English - Page 2

1. Programming

1.1 General notes on programming

Advice:

As soon as the button P is pressed lon-

ger than 10 sec., the control unit

changes to the extended operator

functions.

Important factory settings can be

changed in this area.

Advice:

The control unit can only be program-

med after the reference point has been

passed 1x in OPEN direction and 1x in

CLOSE direction.

The programming of the operator is divided in two areas:

1. Programming of the basic level:

The basic functions of the operator are programmed

in this level. This programming process is carried out

consecutively and it is compulsory.

2. Programming of the extended operator functions:

The programming of the extended operator functions

consists of four levels. Changes in these levels may

only be carried out by specialist personnel.

This programming process is consecutive; several levels

can be skipped when pressing button P.

To come to the programming of the basic level, button P

must be pressed longer than 2 sec but less than 10 sec.

Programming is carried out with the buttons +, -, and P.

If none of the buttons is actuated within 120 sec. in

programming mode, the control unit changes back to

the operating mode.

An error message is displayed accordingly.

During this procedure following is displayed:

The operator is between the reference point

and the end position OPEN.

The operator is between the reference point

and the end position CLOSED.

Advice:

The control unit travels without

press-and-hold.

The "end position OPEN" and the "end position

CLOSED" can be programmed in two different ways:

1. Coarse adjustment by permanently holding a

button

The setting is carried out when button + or - is pressed

permanently.

The door travels correspondingly to the OPEN or

CLOSED position.

2. Fine adjustment by a short button impulse

The setting is carried out by a short button impulse

on button + or -. The door does not move during this

procedure.

Every time the button is pressed the end position is

shifted by 4 mm to the respective direction.

To test the end position, the door has to be travelled

over the reference point to the OPEN position or to the

CLOSED position.

During the button impulse the LED 7 is

flashing quickly.

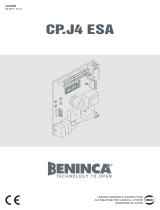

Legend:

LED off

LED on

LED flashing slowly

LED flashing quickly