Page is loading ...

Item

Part Name

No.

1 Magnetic Hexagon Socket

2 Locator (A)

3 Tapping Screw D5×35

4 Fringer (A)

6 O-Ring (1AP-15)

7A Tapping Screw D5×45

8 Gear Cover Ass’y

9 Set Ring

10 Steel Ball D3. 17

11 Socket

12 Spring (A)

13 Steel Ball D5. 556

14A Gear (A)

15 Gear Shaft

16 Ball Bearing (608VVMC2EPS2L)

17 Washer (A)

18 Hook

19 Inner Cover

20 Bearing Holder

21 Flat Hd. Screw M4×10

22 Armature

23 Fan Guide

24 Machine Screw M4×55

25 Spring Washer M4

26 Stator

27 Bearing Lock

28 Housing

29 Name Plate

31

Tapping Screw (W/Washer)

D4×25

32 Handle Cover

Item

Part Name

No.

35 Packing (A)

36 Switch

37 Support (B)

38 Noise Suppressor

39 Terminal

40 Tube (D)

41 Tapping Screw D4×16

42 Holder Piece

43 Connector (50091)

44 Tube (D)

45 Carbon Brush

46 Brush Holder

47 Pillar Termila (A)

48 Nut M4

49 HITACHI Label

50 Reversing Switch

51 Support (B)

52

Tapping Screw (W/Flange)

D4×16

53 Cord

54 Cord Clip

55 Cord Armor

501A

Side Handle

Parts are subject to possible modifica-

tion without notice due to improve-

ments.

The exploded assembly drawing should be used only for authorized service

center.

Page is loading ...

2

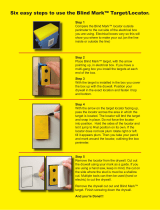

English Deutsch Français

1 Lever Hebel Levier

2 L side L Seite Côté L

3 Locator Aufnehmer Positionneur

4 Lock sleeve Sperrhülse Manchon de blocage

5 Spline Keilnuta Cannelure

6 Gear cover Getriebedeckel Couvercle d’engrenage

7 Locator assembly Aufnahmevorrichtung Ensemble positinneur

8 Hex. head screw Sechskantschraube Vis à tête six pans

9 Drywall screw Drywall-Schraube Vis Drywall

0 Self-drilling Hohlwandschraube Vis autopercense

A Magnetic hex. socket Magnetische Seckskantmuffe

Manchon sic pans magnétique

B Bit Bit Schraubenzieher Tête de vissage

C Bit holder Bohrspitzenhalter Porte-mèche

D Wear limit Verschleißgrenze Limite d’usure

E No. of carbon brush Nr. der Kohlenburste No. de balai carbone

F Usual carbon brush Gewöhnliche Kohlenbürste Balai carbone ordinaire

G Auto-stop carbon brush Auto-Stop Kohlenbürste

Balai carbone à arrêt

automatique

H Carbon brush Kohlenbürste Balai carbone

I Brush holder Bürstenhalter Support du balai

J Holder piece Halterteil Porte-outil

Italiano Nederlands Español

1 Leva Hendel Palanca

2 Lato L L Lado-L

3 Locatore Locator Ubicador

4 Manicotto di bloccaggio Klemkoppel Cubierta de engranaje

5 Scanaltura Spie Ranura

6 Coperchio degli ingranaggi Beschermlngskap Cubierta de engranaje

7 Dispositivo del locatore Locator-eenheid Conjunto de ubicador

8 Bullone esagonale Schroef met zeskante kop Tornillo de cabeza hexagonal

9 Vite Drywall Drywall-Schraube Tornillo-Drywall

0 Vite autofilettante Zelf-borende schroef Tornillo autorroscante

A

Alloggiamento magnetizzato

Magnetische zeskante bus

Portatornillos hexagonal

per viti esagonali magnético

B Punta Schroevedraaler Broca

C Punta positiva Boorhouder Sporte de broca

D Limite de usura Slijtagerens Límite de uso

E N. della spazzola di carbone Nr. van der koolborstel No. de carbón de contacto

F Spazzole di carbon normali Normale koolborstel Escobilla de carbón usual

G

Spazzole di carbon per

Auto-stop koolborstel

Escobilla de carbón de

arresto automatico auto-parada

H Carbone Koolborstel Carbón

I Porta-spazzola Borstelhouder Sujetador de carbón

J Pezzo di sostegno Houderstuk Sujetador

3

English

SPECIFICATIONS

GENERAL OPERATIONAL PRECAUTIONS

WARNING! When using electric tools, basic safety

precautions should always be followed to reduce the risk

of fire, electric shock and personal injury, including the

following.

