Ransomes 69168, 69169 User manual

- Category

- Lawnmowers

- Type

- User manual

Technical Repair Manual

600 Series Turfcat

Models 69168 & 69169

Technical Repair Manual

600 Series Turfcat

Models 69168 & 69169

!

WARNING: If incorrectly used this machine can cause sever injury. Those

who use and maintain this machine should be trained in its proper use,

warned of its dangers and should read the entire manual before attempting

to set up, operate, adjust or service the machine.

Litho in the U.S.A. 1/2011

Part Number 4241622

©2011, Jacobsen, A Textron Company. All rights reserved.

SECTION 1

INTRODUCTION

1A General Information........................................................................................................................................ 1

Contents................................................................................................................................................... 1

Index Numbers......................................................................................................................................... 1

Replacement Parts................................................................................................................................... 1

California Proposition 65 Warning............................................................................................................ 2

Specifications........................................................................................................................................... 2

Serial Numbers ........................................................................................................................................ 4

General Cleaning..................................................................................................................................... 4

Safety....................................................................................................................................................... 4

Torque Values .......................................................................................................................................... 5

1

Page Intentionally Blank

INTRODUCTION

1A-1

SECTION 1A. GENERAL INFORMATION

CONTENTS

This manual contains repair instructions for major trac-

tor components, attachments, and options. The Table

of Contents at the start of each section lists the con-

tents of that section. Sections are identified by tabs in

the right hand margin.

This manual is to be used in conjunction with the Oper-

ator’s Manual and Parts Catalog.

Normal maintenance, adjustment, and operating pro-

cedures are also covered in the Operator’s Manual and

are only included where appropriate in this Service and

Repair Manual.

Engine repair is not covered in this manual. Refer to

the appropriate engine manufacturer’s instructions for

engine service and repair.

This manual includes all removal, disassembly, inspec-

tion, repair, reassembly, installation, adjustment, and

testing procedures. If you, as the user of this machine,

do not consider yourself or your repair facilities capable

of a given procedure, please contact your Jacobsen

dealer or distributor.

Information, specifications, illustrations, and proce-

dures in this manual are based on information in effect

at the time this manual was published. Improvements

and product changes due to continual advancements

of the product design may cause changes to your prod-

uct that may not be included in this manual. Each man-

ual is reviewed and updated as required to include

changes and product improvements.

Read each section completely before proceeding with

specific repairs in that section. You will minimize errors

by understanding what you will be doing and how the

component relates to others in its system. Lists of

repair tools and materials for each section of the man-

ual are given at the start of that section.

The designations L.H. (left hand) and R.H. (right hand)

are used throughout this manual and refer to the oper-

ator’s left or right when sitting in the normal operating

position.

INDEX NUMBERS

Illustrations showing removal, disassembly, reassem-

bly, and illustration may have index numbers to call out

the sequence of procedures.

Where the sequence of procedures is not important or

self-evident (e.g. linkages, hoses, clamps, etc.) index

numbers are not included.

Repair procedures for items not subject to wear (e.g.

panels, brackets, frames) are not included in this man-

ual except for the general procedures given.

Exercise common sense during disassembly or reas-

sembly; remove only the items required to accomplish

the necessary repair or service.

REPLACEMENT PARTS

Use the appropriate Parts & Maintenance Manual

when ordering replacement parts. Follow the installa-

tion instructions shipped with service parts or kits.

When ordering parts, always give the serial number

and product number and description of the parts

needed.

To eliminate error and speed delivery:

1. Write your NAME and ADDRESS on your order

plainly.

2. Explain WHERE and HOW to make shipment.

3. Give the PRODUCT NUMBER, NAME, and

SERIAL NUMBER that is stamped on the NAME

and SERIAL PLATE of your product.

4. Order by QUANTITY DESIRED, the PART NUM-

BER, and the PART DESCRIPTION.

5. Send your order to or visit your nearest Jacobsen

dealer or distributor.

6. INSPECT ALL SHIPMENTS UPON RECEIPT. If

any parts are damaged or missing, file a claim

with the carrier before accepting.

7. Do not return material to your Jacobsen dealer or

distributor without a letter of explanation. Make a

list of all returned parts, show your name and

address, and include the letter and list with the

shipment. TRANSPORTATION CHARGES MUST

BE PREPAID.

