Page is loading ...

MODELS

United States 0G531301 and ABOVE. .

Belgium 09974454 and ABOVE. . . . . . .

With Serial Numbers

SERVICE

MANUAL

40·50·55·60

Printed in U.S.A.

1997, Mercury Marine

90-852572R1 JANUARY 1998

90-852572R1 JANUARY 1998 i

Notice

Throughout this publication, “Dangers”, “Warnings”

and “Cautions” (accompanied by the International

HAZARD Symbol

) are used to alert the mechanic

to special instructions concerning a particular service

or operation that may be hazardous if performed in-

correctly or carelessly.

OBSERVE THEM CARE-

FULLY!

These “Safety Alerts” alone cannot eliminate the haz-

ards that they signal. Strict compliance to these spe-

cial instructions when performing the service, plus

“Common Sense” operation, are major accident pre-

vention measures.

DANGER

DANGER - Immediate hazards which WILL result

in severe personal injury or death.

WARNING

WARNING - Hazards or unsafe practices which

COULD result in severe personal injury or death.

CAUTION

Hazards or unsafe practices which could result

in minor personal injury or product or property

damage.

Notice to Users of This

Manual

This service manual has been written and published

by the Service Department of Mercury Marine to aid

our dealers’ mechanics and company service per-

sonnel when servicing the products described here-

in.

It is assumed that these personnel are familiar with

the servicing procedures of these products, or like or

similar products manufactured and marketed by

Mercury Marine, that they have been trained in the

recommended servicing procedures of these prod-

ucts which includes the use of mechanics’ common

hand tools and the special Mercury Marine or recom-

mended tools from other suppliers.

We could not possibly know of and advise the service

trade of all conceivable procedures by which a ser-

vice might be performed and of the possible hazards

and/or results of each method. We have not under-

taken any such wide evaluation. Therefore, anyone

who uses a service procedure and/or tool, which is

not recommended by the manufacturer, first must

completely satisfy himself that neither his nor the

products safety will be endangered by the service

procedure selected.

All information, illustrations and specifications con-

tained in this manual are based on the latest product

information available at the time of publication. As re-

quired, revisions to this manual will be sent to all deal-

ers contracted by us to sell and/or service these prod-

ucts.

It should be kept in mind, while working on the prod-

uct, that the electrical system and ignition system are

capable of violent and damaging short circuits or se-

vere electrical shocks. When performing any work

where electrical terminals could possibly be

grounded or touched by the mechanic, the battery

cables should be disconnected at the battery.

Any time the intake or exhaust openings are exposed

during service they should be covered to protect

against accidental entrance of foreign material which

could enter the cylinders and cause extensive inter-

nal damage when the engine is started.

It is important to note, during any maintenance proce-

dure replacement fasteners must have the same

measurements and strength as those removed.

Numbers on the heads of the metric bolts and on the

surfaces of metric nuts indicate their strength. Ameri-

can bolts use radial lines for this purpose, while most

American nuts do not have strength markings. Mis-

matched or incorrect fasteners can result in damage

or malfunction, or possibly personal injury. There-

fore, fasteners removed should be saved for reuse in

the same locations whenever possible. Where the

fasteners are not satisfactory for re-use, care should

be taken to select a replacement that matches the

original.

ii 90-852572R1 JANUARY 1998

Cleanliness and Care of

Outboard Motor

A marine power product is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the ten thousands of

an inch./mm. When any product component is serv-

iced, care and cleanliness are important. Throughout

this manual, it should be understood that proper

cleaning, and protection of machined surfaces and

friction areas is a part of the repair procedure. This is

considered standard shop practice even if not specif-

ically stated.

Whenever components are removed for service,

they should be retained in order. At the time of instal-

lation, they should be installed in the same locations

and with the same mating surfaces as when re-

moved.

Before raising or removing and outboard engine from

a boat, the following precautions should be adhered

to:

1. Check that flywheel is secured to end of crank-

shaft with a locknut and lifting eye is threaded into

flywheel a minimum of 5 turns.

2. Connect a hoist of suitable strength to the lifting

eye.

In addition, personnel should not work on or under an

outboard which is suspended. Outboards should be

attached to work stands, or lowered to ground as

soon as possible.

