down to a temperature lower than the dew point, thus

causing the condensation of the water vapour contained in the flue

gases in the lower section of the heat exchanger. The heat released

during this condensation process (the latent heat or condensing heat)

is also transferred to the heating water. The cooled combustion gases

are evacuated via the combustion gas outlet flue. The condensation

water is evacuated via a condensate trap.

4.4.3. Heating and domestic hot water production

On combi boilers, an integrated plate exchanger heats the domestic

water. A

3-way valve determines whether the heated water is fed into

the heating system or the plate exchanger. A pick-up sensor signals

that a hot water tap is being opened. This signal is transmitted to the

control panel, which then switches the 3-way valve to the hot water

position and trips the heating pump. The 3-way valve is spring-loaded

but only consumes electricity when it switches to another position.

The heating water reheats the domestic water in the plate

exchanger. In comfort mode, if there is no hot water draw-off, the

boiler handles the periodic reheating of the plate exchanger. Any

limescale particles are kept out of the plate exchanger by a self-

cleaning water filter (self-cleans once every 76 hours).

4.4.4. Control system

Control of the boiler ensures reliable delivery of heat. This means that

the boiler treats external negative influences in a practical manner

(notably when

the water-flow is insufficient or there are problems with

air supply). In the presence of such influences, the boiler doesn’t

switch into locking mode, but first reduces his power and, depending

on the nature of the circumstances, will be temporarily out of service

(blocking or stop). The boiler will continue to supply heat as long as

the situation does not become dangerous.

4.4.5. Adjustment

The power of the boiler can be adjusted in the following ways:

4 On/Off setting

The output between the minimum and maximum values varies

based on the heating flow set point temperature.

4 Adjustable control

The output between the minimum and maximum values varies

based on the heating flow temperature determined by the

modulating control system.

Baxi MainEco Combi and System 24 - 28 - 35 / 18 - 24 4. Technical description

02092014 - 7619497-02

15

4.4.6. Regulation of the water temperature

The boiler is fitted with an electronic temperature regulator having an

outlet and return

temperature probe. The flow temperature can be set

between 20°C and 90°C. The boiler reduces its power when the set

outlet-temperature is attained. The cutout temperature is the set

heating outlet-temperature + 5 °C.

4.4.7. Protection against low water or no

circulation

The boiler is fitted with a safety device to prevent the shortage of water

based on temperature measurements. By reducing its output when

the water flow rate is in danger of becoming insufficient, the boiler

continues to operate as long as possible. In case of insufficient ΔT

≥ 50°C flow or an excessive increase in flow temperature, the boiler

will enter shutdown mode for

10 minutes. When there is no water in

the boiler, or if the pump is not running, the system is locked

(breakdown)

In the event of a fault, the status signal for the B button on

the connection box flashes red.

¼

For more detailed information, see chapter: "Shutdowns and

lock-outs", page 63.

4.4.8. Overheat temperature protection

The maximum temperature protection locks the boiler if the water

temperature becomes too high (110°C).

In the event of a fault, the status signal for the B button on

the connection box flashes red.

¼

For more detailed information, see chapter: "Shutdowns and

lock-outs", page 63.

Anticycle function is active when heat demand is active and

the flow temperature is too high with respect to the

setpoint. The anticycle time can be active between 3

and 9 minutes depending on system temperatures.

4.5 Circulating pump (Available pump head)

The boiler is fitted with an on/off circulation pump.

1 Combi 24 - 28

2 Combi 35

H

Manometric height central heating circuit

Q

Water flow ( ΔT=20K)

R000684-A

12001000600 800400200

0

0

100

200

300

400

500

600

Q (l/h)

16001400

700

H (mbar)

1250

30 kW

317

1500

860

1030

20 kW

24 kW

253

127

1

2

4. Technical description Baxi MainEco Combi and System 24 - 28 - 35 / 18 - 24

16

02092014 - 7619497-02

System 18

H

Manometric height central heating circuit

Q

Water flow ( ΔT=20K)

System 24

H

Manometric height central heating circuit

Q

Water flow ( ΔT=20K)

4.6 Technical specifications

Boiler type MainEco

Combi 24 Combi 28 Combi 35 System 18 System 24

General

EC indentification no. PIN

0063CM3019

Input control Adjustable

Modulating, Start/Stop

Nominal output (Pn)

Heating System (80/60 °C)

min - max kW 5.5 - 19.5 5.5 - 23.4 7.7 - 29.2 5.5 - 17.7 5.5 - 23.4

Factory setting kW 19.5 19.5 29.2 17.7 23.4

Nominal output (Pn)

Heating System (50/30 °C)

min - max kW 6.1 - 20.9 6.1 - 24.8 8.5 - 31.0 6.1 - 18.8 6.1 - 24.8

Factory setting kW 20.9 20.7 31.0 18.8 24.8

Nominal output (Pn)