1A

INTRODUCTION

1A-2

CALIFORNIA PROPOSITION 65

WARNING

SPECIFICATIONS

Product Information

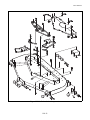

An identification plate, like the one shown, listing the

serial number, is attached to the frame of the tractor

near the center lift arm mount (Figure 1A-2).

Always provide the serial number of the unit when

ordering replacement parts or requesting service infor-

mation.

Figure 1A-1. Serial Plate

Engine

Make/Model..........................D1305-E3B Kubota Diesel

Cylinders..................................................................... 3

Displacement..............................76.95 cu. in. (1261 cc)

Cooling.....Liquid Cooled/w 15 in (381 mm) 8 blade fan

Air filter..............Donaldson dry type w/evacuator valve

Alternator .......................................................... 40 amp

Max rated horsepower ......29.1 (21.7 kW) @ 3000 rpm

Torque......................59.1 ft-lbs (80.1 Nm) @ 2000 rpm

High idle speed ..............................................3220 rpm

Low idle speed...............................................1750 rpm

Fuel capacity....................................9 US gal (34 liters)

Hydraulic System

Capacity...........................................6.8 gal (25.7 liters)

Fluid Type ................................................Jac. (10W30)

Cooling (type)..........................................Hyd. oil cooler

Filter micron rating ......10 micron suction filter w/gauge

Traction System

Drive..Hydrostatic Traction Pump to front wheel motors

in a parallel-series flow to rear wheel motors (4WD).

Forward speed...........................0-10 mph (0-16.1 kph)

Mow speed.....................................0-6 mph (0-9.6 kph)

Reverse speed...............................0-3 mph (0-4.8 kph)

Traction Pump max flow..............18.8 gpm (71.16 lpm)

System relief setting......................... 3625 psi (250 bar)

Deck System

Drive...........Hydraulic gear pump and motor w/ electro/

hydraulic control valve

Deck number & size...(1) 63 in or 72 in side discharge,

60 in or 72 in rear discharge, 60 in or 72 in Envirodeck,

or 60 in Fine-cut Flail

Deck section pump flow...................14 gpm (52.9 lpm)

Deck section relief setting.............3200 psi (220.7 bar)

60 in rear discharge

Number of blades & size per deck............................(3)

................0.25 in (6.4 mm) thick x 21 in (533 mm) long

Blade tip speed ......................12744 ft/min (4189 m/m)

Deck material thickness

.......................................11 gauge 0.1196 in (3.74 mm)

...............................7 gauge skirts 0.1875 in (4.76 mm)

Height of cut range..................1-4.75 in (25.4-121 mm)

63 in side discharge

Number of blades & size per deck............................(3)

................0.25 in (6.4 mm) thick x 22 in (559 mm) long

Blade tip speed ................... 14399 ft/min (4388.8 m/m)

Deck material thickness

.......................................11 gauge 0.1196 in (3.74 mm)

...............................7 gauge skirts 0.1875 in (4.76 mm)

Height of cut range..................1-4.75 in (25.4-121 mm)

72 in side and rear discharge

Number of blades & size per deck............................(3)

................0.25 in (6.4 mm) thick x 25 in (635 mm) long

Blade tip speed ......................14071 ft/min (4289 m/m)

Deck material thickness

.......................................11 gauge 0.1196 in (3.74 mm)

...............................7 gauge skirts 0.1875 in (4.76 mm)

Height of cut range..................1-4.75 in (25.4-121 mm)

72 in Envirodeck

Number of blades & size per deck............................(3)

..........0.25 in (6.4 mm) thick x 24.9 in (632.5 mm) long

Blade tip speed ......................17540 ft/min (5346 m/m)

Deck material thickness....10 gauge 0.135 in (3.4 mm)

Height of cut range..................1-4.75 in (25.4-121 mm)

WARNING

Certain vehicle components contain or emit chemi-

cals known to the state of California to cause cancer

and birth defects or other reproductive harm.

!

