5- Accessories

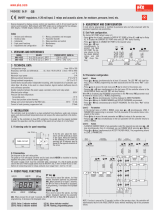

PARAMETERS TRANSFER

AKO-14918 portable server, with no power supply, in which

parameters programmed in a powered controller can be copied by

transfer. Parameters can be transferred again from the server to

other identical powered controllers.

6- Maintenance and Warnings

Clean the controller surface with a soft cloth and soap and water.

Do not use abrasive detergents, petrol, alcohol or solvents.

The use of the unit without observing the manufacturer's

instructions may alter its safety qualification. To ensure correct

operation of the apparatus, only probes supplied by AKO should be

used.

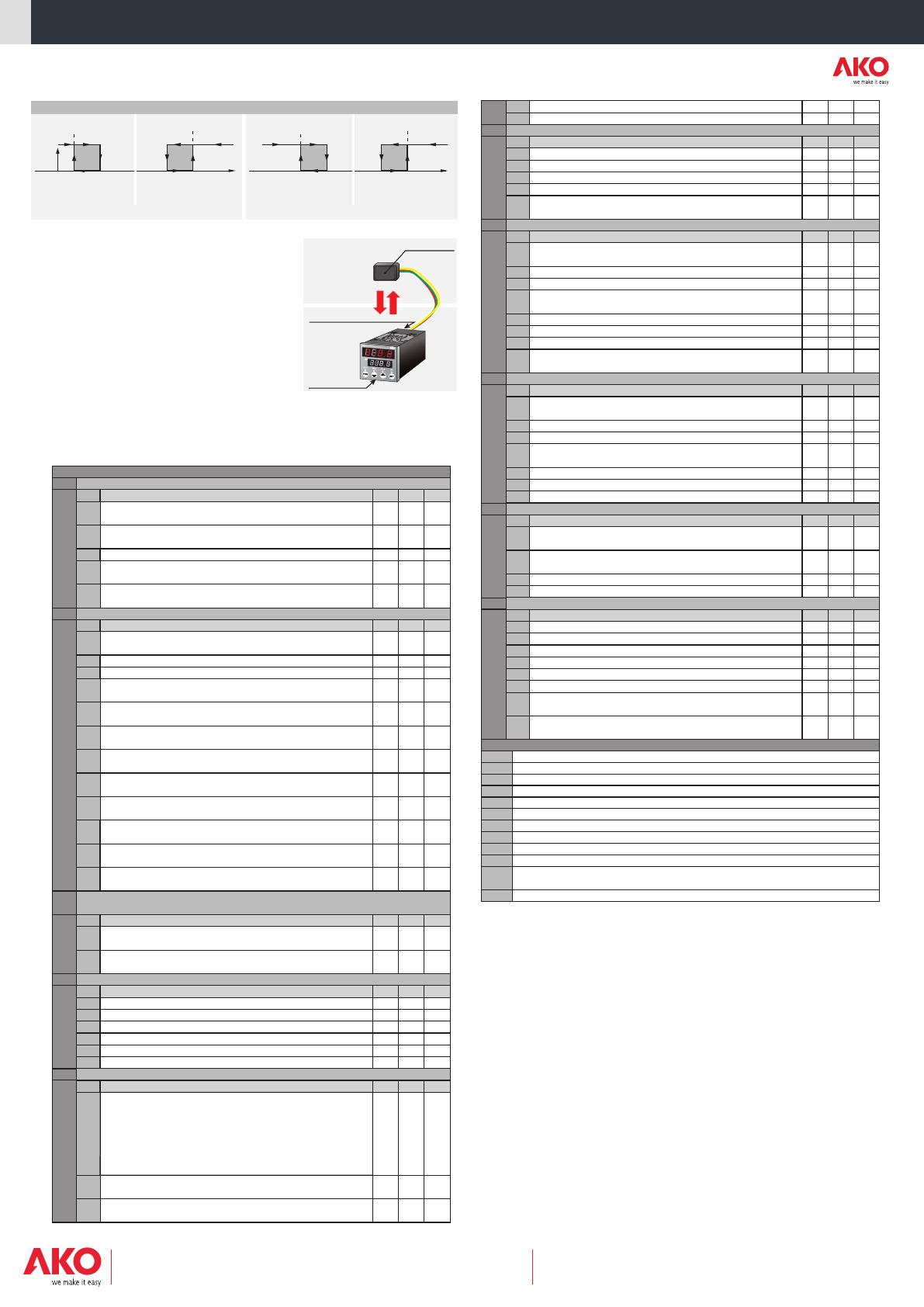

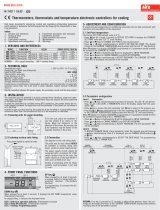

7- Parameters and messages

Values in the Def. column are factory-set.

AKO-14918

Transfer

Power supply

Programming

Level 2

Level 2

PAr

Ct

PAS1

CAd

CtHA

CtLA

Ctdy

CtUA

Ctin

Ctou

PdE

Ptr

CtEr

CtLC

General Parameters

CT Current transformer parameters (If CtEn=1 in CT module)

Level 3

Level 3

Description

Description

Values

Values

Min.

Min.

Def.

Def.

Max.

Max.

Password to parameters and information

Address for units with communication

Max for Alarm CT

Min for Alarm CT

Alarm CT delay from the moment at which it should enabled

Current load value (display)

Primary current value CT transformer

Secondary current value CT transformer (0=0,05A)

Initial parameters

(1=YES, configure to “Def” and exit programming)

Parameters transfer

(0=Disabled) (1=Send) (2=Receive)

Output CONTROL 1 status in case of CT alarm:

(0=OFF) (1=No change)

CT alarm memory

(0=Without memory) (1=With memory)

0

0

0,0

0,0

0

0,0

0

0

0

0

0

0

0

2

0

100,0

0,0

0

Value

25

0

0

0

0

1

1

999

254

100,0

100,0

250

100,0

999

999

250

1

2

1

1

(A)

(A)

(min.)

(A)

(A)

(A)

