Page is loading ...

TEMLOCSafetyGuidelines

Caution:Somepartshavesharpedges.Protectivewear,suchasgloves,mustbeworn

whenhandlingbuildingparts.Pleasereadallsafetyinstructionbeforebeginningproject.

Generalunderstandingofmakingabuildingsquareandplumbisrequiredinorderto

assembleaTemloc building.

REV.022014

2

TEMLOCSafetyGuidelines

AssemblyInstructions

Beforebeginningassembly‐checkwithyourlocaljurisdictionaboutbuildingcoderequirments.

Assemblyteammate

TEMLOCrecommendsthataminimumoftwoadultsassemblethebuildingtogether.Donotattempttoassemblethisbuildingalone.

PersonalSafetyandProtections

Takecareofyourpersonalsafetybywearingeyeprotection,handprotection,foot

protectionandprotectiveclothing.Someofthebuildingpartscanbesharp

andwillcauseinjuryifnothandledproperly.Donotuseanypartofthebuildingscomponentstosupportapersonoranyother unintendeduse.

LadderSafety

PleasefollowalloftheUnitedStatesDept.ofLaborguidelinesassociated

withladdersafety.Pleasereferto

http://www.osha.gov/Publications/portable_ladder_gc.html withanyquestions.

IMPORTANT:TEMLOCSTEELBUILDINGSONLYOFFERSTHESEWARNINGSANDINSTRUCTIONSASGUIDELINES.ITISTHESOLERESPONSIBILITYOFTHE

ASSEMBLERFORSAFETYINHANDLING,ANDASSEMBLYOFTHEPARTS,ANDTHEBUILDING.

IMPORTANT:MANUFACTURERCANNOTBEHELDRESPONSIBLEFORANYCONSEQUENCESDUETOBUILDINGSTHATARENOTINSTALLEDPERINSTRUCTIONS

ORFOR

DAMAGEDUETOWEATHERCONDITIONSORACTSOFGOD.

REV.022014

3

TEMLOCSiteSelection

Guidelines

SiteSelection

Therearesev eralconsiderationsyouneedtotakeintoaccountwhenselectingthesiteforyourbuilding.Checkwithyourlocal jurisdictionaboutbuilding

coderequirements.

Belowisalimitedlistofconsiderationswhenchoosingasite:

1.Properdrainageawayfromtheperimeterofthebuilding.Youmayneedto

buildupapad,oradjustthegradesoyoucreatepositive

drainageandwaterwillnotrunintothefloororfoundation.

2.Markwhereallthesprinklerheads aretoavoidhavingonelocatedunderthebuilding.Oncethebuildingissetyoumaylookatchanging

outtheheads

tomakesuretheyfaceawayfromthebuilding.

3.UndergroundUtilities–Checkforlocationsofseptictanksorundergroundutilities.Neverlocateabuildingoveraseptictank,electrical

lineorgaslines.

4.Roofdrainagefromexistingstructuresandtherunofffromthebuildingitself.Thebuildingshave

a3”overhangdownthelengthoneach

side.

5.Overheadobstaclessuchaslimbsandpowerlines.

Thepropersiteconsiderationswillpreventissueswiththeinstallationinthefuture.TEMLOCSTEELBUILDINGSONLYOFFERSTHESECONSIDERATIONS

GUIDELINES.Itisthesoleresponsibilityofthecustomertoinsureproperinstallation.

REV.022014

4

TEMLOCToolGuidelines

ToolsRequired:

• 3footlevel

• 25’tapemeasure

• 18voltdrillorimpactwithchargerandextrabattery

• 2StepLadders6or8foot

• Tinsnips

• ½”Socketfor5/16”bolts

• Ratchet

• ½”BoxEndWrench

• 5/16”MagneticHexHeadDriverfortheTeks androofingscre ws

• Extensioncordfor

batterycharger

• Skillsawifyouarebuildingfloorforcuttingthedecking

• SafetyGlasses

• LeatherGlovesforhandlingsteel

• CaulkingGunandglueifyouaregluingthedeckingtothejoists

REV.022014

5

TEMLOCSteelStorageBuilding

PartsList

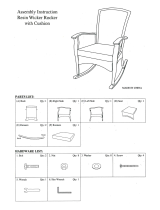

Note:Numberson

thispagecorrespond

toitemnumbers

Onpackinglist

6

TEMLOCSteelStorageBuilding

PartsList

Note:Numberson

thispagecorrespond

toitemnumbers

Onpackinglist

7

RollCaulk

QTY:2

TEMLOCSteelStorageBuilding

PartsList

Note:Numberson

thispagecorrespond

toitemnumbers

Onpackinglist

8

27

ClosedCellGasket

QTY:150LIN Ft.