We reserve the right to make changes to this manual

without prior notification.

Refer to dealer service bulletins for other pertinent in-

formation concerning the products described in this

manual.

Page Numbering

Two number groups appear at the bottom of each

page. The example below is self-explanatory.

EXAMPLE:

90-826148R1 JANUARY 1997

LOWER UNIT - 6A-7

Revision No. 1

Month of Printing

Year of Printing

Section Description

Section Number

Part of Section Letter

Page Number

Important

Information

Electrical

Fuel System

Powerhead

Mid-Section

Lower Unit

Attachments/

Control Linkage

Manual Starter

8

1

2

3

4

5

6

7

90-852572R1 JANUARY 1998

iii

Service Manual Outline

Section 1 - Important Information

A - Specifications

B - Maintenance

C - General Information

D - Outboard Installation

Section 2 - Electrical

A - Ignition

B - Charging & Starting System

C - Timing, Synchronizing & Adjusting

D - Wiring Diagrams

Section 3 - Fuel System

A - Fuel Pump

B - Carburetor

C - Oil Injection

D - Emissions

Section 4 - Powerhead

Section 5 - Mid-Section

A - 40/50 Clamp/Swivel Brackets & Drive Shaft Housing

B - 55/60 Clamp/Swivel Brackets & Drive Shaft Housing

C - 40/50 Power Trim

D - 55/60 Power Trim

E - 40/50 Manual Tilt

F - 55/60 Manual Tilt

Section 6 - Lower Unit

A - 40/50 Lower Unit

B - 55/60 Lower Unit

C - 60 Bigfoot

D - Jet Drive

Section 7 - Attachments/Control Linkage

A - Throttle/Shift Linkage

B - Tiller Handle

Section 8 - Manual Starter

A

1

IMPORTANT

INFORMATION

SPECIFICATIONS

1A-0 - IMPORTANT INFORMATION 90-852572R1 JANUARY 1998

Table of Contents

Page

Specifications 1A-1. . . . . . . . . . . . . . . . . . . . . . . . . .

Propeller Information Charts 1A-4. . . . . . . . . . . . .

Mercury/Mariner 40 HP (3 Cyl.) 1A-4. . . . . . . . .

Mercury/Mariner 50 HP (3 Cyl.) 1A-5. . . . . . . . .

Mercury/Mariner 55 HP (3 Cyl.) 1A-6. . . . . . . . .

Mercury/Mariner 60 HP (3 Cyl.) 1A-7. . . . . . . . .

Mercury/Mariner 60 HP (3 Cyl.) Bigfoot 1A-8. .

90-852572R1 JANUARY 1998 IMPORTANT INFORMATION - 1A-1

Specifications

Models 40/50/55/60

HORSEPOWER

(kW)

Model 40

Model 50

Model 55

Model 60

40 (29.8)

50 (37.3)

55 (41.0)

60 (44.7)

OUTBOARD WEIGHT

Manual

40/50 ML

55 ML

Electric

40/50 ELPTO

40/50 ELO

60 ELPTO

60 ELO

205 lbs. (93.0 kg)

220 lbs. (99.8 kg)

204 lbs. (92.5 kg)

200 lbs. (90.7 kg)

219 lbs. (99.3 kg)

215 lbs. (97.5 kg)

CYLINDER BLOCK

Type

Displacement

3 Cylinder-2 Cycle-Loop Charged

59 cu. in. (967 cc)

STROKE Length 2.796 in. (71 mm)

CYLINDER BORE

Diameter

Taper/Out of Round Maximum

Bore Type

2.993 in. (76 mm)

0.003 in. (0.08 mm)

Cast Iron

PISTON

Type

Standard Diameter

0.015 in. (0.381 mm) Oversize

0.030 in. (0.762 mm) Oversize

Aluminum

2.988 in. (75.895 mm)

3.003 in. (76.276 mm)

3.018 in. (76.657 mm)

REEDS

Reed Stand Open (Max.)

Reed Stop (Max.)

