8

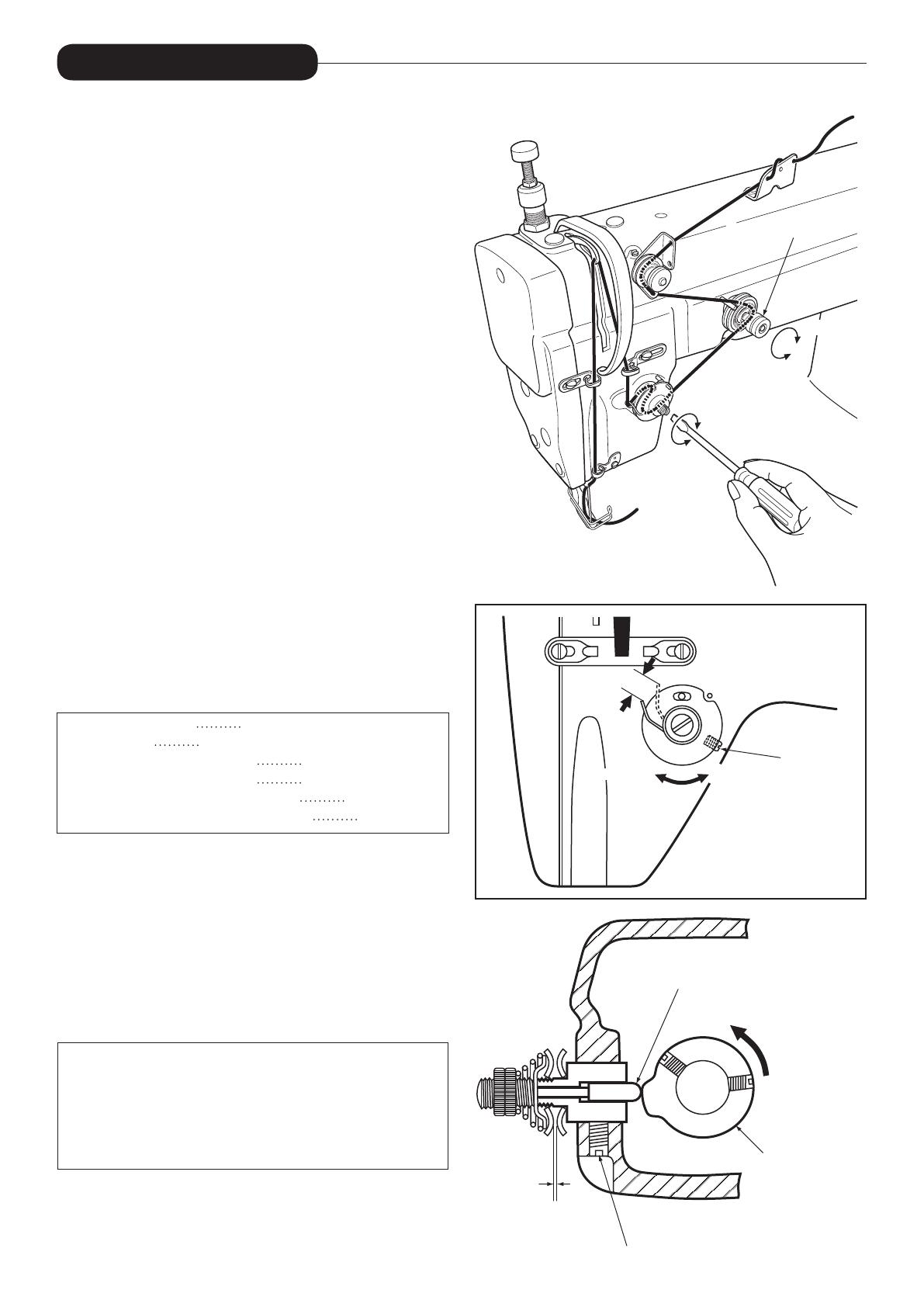

Adjustment of the needle thread tension

Theneedlethreadtensioncanbeadjustedby

changingpressureofthetensiondisk,andforce

andstrokeofthethreadtake-upspring.

●Adjustment of the tension disk pressure

1 . Inmostcases,threadtensioncanbeproperly

adjustedonlybychangingtightnessofthe

threadtensionnutⒶ.

2 . Toincreasepressure,turnthenutclockwise.

3 . Todecreasepressure,turnthenut

counterclockwise.

●Adjustment of the thread take-up spring force

Applyascrewdrivertothethreadtake-upspring

studandturnthestud.

Thespringforceincreaseswhenthescrewdriver

isturnedcounterclockwise,anddecreaseswhen

turnedclockwise.

Ifthestudistight,removethefaceplateand

loosenthescrewoftensionregulatorslightly.