INTRODUCTION

1A-3

60 in Flail

Number of blades.................................................... 144

Blade speed............................. 8042 ft/min (2451 m/m)

Deck material thickness....10 gauge 0.135 in (3.4 mm)

Height of cut range............................0-4 in (0-102 mm)

Lift System

Type ..........Hand operated single lever hydraulic circuit

Lift system flow................................ 5.9 gpm (22.3 lpm)

Lift system relief setting...................... 915 psi (63 bars)

Steering System

Type .......................Hydrostatic steering to rear wheels

Steering system pump flow............. 5.9 gpm (22.3 lpm)

Steering system relief setting............. 915 psi (63 bars)

Tractor Specifications

Tire size - front......................23 x 10.5 - 12:4 ply rating

......................................(584 mm x 266 mm - 305 mm)

Tire size -rear..........................18 x 18.5 - 8:4 ply rating

......................................(457 mm x 216 mm - 203 mm)

Brakes - service .................... Dynamic braking through

traction circuit

Brakes - parking..............7 x 1.75 in (177.8 x 44.4 mm)

...........................................................Mechanical drum

Turning radius................................. 12.0 in (304.8 mm)

Zero at inside wheel with optional traction-assist brake

on left and right wheel

Sound level rating at operator’s ear (w/72 in deck).......

........................................................................88.1 dBa

Production

60 in ..................................2.8 acres per hour at 6 mph

72 in ..................................3.5 acres per hour at 6 mph

.....................................................(80% of full capacity)

Dimensions

Length with longest deck ................ 122.12 in (310 cm)

Height (to top of hood) .........................44.5 in (113 cm)

Height (to top of ROPS)......................... 82 in (208 cm)

Width (tractor) ........................................ 52 in (132 cm)

Transport width w/ widest deck........... 85.5 in (217 cm)

Ground clearance ................................ 6.5 in (16.5 cm)

Weights

Tractor only

2WD...................................................1440 lbs (653 kg)

4WD...................................................1490 lbs (676 kg)

Decks

63 in side discharge.............................474 lbs (215 kg)

60 in rear discharge .............................390 lbs (177 kg)

72 in side discharge.............................492 lbs (223 kg)

72 in rear discharge .............................505 lbs (229 kg)

72 in Envirodeck...................................485 lbs (220 kg)

60 in Flail..............................................366 lbs (166 kg)

NOTE:

All pump flows and blade tip speeds are at high

idle engine speed and maximum volumetric effi-

ciency.

Accessories and Support Literature

Contact your area Jacobsen dealer for a complete list-

ing of accessories and attachments

Accessories

Canopy / Sunshade Kit

Exhaust Spark Arrestor (Required in California

Leaf Mulcher (For 72 in. Side Discharge Cutting Deck)

Counter Weights

Tie-Down Brackets

Traction Assist / Steering Brakes

High Volume Wheel Motor Kit

Differential Lock Kit - 2WD model only

Support Literature

Safety & Operation Manual

Parts & Maintenance Manual

Engine Parts Catalog

Operator Training Video

Service & Repair Manual

CAUTION

Use of other than Jacobsen authorized parts and

accessories may cause personal injury or damage to

the equipment and will void the warranty.

!

INTRODUCTION

1A-4

SERIAL NUMBERS

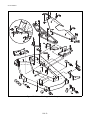

See Figure 1A-2 for location of tractor assembly serial

number.

Figure 1A-2. Serial Number Location

GENERAL CLEANING

Improper cleaning and lubrication of your machine

results in equipment failures. Before any repairs are

undertaken, thoroughly clean the exterior of the com-

ponent to be removed.

Use a clean surface to lay out parts being removed.

Keep lubricants clean and cover containers not being

used. Plug or cap all hydraulic lines and ports to

hydraulic components immediately after disconnecting.

SAFETY

Safety should always be the rule when working on or

with machinery. Always use safe practices and com-

mon sense when using hand or power tools. Use the

suggested procedures in this manual when working

with the tractor.

Throughout this manual signal words will be used to

highlight special procedures. The signal words and

their meanings are as follows:

Any task needing specialized special care when

performing a procedure.

Decals on the machine denote cautions, warnings, and

dangers. These cautions, warnings, and danger decals

must be on the machine at all times. If they become

worn, torn, or painted over, new decals should be

installed as shown in SECTION 14A. of this manual.

DANGER

Imminent hazards which will result in severe per-

sonal injury or death if precautions are not taken.

Serial No. Plate

On Right Side of Frame

!

WARNING

Hazards or unsafe practices which could result in

severe personal injury or death.

CAUTION

Hazards or unsafe practices which may result in per-

sonal injury, or product or property damage.

NOTICE

Indicates a potentially hazardous situation which,

if not avoided, MAY result in property damage. It

may also be used to alert against unsafe

practices.

CAUTION

Disconnect leads at the alternator before electric

welding is done on components in common ground

with the engine.