40

50/55/60

Reed Thickness

0.020 in. (0.50 mm)

0.090 in. (2.286 mm)

Not Adjustable

0.010 in. (0.254 mm)

FUEL SYSTEM

Recommended Gasoline

Recommended Oil

Break-in Gasoline/Oil Ratio

Manual Start Models

Electric Start Models

After Break-in Gasoline/Oil Ratio

Manual Start Models

Electric Start Models

Fuel Pressure

@ Idle

@ W.O.T.

Unleaded-87 Octane Minimum

Quicksilver TC-WII or TC-W3

2 Cycle Outboard Oil

Pre-mixed Gasoline and Oil 25:1

50:1 (In Fuel Tank)

Pre-mixed Gasoline and Oil 50:1

Straight Gasoline

3.5 PSI (24 kPa)

6.0 PSI (41 kPa)

1A-2 - IMPORTANT INFORMATION 90-852572R1 JANUARY 1998

GEAR HOUSING

40/50

Gear Ratio

Gearcase Capacity

Lubricant Type

Forward Gear

Number of Teeth

Pinion Gear

Number of Teeth

Pinion Height

Forward Gear Backlash

Water Pressure

@ Idle

@ W.O.T.

Pressure Test

55/60

Gear Ratio

Gearcase Capacity

Lubricant Type

Forward Gear

Number of Teeth

Pinion Gear

Number of Teeth

Pinion Height

Forward Gear Backlash

Water Pressure

@ Idle

@ W.O.T.

Pressure Test

60 Bigfoot

Gear Ratio

Gearcase Capacity

Lubricant Type

Forward Gear

Number of Teeth

Pinion Gear

Number of Teeth

Pinion Height

Forward Gear Backlash

Water Pressure

@ Idle

@ W.O.T.

Pressure Test

1.83:1

14.9 fl. oz. (440 mL)

Quicksilver Gear Lube-Premium Blend

22 Spiral/Bevel

12 Spiral/Bevel

0.025 in. (0.64 mm)

No Adjustment

0.5-1.5 PSI (3-10 kPa)

5.0–7.0 PSI (35-48 kPa)

10-12 PSI (69-83 kPa)

for 5 Minutes

1.64:1

11.5 fl. oz. (340 mL)

Quicksilver Gear Lube-Premium Blend

23

14

0.025 in. (0.64 mm)

Pinion Gear Locating Tool

(91-817008A2)

0.013-0.019 in. (0.33-0.48 mm)

1–3 PSI (7-20 kPa)

7–12 PSI (48-83 kPa)

10-12 PSI (69-83 kPa)

for 5 Minutes

2.3:1

22.5 fl. oz. (655 mL)

Quicksilver Gear Lube-Premium Blend

30

13

0.025 in. (0.64 mm)

0.012 in.-0.019 in. (0.30 mm-0.48 mm)

10-15 PSI (69-103 kPa) @ 5250 RPM

2-7 PSI (14–48 kPa)

10-15 PSI (69-104 kPa)

10-12 PSI (69-83 kPa)

for 5 Minutes

90-852572R1 JANUARY 1998 IMPORTANT INFORMATION - 1A-3

STARTING SYSTEM

Manual Start

Electric Start

Starter Draw (Under Load)

Battery Rating

Recoil Starter

125 Amperes

Min. Reserve Cap. Rating of 100

Min. and CCA of 350 Amperes

IGNITION SYSTEM

Type

Spark Plug Type

Spark Plug Gap

Firing Order

Capacitor Discharge

NGK BP8H-N-10

*NGK BPZ8H-N-10

0.040 in. (1.0mm)

1-2-3

CHARGING SYSTEM

Alternator Output

Electric Models

Manual Models (Not Regulated)

Single Phase (12 Pole)

16 Amperes @ 3000 RPM

9 Amperes @ 3000 RPM

7 Amperes @ 3000 RPM

CARBURETOR

Idle RPM

Wide Open Throttle (W.O.T.) RPM

Idle Mixture Screw Adjustment

Preset (Turns Out)

Float Adjustment

Float Level

Main Jet

Model 40 (WME-53, 69)

Model 50 (WME-68)

Model 55 (WME-57)

Model 60 (WME-58)

675 ± 25

5000-5500

1

1

/

4

±

1

/

4

9

/

16

in. (14 mm)

0.044 in.