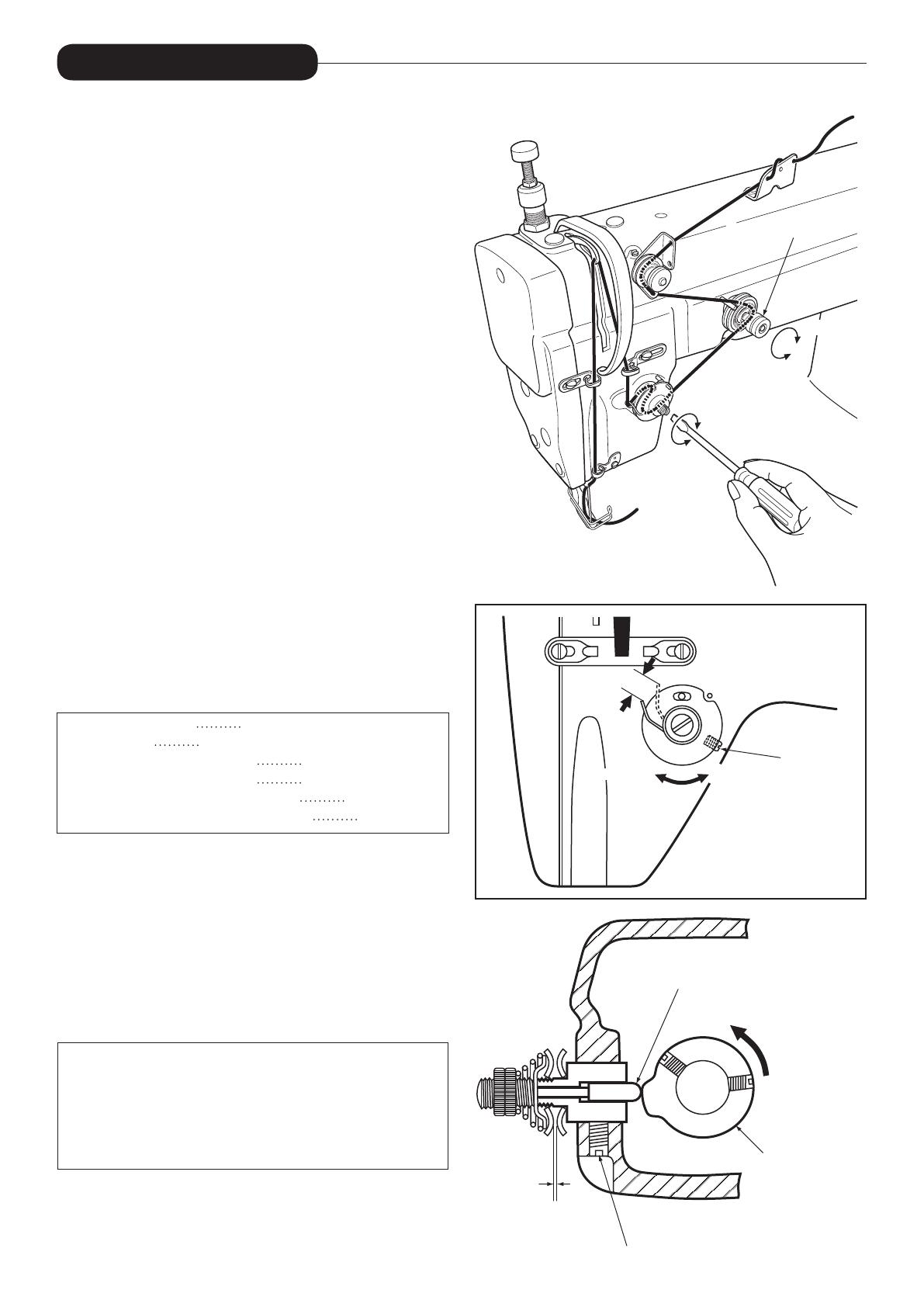

●Adjustment of the thread take-up spring stroke

1 . Loosenthesetscrewusedtosecurethe

threadtensionregulatorslightly.

2 . Applyascrewdrivertothethreadtake-

upspringstudandturnthescrewdriver

counterclockwisetoincreasethestroke.

3 .

Turnthescrewdriverclockwisetodecreasethestroke.

4 .

Afteradjusting,besuretotightenthesetscrew.

Thestandardstrokeofthreadtake-upspring

isfrom6to8mm.

9

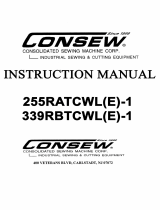

Adjustment of the thread tension releasing

1 .

Adjustment of the thread tension regulator setting position.

Thestandardgapisabout0.5mmwhenthe

tensionreleasecamsalienceisincontactwith

thetensionreleasepin.

Toadjust,loosenscrewⒶandchangeposition

ofthethreadtensionregulatorproperly.

2 . Adjustment of the tension release timing

Note: Thetensionreleasetiminglargelyaects

stitchingoperation.Ifthegap betweenthe

tensiondisksis toosmall, theneedlethreadis

notdrawnproperly.Onthe contraryifthegap

istoolarge,the needlethreadmaybereleased

earlierandbecomeloose.

Thetensionreleasecamshouldbesetsothatthe

tensionreleasediskscometoopenatthetime

whentheredmarkpointonthepulleycomesin

linewiththeblackmarkpointonthearm.

Ex.:

ThreadusedCotton#40(doubletwist)

FabricGeneralapparelandpad

Needlethreadtension40-60g

Bobbinthreadtension5-10g

Threadtake-upspringforce15-20g

Threadtake-upspringstroke6-8mm

HOW TO USE

— 6 —

From the library of Superior Sewing Machine & Supply LLC - www.supsew.com