Evo CS95-GEN2 Owner's manual

- Category

- Heat pumps

- Type

- Owner's manual

This manual is also suitable for

CS Installation Manual Updated: June 2019 Page: 1

CS Installation Manual Updated: Dec 2019 Page: 2

EVO CS INSTALLATION MANUAL

IMPORTANT: EvoHeat heat pumps MUST be connected by a licensed electrician. Under no circumstances should

an unlicensed person attempt to install or repair an EvoHeat heat pump themselves. Heater electrical installation

undertaken by an unlicensed installer will void the warranty. Installation of your EVOHEAT heat pump must be in

accordance with the procedures in the product manual. Always check that your installation will comply with local

building and council regulations. Refer to the cautions and warnings page for more information.

CONTENTS

PAGE

Dimensions

3 to 4

Prior to installation

5

Installation & Connection diagrams

6

Installation requirements

7 to 9

Water pump connection

10

Remote Controller Connection

11

Swimming Pool Heat Pump Plumbing

11

Initial start-up of the heat pump

12

Time delay

12

Cable specifications

13

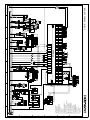

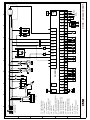

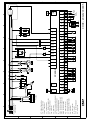

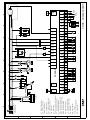

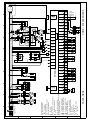

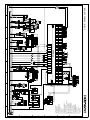

Wiring diagrams

Page 14 to 21

Cautions & warnings

22

For controller settings, error codes, maintenance and warranty information please refer to the owner’s manual.

EvoHeat have their own dedicated EvoHeat YouTube Channel that features step by step video instructions on how to

use your EvoHeat controller.

https://www.youtube.com/channel/UCfYiOxHuybBuC1NZcqUnrcA

CS Installation Manual Updated: Dec 2019 Page: 3

CS RANGE DIMENSIONS

CS38, CS47 & CS57

CS Installation Manual Updated: Dec 2019 Page: 4

CS-GEN2 DIMENSIONS

CS95- GEN2

CS120-GEN2 & CS145-GEN2

CS200-GEN2

CS Installation Manual Updated: Dec 2019 Page: 5

PRIOR TO INSTALLATION

Before installation it is very important to ensure 4 variables are carefully checked to allow the unit to operate

correctly:

1. Adequate Air Flow

2. Correct water flow volume

3. Correct electrical connection & supply

4. Heater condition

1. AIR FLOW

Installing the heater indoors or in an enclosed space will result in very poor performance and can in extreme cases

damage the heater. Ensure the heater is installed in a well-ventilated area with plenty of fresh air, a minimum gap

between walls/fences etc of 1000mm on the sides and 1500mm overhead clearance. If you do not have a location

with these suggested clearances, please contact our EvoHeat Tech Support Specialist to discuss appropriate

installation locations.

2. WATER FLOW

It is CRITICAL that there is sufficient water flow to the unit. Incorrect water flow can cause a loss of efficiency and

possible damage to the unit. Optimal water flow rates are listed in the EvoHeat brochure and tech data sheets. It is

imperative that water flow is kept as close as possible to these flow rates. Correct water flow not only offers

optimal heater performance but may also prevent possible damage to your heater.

3. ELECTRICAL CONNECTION

Always use a qualified Electrician to perform any electrical work.

Ensure the power cable and circuit breaker are of a suitable size for the heater being installed. Also check that there

is adequate voltage and current available at the heater connection to run the unit.

Voltage range should be 220-240 volts for single phase, and 380-415 volts for 3 phase units. Voltage ranges outside

these parameters will cause heater damage and void your warranty.

Correct phase connection is important with 3 phase heaters. Take note of the 3 phase relay monitor lights inside the

unit- both lights must be lit – refer to page 8 for more information.

4. HEATER CONDITION

Check the heater packaging upon delivery for any obvious signs of damage. Inform your supplier IMMEDIATELY if

there is any evidence of rough handling. When the heater has been removed from the packaging check the

refrigerant gauge on the front panel of the unit. The gauge should be showing a pressure of approx 10-20 on the

outside red band – any less than this figure means there may be a leak in the refrigerant system, and you should

immediately contact your EvoHeat Dealer.

CS Installation Manual Updated: Dec 2019 Page: 6

INSTALLATION & CONNECTION DIAGRAM

The schematic diagram is for reference only. Please check the water inlet/outlet label on the heat pump while

plumbing the unit.

INSTALLATION ITEMS

EvoHeat only provide the main EvoHeat unit and EvoHeat accessories; other items in the illustration above should

be provided by the user or the installer.

EVOHEAT ACCESSORIES – DO NOT THROW AWAY

All EvoHeat units are provided with rubber feet, controller and leads for the controller– do not throw them

away as they are required as part of the installation.

RUBBER FEET

EvoHeat highly recommend that the rubber feet are installed – the rubber feet help reduce vibration of the unit.

General installation information disclaimer: Install your EVOHEAT heat pump in accordance with the procedures

in the product manual. Always check that your installation will comply with local building and council regulations.

CS Installation Manual Updated: Dec 2019 Page: 7

INSTALLATION REQUIREMENTS

Correct installation is required to ensure safe and efficient operation of your pool heater. Installation requirements

for EVOHEAT heat pumps include the following:

1. Location and clearances

2. Clearances

3. Correct electrical connection

4. Adequate water flow

1. LOCATION & MINIMUM CLEARANCES RECOMMENDATIONS

EvoHeat recommend the heat pump should ONLY be installed in an outdoor location with appropriate ventilation.

Installing the heater indoors without adequate ventilation, or in a poorly ventilated enclosed space, will result in

very poor performance and can, in extreme cases, damage the heater. Ensure the heater is installed in a well-

ventilated area with plenty of fresh air.

If installing the heater on an existing pump/filtration system, the heater must be installed AFTER the filter and

BEFORE the chlorinator/sanitizer.

The heat pump should be installed on a flat level surface as close as possible to the pool.

The Evo pool heat pump should be installed with a minimum clearance of at least 3.5m to the water’s edge.

