Siemens Building Technologies QFA3280.FWSC Installation guide

- Type

- Installation guide

This manual is also suitable for

The Siemens Building Technologies QFA3280.FWSC is a room unit that allows users to view and adjust temperature and humidity setpoints in their environment. It works with various terminal equipment controllers (TECs) and actuator terminal controllers (ATECs) offered by Siemens Industry, Inc. The QFA3280.FWSC incorporates a solid state or 10K NTC sensing element to detect temperature and humidity, with an effective sensing and setpoint range of 55°F to 95°F (13°C to 35°C). This device can be mounted on electrical boxes, stud-type mounting brackets, or drywall.

The Siemens Building Technologies QFA3280.FWSC is a room unit that allows users to view and adjust temperature and humidity setpoints in their environment. It works with various terminal equipment controllers (TECs) and actuator terminal controllers (ATECs) offered by Siemens Industry, Inc. The QFA3280.FWSC incorporates a solid state or 10K NTC sensing element to detect temperature and humidity, with an effective sensing and setpoint range of 55°F to 95°F (13°C to 35°C). This device can be mounted on electrical boxes, stud-type mounting brackets, or drywall.

-

1

1

-

2

2

-

3

3

Siemens Building Technologies QFA3280.FWSC Installation guide

- Type

- Installation guide

- This manual is also suitable for

The Siemens Building Technologies QFA3280.FWSC is a room unit that allows users to view and adjust temperature and humidity setpoints in their environment. It works with various terminal equipment controllers (TECs) and actuator terminal controllers (ATECs) offered by Siemens Industry, Inc. The QFA3280.FWSC incorporates a solid state or 10K NTC sensing element to detect temperature and humidity, with an effective sensing and setpoint range of 55°F to 95°F (13°C to 35°C). This device can be mounted on electrical boxes, stud-type mounting brackets, or drywall.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Other documents

-

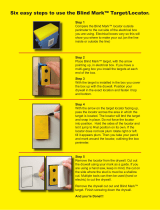

Calculated Industries BMWK Operating instructions

Calculated Industries BMWK Operating instructions

-

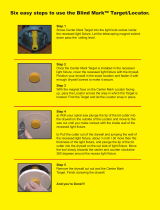

Calculated Industries 8110 Operating instructions

Calculated Industries 8110 Operating instructions

-

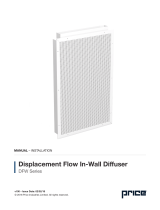

Price DFW series Installation guide

Price DFW series Installation guide

-

Atec N1 User manual

-

Bard Q-TEC Q24H1 User manual

-

Bard I36Z1-C Installation Instructions Manual

-

Bard I36Z1-C Installation Instructions Manual

-

Regency Fireplace Products San Francisco Bay 40 Owner's manual

Regency Fireplace Products San Francisco Bay 40 Owner's manual

-

Regency Fireplace Products New York View 40 Owner's manual

Regency Fireplace Products New York View 40 Owner's manual

-

Bard QW302 User manual