0.052 in.

0.058 in.

0.060 in.

OIL

INJECTION

Recommended Oil

Oil Tank Capacity/Approx. Time

Reserve Capacity/Approx. Time

Oil Output With Engine RPM of 1500

and Oil Pump @ W.O.T.

Model 40

Model 50/60

Quicksilver TC-WII or TC-W3

2 Cycle Outboard Oil

3.0 qts. (2.8 L) 7 hours

14.5 fl. oz. (0.43 L)

1

/

2

hour

15.0 ± 3.0 cc of oil in 10 minutes

22.0 ± 3.0 cc of oil in 10 minutes

TIMING

Idle

Maximum Timing

@ Cranking Speed

-Model 40/50/60

-Model 55/60 Seapro-Marathon

@ 5000 RPM

– Model 40/50/60

– Model 55/60 Seapro-Marathon

T.D.C. ± 2°

24° B.T.D.C.

18° B.T.D.C.

22° B.T.D.C.

16° B.T.D.C.

TEMPERATURE

SWITCH

Temperature

Normal

190°F ± 8° (88°C ± 4°C)

170°F ± 8° (77°C ± 4°C)

Open - No Continuity

Closed - Full Continuity

Open - No Continuity

*Suppressor (resistor) spark plug

1A-4 - IMPORTANT INFORMATION 90-852572R1 JANUARY 1998

Propeller Information Charts

Mercury/Mariner 40 HP (3 Cyl.)

Wide Open Throttle RPM: 5000-5500

Recommended Transom Heights : 15”, 20”

Right Hand Rotation Standard

Gear Reduction : 1.83:1

Diameter

Pitch

No. of

Blades

Material

Approx.

Gross Boat

Wgt. (lbs)

Approx.

Boat

Length

Speed

Range

(mph)

Propeller

Part Number

10” 19” 3 Alum Up to 900 Up to 14’ 41-49 48-73146A40

10” 17” 3 Alum Up to 900 Up to 14’ 35-43 48-73144A40

10” 16” 3 SS Up to 1200 Up to 15’ 32-40 48-91818A5

10” 16” 3 Alum Up to 1200 Up to 15’ 32-40 48-73142A40

10-1/8” 15” 3 SS 1000-1500 13-15’ 28-37 48-855862A5

10-1/8” 15” 3 Alum 1000-1500 13-15’ 28-37 48-73140A40

10-3/8” 14” 3 Alum 1100-1700 14-16’ 25-34 48-816706A40

10-1/4” 14” 3 SS 1100-1700 14-16’ 25-34 48-855860A5

10-1/4” 14” 3 Alum 1100-1700 14-16’ 25-34 48-73138A40

10-1/2” 13” 3 Alum 1300-2100 14-17’ 21-31 48-816704A40

10-3/8” 13” 3 SS 1300-2100 14-17’ 21-31 48-855858A5

10-3/8” 13” 3 Alum 1300-2100 14-17’ 21-31 48-73136A40

10-3/4” 12” 3 Alum 1500-2500 15-19’ 18-27 48-816702A40

10-5/8” 12” 3 SS 1500-2500 15-19’ 18-27 48-855856A5

10-5/8” 12” 3 Alum 1500-2500 15-19’ 18-27 48-73134A40

10-7/8” 11” 3 Alum 1800-3500 16-21’ 14-24 48-85632A40

11-1/4” 10” 3 Alum 2000+ 17’+ 11-21 48-73132A40

11-5/8” 11” 3 SS 1800-3500 16-21’ 14-24 48-823478A5

11-5/8” 10-1/2” 3 Alum 2000+ 17’+ 13-23 48-827312A10

12-1/4” 9” 3 Alum 2500+ 18’+ 8-17 48-87818A10

12-1/4” 9” 3 SS 2500+ 18’+ 8-17 48-97868A10

12-1/2” 8” 3 Alum 3000+ 20’+ 1-14 48-42738A10

90-852572R1 JANUARY 1998 IMPORTANT INFORMATION - 1A-5

Mercury/Mariner 50 HP (3 Cyl.)