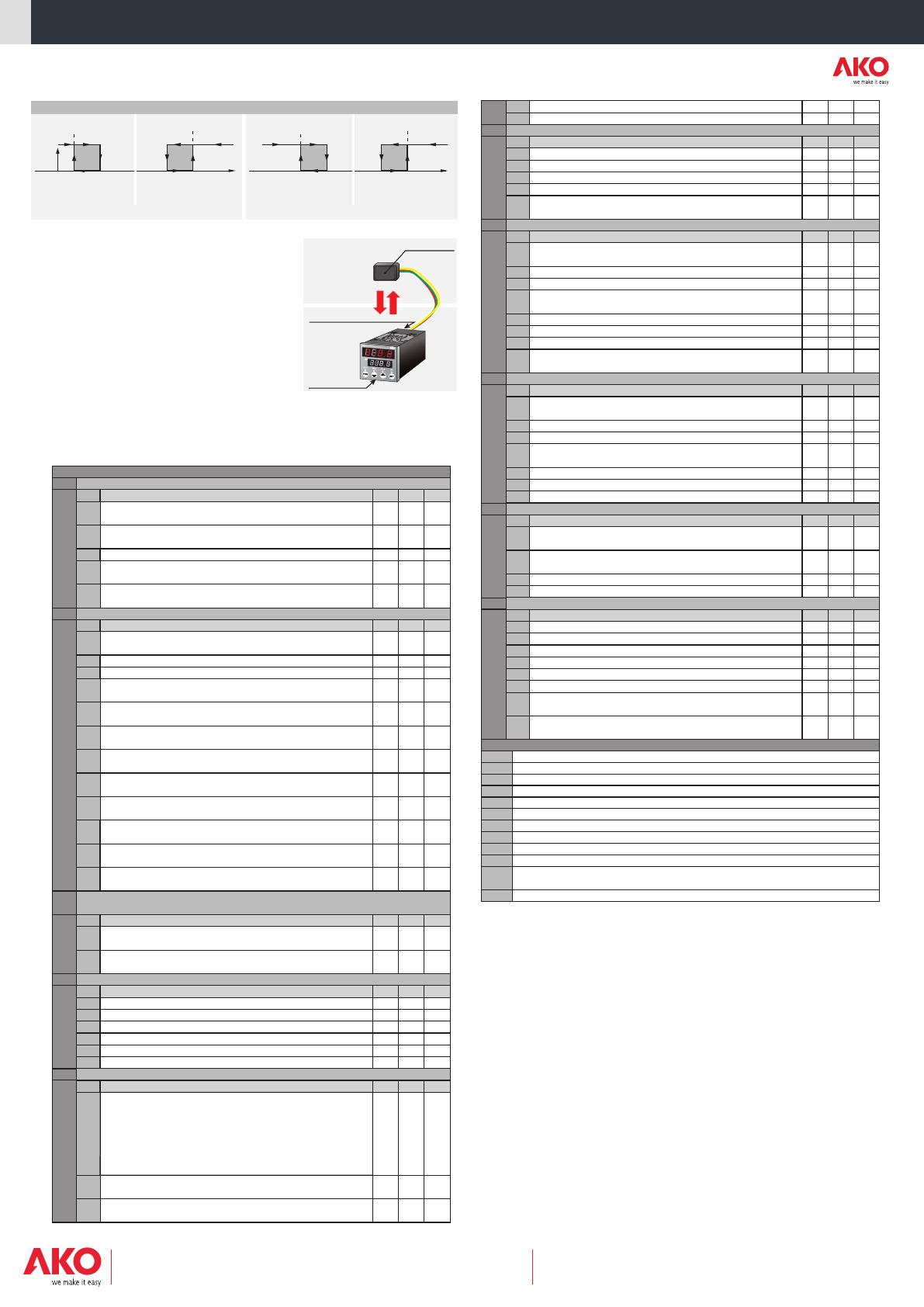

Level 2

Level 2

Level 2

ALr1

ALr2

Pld

GAin

AHt1

AHt2

Adl1

Adl2

ALt1

ALt2

AdE1

AdE2

Ado1

Ado2

ti

td

toUt

IdY

USI1

AtEn

tAL1

tAL2

ACo1

AtA

ACo2

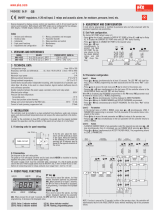

Alarm 1 Parameters

Alarm 2 Parameters (If Clo=0, 4, R1=Alarm 2)

PID Parameters (only if rEG=0)

Level 3

Level 3

Level 3

Description

Description

Description

Values

Values

Values

Min.

Min.

Min.

Def.

Def.

Def.

Max.

Max.

Max.

Gain (see item 4.1)

Max for Alarm 1

Max for Alarm 2

Alarm 1 differential

Alarm 2 differential

Min for Alarm 1

Min for Alarm 2

Alarm 1 delay from the moment at which it should enabled

Alarm 2 delay from the moment at which it should enabled

Alarm 1 delay at start-up

Alarm 2 delay at start-up

Overall time (see item 4.1)

Derivative time (see item 4.1)

Cycle Control time

Digital input enabling delay

Set point SP 1 variation if CdIn=1

AT key blocking

(0=Yes, blocked) (1=No, unblocked)

Alarm 1 type

(0=Max) (1=Min) (2=Max+Min)

Alarm 2 type

(0=Max) (1=Min) (2=Max+Min)

Alarm 1 configuration (0=Absolute)

(1=Relative to set point SP1) (2=Relative to set point SP2)

Optional cancellation of output alarms by pressing once a key.