DHW System

min - max kW 5.5 - 23.4 5.5 - 27.5 7.7 - 33.9 - -

Factory setting kW 23.4 27.5 33.9 - -

Nominal input (Qn)

Heating System (Hi)

min - max kW 5.6 - 20.0 5.6 - 24.0 7.8 - 30.0 5.6 - 18.0 5.6 - 24.0

Factory setting kW 20.0 20.0 30.0 18.0 24.0

Nominal input (Qn)

Heating System (Hs)

min - max kW 6.2 - 22.2 6.2 - 26.7 8.7 - 33.3 6.2 - 20.0 6.2 - 26.7

Factory setting kW 22.2 22.2 33.3 20.0 26.7

Nominal input (Qnw)

DHW System (Hi)

min - max kW 5.6 - 24.0 5.6 - 28.2 7.8 - 34.9 - -

Factory setting kW 24.0 28.2 34.9 - -

Nominal input (Qnw)

DHW System (Hs)

min - max kW 6.2 - 26.7 6.2 - 31.3 8.7 - 38.8 - -

Factory setting kW 26.7 31.3 38.8 - -

Heating efficiency under full load (Hi) (80/60 °C) % 97.6 97.6 97.2 98.2 97.6

Heating efficiency under full load (Hi) (50/30 °C) % 104.5 103.3 103.3 104.5 103.3

Heating efficiency under partial load (Hi)

(Return temperature 60°C)

% 97.8 97.8 98.4 97.8 97.8

Heating efficiency under partial load (Hi) (92/42

EEG) (Return temperature 30°C)

% 109.2 109.2 108.8 109.3 109.2

SEDBUK 2005 - 2009 % 90.4 - 89.4 90.3 - 89.3 90.1 - 89.1 90.4 - 89.4 90.3 - 89.3

Data on the gases and combustion gases

Equipment categories - I

2H

Type of air/flue gas connection - C

13

, C

33

, C

53

Gas inlet pressure G20 min - max mbar 17 - 23

Connecting pressure G20 mbar 20

Gas consumption G20 max

m

3

/h

2.54 2.98 3.68 1.90 2.54

NOx annual emission (n=1) mg/kWh 53 58 52 41 58

Mass flue gas flow rate maximum kg/h 9.4 - 38.7 9.4 - 45.5 13.1 - 56.2 9.4 - 29.1 9.4 - 38.7

(1) Front panel removed

R000685-A

12001000600 800400200

0

0

100

200

300

400

500

600

H (mbar)

Q (l/h)

16001400

775

18 kW

280

R000365-A

12001000600 800400200

0

0

100

200

300

400

500

600

H (mbar)

Q (l/h)

16001400

860

1030

20 kW

24 kW

253

127

Baxi MainEco Combi and System 24 - 28 - 35 / 18 - 24 4. Technical description

02092014 - 7619497-02

17

Boiler type MainEco

Combi 24 Combi 28 Combi 35 System 18 System 24

Flue gas temperature min - max °C 32 - 78 32 - 84 31 - 82 32 - 65 32 - 78

Maximum counter pressure Pa 80 116 105 - 80

Characteristics of the heating circuit

Water content l 1.6 1.6 1.7 1.4 1.4

Water operating pressure minimum bar 0.8 0.8 0.8 0.8 0.8

Water operating pressure (PMS) maximum bar 2.5 2.5 2.5 2.5 2.5

Water temperature maximum °C 110 110 110 110 110

Operating temperature maximum °C 90 90 90 90 90

Manometric height central heating circuit (ΔT = 20K) mbar 253 127 317 280 275

Characteristics of the domestic hot water circuit

Specific hot water flow Rate 35 °C Rise l/min 9.8 11.4 14.3 - -

Domestic water resistance (without flow restrictor) mbar 96 123 215 - -

Flow rate threshold minimum l/min 1.2 1.2 1.2 - -

Water content l 0.16 0.16 0.18 - -

Operating pressure (Pmw) maximum bar 8 8 8 - -

Electrical characteristics

Power supply voltage VAC 230 230 230 230 230

Power consumption - Full load maximum W 105 117 145 92 103

Power consumption - Part load maximum W 82 82 101 82 82

Power consumption - Standby maximum W 3 3 3 3 3

Electrical protection index IP X4D

Other characteristics

Weight (empty)

Total kg 26 26 28.5 25 24.5

Mounting

(1)

kg 24 24 27 23 23

Acoustic level at 1

metre

maximum Heating System dB(A) 38 38 42 38 40

maximum DHW System dB(A) 40 42 45 - -

(1) Front panel removed

4. Technical description Baxi MainEco Combi and System 24 - 28 - 35 / 18 - 24

18

02092014 - 7619497-02

/