Page is loading ...

Curtain/Barrier Sensors Installation Manual

MiE9622416079Q_1105.pmd

SECO-LARM

®

U.S.A., Inc., 16842 Millikan Avenue, Irvine, CA 92606

Website: www.seco-larm.com

E-mail: sales

@

seco-larm.com

Tel: 800-662-0800 / 949-261-2999 Fax: 949-261-7326

NOTICE:

The information and specifications printed in this manual are current at the time of publication.

However, the SECO-LARM policy is one of continual development and improvement. For this reason,

SECO-LARM reserves the right to change specifications without notice. SECO-LARM is also not responsible for

misprints or typographical errors.

Copyright © 2011 SECO-LARM U.S.A., Inc. All rights reserved. This material may not be reproduced or copied,

in whole or in part, without the written permission of SECO-LARM.

Also available from SECO-LARM:

Quad and Twin

Photobeam Detectors

Up to 660' (200 m)

Flush-Mount

Photobeam Sensors

Up to 33' (10 m)

Entry Alert System

Photobeam Sensors

Up to 22' (7 m)

E-932-S16RRQ

E-964-Q660Q

(Shown)

E-932-D33TBQ

E-931CS22RRCQ

Note: Products with model numbers that end with "Q" or that have a round green"Q"sticker are RoHS compliant.

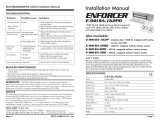

Manual

SECO-LARM

®

Curtain / Barrier

Sensors

Black

White

Black

White

Black

White

Black

White

No. ofNo. of

No. ofNo. of

No. of

BeamBeam

BeamBeam

Beam

LengthLength

LengthLength

Length

Model #Model #

Model #Model #

Model #

ColorColor

ColorColor

Color

Two

Four

Six

Eight

E-9622C2B25Q

E-9622C2W25Q

E-9641C4B25Q

E-9641C4W25Q

E-9660C6B25Q

E-9660C6W25Q

E-9679C8B25Q

E-9679C8W25Q

PITSW3

(E-9622C2B25Q shown)

Page 12

WARRANTY:

This SECO-LARM product is warranted against defects in material and workmanship while

used in normal service for a period of one (1) year from the date of sale to the original consumer customer.

SECO-LARM’s obligation is limited to the repair or replacement of any defective part if the unit is returned, transportation

prepaid, to SECO-LARM. This Warranty is void if damage is caused by or attributed to acts of God, physical or

electrical misuse or abuse, neglect, repair, or alteration, improper or abnormal usage, or faulty installation, or if for any

other reason SECO-LARM determines that such equipment is not operating properly as a result of causes other than

defects in material and workmanship. The sole obligation of SECO-LARM, and the purchaser’s exclusive remedy,

shall be limited to replacement or repair only, at SECO-LARM’s option. In no event shall SECO-LARM be liable for any

special, collateral, incidental, or consequential personal or property damages of any kind to the purchaser or anyone else.

Dimensions:

1

3

/

8

” (35mm)

1

1

/

8

” (29mm)

22.56” (57.3cm) --E-9622C2B25Q

Side View

1

3

/

16

” (30mm)

15

/

16

” (24mm)

22

7

/

16

”

41

21

/

64

”

60”

79”

(570 mm )

(1,050 mm )

(1,524 mm )

(2,008 mm )

Curtain/Barrier Sensors Installation ManualCurtain/Barrier Sensors Installation Manual

SECO-LARM U.S.A., Inc.

