Page is loading ...

S

1

T

O

R

T

b

A

P

A

C

T

w

s

S

ILICON VALLE

Y

080 North 11th

S

T

BX

P

O

PE

R

R

ev 2 (11/23

/

2

0

T

he TBX has n

o

b

een preset to

A

djusting th

e

1. Use a 1/

4

2. Insert th

e

clockwis

e

3. Cycle wr

e

4. Take 10

the reco

m

hex key.

Note: D

o

torque s

e

P

lacing He

a

1. Slide

"

A

pplying To

r

1. Grab the

toward t

h

depende

2. Tighten

f

tightenin

g

3. The wre

n

C

alibrating

B

T

o calibrate br

e

w

renches, cali

b

s

moothly.

1. Select a

tester or

2. Apply to

r

3. Adjust w

r

4. Test and

5. Recalibr

a

Y

HEADQUARTE

R

S

treet, San Jos

e

P

RES

E

R

ATIN

G

0

22)

o

external adj

u

a set torque v

a

e

Torque S

e

4

" hex key and

e

1/4" hex key

i

e

to increase t

o

e

nch 10 times

consistent rea

d

m

mended torq

u

o

not adjust th

e

e

nsor as you

c

a

ds on Wr

e

"

head" onto th

e

r

que

handle with t

h

h

e head, you

w

nt tool).

f

astener or bol

t

g

. When pre-s

e

n

ch will autom

a

B

reak-Over-

O

e

ak-over wren

c

b

rate torque in

torque tester

o

sensor and us

r

que clockwise

r

ench to requir

repeat adjust

m

a

te break-over

R

S

e

, CA 95112 | Ph

E

T BR

G

INS

T

u

stment scale

a

a

lue, then follo

w

e

tting for a P

remove the e

n

i

nto the torque

o

rque and cou

n

before taking

r

d

ings on the T

o

u

e ranges for t

h

e

torque settin

g

c

an over-torqu

e

e

nch

e

end of the wr

h

e center area

o

w

ill apply more

t

t

by applying e

v

e

t torque is re

a

a

tically reset it

s

O

ver Wrenc

c

h, either use

a

"Peak" mode

w

o

r torque sens

o

e

the appropri

a

slowly until w

r

ed torque setti

m

ent as neces

s

wrench at pre

s

one: (408) 292-

2

EAK-

O

T

RU

C

a

nd must be p

r

w

the direction

s

reset Value

n

d cap from th

e

adjuster mec

h

n

ter-clockwise

r

eadings.

o

rque Analyze

r

h

e torque wre

n

g

while the wre

n

e

and damage

t

ench. Align th

e

o

f the grip to a

p

t

orque than th

e

v

en pull. The

w

a

ched, the wre

n

s

elf for the nex

t

h

a

torque analy

z

w

ith a torque t

e

o

r that covers t

h

a

te adapters.

r

ench 'breaks-

o

ng as describ

e

s

ary to obtain

d

s

cribed interva

2

214 | Fax: (408

)

O

VER

C

TION

S

r

eset using a t

o

s

for adjusting

e

wrench anti-

c

h

anism and tur

n

to decrease to

r

to confirm th

e

n

ch or torque a

n

ch is connect

e

t

he sensor.

e

pin with the h

p

ply torque. (If

e

wrench's sett

w

rench should

b

n

ch will 'break-

t

application.

z

er or torque s

e

e

ster or torque

h

e torque rang

o

ver' and note

r

e

d above.

d

esired torque

ls.

)

292-2733 | mo

u

WRE

S

o

rque analyzer

the torque set

t

c

lockwise dire

c

n

the hex key

rque.

e

torque settin

g

nalyzer. Hand

e

d to a torque

ead's pin slot.

you the grab

h

ing. The wren

c

b

e kept at 90

d

over.'

e

nsor within th

e

sensor. Make

s

e of the wrenc

h

r

eading.

value.

u

ntztorque.com

NCH

or torque sen

s

t

ing before usi

n

c

tion.

g

. Do not adjus

tighten end-c

a

analyzer or

h

andle closer

c

h is a length-

d

egrees to the

a

e

torque wren

c

s

ure to apply t

h

h

. Connect th

e

s

or. If the tool

h

n

g the wrench.

t torque above

a

p back on usi

n

a

xis of the bolt

c

h range. For b

h

e torque slo

w

e

wrench to the

Exam

p

Example:

TBX-12 ESD

m

Example:

TBX-12 ESD

m

1

h

as not

or below

n

g a 1/4"

during

reak-over

w

ly and

torque

p

le: TBX-25 ESD mod

e

m

odel

m

odel

Exam

p

TBX-12

m

e

l

p

le:

m

odel

SILICON VALLEY HEADQUARTERS

1080 North 11th Street, San Jose, CA 95112 | Phone: (408) 292-2214 | Fax: (408) 292-2733 | mountztorque.com 2

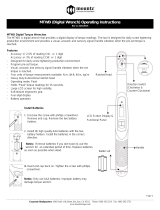

TBX-12 Stop Collar

TBX-12 model supplied with a removable stop collar, which restricts the "break" angle to 20º. If the

collar is removed, the "break" angle increases to 90º.

Maintenance Schedule

Like an automobile, torque wrenches contain moving parts that require periodic servicing and

lubrication.

Period Between Resetting of Torque

20,000 fastening operations. It is acknowledged that some tools may achieve 20,000 operations in a relatively short period of

time. Under these circumstances, the user may decide, with the benefit of their experience, to increase the period between

calibration intervals.

Routine Maintenance

After 60,000 operations, strip, clean, and re-grease the spring and internal components. Any worn parts should be replaced.

Note: Any tool that is dismantled during its life must be re-lubricated in accordance with the Mountz recommendations. Do not

clean tools by immersing them in a solvent, as this will destroy the internal lubrication and cause the tool's failure.

Testing and Servicing

Torque tools go out of calibration with use. Calibrating a torque tool is a fine-tuning process of bringing the tool back within its

tolerance. Regular torque calibration of a break-over wrench ensures accuracy, repeatable tool performance, and adherence

to international standards.

We recommend a general once a year calibration interval. However, the user's organization must determine suitable intervals

based upon equipment performance, application, degree of usage, and management objectives.

Mountz Calibration and Repair Services

Mountz Inc. features an experienced calibration and repair staff. Our trained technicians

can calibrate and repair almost any tool. Mountz provides rapid service with quality that

you can trust as we offer two state-of-the-art calibration labs and repair facilities that can

calibrate up to 20,000 lbf.ft.

About Mountz

Mountz, The Torque Tool Specialists®, has been a leader in the torque tool industry for

over 57 years. Engineered in Silicon Valley and serving the globe, Mountz focuses on

delivering high-quality torque products, services, and solutions to ensure customers can

always proceed with confidence. We are committed to forging a safer world through

precision and accuracy and by innovating every day.

Mountz Service Locations

Eastern Service Center

19051 Underwood Rd.

Foley, AL 36535

Phone: (251) 943-4125

Fax: (251) 943-4979

Western Service Center

1080 N.11th Street

San Jose, CA 95112

Phone: (408) 292-2214

Fax: (408) 292-2733

UK Service Center

Pier Copse Courtyard, Milland Lane,

Liphook, Hampshire, GU30 7JN, UK

Phone: 00 44 1428 741756

www.mountztorque.com

20º

90º

/