Furthermore, EvoHeat recommend installing the heat pump no greater than 7.5 meters away from the water’s

edge due to heat loss from the piping.

A rough estimate of heat loss over a 30m pipe run can be as high as 600 Watts per hour per 5 degrees of

temperature difference between the air/ground and the pool water. These losses need to be taken into account

over long distances and piping may need to be insulated to reduce heat leakage.

The heat pump should be installed a maximum of 5m below the water level of the pool/spa. If further than 5M

please discuss with your EvoHeat specialist for the best advice.

Make sure the heat pump is not located where large amounts of water may run-off from a roof into the unit. Sharp

sloping roofs without gutters will allow excessive amounts of rainwater mixed with debris from the roof to be forced

through the unit. A water deflector may be needed to protect the heat pump.

In the event that a suitable outdoor location is unavailable please contact Evo Industries for specialist technical

advice ON 1300 859 933

CS Installation Manual Updated: Dec 2019 Page: 8

2. AIR FLOW CLEARANCES

The unit needs continuous fresh air whilst running. The heater draws up to 47000 m3/h ambient air, so it is

important to leave sufficient space for unobstructed airflow into and out of the heater. Do not locate the heater

in an enclosed area, or the discharged cold air will recirculate into the unit and consequently lower the

heating efficiency.

Leave sufficient space for unobstructed airflow into and out of the heater. Do not locate the heater in an enclosed

area, or the discharged cold air will recirculate into the unit and consequently lower the heating efficiency as well as

possibly icing up.

Leave sufficient space for servicing the units, ensure the service doors can be easily accessed by the service

technician.

If you do not have a location with these suggested clearances, please contact our EvoHeat Tech Support Specialist

to discuss appropriate installation locations.

CS Installation Manual Updated: Dec 2019 Page: 9

3. CORRECT ELECTRICAL CONNECTION

IMPORTANT: Always use a qualified Electrician to perform any electrical work. A licensed electrician must read the

information before connecting.

Ensure the power cable and circuit breaker are of a suitable size for the heater being installed. Also check that there

is adequate voltage and current available at the heater connection to run the unit.

Voltage range should be 220-240 volts for single phase, and 380-415 volts for 3 phase units. Voltage ranges outside

these parameters will cause heater damage and void your warranty.

1. Ensure power is disconnected during installation or service.

2. Always comply with the national and local electrical codes and standards.

3. Ensure electrical cable size is adequate for heater requirements at the installation location.

4. The heater must be equipped with a circuit breaker and isolation device.

5. Circuit breaker must be installed between the heater and the water circulation pump if the water pump is

hard-wired into the heater. Please note recommended circuit breaker sizes make no allowance for a water

pump hard wired into the heater.

6. The unit must be well earthed. Remove the front panel to access the electrical connection terminals of the

heater. The electrical wiring diagram is affixed to the inside of the front panel or refer to the wiring diagrams

within the manual.

Correct phase connection is important with 3 phase heaters. NOTE: if 2 lights are showing on the 3 PHASE relay

monitor this means the EvoHeat heat pump has been wired correctly (one orange light and one green light). If

only one light is showing, the phases are out of rotation and need to be rotated to get the correct phase rotation.

4. ADEQUATE WATER FLOW

All EVOHEAT heat pumps have a factory pre-set internal water flow switch. If there is insufficient water flow the

heater will not operate.

Before connecting the heater to the plumbing, all piping must be thoroughly flushed to ensure no debris can enter

the heater. Failure to remove pipe debris can jam or damage the flow switch and may cause damage to the heater.

When cleaning the pool it is advisable to turn off your heater as restricted water flow may cause the heater to shut

down and indicate low water flow fault (E03 error) or high pressure fault (E01 error).

CS Installation Manual Updated: Dec 2019 Page: 10

WATER PUMP CONNECTION

IMPORTANT: A Variable speed pump or bypass valve and plumbing MUST be fitted to allow water flow to be

adjusted through the heater. Do not direct connect a water pump with higher flow than required to the heat

pump.

WATER PUMP CONNECTION

How do I connect up my new EVO heater to my pool or spa? The EVO J-Box is the answer.

The J-Box will save you money on water pumps and running costs. The J-Box allows either the heater OR the

chlorinator to supply power to the water pump so each system can run independently of the other. There are 3

methods to install an Evo heat pump:

SLAVE MODE

Heater is connected to the filtration system but relies on

water flow from the chlorinator for start and stop times.

SEPARATE SYSTEMS

Heater runs on a dedicated circuit to the filtration

system. The heater controls the start and stop times of

this pump.

EVO J-BOX

Heater is connected into the filtration plumbing.

After installing the Evo J-Box and having your

electrician hard wire the J-Box to the heater, simply

plug the water pumpinto the J-Box and plug the J-Box

into the Chlorintor.

CS Installation Manual Updated: Dec 2019 Page: 11

REMOTE CONTROLLER CONNECTION

All Evo heaters can be controlled remotely by any device capable of opening and closing a circuit. The circuit must be

low voltage 5V or lower.

Remove the cable loop noted on the wiring diagram on the PCB and connect the remote cable from the external

controller into these terminals – this differs between models.

When this circuit is open (no connection) the Evo heat pump will not operate.

When the circuit is closed the unit will operate according to the parameters set on the controller(s).

This can change based on model, please check the wiring diagram that comes with the heater inside the electric

box cover or refer to the wiring diagrams within this manual.

SWIMMING POOL HEAT PUMP PLUMBING

The Swimming Pool Heat Pumps exclusive rated flow titanium heat exchanger requires no special plumbing

arrangements except bypass (please set the flow rate according to the nameplate). The water pressure drop is less

than 10kPa at max.

Flow rate: Since there is no residual heat or flame Temperatures, the unit does not need copper heat sink piping.

PVC pipe can be run straight into the unit.

Location: Connect the unit in the pool pump discharge (return) line downstream of all filter and pool pumps, and

upstream of any chlorinators, ozonators or chemical pumps.

Standard model have slip glue fittings which accept 50mm or 100 mm PVC pipe for connection to the pool or spa

filtration piping.

Give serious consideration to adding a quick coupler fitting at the unit inlet and outlet to allow easy draining of unit

for winterizing and to provide easier access should servicing be required.