Read all these instructions before operating this product

and save these instructions.

For safe operations:

1. Keep work area clean. Cluttered areas and benches

invite injuries.

2. Consider work area environment. Do not expose

power tools to rain. Do not use power tools in

damp or wet locations. Keep work area well lit.

Do not use power tools where there is risk to

cause fire or explosion.

3. Guard against electric shock. Avoid body contact

with earthed or grounded surfaces. (e.g. pipes,

radiators, ranges, refrigerators).

4. Keep children away. Do not let visitors touch the

tool or extension cord. All visitors should be kept

away from work area.

5. Store idle tools. When not in use, tools should

be stored in a dry, high or locked up place, out

of reach of children.

6. Do not force the tool. It will do the job better and

safer at the rate for which it was intended.

7. Use the right tool. Do not force small tools or

attachments to do the job of a heavy duty tool.

Do not use tools for purposes not intended; for

example, do not use circular saw to cut tree limbs

or logs.

8. Dress properly. Do not wear loose clothing or

jewellery, they can be caught in moving parts.

Rubber gloves and non-skid footwear are recom-

mended when working outdoors. Wear protecting

hair covering to contain long hair.

9. Use eye protection. Also use face or dust mask

if the cutting operation is dusty.

10. Connect dust extraction equipment.

If devices are provided for the connection of dust

extraction and collection facilities ensure these are

connected and properly used.

11. Do not abuse the cord. Never carry the tool by

the cord or yank it to disconnect it from the

receptacle. Keep the cord away from heat, oil and

sharp edges.

12. Secure work. Use clamps or a vise to hold the

work. It is safer than using your hand and it frees

both hands to operate tool.

13. Do not overreach. Keep proper footing and balance

at all times.

14. Maintain tools with care. Keep cutting tools sharp

and clean for better and safer performance. Follow

instructions for lubrication and changing accesso-

ries. Inspect tool cords periodically and if dam-

aged, have it repaired by authorized service center.

Inspect extension cords periodically and replace,

if damaged. Keep handles dry, clean, and free

from oil and grease.

15. Disconnect tools. When not in use, before serv-

icing, and when changing accessories such as

blades, bits and cutters.

16. Remove adjusting keys and wrenches. Form the

habit of checking to see that keys and adjusting

wrenches are removed from the tool before turning

it on.

17. Avoid unintentional starting. Do not carry a

plugged-in tool with a finger on the switch. Ensure

switch is off when plugging in.

18. Use outdoor extension leads. When tool is used

outdoors, use only extension cords intended for

outdoor use.

19. Stay alert. Watch what you are doing. Use com-

mon sense. Do not operate tool when you are

tired.

20. Check damaged parts. Before further use of the

tool, a guard or other part that is damaged should

be carefully checked to determine that it will

operate properly and perform its intended func-

tion. Check for alignment of moving parts, free

running of moving parts, breakage of parts,

mounting and any other conditions that may affect

its operation. A guard or other part that is damaged

should be properly repaired or replaced by an

authorized service center unless otherwise

indicated in this handling instructions. Have

defective switches replaced by an authorized

service center. Do not use the tool if the switch

does not turn it on and off.

21. Warning

The use of any accessory or attachment, other

than those recommended in this handling

instructions, may present a risk of personal injury.

22. Have your tool repaired by a qualified person.

This electric tool is in accordance with the relevant

safety requirements. Repairs should only be carried

out by qualified persons using original spare parts.

Otherwise this may result in considerable danger

to the user.

