found on Danfoss decentralized products, as the housings are fully coated and nylon washers underneath the screws protects the coating. The complete

coating and the unique gasket design prevent pitting corrosion, which can occur under gaskets.

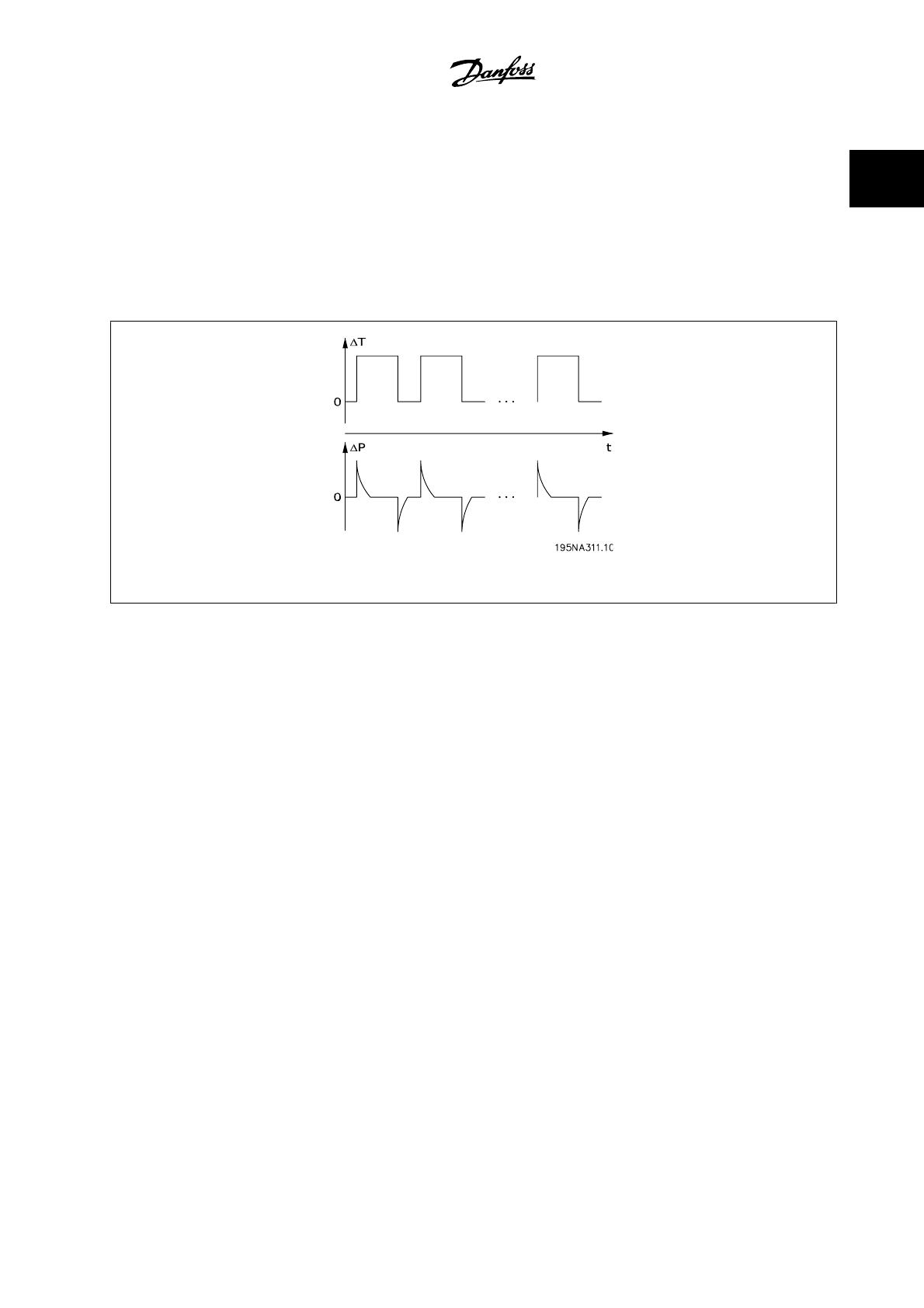

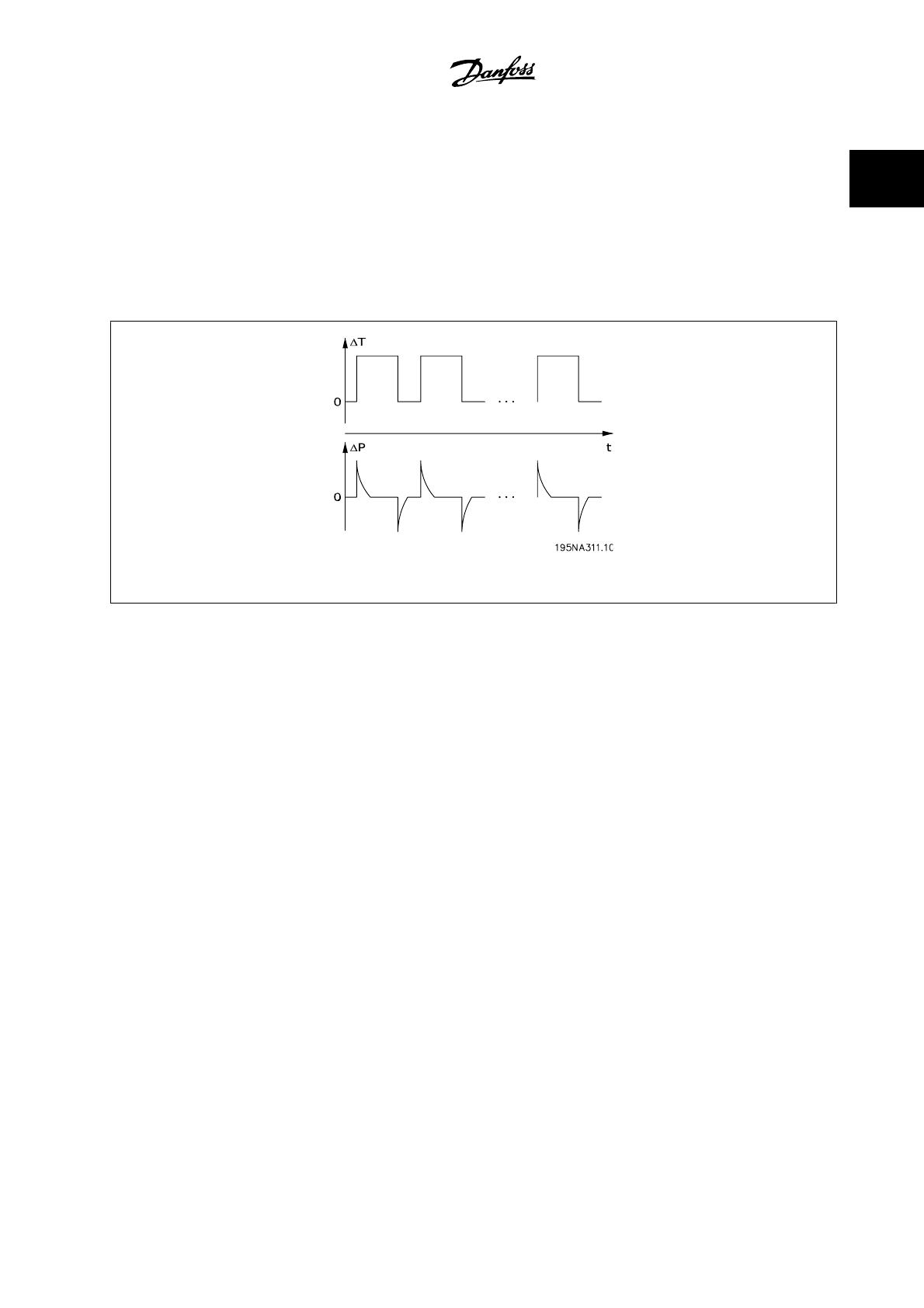

Tightly enclosed equipment is susceptible to water build-up inside the enclosure. This is especially the case where equipment is exposed to ambient

temperature differences under wet conditions. As a decreasing ambient temperature lowers the surface temperature inside the enclosure, water vapor

tends to condensate. At the same time, pressure inside the enclosure will drop and cause humid air from the outside to penetrate non-hermetic polymer

gasket materials and cable connectors. When the enclosure heats up again, only the vaporized water will escape, leaving more and more condensed

water inside the enclosure. This can lead to water build-up inside the enclosure and eventually cause malfunction. The phenomenon is illustrated in the

figure, with a cyclic temperature fluctuation.

Figure 1.10: The pumping effect in tight enclosures

Build-up of water inside enclosures can be prevented by membranes that prevent fluids from penetrating but allow for vapor to pass, as known from

fabrics used for outdoor clothing. A special cable connector with this kind of material is offered by Danfoss to eliminate this problem. The cable connector

should be used in applications exposed to frequent temperature fluctuations and humid environments as in equipment used only during daytime where

the inside temperature tends to fall to the ambient temperature during the night.

1.2.8 Installation Flexibility

Danfoss decentralized solutions offer exceptional installation flexibility. Flexibility is supported by a number of benefits:

• Mountable on Danfoss geared motors

• Decentralized panel mounting possible

• Handheld control panels

• PC software for configuring and logging

• Single or double-sided installation

•Service switch optional

• Brake chopper and resistor optional

• External 24 V backup supply optional

• M12 connections for external sensors optional

• Han 10E motor connector optional

• Serial communication bus support (Profibus DP V1, DeviceNet, AS-Interface)

• Compatibility with standard line power systems (TN, TT, IT, delta-grounded)

For further details, see the chapter on

The Decentralized Product Range

.

VLT

®

Decentral FCD 300 Design Guide 1 The Decentral Concept

MG.90.S1.22 - VLT

®

is a registered Danfoss trademark

1-9

1