CS Installation Manual Updated: Dec 2019 Page: 12

INITIAL START UP OF THE UNIT

NOTE: In order for the unit to heat the pool or spa, the filter pump must be running to circulate water through the

heat exchanger.

START-UP PROCEDURE

After installation is completed, follow the steps below:

1. Turn on your filter pump. Check for water leaks and verify flow to and from the pool.

2. Turn on the electrical power supply to the unit, then press the key ON/OFF of wire controller, it should start after

several seconds.

3. After running a few minutes make sure the air leaving the top of the unit is cooler (between 5-10 ℃

4. With the unit operating turn the filter pump off. The unit should also turn off automatically.

5. Allow the unit and pool pump to run 24 hours per day until desired pool water temperature is reached. When

the water-in temperature reaches the set temperature the unit will shut off. The unit will now automatically

restart (as long as your pool pump is running) when the pool temperature drops more than 1℃ below the set

temperature.

TIME DELAY

The unit is equipped with a 3-minute built-in solid-state restart delay included to protect control circuit components

and to eliminate restart cycling and contactor chatter. This time delay will automatically restart the unit

approximately 3 minutes after each control circuit interruption. Even a brief power interruption will activate the

solid state 3-minute restart delay and prevent the unit from starting until the 5 minute countdown is completed.

Power interruptions during the delay period will have no effect on the 3-minute countdown.

CS Installation Manual Updated: Dec 2019 Page: 13

CABLE SPECIFICATIONS

If the unit is to be installed outdoors, ensure that a cable is used which has protection against UV.

Q

3

COMP1

U

V

W

3

COMP2

U

V

W

KM2KM1

L11

RED

L1

N

KM2

KM1

K2

K1

BLU

Y/G

BRN

N

N

N

Controller

KM1 KM2

0 123456789

A

B

C

D

E

F

A

B

C

D

E

F

CODE:20121207-0005

N

N

L1

N

N

N

CH1 CH2

3

13

24

5

6

7

8

01

U1

V1

W1

U2

V2

W2

N14

RO 01

L

N

N

CN6

RO 02

RO 03

RO 04

RO 05

RO 06

RO 07

RO 08

RO 09

PC4001

GND

AI 07

DI 12

DI 11

DI 10

DI 09

DI 08

DI 07

DI 06

DI 05

DI 04

DI 03

DI 02

AI 12(50)

AI 09

AI 08

AI 06

AI 05

AI 04

AI 03

AI 02

AI 01

5V

DI 01

NET

12V

DI /DO 2

DI /DO 1

AI 11(50)

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

CN5

CN1

L1

K3

L1

L2L3

N

N14

L3(C)

L2(B)

L1(A)

11

14

12

PM

t

50K

t

50K

t

5K

t

5K

t

5K

t

5K

t

5K

4V

HP1

HP1

LP1

LP1

HP2

HP2

LP2

LP2

LP2HP2LP1HP1ET2ET1

AT

AT

AT

CT2

CT2

CT2CT1

CT1

CT1

OT

OT

IT

IT

OTIT

N

N

K2

K1

K3

t

5K

t

5K

SUT1 SUT2

SUT1

SUT1

SUT2

SUT2

ET1

ET1

ET2

ET2

13

24

5

6

7

8

02

4V2

4V1

4V1

4V2

N

N

4V

N

N4V

N

N

N

AI 10

GND

EEV1

5

EEV2

5

KM5

K5 K5

N

N

TO POWER SUPPLY

415V/3N~/50Hz

WHT

BLU

BLK

RED WHT BLU RED WHT BLU

Remote

Cool/heat

ON/OFF

input

N

PH1 PH2

N

1

3

24

5

6

7

8

03

N

PH N

NN

L2

L3

L1

L2

L3

L1

L2

L3

L1

L2

L3

L1

L2

L3

L1

L1

L12

ON/OFF

output

N

FM1

RED

WHT

FM2

RED

WHT

K3

F

K3

L2

KM5

NN

P1

L1

L2

L3

L2

L1

L3

P3

P2

P1

P3

P2

F

L2

L1

N

To pump

L2 L3

L1

L1

PH

PH

FS

FOHP2

AT:Ambient temperature

CH:Compressor heater

COMP:Compressor

CT:Coil temperature

ET:Exhaust temperature

FM:Fan motor

IT:Inlet water temperature

LP:Low pressure protection

KM1:Contactor of compressor1

KM2:Contactor of compressor2

K3:Relay of fan motor

KM5:Contactor of pump

OT:Outlet water temperature

Q: Air switch

HP:High pressure protection

4V: 4 way valve

EEV:Electronic expand valve

SUT:Suction temperature

PH:Pan heater

FS:Flow switch

PM:Phase monitor

FOHP:Fan-motor overheat protect

FS

FS

FS

4

1

1

4

FOHP1

FOHP1

FOHP1

FOHP2

FOHP2

1234

Q

3

COMP1

U

V

W

3

COMP2

U

V

W

KM2KM1

L11

RED

L1

N

KM2

KM1

K2

K1

BLU

Y/G

BRN

N

N

N

Controller

KM1 KM2

0 123456789

A

B

C

D

E

F

A

B

C

D

E

F

CODE:20121207-0005

N

N

L1

N

N

N

CH1 CH2

3

13

24

5

6

7

8

01

U1

V1

W1

U2

V2

W2

N14

RO 01

L

N

N

CN6

RO 02

RO 03

RO 04

RO 05

RO 06

RO 07

RO 08

RO 09

PC4001

GND

AI 07

DI 12

DI 11

DI 10

DI 09

DI 08

DI 07

DI 06

DI 05

DI 04

DI 03

DI 02

AI 12(50)

AI 09

AI 08

AI 06

AI 05

AI 04

AI 03

AI 02

AI 01

5V

DI 01

NET

12V

DI /DO 2

DI /DO 1

AI 11(50)

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

CN5

CN1

L1

K3

L1

L2L3

N

N14

L3(C)

L2(B)

L1(A)