(0=Allows to cancel the output alarms) (1=Not allows to cancel the output alarms)

Alarm 2 configuration (0=Absolute)

(1=Relative to set point SP1) (2=Relative to set point SP2)

0

-99,9

-99,9

1,0

1,0

-99,9

-99,9

0

0

0

0

0

1,0

0

-99,9

0

0

0

0

0

0

50

999,9

999,9

1,0

1,0

-99,9

-99,9

0

0

0

100

25

2,0

0

0,0

0

0

0

0

0

0

100

2500

2500

20,0

20,0

2500

2500

250

250

250

999

999

100,0

250

2500

1

2

2

2

1

2

(%)

(sec.)

(sec.)

(sec.)

(ºC/ºF/mA)

(ºC/ºF/mA)

(ºC/ºF/mA)

(ºC/ºF/mA)

(ºC/ºF/mA)

(ºC/ºF/mA)

(ºC/ºF/mA)

(min.)

(min.)

(min.)

(min.)

(sec.)

MESSAGES

Flashing with temperature - Sensor temperature exceeds the parameter programmed in AHt1

Flashing with temperature - Sensor temperature exceeds the parameter programmed in AHt2

Flashing with temperature - Sensor temperature is lower than the parameter programmed in ALt1

Flashing with temperature - Sensor temperature is lower than the parameter programmed in ALt2

Flashing with temperature - Active digital input

Stopped controller if CdIn=2 and digital input enabled

Sensor failure (Open circuit, crossed, temperature out of range)

EEPROM memory failure

RAM memory failure

Password request to enter programming parameters

Incorrect resolution - See rES parameter

Flashing with temperature - The load intensity circulating through the CT current transformer exceeds

the programmed parameter in CtHA or is lower than the programmed parameter in CtLA

AH1

AH2

AL1

AL2

EAL

StoP

E1

EE

rA

PAS

----

ACt

VALUE

OFF

AL1 AL2 AL2

VALUE

Alarm 2 Operation

ACo1 is the alarm 1 configuration parameter ACo2 is the alarm 2 configuration parameter

tAL1=0 (Max.) tAL2=0 (Max.)tAL2=1 (Min)

SP2+ALt2+Adi2SP2+ALt1+Adi1 SP2+AHt2+Adi2SP2+AHt1+Adi1 SP2+AHt2SP2+AHt1

SP1+ALt2+Adi2SP1+ALt1+Adi1 SP1+AHt2+Adi2SP1+AHt1+Adi1 SP1+AHt2SP1+AHt1

ALt2+Adi2ALt1+Adi1 AHt2+Adi2AHt1+Adi1 AHt2AHt21

SP2+ALt2SP2+ALt1

SP1+ALt2SP1+ALt1

ALt2ALt1 Si ACo2 = 0Si ACo1 = 0

Si ACo2 = 1Si ACo1 = 1

Si ACo2 = 2Si ACo1 = 2

StartStart StartStart StopStop StopStop

Alarm 1 Operation

ON

AL1

tAL1=1 (Min)

8- Technical data

Range according to type of sensor configured:

Pt 100.............................................................................-99,9 ºC to 850,0 ºC (-148 ºF to 1562 ºF)

J Thermocouple.................................................................-99,9 ºC to 800,0 ºC (-148 ºF to 1472 ºF)

K Thermocouple.................................................................-99,9 ºC to 1370 ºC (-148 ºF to 2498 ºF)

4-20 mA.......................................................................................4 mA = 0% to 20 mA = 100%

Set Point 1 range...................................................................................................-99.9 to 2500

Set Point 2 range...................................................................................................-99.9 to 2500

Resolution, Set Point and differential ........................................0,1 or 1 configurable by parameter rES

Accuracy...........................................................................±0,25 % (Pt100, TcJ, TcK); ±1,5% (mA)

R1/OUT relay: CONTROL 2 or ALARM 1 or 2 (configurable by param. CIo) .....SPST-NO, 6A, 250V, cosj=1

R2/AL relay: CONTROL 1 or ALARM 1 (configurable by param. CIo)...................SPDT, 5A, 250V, cosj=1

R3 relay: CONTROL 2 (with Relay 3 module) (configurable by param. CIo) ..........SPDT, 5A, 250V, cosj=1

Maximum input power .......................................................................................................3 VA

Working ambient temperature.................................................................................. 0 ºC to 55 ºC

Storage ambient temperature ................................................................................-30 ºC to 70 ºC

Installation category.........................................................................II under EN 61010-1 standard

Pollution degree ..............................................................................II under EN 61010-1 standard

Double insulation between the power supply, the secondary circuit and the relay output.