Page 11Page 2

Table of Contents:

What’s Included ------------------------------------------- 2

Typical Installations - Fig. 1--------------------------3

Features ------------------------------------------------------ 3

Choosing a Location ------------------------------------- 4

Beware Natural Interference - Fig. 2 ------------- 4

Orientation to Sun - Fig. 3 ---------------------------- 4

Orientation - Fig. 4 --------------------------------------- 5

Forming Barriers - Fig. 5 ------------------------------- 5

Mounting the Curtain Sensor ------------------------ 5

Running the Wires ----------------------------------------5

Connecting the Wires -----------------------------------6

Maximum Wire Length - Table 1 ---------------------6

Maximum Distance - Fig. 6 ---------------------------- 6

Programming - Table 3 ---------------------------------- 7

Wiring the Receiver - Fig. 7 -------------------------- 7

Wiring the Transmitter - Fig. 8-----------------------7

Connecting One or More Sensors - Fig. 9 ------- 8

Connecting Multiple Curtain Sensors------------- 9

Mount Transmitter & Receiver, & Test Sensor -9

Tamper Protection ---------------------------------------- 9

Adjusting the location of sensor’s IR beam ----9

Troubleshooting - Table 4 ------------------------------ 11

Specifications ---------------------------------------------- 11

Dimensions -------------------------------------------------- 12

Warranty ------------------------------------------------------12

Mounting

Hardware

Manual

L-Bracket x 4

Transmitter

Receiver

What’s Included:

Possible cause

!

Power not connected, or power wires cut

Transmitter and receiver are out of alignment

Mounted too close to a shiny surface which causes

the beam to reflect in multiple angles

!

Transmitter and receiver are out of alignment

!

The cover on the end cap of the receiver with the

tamper button is not snapped in place, or the

tamper button is not in the right position

!

Interference from other sensors

!

Wind blowing leaves into beam

!

Rain water running into the beam

!

Other interference outdoors

Possible solution

!

Test the power and ground wire with a

voltage meter to ensure power is

connected and is of the correct voltage.

Re-align the transmitter and receiver.

Remount the curtain sensor, or repaint the

surface to cut down on the reflection.

!

Re-align the transmitter and receiver.

!

Check that the tamper button and the cover

for the tamper button are mounted correctly.

!

Re-install so that one sensor does not

interfere with another sensor.

!

Cut back leafy vegetation, and/or

!

Program for two-beam use (see table 2).

!

Do not mount under the edge of the roof.

!

Mount under a roof or shelter.

Problem

Receiver or transmitter

green LED (power

indicator) never turns ON

Receiver’s red LED

constantly turn ON

Does not trigger when

beam is broken

Receiver continuously

triggers the alarm

False alarm

Table 4: Troubleshooting

25’(8m) outdoor, 50’(16m) indoor

10~30VDC

E-9622C2B25Q E-9641C4B25Q E-9660C6B25Q E-9679C8B25Q

60mA 70mA 80mA 90mA

2 4 6 8

35 x 30 x 570 mm 35 x 30 x 1050 mm 35 x 30 x 1524 mm 35 x 30 x 2008

mm

Breaking of any single beam for 2 sec. and

simultaneous breaking of any 2 adjacent beams for 0.5 sec.

Selectable by dip switch @ 50/100/150/200ms

Selectable by jumper (Rx side), buzzer sound when beam interrupted

NO./NC./COM relay output, 1A @ 120VAC/24VDC

-45°~55°C

IP65 / Al alloy

Included

Operating Voltage

Current Drain

Number of Beams

Dimensions

Detection method

Response time

Buzzer indicator

Output

Operating temp.

LED Indicator

Enclosure / Case

Mounting brackets

Range

Red LED – (OFF) Aligned properly, (ON) Beam is broken

Green LED – (OFF) Power OFF, (ON): Power ON

Specifications:

1

3

/

8

”x 1

3

/

16

”x22

7

/

16

”1

3

/

8

”x 1

3

/

16

”x41

21

/

64

”1

3

/

8

”x 1

3

/

16

”x60”

1

3

/

8

”x 1

3

/

16

”x79”

E-9622C2W25Q E-9641C4W25Q E-9660C6W25Q E-9679C8W25Q

Curtain/Barrier Sensors Installation ManualCurtain/Barrier Sensors Installation Manual

SECO-LARM U.S.A., Inc.

Page 10 Page 3

Fig. 1: Typical Installations

Windows

Indoor Fence Tops

Skylights

Garages / Gates / Walls

Typical

Door/Window

Frame

*See “Choose a Location” on page 4 for details on mounting the sensor outdoors.

Features:

!