11

14

12

PM

t

50K

t

50K

t

5K

t

5K

t

5K

t

5K

t

5K

4V

HP1

HP1

LP1

LP1

HP2

HP2

LP2

LP2

LP2HP2LP1HP1ET2ET1

AT

AT

AT

CT2

CT2

CT2CT1

CT1

CT1

OT

OT

IT

IT

OTIT

N

N

K2

K1

K3

t

5K

t

5K

SUT1 SUT2

SUT1

SUT1

SUT2

SUT2

ET1

ET1

ET2

ET2

13

24

5

6

7

8

02

4V2

4V1

4V1

4V2

N

N

4V

N

N4V

N

N

N

AI 10

GND

EEV1

5

EEV2

5

KM5

K5 K5

N

N

TO POWER SUPPLY

415V/3N~/50Hz

WHT

BLU

BLK

RED WHT BLU RED WHT BLU

Remote

Cool/heat

ON/OFF

input

N

PH1 PH2

N

1

3

24

5

6

7

8

03

N

PH N

NN

L2

L3

L1

L2

L3

L1

L2

L3

L1

L2

L3

L1

L2

L3

L1

L1

L12

ON/OFF

output

N

FM1

RED

WHT

FM2

RED

WHT

K3

F

K3

L2

KM5

NN

P1

L1

L2

L3

L2

L1

L3

P3

P2

P1

P3

P2

F

L2

L1

N

To pump

L2 L3

L1

L1

PH

PH

FS

FOHP2

AT:Ambient temperature

CH:Compressor heater

COMP:Compressor

CT:Coil temperature

ET:Exhaust temperature

FM:Fan motor

IT:Inlet water temperature

LP:Low pressure protection

KM1:Contactor of compressor1

KM2:Contactor of compressor2

K3:Relay of fan motor

KM5:Contactor of pump

OT:Outlet water temperature

Q: Air switch

HP:High pressure protection

4V: 4 way valve

EEV:Electronic expand valve

SUT:Suction temperature

PH:Pan heater

FS:Flow switch

PM:Phase monitor

FOHP:Fan-motor overheat protect

FS

FS

FS

4

1

1

4

FOHP1

FOHP1

FOHP1

FOHP2

FOHP2

1234

Q

3

COMP1

U

V

W

3

COMP2

U

V

W

KM2KM1

L11

RED

L1

N

KM2

KM1

K2

K1

BLU

Y/G

BRN

N

N

N

Controller

KM1 KM2

0 123456789

A

B

C

D

E

F

A

B

C

D

E

F

CODE:20121207-0005

N

N

L1

N

N

N

CH1 CH2

3

13

24

5

6

7

8

01

U1

V1

W1

U2

V2

W2

N14

RO 01

L

N

N

CN6

RO 02

RO 03

RO 04

RO 05

RO 06

RO 07

RO 08

RO 09

PC4001

GND

AI 07

DI 12

DI 11

DI 10

DI 09

DI 08

DI 07

DI 06

DI 05

DI 04

DI 03

DI 02

AI 12(50)

AI 09

AI 08

AI 06

AI 05

AI 04

AI 03

AI 02

AI 01

5V

DI 01

NET

12V

DI /DO 2

DI /DO 1

AI 11(50)

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

CN5

CN1

L1

K3

L1

L2L3

N

N14

L3(C)

L2(B)

L1(A)

11

14

12

PM

t

50K

t

50K

t

5K

t

5K

t

5K

t

5K

t

5K

4V

HP1

HP1

LP1

LP1

HP2

HP2

LP2

LP2

LP2HP2LP1HP1ET2ET1

AT

AT

AT

CT2

CT2

CT2CT1

CT1

CT1

OT

OT

IT

IT

OTIT

N

N

K2

K1

K3

t

5K

t

5K

SUT1 SUT2

SUT1

SUT1

SUT2

SUT2

ET1

ET1

ET2

ET2

13

24

5

6

7

8

02

4V2

4V1

4V1

4V2

N

N

4V

N

N4V

N

N

N

AI 10

GND

EEV1

5

EEV2

5

KM5

K5 K5

N

N

TO POWER SUPPLY

415V/3N~/50Hz

WHT

BLU

BLK

RED WHT BLU RED WHT BLU

Remote

Cool/heat

ON/OFF

input

N

PH1 PH2

N

1

3

24

5

6

7

8

03

N

PH N

NN

L2

L3

L1

L2

L3

L1

L2

L3

L1

L2

L3

L1

L2

L3

L1

L1

L12

ON/OFF

output

N

FM1

RED

WHT

FM2

RED

WHT

K3

F

K3

L2

KM5

NN

P1

L1

L2

L3

L2

L1

L3

P3

P2

P1

P3

P2

F

L2

L1

N

To pump

L2 L3

L1

L1

PH

PH

FS

FOHP2

AT:Ambient temperature

CH:Compressor heater

COMP:Compressor

CT:Coil temperature

ET:Exhaust temperature

FM:Fan motor

IT:Inlet water temperature

LP:Low pressure protection

KM1:Contactor of compressor1

KM2:Contactor of compressor2

K3:Relay of fan motor

KM5:Contactor of pump

OT:Outlet water temperature

Q: Air switch

HP:High pressure protection

4V: 4 way valve

EEV:Electronic expand valve

SUT:Suction temperature

PH:Pan heater

FS:Flow switch

PM:Phase monitor

FOHP:Fan-motor overheat protect

FS

FS

FS

4

1

1

4

FOHP1

FOHP1

FOHP1

FOHP2

FOHP2

1234

RO 01

L

L

L

N

N

RO 02

RO 03

RO 04

RO 05

RO 06

RO 07

RO 08

RO 09

RO 10

RO 11

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

NET

12V

5V

0-10V

GND

GND

AI 01

AC12V

AC12V

RS485B

RS485A

AI 02

AI 03

AI 04

AI 05

AI 06

AI 07

AI 08

AI 09

AI 10

AI 11

AI 12

AI 13

AI 14

AI 15

AI 16

DI 01

DI 02

DI 03

DI 04

DI 05

DI 06

DI 07

DI 08

DI 09

DI 10

DI /DO01

DI /DO02

DI /DO03

DI 11

0 123456789

A

B

C

D

E

F

A

B

C

D

E

F

KM1

L3(C)