Voltage (by areas)* (110V, 115V, 120V, 127V, 220V, 230V, 240V)

Power input* 520W

No-load speed 0 ~ 2600/min

Capacities 6 mm

Bit shank size 6.35 mm Hex.

Weight (without cord) 1.7 kg

* Be sure to check the nameplate on product as it is subject to change by areas.

English

4

STANDARD ACCESSORY

(1) Magnetic hex socket (H= 10 mm).............................1

(2 Side handle .................................................................1

Standard accessory is subject to change without notice.

OPTIONAL ACCESSORIES (sold separately)

1. For hex-head screws

Hex-socket Locator (A) ass’y

Indication

Magnetic type

H = 6.35 mm

H = 7.94 mm

H = 9.53 mm

H = 10 mm

Non magnetic type

H = 6.35 mm

H = 7.94 mm

H = 9.53 mm

H = 10 mm

H 1/4

H 5/16

H 3/8

H 3/8

Bit type Locator ass’y

2. For other screws

Bit holder

Screw

head

No.1

No.2

No.3

No.1

No.2

No.1

No.2

No.3

No.1

No.2

B Size

4 mm

5 mm

Magnetic bit holder

Non-magnetic bit bolder

Aluminum bush

Locator ass’y

Stainless bush

Locator ass’y (B)

3. Steel carring case

Optional accessories are subject to change without

notice.

APPLICATIONS

䡬 Tightening hex-head screws

䡬 Tightening drywall screws, wood screws and self-

drilling screws.

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specified on the product

nameplate.

5

English

2. Power switch

Ensure that the power switch is in the OFF position.

If the plug is connected to a receptacle while the

power switch is in the ON position, the power tool

will start operating immediately, inviting serious

accident.

3. Extension cord

When the work area is removed from the power

source, use an extension cord of sufficient thickness

and rated capacity. The extension cord should be

kept as short as practicable.

4. Confirm the direction of bit rotation (Fig.1)

The bit rotates clockwise (viewed from the rear side)

when the reversing switch lever is set to the “R” side

position. When the lever is set to the “L” side position,

the bit rotates counterclockwise and can be used to

loosen and retract screws.

5. Adjusting the tightening depth (Fig.2)

Pull the lock sleeve in the direction of arrow to remove

it from the spline installed in the gear cover. When

the lock sleeve is released, the lock sleeve returns to

the gear cover. While pulling the lock sleeve and

turning it right and left, adjust the position of locator.

Release the lock sleeve and aligen the gear cover

spline with the lock sleeve spline.

The lock sleeve is automatically inserted onto the

gear cover spline and locked.

(1) For hex-head screws:

Mount a hex-head screw on the hex-socket and set

the distance between the locator assembly end and

the screw head bottom to 1.5–2 mm, as shown in

Fig.3.

(2) For drywall screws:

Mount a drywall screw on the bit, and set the distance

between the locator assembly end and the screw

head to 0.5–1 mm, as shown in Fig.4.

(3) For plus-head self-drilling screws:

Mount a self-drilling screw on the bit, and set the

distance between the locator assembly end and the

screw head bottom to 1–1.5 mm, as shown in Fig.5.

6. Mounting the bit

For details, refer to the item “Mounting and

dismounting the bit”.

7. Fixing the side handle

Always hold the body handle and side handle of the

screw driver firmly. Otherwise the counterforce

produced may result in inaccurate and even

dangerous operation.

MOUNTING AND DISMOUNTING THE HEX-

SOCKET OR THE BIT

1. Dismounting the hex-socket (Figs.6 and 7)

(1) Hold the locator without turning it and fully pull the

lock sleeve in the direction of arrow A.

Turn the clock sleeve about 0.2 " clockwise or

counterclockwise. The locator claw is engaged with

the groove in the inner part of the lock sleeve spline

over circumference. The lock sleeve is now locked to

the locator. Though the lock sleeve is not held, it

does not return to the gear cover. Turn the locator in

the direction of arrow B and remove the locator

ass’y.

(2) Remove the hex-socket, hold it with the opposite

side of bit with hand or vice and pull out the bit with

a pliers.

2. Dismounting the bit (Figs. 6 and 8)

Remove the locator alike case of hex-head socket

and remove the bit holder, then pull out the bit with

a pliers.