5/16” FlangeNut

QTY:180

5/16”x¾”HexBolt

QTY:160

#10PanHeadTek Screw

QTY:160

#10Tek Screws(Painted)

QTY:260

TEMLOCSteelStorageBuilding

PartsList

Note:Numberson

thispagecorrespond

toitemnumbers

Onpackinglist

32

30

REV.022014

9

31

28

ClosureStripInside

QTY:11

ClosureStrip Outside

QTY:11

1”RoofScrew

QTY:180

OctagonWindow

QTY:2

#2SquareDrive

QTY:1

TEMLOCSteelStorageBuilding

PartsList

Note:Numberson

thispagecorrespond

toitemnumbers

Onpackinglist

39

38

40

REV.022014

10

41

42

12x1ExteriorTek Screws

QTY:260

WoodtoMetalTek Screw

QTY:350

TEMLOCSteelStorageBuilding

PartsList

Note:Numberson

thispagecorrespond

toitemnumbers

Onpackinglist

F7

F8

REV.022014

11

REV.022014

12

1. AssemblyofFloorJoists

A. Attachpart1and2matchingupholes

B. Use#12x1ext.tek screwsF7

C. Part1goesoverpart2

D. Assembleremainingfloorjoists

REV.022014

13

1. SideBandConnections

A. Attachlongpiecesusing#12ext.Tek screwsF7

B. Seedrawingfordetail

C. Duplicateforrightandleftside

REV.022014

14

1. RailAssembly

A. Markthetopofsidebandsat16”oncenterstartingatfrontofbothsides

B. Installendjoist

C. Seedetailatfrontthereisdoublejoistandasingleatback

D. Use#12ext.Tek screwsF7throughpre‐punchedholestoattachjoists(centerjoistsonmarks)

E. Continuetofill

betweentheendswiththeotherfloorjoists

F. Recommendedtofacejoistssamewaybutnotrequired

G. Theendjoistssolidportionshouldfaceout

H. Nowyouarereadytoblockandlevel

I. Squarefloorandanchorit

J. Attachdeckingofyourchoice

K. Refertoadditionalsizetableformoresquaringinstructions

REV.022014

15

1. LayoutParts

A. Layoutallparts

B. Beforeyoustartmakesureyourfloorissquare&leveland

measures10’widex16’long

C. Crosstapedimensionforasquarefloorshouldbe18’107/16”

HelpfulHint:

Layingoutpartsbef oreassemblysavestime.

REV.022014

16

PurlinInstallationDetails

Forfurtherroofinginstructions,see

page45

TRUSSCAP&SEALINSTALLATIONDETAIL

LayoutParts

Step1

41

1. LayoutZBase

A. AttachZBasetofoundationusing#10Tek screws32

B. Seedetailviewformoreinstruction

C. Openingwidthbetweenpart4&5is7’0”

HelpfulHint:

Noticethecriticaldimension.Thismustbeheld.

NOTE:

Screwonlytothedecking.NoscrewsintheverticalpartoftheZBase.Start

screws2”fromedge&spaced12”betweentherestwith#10tek screws.

REV.022014

17

4.Preassembleallthetruss halves

A. Use5/16”bolts30andflangenuts29toattachtruss

halves17

B. Aligntrusshalves

C. Attachsplice16using#10panheadTek screws31

D. Seetrusssplicedetail

HelpfulHint:

Assemblethetrussesonalevelsurface.Alignthetopand

bottombeforetightening.Witha

markermarkthepurlin

placementat2”fromtheend.

REV.022014

18

5.Installwallpanels

A. Installtherightcornerpanels11&9

B. Seecornerpanelslayoutviewatbottomleftcornerofpage

C. Alignthepanelsatthetop&bottom

D. Use#10Tek screws32toattachpanel11topanel9throughpilot

holes

E. Use#10Tek screws32toattachpanelstofloor

throughpilotholes

F. Repeatfortheleftside

HelpfulHint:

Installonecorneratatime.The30”frontwall

piecefirst.Thatpanelshouldlineuponthe

floorbasetoholdtodooropeningtrue.Align

atthetopandbottomofthefrontpanelbefore

screwinginthepilot

holes.

TopView

REV.022014

19

6. Installwallcaps

A. Placewallcap14&15ontopofpanels(theserestfreelyontop)

B. AttachdoorheaderD2topanelsusing#10Tek screws32

HelpfulHint:

Topwallcapsjustsitontopofthewallpanelsuntiltheheaderis

secured.Thesolidsurfaceoftheheaderfaces

totheoutside.

NOTE:

Installdoorheadersolidsurfacefacingdown

andtotheoutside,verticallegtighttothewall

capandflushtothetoppanel.

REV.022014

20

1/56