L2(B)

L1(A) 11

14

12

PM

L1L2L3

Q

KM3

KM4

12V

TC1

KM7

L1

L2

L3

N

KM2

K2

KM7

K5

K7

N

N

N14 N

t

5K

t

5K

t

5K

t

5K

t

5K

t

5K

t

5K

N

N

N

KM1

3

COMP1

U

V

W

U1

V1

W1

12V

TC2

CN2

BHB10(1)

CN3

RLY1RLY2RLY3RLY4

CN5

CN6

12V

NET

GND

DI01

AI01

AI02

AI03

AI04

AI05

AI06

AI07

AI08

CT1 CT2

CN4

GND

GND

GND

GND

GND

GND

GND

GND

GND

CC04

AI09

GND

RO04 CC03 RO03 CC02 RO02 CC01RO01

6.8K

6.8K

6.8K

6.8K

3

Detector

t

50K

ET2ET1

ET1

ET1

ET2

ET2

L1

L2

L3

L1

t

50K

6.8K

CN2

BHB10(2)

CN3

RLY1RLY2RLY3RLY4

CN5

CN6

12V

NET

GND

DI01

AI01

AI02

AI03

AI04

AI05

AI06

AI07

AI08

CT1 CT2

CN4

GND

GND

GND

GND

GND

GND

GND

GND

GND

CC04

AI09

GND

RO04 CC03 RO03 CC02 RO02 CC01RO01

6.8K

6.8K

6.8K

6.8K

3

3

COMP4

U

V

W

L1

L2

L3

U4

V4

W4

L2

L3

t

50K

ET4ET3

ET3

ET3

ET4

ET4

L1

L2

L3

L1

t

50K

6.8K

L1

L2

L3

N

L1

L1

L1

N

N

Controller

3

N

13

24

5

6

7

8

02

4V

13

24

5

6

7

8

03

4V1

4V2

4V3

4V4

4V

4V

4V

4V

4V

N

N

N

N

N

N

N

N

N

IT

IT

OT

OT

FS

FR5

CT1

CT1

CT2

CT2

AT

AT

ITOTCT1CT2AT

15 13

HP2 HP1

19

HP4

17

HP3

CN2

CN3

Detector

CT3

CT3

CT3

CT4

CT4

CT4

6.8K

6.8K

6.8K

6.8K

N

L1

HP1

HP1

13

LP4

LP4

LP4

LP3

LP3

LP3

HP2

HP2

15

HP3

HP3

17

LP2

LP2

LP2

HP4

HP4

19

LP1

LP1

LP1

HP1HP2HP3

HP4

HP1

HP2

HP3

HP4

13

15

17

19

N

N

N

2

2

K5

FM2

C2

FM3

C3

FM1

C1

N

N

13

24

5

6

7

8

04

L2

N

N

N

N

L2

N

KM4

N

KM3

N

KM2

N

KM1

N

CH1

CH2

CH3

CH4

N

13

24

5

6

7

8

01

N

N

N

N

N

N

N

N

N

CODE:20160512-0003

CS95-GEN2

N

N

N

N

N

N

L11

BLUY/G BRN

TO PUMP

TO POWER SUPPLY

RED

RED

Y/G

BLU

BRN

Y/G

BLU

BRN

BLU BLK

RED

BLU

BLK

RED

BLU

BLK

RED

L17

L27

L37

L1

380-415V~/3N/50Hz

L1

L1

L1

L1

L1

L12

L13

L14

L11

L12

L13

L14

WHT

BLU

BLU

WHT

CN3

CN2

EEV3

CN7

CN6

CN5

CN4

GND

EEV2

PZF10

5

5

EEV3

12V

5

5

EEV2

EEV1

EEV GND

EEV4

5

5

GND

EEV

13

24

5

6

7

8

05

NL18

PH2

PH1

L18

MTS

HC

L1

L1

t

5K

t

5K

t

5K

t

5K

SUT1

SUT1

SUT2

SUT2

SUT3

SUT3

SUT4

SUT4

SUT1SUT2SUT3

SUT4

RED

L1

N

WHT

BLU

BLK

L2

L3

L1 N

L2

L3

K6

K6

F1

13

24

5

6

7

8

06

N

N

K6

F2

L2

F2

K5

L2

F1

F1

F2

ORG

ORG

ORG

WHT

WHT

WHT

N

COMP:Compressor

HP:High pressure protection

LP:Low pressure protection

TC:Transformer

Q:Air switch

ET:Environment temperature

FM:Fan motor

KM1:Contactor coil of compressor1

KM2:Contactor coil of compressor2

KM3:Contactor coil of compressor3

K5:Relay coil of High-speed fan

KM7:Contactor coil of pump

PM:Phase monitor

IT:Inlet water temperature

KM4:Contactor coil of compressor4

CH:Crankcase heater

FS:Flow switch

OT:Outlet water temperature

4V: 4 way valve

AT:Ambient temperature

CT:Coil temperature

PH:Pan heater

EEV:Electronic expansion valve

SUT:Suction temperature

K6:Relay coil of Low-speed fan

KM4

FR1

KM2

3

COMP2

U

V

W

L1

L2

L3

U2

V2

W2

L2

L3

RED

WHT

BLU

FR2

L2

KM3

3

COMP3

U

V

W

U3

V3

W3

RED

WHT

BLU

FR3

L1

FR4

FR:Thermal relay

FR7

13

24

5

6

7

8

07

L1

L1

L1

L1

L1

L1

L1

12

2

2

1

FR7

FU

1A

FU

3.15A

FU

3.15A

FU:Fuse

FU

1A

L1

FR1

L15

N

L16

FR2FR3

L17

FR4

K1

K3

K4

L18

FU

5A

Q

3

COMP1

U

V

W

3

COMP2

U

V

W

RED

L1

N

KM2

KM1

K2

K1

BLU

Y/G

BRN

Controller

KM1 KM2

0 123456789

A

B

C

D

E

F

A

B

C

D

E

F

CODE:20160512-0004

KM3

N

N

L1

3

U1

V1

W1

U2

V2

W2

N14

RO 01

L

N

N

CN6

RO 02

RO 03

RO 04

RO 05

RO 06

RO 07

RO 08

RO 09

PC4001

GND

AI 07

DI 12

DI 11

DI 10

DI 09

DI 08

DI 07

DI 06

DI 05

DI 04

DI 03

DI 02

AI 12(50)