Wide Open Throttle RPM: 5000-5500

Recommended Transom Heights : 15”, 20”, 22-1/2”

Right Hand Rotation Standard

Gear Reduction : 1.83:1

Diameter

Pitch

No. of

Blades

Material

Approx.

Gross Boat

Wgt. (lbs)

Approx.

Boat

Length

Speed

Range

(mph)

Propeller

Part Number

10” 19” 3 Alum Up to 1100 Up to 14’ 41-49 48-73146A40

10” 17” 3 Alum Up to 1400 Up to 14’ 35-43 48-73144A40

10” 16” 3 SS 1200-1500 Up to 15’ 32-40 48-91818A5

10” 16” 3 Alum 1200-1500 Up to 15’ 32-40 48-73142A40

10-1/8” 15” 3 SS 1300-1800 13-15’ 28-37 48-855862A5

10-1/8” 15” 3 Alum 1300-1800 13-15’ 28-37 48-73140A40

10-3/8” 14” 3 Alum 1400-2100 14-16’ 25-34 48-816706A40

10-1/4” 14” 3 SS 1400-2100 14-16’ 25-34 48-855860A5

10-1/4” 14” 3 Alum 1400-2100 14-16’ 25-34 48-73138A40

10-1/2” 13” 3 Alum 1600-2600 14-17’ 21-31 48-816704A40

10-3/8” 13” 3 SS 1600-2600 14-17’ 21-31 48-855858A5

10-3/8” 13” 3 Alum 1600-2600 14-17’ 21-31 48-73136A40

10-3/4” 12” 3 Alum 1900-3200 15-19’ 18-27 48-816702A40

10-5/8” 12” 3 SS 1900-3200 15-19’ 18-27 48-855856A5

10-5/8” 12” 3 Alum 1900-3200 15-19’ 18-27 48-73134A40

10-7/8” 11” 3 Alum 2200-4300 16-21’ 14-24 48-85632A40

11-1/4” 10” 3 Alum 2500+ 17’+ 11-21 48-73132A40

11-5/8” 11” 3 SS 2200-4300 16-21’ 14-24 48-823478A5

11-5/8” 10-1/2” 3 Alum 2200+ 17’+ 13-23 48-827312A10

12-1/4” 9” 3 Alum 3000+ 18’+ 8-17 48-87818A10

12-1/4” 9” 3 SS 3000+ 18’+ 8-17 48-97868A10

12-1/2” 8” 3 Alum 3500+ 20’+ 1-14 48-42738A10

1A-6 - IMPORTANT INFORMATION 90-852572R1 JANUARY 1998

Mercury/Mariner 55 HP (3 Cyl.)

Wide Open Throttle RPM: 5000-5500

Recommended Transom Heights : 16-1/2”, 21”, 23-1/2”

Right Hand Rotation Standard

Gear Reduction : 2.3:1

Diameter

Pitch

No. of

Blades

Material

Approx.

Gross Boat

Wgt. (lbs)

Approx.

Boat

Length

Speed

Range

(mph)