351540502 REV.02 2009

AKO ELECTROMECÀNICA, S.A.L.

We reserve the right to supply materials that might vary slightly to those described in our

Technical Sheets. Updated information is available on our website: www.ako.com

Av. Roquetes, 30-38 | 08812 Sant Pere de Ribes | Barcelona | España

Apartado (P.O. Box), 5 | 08800 Vilanova i la Geltrú | Barcelona | España

www.ako.com

Temperature display mode: (0 = Integers in ºC) (1 = One decimal in ºC)

(2 = Integers in ºF) (3 = One decimal in ºF) (4 = Integers in mA) (5 = One decimal in mA)

(ºC/ºF/mA)

-20,0

-99,9

-99,9

LL1

LL2

-99,9

0

0

0

0

0

0

-99,9

0,0

100,0

0

999,9

999,9

-99,9

0

0

1

1

0

1

-99,9

20,0

2500

2500

2500

2500

HL1

1

1

1

1

2

5

HL2

(ºC/ºF/mA)

(ºC/ºF/mA)

(ºC/ºF/mA)

(ºC/ºF/mA)

0

0

3

AnCF

Description

4-20 mA or onfiguration parameters

(only if CIo=0, 1, 2) and 4-20 mA / 0-10 V module

converter repeater c

Values

Min. Def. Max.

Values

Min. Def. Max.

Level 2

CFG

Configuration Parameters

Level 3

Description

Level 1

Menus and Description

Level 2

SPCF

Set Point parameters

Level 3

Description

CAn

HES

LES

HL1

LL1

bES

rEG

HC1

HC2

o2C

rES

LL2

HL2

Sensor calibration (Offset)

Maximum scale value for the sensor type in mA (Only if PbS=3)

Minimum scale value for sensor type in mA (Only if PbS=3)

Set point upper limit

(It cannot be set above this value)

Set point lower limit

(It cannot be set below this value)

Sensor type selection

(0=Pt100) (1=TcJ) (2=TcK) (3=4-20mA)

Blocking the scale between HES and LES (Only if PbS=3)

(0=Free scale) (1=Blocked scale)

Type of control: (0=PID for CONTROL 1) (1=ON/OFF for CONTROL 1)

(CONTROL 2 always ON/OFF, only if Clo=1,2,3)

Type of operation in CONTROL 1

(0=Direct, cold)(1= Reverse, heat)

Type of operation in CONTROL 2

(0=Direct, cold)(1= Reverse, heat) (Only if Clo=1,2,3)

CONTROL 1, CONTROL 2 Ratio Type (Only if CONTROL 2 CIo=1, 2, 3)

(0 = Two independent stages) (1 = Two related stages) (2 = Neutral Zone)

Set Point 2 lower limit

(It cannot be set below this value) (only CONTROL 2 CIo=1, 2, 3)

Set Point 2 upper limit

(It cannot be set above this value) (only CONTROL 2 CIo=1, 2, 3)

PbS

Level 2

Level 2

inPt

onoF

diF1

diF2

ton1

ton2

toF1

toF2

Cdln

IPo

Clo

Er1

Er2

CtEn

ON/OFF Configuration Parameters (only if rEG=1) or (Clo=1,2,3)

Level 3

Level 3

Description

Digital INPUT/OUTPUT (I/O, 5-, 6+) and Relays R1, R2, R3 configuration

Description

Values

Values

Min.