Install on windows, doorways, skylights,

fence tops, and any place where space is

limited.

!

Perfect for indoor and outdoor* perimeter

security.

!

Slim-line design (1

1

/

8

” x 1

5

/

16

”).

!

2,4,6 or 8 separate photoelectric beam

sensors. Programmable trigger options –

Breaking of any single beam and simultaneous

breaking of any 2 adjacent beams (default

setting), or simultaneous breaking of any 2

adjacent beams only.

!

Rugged aluminum construction.

!

Anti-tamper circuit for use when power is cut

or end cap is removed.

!

No synchronizing wires required.

!

N.O./N.C. relay output.

!

LED alignment indicator.

!

Brackets and mounting hardware included.

Fig. 10: Removing the

end caps.

End caps

Fig. 13: Adjusting the location of the lens module

Fig. 11: Remove the lens strip.

Lens strip

Fig. 12: Unplug the wire connector

Wire connector

Adjustable IR modules

Fixed IR modules

Loosen screws

to adjust IR module

Cut to desired

length if necessary

Need to

drill 2 holes

Use this as template when drilling the 2 holes

Aluminum housing

End caps

Curtain/Barrier Sensors Installation ManualCurtain/Barrier Sensors Installation Manual

SECO-LARM U.S.A., Inc.

Page 4 Page 9

Important

Do not connect to power until the sensor is

completely installed and the installation has

been double-checked.

If it becomes necessary to replace a sensor

for maintenance purposes, always replace

both the transmitter and receiver at the same

time.

Choose a Location

When used outdoors, place the curtain sensor

under a roof or shelter. This will reduce the

chance of false alarms caused by rain or snow.

To prevent erratic operation and/or false

alarms:

!

Wind will not directly cause false alarms,

but could cause leaves or similar objects

to fly or wave into the beams. Do not

mount near trees, bushes, or other leafy

vegetation (see fig. 2).

!

Do not mount where water which runs off

the roof might break the beam (see fig. 2).

In such a case, the sensor must be

sheltered.

!

Do not mount near reflective surfaces, as

this could prevent the sensor from working

properly.

!

Do not mount where the transmitter or

receiver could be splashed by water or mud.

!

Do not mount where the unit could be

suddenly exposed to a bright light, such as a

floodlight or a passing automobile’s

headlight.

!

Do not let sunlight or any direct beam of

light shine directly on curtain beam sensor.

If unavoidable, mount so the transmitter,

not the receiver, faces the sun (see fig. 3).

!

Do not mount where animals or other

objects could accidently break the beams.

Fig. 3: Orientation to Sun

Fig. 2: Beware Natural Interference

Rain running directly

off roof thru beams

Tree or shrub leaves

passing thru beams

* Note: Only if unavoidable,

mount so transmitter, not

receiver, faces the sun

OK*

NO!

Tx

Rx

Rx

Tx

Connecting Multiple Curtain Sensors

Several units can be connected together in parallel

to the same power supply output and alarm input of

an alarm control panel, as shown in fig. 9.

Mount the Transmitter and Receiver,

and Test the Sensor

1. Temporarily mount the transmitter and receiver to

where they are expected to be mounted, so the

mounting position can be changed if necessary.

2. Connect the transmitter and the receiver.

3. Once it is powered up the green LED on the

receiver & transmitter will turn ON. Test the curtain

sensor by breaking two adjacent beams or any single

beam.

Note: Breaking of 1 beam takes 2 sec. to trigger and

breaking of 2 adjacent beams takes 0.5 sec. to

trigger.

4.Aside from the buzzer alignment indicator, the

curtain sensor also has a red LED located on the

receiver which can be used for testing purposes. If

the red LED is ON, it indicates the beam is broken.

5. After the curtain sensor is tested and aligned,

replace the end caps & permanently mount it.

6. After it is mounted, test the curtain sensor again.

Tamper Protection

The receiver and the transmitter both have a

tamper switch on one end to protect against

someone attempting to open the unit. However,

there is no separate tamper output to the alarm

control panel. Instead, the alarm output is triggered

if the cover of the end cap with the tamper button is

removed, if the transmitter or receiver is moved out

of alignment, or if power is disconnected.