Propeller

Part Number

12-3/4” 26” 5 SS Up to 800 Up to 15’ 48-54 48-815748A45

13-1/2” 26” 3 SS Up to 800 Up to 15’ 48-54 48-16996A30

12-3/4” 24” 5 SS Up to1000 Up to 15’ 46-52 48-815746A45

13-1/2” 24” 3 SS Up to 1000 Up to 15’ 46-52 48-16994A30

12-1/2” 23” 3 Alum 700-1100 Up to 15’ 45-51 48-77350A45

12-3/4” 22” 5 SS 700-1100 Up to 15’ 43-49 48-815744A45

13-1/2” 22” 3 SS 700-1100 Up to 15’ 43-59 48-16992A30

12-3/4” 21” 3 Alum 800-1200 13-16’ 40-47 48-77348A45

12-3/4” 20” 5 SS 800-1200 13-16’ 38-45 48-816612A45

13-1/2” 20” 3 SS 800-1200 13-17’ 38-45 48-16990A30

13” 19” 3 Alum 1000-1400 14-17’ 35-42 48-77346A45

13” 18” 3 SS 1000-1400 14-17’ 33-40 48-16988A30

13-1/4” 17” 3 Alum 1200-1700 15-18’ 31-38 48-77344A45

13-1/8” 16” 3 SS 1200-1700 15-18’ 29-36 48-16986A30

13-3/4” 15” 3 Alum 1500-2100 16-19’ 26-33 48-77342A45

13-3/8” 14” 3 SS 1500-2100 16-19’ 23-31 48-17314A30

14” 13” 3 Alum 1900-2500 17’+ 20-28 48-77340A45

14” 12” 3 SS 1900-2500 17’+ 17-26 48-17312A30

14” 11” 3 Alum 2200+ 18’+ 1-22 48-77338A45

14” 10” 3 SS 2400+ 19’+ 1-20 48-17310A30

90-852572R1 JANUARY 1998 IMPORTANT INFORMATION - 1A-7

Mercury/Mariner 60 HP (3 Cyl.)

Wide Open Throttle RPM: 5000-5500

Recommended Transom Heights : 15”, 20”

Right Hand Rotation Standard

Gear Reduction : 1.64:1

Diameter

Pitch

No. of

Blades

Material

Approx.

Gross Boat

Wgt. (lbs)

Approx.

Boat

Length

Speed

Range

(mph)

Propeller

Part Number

10” 19” 3 Alum Up to 800 Up to 14’ 48-55 48-73146A40

10” 17” 3 Alum Up to 1000 Up to 15’ 44-51 48-73144A40

10” 16” 3 SS 700-1100 Up to 15’ 41-48 48-91818A5

10” 16” 3 Alum 700-1100 Up to 15’ 41-48 48-73142A40

10-1/8” 15” 3 SS 800-1200 13-15’ 38-45 48-855862A5

10-1/8” 15” 3 Alum 800-1200 13-15’ 38-45 48-73140A40

10-1/4” 14” 3 SS 900-1500 14-16’ 35-41 48-816706A40

10-3/8” 14” 3 Alum 900-1500 14-16’ 35-41 48-855860A5

10-3/8” 13” 3 SS 1200-1800 15-17’ 32-38 48-73138A40

10-1/2” 13” 3 Alum 1200-1800 15-17’ 32-38 48-816704A40

10-5/8” 12” 3 SS 1500-2100 16-18’ 28-34 48-855858A5

10-3/4” 12” 3 Alum 1500-2100 16-18’ 28-34 48-73136A40

10-7/8” 11” 3 Alum 1800-2400 16-18’ 24-30 48-816702A40

11-5/8” 11” 3 SS Workboat 16’+ 24-30 48-855856A5

12” 10-1/2” 3 Alum 2000-2600 17’+ 22-28 48-73134A40

11-5/8” 10-1/2” 3 Alum 2000-2600 17’+ 22-28 48-85632A40

11-1/4” 10” 3 Alum 2100-2600 17’+ 20-26 48-73132A40

12-1/4” 9” 3 SS 2400+ 18’+ 14-22 48-823478A5

12-1/4” 9” 3 Alum 2400+ 18’+ 14-22 48-827312A10

12-1/2” 8” 3 Alum 2800+ 19’+ 1-18 48-87818A10

1A-8 - IMPORTANT INFORMATION 90-852572R1 JANUARY 1998

Mercury/Mariner 60 HP (3 Cyl.) Bigfoot

Wide Open Throttle RPM: 5000-5500

Recommended Transom Heights : 15”, 20”, 22-1/2”

Right Hand Rotation Standard

Gear Reduction : 2.31:1

Diameter

Pitch

No. of

Blades

Material

Approx.

Gross Boat

Wgt. (lbs)

Approx.