AI 09

AI 08

AI 06

AI 05

AI 04

AI 03

AI 02

AI 01

5V

DI 01

NET

12V

DI /DO 2

DI /DO 1

AI 11(50)

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

CN5

CN1

L1

K3

L1

L2L3

N

N14

L3(C)

L2(B)

L1(A)

11

14

12

PM

t

50K

t

50K

t

5K

t

5K

t

5K

t

5K

t

5K

4V

HP1

HP1

LP1

LP1

HP2

HP2

LP2

LP2

FR5

LP2HP2LP1HP1ET2ET1

AT

AT

AT

CT2

CT2

CT2CT1

CT1

CT1

OT

OT

IT

IT

OTIT

N

N

K2

K1

K3

t

5K

t

5K

SUT1 SUT2

SUT1

SUT1

SUT2

SUT2

ET1

ET1

ET2

ET2

13

24

5

6

7

8

06

4V2

4V1

4V1

4V2

N

N

4V

N

N4V

N

N

N3

AI 10GND

EEV1

EEV2

5

KM5

L1 N

NN

P1

TO PUMP

KM5

K5 K5

N

N

TO POWER SUPPLY

415V/3N~/50Hz

WHT

BLU

BLK

RED WHT BLU RED WHT BLU

Remote

Cool/heat

ON/OFF

input

N

PH1

PH2

1

3

24

5

6

7

8

07

PH N

NN

L2

L3

L1

L2

L3

L1

L3

L1

L1

L2

L3

L2

L1

L3

P3

P2

P1

P3

P2

ON/OFF

output

FOHP2

L2 L3

L2

L2

L1

L3

L1

L2

L3

L1

L2

L2

L3

L3

L1

L2

L3

L1

L2

L3

PH

PH

5

KM2KM1

L14N

N

CH1

CH2

L15

L1

L1

N

N

3

FM1

U

V

W

3

FM2

U

V

W

KM4KM3

K4 IR4

L2

L3

L2

L3

UL

VL

WL

UL

VL

WL

UH

VH

WH

WH

WH

VH

VH

UH

UH

UH

UH

UH

UH

UH

U2(BRN)

13

24

5

6

7

8

03

13

24

5

6

7

8

04

13

24

5

6

7

8

05 WLVLULWHVHUH

13

24

5

6

7

8

02

UH

13

24

5

6

7

8

01

VH WH

VH

VH

VH

WH

WH WH

WH

UH

UH

VL

WL VH

UL

IR5 IR5 IR3

KM3

L2

L1

L2

L3

L1

L2

L3

L2

K8

N

N

N

K8K8

K8K8

K8

U2-2

Y/G

Y/G

V2(BLK)

V2-2

W2-2

U1-2

V1-2

W1-2

W2(BLU)

U1(YEL)

V1(BLK)

W1(WHT)

U2-1

V2-1

W2-1

U1-1

V1-1

W1-1

U2(BRN)

V2(BLK)

W2(BLU)

U1(YEL)

V1(BLK)

W1(WHT)

L1

L1

N

KM4

IR4

IR3

N

N

N

N4

K4 K4

1

FOHP1 FOHP2FS

FOHP2

FOHP1

FOHP1

2

234

3

FR3

6

6

13

24

5

6

7

8

08

KM4

L2

K4

N

N

K7K7K7

IR4

K7K7

K4

L2

N

N

IR3IR5

AT:Ambient temperature

CH:Compressor heater

COMP:Compressor

CT:Coil temperature

ET:Exhaust temperature

FM:Fan motor

FS:Flow switch

IT:Inlet water temperature

LP:Low pressure protection

KM1:Contactor of compressor1

KM2:Contactor of compressor2

KM3:Contactor of high fan motor

KM5:Contactor of pump

OT:Outlet water temperature

Q: Air switch

HP:High pressure protection

4V: 4 way valve

EEV:Electronic expand valve

SUT:Suction temperature

PH:Pan heater

PM:Phase monitor

FOHP:Fan-motor overheat protect

KM4:Contactor of low fan motor

K4:Relay of high fan motor

IR3/4/5:Relay electronic of high fan motor

FR:Thermal relay

FR3

FR4

FR1

FR2

FR5

FU

2A

FU

2A

L1

FU

2A

L1

L1

L2

L1

L2

FR1

FR2

FS

FS

1

2

FR5

56

FR3

FR4

Q

3

COMP1

U

V

W

3

COMP2

U

V

W

RED

L1

N

KM2

KM1

K2

L15

BLU

Y/G

BRN

Controller

KM1

KM2

0 123456789

A

B

C

D

E

F

A

B

C

D

E

F

KM3

N

N

3

U1

V1

W1

U2

V2

W2

N14

RO 01

L

N

N

CN6

RO 02

RO 03

RO 04

RO 05

RO 06

RO 07

RO 08

RO 09

PC4001

GND

AI 07

DI 12

DI 11

DI 10

DI 09

DI 08

DI 07

DI 06

DI 05

DI 04

DI 03

DI 02

AI 12(50)

AI 09

AI 08

AI 06

AI 05

AI 04

AI 03

AI 02

AI 01

5V

DI 01

NET

12V

DI /DO 2

DI /DO 1

AI 11(50)

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

CN6

CN1

L1

L1

L2L3

N

N14

L3(C)

L2(B)

L1(A)