Adjusting the location of sensor’s IR beam (applicable for 4,6 & 8 beam models only)

The location of sensor’s IR beam can be adjusted by following the steps below.

1. Remove the end caps of the transmitter, see fig.10.

2. Remove the curtain sensor’s lens strip as shown on fig.11

3. Unplug the wire connector as shown in fig.12

4. Loosen the 2 screws on each IR module and adjust the distance of the IR module to desired location

and tighten the screw to secure it. see fig.13

5. Cut the aluminum housing of the curtain sensor to shorten it if necessary as shown in fig.13

6. Drill 2 holes at the end of the aluminum housing by using the cut-off piece as a template. See fig.13

7. Cut the curtain sensor’s lens strip to correspond to the length of the aluminum housing.

8. Plug back the wire connector, replace the lens strip and end caps of the curtain sensor.

9. Repeat the procedure on the curtain sensor’s receiver’s side.

Important Note:

a. The cut-off edge of the aluminum & lens strip must be free of burr.

b. Every screw had a rubber o-ring, take care not to misplace these o-rings.

c. The location of IR modules of both the receiver and transmitter must be the same.

Curtain/Barrier Sensors Installation ManualCurtain/Barrier Sensors Installation Manual

SECO-LARM U.S.A., Inc.

Page 8 Page 5

Fig. 9: Connecting One or More Sensors

Please reference fig. 7 & 8 for terminal blocks.

Control panel

(12VDC)

}

Power

Transmitter

Receiver

Control panel

(12VDC)

}

Power

}

Alarm N.C. signal

Transmitter

Receiver

Example connection 3 - In-line, Single Alarm Channel

Transmitter

Receiver

Control panel

(12VDC)

}Power

}

Alarm N.O./N.C.(ch. 1)

Transmitter

Receiver

Example connection 2 - Dual Sensors, Separate Alarm Channels

Transmitter

}

Alarm N.O./N.C.(ch. 2)

Example connection 1 - Standard

Receiver

}

Alarm N.O./N.C.signal

}

Tamper input

}

Tamper input

}

Tamper input

Fig. 5: Forming Barriers

OK

NO!

T

T

R R

T R

R

T

OKNO!

T

T

R

R

T

R

R

T

Parallel barriers

Consecutive barriers

Mounting the Curtain Sensor

1. Find a suitable location (see fig. 1):

a. The transmitter and receiver can be mounted

at any angle as long as they are parallel to

each other and directly facing each other, and

as long as the wires come out of the same

ends of both units (see fig. 4).

b. If multiple curtain sensors are set up to form

longer or deeper barriers, mount so that one

transmitter is not facing multiple receivers

(see fig.5).

c. The transmitter and receiver must not be

separated by more than the allowable

maximum range (see page 8).

2. Mount the transmitter and the receiver in such a

way that surface-mounted wires do not come out

from above the units. This is to prevent water

from entering via the wire holes. If this is

unavoidable, use silicone to completely cover the

area where the wires come out the holes to

prevent water from entering (see fig. 4).

3. Once a suitable mounting location has been

found, remove the two end caps of the transmitter

& receiver careful not to loose the small O-ring.

Locate the mounting holes. Use these holes as a

template, and mark their location on the wall with

a pencil.

4. Connect the wires (see figs. 7 and 8) before

permanently mounting the units to the wall.

Running the Wires

Run seven wires – 2 wires for power, 2 wires for

tamper switch, plus 3 wires for N.O., N.C. and

COM (if necessary) – from the alarm control

panel to the receiver of the curtain sensor.

Shielded cable is strongly suggested. See Table 1

for maximum wire length. Another four wires

must be run to the transmitter.

It may be more convenient to connect the two

power wires of the transmitter to the receiver’s

power wires. In this case, run nine wires to the

receiver: two wires to the power source, two

wires for the tamper switch, two (or three wires

depending on application) for the alarm signal,

and two to the transmitter.