WARNING

This machine is equipped with an interlock system

intended to protect the operator and others from

injury by preventing the engine from starting, unless

the PTO switch is in the “OFF” position, traction

pedal is in the “Neutral” position and the brake is set.

The system also shuts off the engine if the operator

leaves the seat with the PTO switch in the “Cut”

position. In the interest of safe operating conditions,

this machine must never be operated with the inter-

lock relays or interlock system disconnected or mal-

functioning.

!

!

!

!

INTRODUCTION

1A-5

TORQUE VALUES

Torque values are given in the “Torque Specifications

Chart.” Special torque values are called out in illustra-

tions and text throughout this manual.

Torque Specifications – Standard

AMERICAN NATIONAL STANDARD FASTENERS

SIZE UNITS

GRADE 5 GRADE 8

Lubricated Dry Lubricated Dry

#6-32 in-lb (Nm) – 20 (2.3) – –

#8-32 in-lb (Nm) – 24 (2.7) – 30 (3.4)

#10-24 in-lb (Nm) – 35 (4.0) – 45 (5.1)

#10-32 in-lb (Nm) – 40 (4.5) – 50 (5.7)

#12-24 in-lb (Nm) – 50 (5.7) – 65 (7.3)

1/4-20 in-lb (Nm) 75 (8.4) 100 (11.3) 107 (12.1) 143 (16.1)

1/4-28 in-lb (Nm) 85 (9.6) 115 (13.0) 120 (13.5) 163 (18.4)

5/16-18 in-lb (Nm) 157 (17.7) 210 (23.7) 220 (24.8) 305 (34.4)

5/16-24 in-lb (Nm) 173 (19.5) 230 (26.0) 245 (27.6) 325 (36.7)

3/8-16 ft-lb (Nm) 23 (31.1) 31 (42.0) 32 (43.3) 44 (59.6)

3/8-24 ft-lb (Nm) 26 (35.2) 35 (47.4) 37 (50.1) 50 (67.8)

7/16-14 ft-lb (Nm) 37 (50.1) 50 (67.8) 53 (71.8) 70 (94.9)

7/16-20 ft-lb (Nm) 42 (56.9) 55 (74.6) 59 (80.0) 78 (105)

1/2-13 ft-lb (Nm) 57 (77.2) 75 (101) 80 (108) 107 (145)

1/2-20 ft-lb (Nm) 64 (86.7) 85 (115) 90 (122) 120 (162)

9/16-12 ft-lb (Nm) 82 (111) 109 (148) 115 (156) 154 (209)

9/16-18 ft-lb (Nm) 92 (124) 122 (165) 129 (174) 172 (233)

5/8-11 ft-lb (Nm) 113 (153) 151 (204) 159 (215) 211 (286)

5/8-18 ft-lb (Nm) 128 (173) 170 (230) 180 (244) 240 (325)

3/4-10 ft-lb (Nm) 200 (271) 266 (360) 282 (382) 376 (509)

3/4-16 ft-lb (Nm) 223 (302) 298 404 315 (427) 420 (569)

7/8-14 ft-lb (Nm) 355 (481) 473 (641) 500 (678) 668 (905)

INTRODUCTION

1A-6

Torque Specifications – Metric

METRIC FASTENERS

SIZE UNITS

Non

Critical

Fasteners

into

Aluminum

Lubricated Dry Lubricated Dry Lubricated Dry Lubricated Dry

M4 Nm

(in-lb)

––––––3.83

(34)

5.11

(45)

2.0

(18)

M5 Nm

(in-lb)

1.80

(16)

2.40

(21)

4.63

(41)

6.18

(54)

6.63

(59)

8.84

(78)

7.75

(68)

10.3

(910

4.0

(35)

M6 Nm

(in-lb)

3.05

(27)

4.07

(36)

7.87

(69)

10.5

(93)

11.3

(102)

15.0

(133)

13.2

(117)

17.6

(156)

6.8

(60)

M8 Nm

(in-lb)

7.41

(65)

9.98

(88)

19.1

(69)

25.5

(226)

27.3

(241)

36.5

(323)

32.0

(283)

42.6

(377)

17.0

(150)

M10 Nm

(ft-lb)

14.7

(11)

19.6

(14)

37.8

(29)

50.5

(37)

54.1

(40)

72.2

(53)

63.3

(46)

84.4

(62)

33.9

(25)

M12 Nm

(ft-lb)

25.6

(19)

34.1

(25)

66.0

(48)

88.0

(65)

94.5

(70)