11

14

12

PM

t

50K

t

50K

t

5K

t

5K

t

5K

t

5K

t

5K

4V

HP1

HP1

LP1

LP1

HP2

HP2

LP2

LP2

FR5

LP2HP2LP1HP1ET2ET1

AT

AT

AT

CT2

CT2

CT2CT1

CT1

CT1

OT

OT

IT

IT

OTIT

t

5K

t

5K

SUT1 SUT2

SUT1

SUT1

SUT2

SUT2

ET1

ET1

ET2

ET2

13

24

5

6

7

8

06

4V2

4V1

4V1

4V2

N

N

4V

N4V

N

AI 10GND

EEV1

EEV2

5

KM5

K5

N

N

FS

TO POWER SUPPLY

415V/3N~/50Hz

BLK

WHT

BLU

RED

BLUWHT

RED

BLU

WHT

Remote

out

Remote

Cool/heat

Remote

in

PH1 PH2

1

3

24

5

6

7

8

07

PH N

L2

L3

L1

L2

L3

L1

L2

L3

L1

L2

L3

L1

L2

L3

L1

L2

L2

L3

L1

L2

L2

L3

L3

KM5

L1 L2 L3 N

N

TO PUMP

L2

L1

L3

KM2

KM1

L12N

N

CH1

CH2

L11

L11

L13

N

L1

L2

L3

N14

N

N

PH

PH

P1

P3

P2

L3

N

N

L1

N

N

N

N

L1

3

FM1

U

V

W

3

FM2

U

V

W

KM4

KM3

K4 IR4

L2

L3

L2

L3

UL

VL

WL

UL

VL

WL

UH

VH

WH

WH

WH

VH

VH

UH

UH

UH

UH

UH

UH

UH

13

24

5

6

7

8

03

13

24

5

6

7

8

04

13

24

5

6

7

8

05 WLVLULWHVHUH

13

24

5

6

7

8

02

UH

13

24

5

6

7

8

01VH WH

VH

VH

VH

WH

WH WH

WH

UH

UH

VL

WL VH

UL

IR5 IR5 IR3

KM3

L2

L1

L2

L3

L1

L2

L3

L22

K6

N

N

N

K6

U2-2

Y/G

Y/G

V2-1

V2-2

W2-2

U1-2

V1-2

W1-2

W2-1

U1-1

V1-1

W1-1

U2-1

V2-1

W2-1

U1-1

V1-1

W1-1

V2-2

W2-2

U1-2

V1-2

W1-2

L1

L1

N

N

KM4

K4

N

L1

L1

U2-1

U2-2

5

34

5

6

FOHP1

FOHP1

FOHP2

FOHP2

2

FS FOHP1FOHP2

IR3IR5

13

24

5

6

7

8

08

KM4

L21

K4

N

N

K4K4K4

IR4

K4K4

K4

L2

N

N

K4:Relay of high fan motor

IR3/4/5:Relay electronic of high fan motor

K6

K6

K6

K6

FU

1A

L11

L11

FU

1A

FU

1A

FR5

FR2

FR1

FR3

FR4

FR5

1

1

2

FR3

FR4

3

6

6

FR3

AT:Ambient temperature

CH:Compressor heater

COMP:Compressor

CT:Coil temperature

ET:Exhaust temperature

FM:Fan motor

FS:Flow switch

IT:Inlet water temperature

LP:Low pressure protection

KM1:Contactor of compressor1

KM2:Contactor of compressor2

KM3:Contactor of high fan motor

KM5:Contactor of pump

OT:Outlet water temperature

Q: Air switch

HP:High pressure protection

4V: 4 way valve

EEV:Electronic expand valve

SUT:Suction temperature

PH:Pan heater

PM:Phase monitor

FOHP:Fan-motor overheat protect

KM4:Contactor of low fan motor

FU:Fuse

FR: Thermal overload relay

CS145-GEN2

CODE:20160329-0005

FR2

L14

FR1

K1

FU

5A

IR4

K3

L16

N

IR3

L17

RO 01

L

L

L

N

N

PC8001

RO 02

RO 03

RO 04

RO 05

RO 06

RO 07

RO 08

RO 09

RO 10

RO 11

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

NET

12V

5V

0-10V

GND

GND

AI 01

AC12V

AC12V

RS485B

RS485A

AI 02

AI 03

AI 04

AI 05

AI 06

AI 07

AI 08

AI 09

AI 10

AI 11

AI 12

AI 13

AI 14

AI 15

AI 16

DI 01

DI 02

DI 03

DI 04

DI 05

DI 06

DI 07

DI 08

DI 09

DI 10

DI /DO01

DI /DO02

DI /DO03

DI 11

0 123456789

A

B

C

D

E

F

A

B

C

D

E

F

CODE:20161112-0006

KM1

L1

TO POWER SUPPLY

415V/3N~/50Hz

L3(C)

L2(B)

L(A) 11

14

12

PM

KM4

N

L14

12V

TC1

KM3

N

L13

KM2

K2

K1

KM7

K7 N

CH3 CH4

N14 N

t

5K

t

5K

t

5K

t

5K

t

5K

t

5K

t

5K

1

N2

N1

3

COMP1

U

V

W

U1

V1

W1

12V

TC2

CN2

BHB10(1)

CN3

RLY1RLY2RLY3RLY4

CN5

CN6

12V

NET

GND

DI01

AI01

AI02

AI03

AI04

AI05

AI06

AI07

AI08

CT1

CT2

CN4

GND

GND

GND

GND

GND

GND

GND

GND

GND

CC04

AI09

GND

RO04 CC03 RO03 CC02 RO02 CC01 RO01

6.8K

6.8K

6.8K

6.8K

3

Detector

N

t

50K

ET2ET1

ET1

ET1

ET2

ET2

t

50K

6.8K

CN2

BHB10(2)