Min.

Def.

Def.

Max.

Max.

CONTROL 1 Differential (Hysteresis) (only if rEG=1)

CONTROL 2 Differential (Hysteresis) (only CONTROL 2 CIo=1, 2, 3)

Minimum CONTROL 1 time in ON (only if rEG=1)

Minimum CONTROL 1 time in OFF (only if rEG=1)

Minimum CONTROL 2 time in ON (only CONTROL 2 CIo=1, 2, 3)

Minimum CONTROL 2 time in OFF (only CONTROL 2 CIo=1, 2, 3)

Maximum output value scale for 20 mA / 10 V

(If PbS=0,1,2,) (If PbS=3, AHES=HES)

Minimum output value scale for 4 mA / 0 V

(If PbS=0,1,2,) (If PbS=3, ALES=HLS)

Digital input configuration if Clo=2,3,4

(0=External alarm) (1=Variation in Set point) (2=Start-Stop)

Digital input status inversion:

(0=Closed contact) (1=Open contact)

Digital Input / Output and R1, R2, R3 relays

(0= Digital Output SSR CONTROL 1, R1=ALARM 2, R2=ALARM 1) *

(1= Digital Output SSR CONTROL 1, R1=CONTROL 2, R2=ALARM 1) *

(2= Digital Input, R1=ALARM 1, R2=CONTROL 1, R3= CONTROL 2) *

(3=Digital Input, MODULE 4-20 mA / 0-10 V CONTROL 1,

R1=CONTROL 2, R2=ALARM 1) (only with MODULE 4-20 mA / 0-10 V)

(4=Digital Input, MODULE 4-20 mA / 0-10 V CONTROL 1,

R1=ALARM 2, R2=ALARM 1) (only with MODULE 4-20 mA / 0-10 V)

CONTROL 1 status with faulty sensor:

(0=OFF) (1=ON)

CONTROL 1 status with faulty sensor: (Only if Clo=1,2,3)

(0=OFF) (1=ON)

Enable / Disable CT alarm

(0=Disabled) (1=Enabled)

-50,0

-50,0

0

0

0

0

-99,9

-99,9

0

0

0

1,0

1,0

0

0

0

0

200,0

-50,0

0

0

0

50,0

50,0

250

250

250

250

2500

2500

2

1

4

(ºC/ºF/mA)

(ºC/ºF/mA)

(sec.)

(sec.)

(sec.)

(sec.)

0

0

0

0

0

1

1

1

1

Level 2

Level 3

AHES

AHES

Values

Min. Def. Max.

* In the 4-20 mA / 0-10 V module, it only acts as a repeater/converter.

1

1

2

2

AKO ON/OFF Controller’s size 48x48 mm Operating instructions

AKO Thermometers, thermostats and electronic controllers, 58 x 25,4 AKO-13xxx Operating instructions

AKO AKO-558241 Quick Manual

AKO 14642 Operating instructions

AKO AKO-55326 Quick Manual

AKO 14212 Operating instructions

AKO Surface differential controller AKO-14801 Operating instructions

AKO Configurable electronic thermostats Operating instructions

AKO 15724 2 Channel Temperature Humidity and Event Logger User manual

AKO AKO-55424 Quick Manual

Ditel SW48 Quick Start

Ditel SW48 Quick Start

PPI ProceX48 User manual

PPI ProceX48 User manual

AKO Electronica AKO-13012 User manual

AKO Electronica AKO-13012 User manual

Omega DP7000 Series Owner's manual

AKO Electronica AKO-14534 User manual

AKO Electronica AKO-14534 User manual

Auber Instruments SYL-1614 Quick Manual

Auber Instruments SYL-1614 Quick Manual

PPI IndeX48 User manual

PPI IndeX48 User manual

Orchard Audio sk-module Operating instructions

Ventev Hard Lid Ceiling Tile Mount User manual

MRC PFY-SERIES User manual

MRC PFY-SERIES User manual