NOTE: If burying the wires is required, make

sure to run them through electrical conduit.

Shielded cable is strongly suggested.

NOTE: If the wires are run along the wall, the

use of an armored cable is strongly suggested.

(See “Mounting the Curtain Sensor,” point 2, for

further considerations.)

Fig. 4: Orientation

NO!

Terminal

Block

OK

Terminal

Blocks

Terminal

Block

Note: If the wires will be

running out the end,

place sensors so wires

are at the bottom. If

sensors must be placed

so wires are at top, seal

the opening with

silicone to prevent

water from leaking in.

{

Curtain/Barrier Sensors Installation ManualCurtain/Barrier Sensors Installation Manual

SECO-LARM U.S.A., Inc.

Page 7Page 6

Fig. 6: Maximum Distance Between

the Transmitter and Receiver

Outdoors: 25’ (8m)

Indoors: 50’ (16m)

Max. Distance

Connecting the Wires

1.Receiver:

a. Locate the end cover where there’s a

label pasted at the back, slide down the

screw cover remove 1 screw and then

take out the end cover to expose the

PCB as shown in see fig. 7.

b. Remove the wire knockout located

beside the mounting hole and run seven

wires (or the no. of wires needed).

c. Then pierce an entry hole into the rubber

grommet and insert the wires. Connect

the wires into the terminal block

accordingly (see fig. 7).

d. Program the “JP1” jumper for buzzer

audio alignment indicator if necessary

(see Table 3).

e. Sensor response time can be program to

50, 100, 150 or 200ms if necesary,

please see fig.7 and table 2. The sensor

default response time is set at 50ms.

f. Program the trigger mode to desired

setting, see fig.7 and table 3.

2. Transmitter:

a. Locate the end cover where there’s a

label pasted at the back, remove 1

screw and then take out the end cover to

expose the PCB as shown in see fig.8.

b. Remove the wire knockout located

beside the mounting hole and run four

wires (or the no. of wires needed).

c. Then pierce an entry hole into the rubber

grommet and insert the wires. Connect

the wires into the terminal block

accordingly (see fig. 8).

d. Program the VR rotary knob for high or

low sensor, see fig.8 and table 3.

Table 3: Transmitter and Receiver Programming

The jumper cover is ON, buzzer

will sound when sensor beam is

not align properly or interrupted.

When “JP1” jumper cover

removed, the buzzer will not

sound.

Default Setting Optional Setting

Receiver

The VR rotary knob is set at

“high” (clockwise end of the knob),

giving the transmitter beam a max.

distance of 25’ (8m).

When VR rotary knob is set at the

counterclockwise end, the

transmitter’s sensor beam is set at

“low,” giving a max. distance of

15.6’ (5m).

Transmitter power

selection ( VR Rotary

Knob)

Transmitter

The jumper cover is ON, the sensor

will trigger when any single beam

is interrupted for 2 sec. and when

any of the 2 adjacent beams is

interrupted.

When “JP2” jumper cover r

emoved, the sensor will only

trigger when any of the 2 adjacent

beams is simultaneously

interrupted.

Trigger programming

( Jumper “JP2“)

Receiver

Table 1: Maximum Wire Length

Voltage Gauge Max. length

12VDC AWG 22 1800 feet (550 meters)

12VDC AWG 20 2600 feet (800 meters)

24VDC AWG 22 2600 feet (800 meters)

24VDC AWG 20 3900 feet (1,200 meters)

Response

time

50ms

100ms

150ms

Switch

position

200ms

Table 2: Response Time Selectable Chart

12

NO

12

NO

12

NO

12

NO

Fig. 8: Wiring the Transmitter

DC

-

Tamper switch

}

DC+

VR Rotary Knob

Fig. 7: Wiring the Receiver

DC+

Normally Open

Common

Tamper switch

DC

-

}

Dip switch (for response time adjustment)

JP1 jumper

(for buzzer audio alignment)

Normally Close

Buzzer audio

alignment indicator

( Jumper “ JP1“)

Note: Grounding may be necessary

depending on location.

JP2 jumper

(for trigger mode programming)

/