Boat

Length

Speed

Range

(mph)

Propeller

Part Number

13” 18” 3 SS Up to 1100 Up to 14’ 41-49 48-16988A45

13-1/4” 17” 3 Alum Up to 1400 Up to 14’ 35-43 48-77344A45

13-1/8” 16” 3 SS 1200-1500 Up to 15’ 32-40 48-16986A45

13-3/4” 15” 3 Alum 1200-1500 Up to 15’ 32-40 48-77342A45

13-3/8” 14” 3 SS 1300-1800 13-15’ 28-37 48-17314A45

14” 13” 3 Alum 1300-1800 13-15’ 28-37 48-77340A45

14” 12” 3 SS 1400-2100 14-16’ 25-34 48-17312A45

14” 11” 3 Alum 1400-2100 14-16’ 25-34 48-77338A45

14” 10” 3 Alum 1400-2100 14-16’ 25-34 48-854342A45

14” 9” 3 Alum 1600-2600 14-17’ 21-31 48-854340A45

B

1

IMPORTANT

INFORMATION

MAINTENANCE

1B-0- IMPORTANT INFORMATION 90-852572R1 JANUARY 1998

Table of Contents

Page

Specifications 1B-1. . . . . . . . . . . . . . . . . . . . . . . . . .

Gear Case Lubricant Capacity 1B-1. . . . . . . . .

Special Tools 1B-1. . . . . . . . . . . . . . . . . . . . . . . . . .

Quicksilver Lubricant/Sealant 1B-1. . . . . . . . . . . .

Inspection and Maintenance Schedule 1B-2. . . .

Before Each Use 1B-2. . . . . . . . . . . . . . . . . . . .

After Each Use 1B-2. . . . . . . . . . . . . . . . . . . . . .

Every 100 Hours of Use or Once Yearly,

Whichever Occurs First 1B-2. . . . . . . . . . . . . . .

Every 300 Hours of Use or Three Years 1B-2

Before Periods of Storage 1B-2. . . . . . . . . . . .

Flushing The Cooling System 1B-3. . . . . . . . . . . .

Fuel System 1B-3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Corrosion Control Anode 1B-4. . . . . . . . . . . . . . . .

Lubrication Points 1B-5. . . . . . . . . . . . . . . . . . . . . .

Checking Power Trim Fluid 1B-7. . . . . . . . . . . . . .

60 HP 1B-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

40/50 HP 1B-7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Gear Case Lubrication 1B-8. . . . . . . . . . . . . . . . . .

Draining Gear Case 1B-8. . . . . . . . . . . . . . . . . .

Checking Lubricant Level and Filling

Gear Case 1B-9. . . . . . . . . . . . . . . . . . . . . . . . . .

Storage Preparations 1B-9. . . . . . . . . . . . . . . . . . .

Protecting External Outboard

Components 1B-9. . . . . . . . . . . . . . . . . . . . . . . .

Protecting Internal Engine Components 1B-9

Gear Case 1B-10. . . . . . . . . . . . . . . . . . . . . . . . . .

Positioning Outboard for Storage 1B-10. . . . . .

Battery Storage 1B-10. . . . . . . . . . . . . . . . . . . . .

90-852572R1 JANUARY 1998 IMPORTANT INFORMATION - 1B-1

Specifications

Gear Case Lubricant Capacity

Gear Case Ratio Capacity

1.83:1

1.64 :1

2.3:1

14.9 fl. oz. (440 mL)

11.5 fl. oz. (340 mL)

22.5 fl. oz. (655 mL)

Special Tools

1. Quicksilver Flushing Attachment (44357A2)

50551

Quicksilver

Lubricant/Sealant

1. Gear Lube-Premium Blend P/N 92-19007A24

2. Quicksilver Anti-Corrosion Grease

P/N 92-78376A6

3. 2-4-C Marine Lubricant with Teflon

P/N 92-825407A12

4. SAE 30W Motor Oil - Obtain Locally

30W

1B-2- IMPORTANT INFORMATION 90-852572R1 JANUARY 1998

Inspection and Maintenance

Schedule

Before Each Use

1. Check that lanyard stop switch stops the engine.

2. Visually inspect the fuel system for deterioration

or leaks.

3. Check outboard for tightness on transom.

4. Check steering system for binding or loose com-

ponents.

5. Remote Control Models – Visually check steering

link rod fasteners for proper tightness.

6. Check propeller blades for damage.

After Each Use

1. Flush out the outboard cooling system if operat-

ing in salt or polluted water.

2. Wash off all salt deposits and flush out the ex-

haust outlet of the propeller and gear case with

fresh water if operating in salt water.

Every 100 Hours of Use or Once

Yearly, Whichever Occurs First

1. Lubricate all lubrication points. Lubricate more

frequently when used in salt water.