125 (92) 110

(81)

147

(108)

61.0

(45)

M14 Nm

(ft-lb)

40.8

(30)

54.3

(40)

105

(77)

140

(103)

150

(110)

200

(147)

175

(129)

234

(172)

94.9

(70)

4.6

8.8

10.9

12.9

CONTROLS

--1

SECTION 2

CONTROLS

2A Service Tools, Materials, and Specifications................................................................................................... 1

Materials Required................................................................................................................................... 1

Specifications........................................................................................................................................... 1

2B Failure Analysis .............................................................................................................................................. 3

General .................................................................................................................................................... 3

2C Control Adjustments ....................................................................................................................................... 5

General .................................................................................................................................................... 5

Throttle..................................................................................................................................................... 5

Neutral Switch.......................................................................................................................................... 6

Traction Pedal Neutral Adjustment........................................................................................................... 6

Maximum Transport Speed...................................................................................................................... 7

Parking Brake........................................................................................................................................... 7

Brake Interlock Switches.......................................................................................................................... 8

2D Gauges and Instruments ................................................................................................................................ 9

Repair....................................................................................................................................................... 9

2

CONTROLS

-0

Page Intentionally Blank

CONTROLS

2A-1

SECTION 2A. SERVICE TOOLS, MATERIALS, AND SPECIFICATIONS

MATERIALS REQUIRED

l

SPECIFICATIONS

Throttle

Engine low idle speed.................................... 1750 rpm

Engine high idle speed................................... 3220 rpm

Neutral Switch

Neutral switch ......................................Normally closed

Traction Pedal

Transport speed.............................10 mph (16.1 km/h)

Parking Brake

Brake pedal free play......0.750 to 1.5 in (19 to 38 mm)

Parking brake switches..........................Normally open

Tools required:

Standard automotive hand tools

Cleaning

materials:

Stoddard solvent or equivalent

Detergent and water

Lubricants:

Refer to Section 11

2A

CONTROLS

2A-2

Page Intentionally Blank

CONTROLS

2B-3

SECTION 2B. FAILURE ANALYSIS

GENERAL

The following table lists common problems, probable

causes, and suggested remedies with section refer-

ences to detailed descriptions of remedial procedures.

PROBLEM PROBABLE CAUSE REMEDY

1. Engine does not turn over a. Not in neutral

b. Electrical fault

c. Neutral start switch not

adjusted or faulty

d. Dead battery

a. Check neutral position

b. See Electrical Failure Analy-

sis (Section 10B)

c. Adjust (Section 2C)

Check (Section 10G)

d. Charge battery or replace as

necessary

2. Engine speed does not

increase when throttle con-

trol is moved

a. Throttle control is not properly

adjusted

b. Throttle control is broken

a. Adjust (Section 2C)

b. Repair or replace

(Section 2C)

3. The unit “creeps” in either

direction when the treadle

pedal is not depressed

a. Traction pedal linkage out of

adjustment

b. Centering spring out of

adjustment

a. Adjust traction (Section 2C)

b. Adjust centering spring

4. Parking brake fails a. Brake not adjusted

b. Worn brake shoes

c. Damaged or broken linkage

a. Adjust brake (Section 2C)

b. Replace pads (Section 5C)

c. Repair as necessary

5. Mower deck does not lift or

lower properly as lever is

activated

a. Control valve leaking or

defective

b. System relief valve too low

c. Faulty lift cylinder

d. Faulty charge pump

a. Test valve (Section 8L)

Repair valve (Section 8I)

b. Adjust (Section 8L)

c. Test cylinder (Section 8L and

Section 8M)

d. Test pump (Section 8M)

6. Slow traction speed a. Engine rpm too low

b. Pedal linkage not adjusted

c. Parking brake not releasing

d. Faulty hydro

a. Adjust (Section 2C)

b. Adjust (Section 2C)

c. Adjust (Section 2C)

d. Test hydro pump

(Section 8M)