CN3

RLY1RLY2RLY3RLY4

CN5

CN6

12V

NET

GND

DI01

AI01

AI02

AI03

AI04

AI05

AI06

AI07

AI08

CT1 CT2

CN4

GND

GND

GND

GND

GND

GND

GND

GND

GND

CC04

AI09

GND

RO04CC03RO03CC02RO02CC01RO01

6.8K

6.8K

6.8K

6.8K

3

Detector

N

t

50K

ET4ET3

ET3

ET3

ET4

ET4

t

50K

6.8K

N

N

Controller

3

4V

13

24

5

6

7

8

02

4V1

4V2

4V3

4V4

4V

4V

4V

4V

4V

N

N

7

1

GND

9

FR7

AT

2

7

8

1

N

13

CN2

CN3

L1

HP1

HP1

13

HP2

HP2

15

HP3

HP3

17

HP4

HP4

19

LP1

LP1

LP1

LP2

LP2

LP2

LP3

LP5

LP4

LP6

15

HP1

HP2

HP3

HP4

HP1HP2

HP1HP2

HP3

13

15

17

19

L1

L2

L3 N

N

N

N

N

3

COMP2

U

V

W

U2

V2

W2

GND

K3

K4

K2

K1

K5

K7

N

N

N

N

3

COMP3

U

V

W

U3

V3

W3

3

COMP4

U

V

W

U4

V4

W4

17

HP3

HP4

12V

12V

220V

N

13

24

5

6

7

8

01

N

N

NN

4V1 4V2 4V3 4V4

N

N

N

2

KM3KM4

K3

K4

N

K6

N

N

N

N

N

Alarm

out

On/off

input

TO PUMP

BLK

RED

WHT

BLU

L1

L1

L1

Y/G

BLU

BRN

Y/G

BLU

BRN

BLURED WHT

BLURED WHT

BLU

REDWHT

BLUREDWHT

BLUY/G BRN

L1

L1

L1

L1

L1L2L3

L2

L3

L2

L3

L2

L3

L2

L3

L11

L11

L2

L3

P1

P2

P3

ITOTCT1CT2AT CT3CT4

AT

CT4

CT4

CT3

CT3

CT2

CT2

CT1

CT1

OT

OT

IT

IT

CN3

CN2

EEV3

CN7

CN6

CN5

CN4

GND

EEV2

PZF10

5

5

EEV3

12V

5

5

EEV2

EEV1

EEV GND

EEV4

5

5

EEV

GND

t

5K

SUT1

SUT1

SUT2

SUT2

SUT3

SUT3

SUT4

SUT4

t

5K

t

5K

t

5K

SUT1SUT2SUT3SUT4

19

HP4

LP3LP4

L1

L1

6.8K

6.8K

6.8K

6.8K

Q

3

FM1

U

V

W

3

FM2

U

V

W

L2

L3

L2

L3

UL

VL

WL

WH

WH

VH

VH

UH

UH

UH

UH

UH

UH

U2-1

13

24

5

6

7

8

05

13

24

5

6

7

8

06

13

24

5

6

7

8

07 WLVLULWH

VHUH

13

24

5

6

7

8

04

UH

13

24

5

6

7

8

03

VH WH

VH

VH VH

WH

WH WH

WH

UH

UH

VL

WL VH

UL

KM5

IR6

KM6

IR5

N

N

N

N

N5

K6

K5

N6

KM5

L2

L22

K5

N

N

N

K5K5

K5K5

K5

U2-2

Y/G

Y/G

V2-1

V2-2

W2-2

U1-2

V1-2

W1-2

W2-1

U1-1

V1-1

W1-1

U2-1

V2-1

W2-1

U1-1

V1-1

W1-1

U2-2

V2-2

W2-2

U1-2

V1-2

W1-2

L1

L1

N

L2

L3

N

N

PH

13

24

5

6

7

8

08

PH

PH

N

N

N

PH2

PH1

3

456

FOHP1

FOHP1

FOHP2

FOHP2

FOHP1

FOHP2

3

6

FR5

6

13

24

5

6

7

8

09

KM6

K6

N

N

N

K6K6K6

N

IR6

K6K6

K6

IR5IR9

IR9 IR9 IR5

IR6

K6

FR7

L1

L2

L3

KM7

KM1

FR1

L2

L3

L1

KM2

FR2

L2

L3

L1

2

KM3

FR3

L2

L3

L1

KM4

FR4

L2

L3

L1

KM5

FR5

L2

L3

L1

KM6

FR6

L2

L3

L1

UH

FR4

FR3 FR2

FR1

N4

N3

N

N

N

N

FR5

FR6

FR7

910

8

8

9

FS

FS

FS

L11

13

24

5

6

7

8

10

L11

L11

L11

L11

L11

KM2

N

L16

KM1

N

L15

CH2

L11

L11

CH1

L2

L21

FU

1A

FU

1A

FU

2A

L11

N4

N3

N2

N1

COMP:Compressor

FS:Flow switch

HP:High pressure protection

LP:Low pressure protection

ET:Environment temperature

FM:Fan motor

KM1:Contactor of compressor1

KM2:Contactor of compressor2

KM3:Contactor of compressor3

KM5:Contactor of high fan motor

KM7:Contactor of pump

OT:Outlet water temperature

IT:Inlet water temperature

KM4:Contactor of compressor4

AT:Ambient temperature

CH:Crankcase heater

CT:Coil temperature

PM: Phase monitor

Q:Micro circuit breaker

FOHP:Fan-motor overheat protect

EEV:Electronic expand valve

SUT:Suction temperature

KM6:Contactor of low fan motor

TC:transformer

4V: 4 way valve

IR5/6/9:Relay electronic of high fan motor

K6:Relay of high fan motor

PH: Pan heater

FR:Thermal relay

FU:Fuse

L11L11

Page is loading ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

Evo CS95-GEN2 Owner's manual

- Category

- Heat pumps

- Type

- Owner's manual

- This manual is also suitable for

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Evo EVO CS & CS-GEN2 Owner's manual

-

Evo EVO CS & CS-GEN2 Owner's manual

-

Evo EVO CS & CS-GEN2 Owner's manual

-

Evo CS-i Owner's manual

-

Evo Force-i Owner's manual

-

Evo Force-i Owner's manual

-

Evo Wi-Fi control set up – pool heater app Owner's manual

-

Evo Force-i Owner's manual

-

Evo CS & CS-GEN2 ManualCommercial Heat Pump Owner's manual

-

Evo EVO Fusion-i Owner's manual

Other documents

-

MECOOL KM7 User manual

-

Motorola ET1 Integrator manual

-

Astralpool CTX Series Operating instructions

-

Motorola ET1 User manual

-

weintek iR-AI04-TR Installation guide

-

Raypak 5100 User manual

-

Intermec CN3e Quick start guide

-

Motorola ET1 Quick start guide

-

Aeropro 07211 User manual

Aeropro 07211 User manual

-

Raypak 100, 115 & 160 User manual