2. Inspect and clean spark plugs.

3. Check engine fuel filter for contaminants.

4. Adjust carburetor(s) (if required).

∗

5. Check engine timing setup.∗

6. Check corrosion control anodes. Check more fre-

quently when used in salt water.

7. Drain and replace gear case lubricant.

8. Lubricate splines on the drive shaft.

9. Check power trim fluid.

10. Inspect battery.

11. Check control cable adjustments.

∗

12. Remove engine deposits with Quicksilver Power

Tune Engine Cleaner.

13. Check tightness of bolts, nuts, and other fasten-

ers.

*

These items should be serviced by an authorized

dealer.

Every 300 Hours of Use or Three

Years

1. Replace water pump impeller (more often if over-

heating occurs or reduced water pressure is

noted).

Before Periods of Storage

Refer to Storage Procedure.

90-852572R1 JANUARY 1998 IMPORTANT INFORMATION - 1B-3

Flushing The Cooling

System

Flush the internal water passages of the outboard

with fresh water after each use in salt, polluted, or

muddy water. This will help prevent a buildup of de-

posits from clogging the internal water passages.

Use a Quicksilver accessory (or equivalent) flushing

attachment.

WARNING

To avoid possible injury when flushing, remove

the propeller. Refer to Propeller Replacement.

1. Remove propeller (refer to Propeller Replace-

ment). Install the flushing attachment so the rub-

ber cups fit tightly over the cooling water intake

holes.

2. Attach a water hose to the flushing attachment.

Turn on the water and adjust the flow so water is

leaking around the rubber cups to ensure the en-

gine receives an adequate supply of cooling wa-

ter.

3. Start the engine and run it at idle speed in neutral

shift position.

4. Adjust water flow (if necessary) so excess water

continues leaking out from around the rubber

cups to ensure the engine is receiving an ade-

quate supply of cooling water.

5. Check for a steady stream of water flowing out of

the water pump indicator hole. Continue flushing

the outboard for 3 to 5 minutes, carefully monitor-

ing water supply at all times.

6. Stop the engine, turn off the water, and remove

the flushing attachment. Reinstall the propeller.

Fuel System

IMPORTANT: Gasoline containing alcohol (etha-

nol or methanol) can cause a formation of acid

during storage and can damage the fuel system.

If the gasoline being used contains alcohol, it is

advisable to drain as much of the remaining gas-

oline as possible from the fuel tank, remote fuel

line, and engine fuel system.

Fill the fuel system (tank, hoses, fuel pump, and car-

buretors) with treated (stabilized) fuel to help prevent

formation of varnish and gum. Proceed with following

instructions.

1. Portable Fuel Tank – Pour the required amount of

Quicksilver Gasoline Stabilizer (follow instruc-

tions on container) into fuel tank. Tip fuel tank

back and forth to mix stabilizer with the fuel.

2. Permanently Installed Fuel Tank – Pour the re-

quired amount of Quicksilver Gasoline Stabilizer

(follow instructions on container) into a separate

container and mix with approximately one quart

(one liter) of gasoline. Pour this mixture into fuel

tank.

1B-4- IMPORTANT INFORMATION 90-852572R1 JANUARY 1998

3. Place the outboard in water or connect flushing

attachment for circulating cooling water. Run the

engine for ten minutes to allow treated fuel to

reach the carburetors.

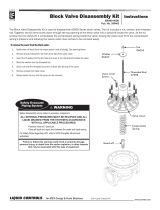

Corrosion Control Anode

1. Your outboard has two corrosion control anodes.

One of the anodes is the trim tab installed on the

gear case and the other is installed on the bottom

of the transom bracket assembly. An anode helps

protect the outboard against galvanic corrosion

by sacrificing its metal to be slowly eroded in-

stead of the outboard metals.

a

b

a - Trim Tab Anode

b - Transom Bracket Anode

NOTE: Each anode requires periodic inspection es-

pecially in salt water which will accelerate the ero-

sion. To maintain this corrosion protection, always re-

place the anode before it is completely eroded. Never

paint or apply a protective coating on the anode as

this will reduce effectiveness of the anode.

/