2B

CONTROLS

2B-4

Page Intentionally Blank

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

-

114

114

-

115

115

-

116

116

-

117

117

-

118

118

-

119

119

-

120

120

-

121

121

-

122

122

-

123

123

-

124

124

-

125

125

-

126

126

-

127

127

-

128

128

-

129

129

-

130

130

-

131

131

-

132

132

-

133

133

-

134

134

-

135

135

-

136

136

-

137

137

-

138

138

-

139

139

-

140

140

-

141

141

-

142

142

-

143

143

-

144

144

-

145

145

-

146

146

-

147

147

-

148

148

-

149

149

-

150

150

-

151

151

-

152

152

-

153

153

-

154

154

-

155

155

-

156

156

-

157

157

-

158

158

-

159

159

-

160

160

-

161

161

-

162

162

-

163

163

-

164

164

-

165

165

-

166

166

-

167

167

-

168

168

-

169

169

-

170

170

-

171

171

-

172

172

-

173

173

-

174

174

-

175

175

-

176

176

-

177

177

-

178

178

-

179

179

-

180

180

-

181

181

-

182

182

-

183

183

-

184

184

-

185

185

-

186

186

-

187

187

-

188

188

-

189

189

-

190

190

-

191

191

-

192

192

-

193

193

-

194

194

-

195

195

-

196

196

-

197

197

-

198

198

-

199

199

-

200

200

-

201

201

-

202

202

-

203

203

-

204

204

-

205

205

-

206

206

-

207

207

-

208

208

-

209

209

-

210

210

-

211

211

-

212

212

-

213

213

-

214

214

-

215

215

-

216

216

-

217

217

-

218

218

-

219

219

-

220

220

-

221

221

-

222

222

-

223

223

-

224

224

-

225

225

-

226

226

-

227

227

-

228

228

-

229

229

-

230

230

-

231

231

-

232

232

-

233

233

-

234

234

-

235

235

-

236

236

-

237

237

-

238

238

-

239

239

-

240

240

-

241

241

-

242

242

-

243

243

-

244

244

-

245

245

-

246

246

-

247

247

-

248

248

-

249

249

-

250

250

-

251

251

-

252

252

-

253

253

-

254

254

-

255

255

-

256

256

-

257

257

-

258

258

-

259

259

-

260

260

-

261

261

-

262

262

-

263

263

-

264

264

-

265

265

-

266

266

-

267

267

-

268

268

-

269

269

-

270

270

-

271

271

-

272

272

-

273

273

-

274

274

-

275

275

-

276

276

-

277

277

-

278

278

-

279

279

-

280

280

-

281

281

-

282

282

-

283

283

-

284

284

-

285

285

-

286

286

-

287

287

-

288

288

-

289

289

-

290

290

-

291

291

-

292

292

-

293

293

-

294

294

-

295

295

-

296

296

-

297

297

-

298

298

-

299

299

-

300

300

-

301

301

-

302

302

-

303

303

-

304

304

-

305

305

-

306

306

-

307

307

-

308

308

-

309

309

-

310

310

-

311

311

-

312

312

-

313

313

-

314

314

-

315

315

-

316

316

-

317

317

-

318

318

-

319

319

-

320

320

-

321

321

-

322

322

-

323

323

-

324

324

-

325

325

-

326

326

-

327

327

-

328

328

-

329

329

-

330

330

-

331

331

-

332

332

Ransomes 69168, 69169 User manual

- Category

- Lawnmowers

- Type

- User manual

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

in other languages

Related papers

-

Textron 4171722 User manual

-

Ransomes 67862, 67863 Owner's manual

-

Ransomes 68080 Installation guide

-

Ransomes 68080 Owner's manual

-

Ransomes 70521 Owner's manual

-

Ransomes 70522, 70523 Owner's manual

-

Ransomes 71064 Owner's manual

-

Ransomes 69180 / 69195 Installation guide

-

Ransomes 69168 / 69169 Installation guide

-

Ransomes 69175 / 69176 Owner's manual

Other documents

-

AmeriHome BSSS1 Assembly Instructions

-

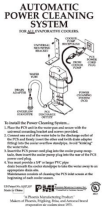

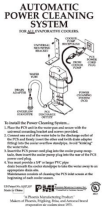

PMI PDP12-1 Operating instructions

PMI PDP12-1 Operating instructions

-

Toro Temperature Sender Kit, Groundsmaster 1000L Installation guide

-

Abus 500107032000 Datasheet

-

Toro Hydraulic System Cooling Kit, GrandStand Mower Installation guide

-

Ferris 5901703 Product information

Ferris 5901703 Product information

-

Ferris 5901703 Product information

Ferris 5901703 Product information

-

Cub Cadet ZTXS5 60 Ultima Series User manual

-

Broan H6HK, 25 Kw 240V,1-Phase Electric Heater Kit Product information

-

Toro Brake Kit, TX 1000 Compact Tool Carrier Installation guide