3. Mounting the hex-socket or the bit

Install the bit in the reverse order to removel.

HOW TO USE THE SCREW DRIVER

1. Switch operation and rotational speed

adjustment

Bit rotational speed can be regulated between 0 and

2600/min varying the degree by which the trigger

switch is pulled. Rotational speed increases as the

trigger switch is pulled, and reaches a maximum

speed of 2600/min when the trigger switch is pulled

fully.

To facilitate continuous operation, pull the trigger

switch and depress the switch stopper. The switch

will then remain ON even when the finger is removed.

By pulling the trigger switch again, the switch stopper

is disengaged and the switch is turned OFF when the

trigger switch is released.

2. Screwdriver operation

When the switch is turned ON, the motor starts to run

but the hex-socket (or the bit) does not rotate. Attach

the hex-socket to the screw head groove, and push

the screwdriver against the screw. The hex-socket

then rotates, tightening the screw.

CAUTION

Ensure that the screwdriver is held truly perpendicular

to the head of the screw.

If held at an angle, the driving force will not be fully

transferred to the screw, and the screw head and/or

hex-socket will be damaged. Hexsocket rotation stops

when pushing force is released.

3. Direction of hex-socket rotation

The hex-socket rotates clockwise (viewed from the

rear side) when the reversing switch lever is set to

the “R” side position. When the lever is set to the “L”

side position, the hex-socket rotates counter-

clockwise, and can be used to loosen and retract

screws.

CAUTION

Never change the direction of hex-socket rotation

while the motor is running. To do so would seriously

damage the motor. Turn the power switch OFF before

changing the direction of hex-socket rotation.

MAINTENANCE AND INSPECTION

1. Inspecting the hex-socket (or bit)

Since continued use of a worn hex-socket (bit) will

damage screw heads, replace the hexsocket (bit) with

a new one as soon as excessive wear is noticed.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. to do

so could result in serious hazard.

English

6

3. Maintenance of the motor

The motor unit winding is the very “heart” of the

power tool. Exercise due care to ensure the winding

does not becomes damaged and/or wet with oil or

water.

4. Inspecting the carbon brushes (Fig.9)

The motor employs carbon brushes which are

consumable parts. When they become worn to or

near “wear limit”, it could result in motor trouble.

When an auto-stop carbon brush is equipped, the

motor will stop automatically.

At that time, replace both carbon brushes with new

ones which have the same carbon brush Nos. shown

in Fig.9.

In addition, always keep carbon brushes clean and

ensure that they slide freely within the brush holders.

5. Replacing a carbon brushes (Fig.10)

Disassembly:

(1) Loosen the three machine screws, and remove the

handle cover.

(2) Remove the holder piece and lift the brush holder

gently with a screwdriver or the like, and remove it

from the housing while suppressing the carbon brush,

as shown in Fig.10. Be careful not to excessively pull

the lead wire.

(3) Remove the carbon brush from the brush holder.

Assembly

(1) Insert the new carbon brush into the brush holder.

(2) Insert the brush holder together with the carbon brush

into the brush holder chamber in the housing.

(3) Ensure that the lead wire and other parts are properly

positioned, and that there is no possibility of the lead

wire coming in contact with the armature or other

moving parts.

(4) Reinstall the handle cover while ensuring that the

Internal wiring does not become pinched between

the cover and the housing, and secure the handle

cover with the three machine screws.

CAUTIONS

䡬 Be sure to follow the above assembly procedures

exactly. Should the internal wiring contact the

armature or become pinched between the handle

cover and housing, a serious risk of electric shock to

the operator would be created.

䡬 Do not tamper with parts other than those necessary

to effect carbon brush replacement.

NOTE

Due to HITACHI’s continuing program of research and

development, the specifications herein are subject to

change without prior notice.

IMPORTANT

Correct connection of the plug

The wires of the mains lead are coloured in accordance

with the following code:

Blue:- Neutral

Brown:- Live

As the colours of the wires in the mains lead of this tool

may not correspond with the coloured markings

identifying the terminals in your plug proceed as follows:

The wire coloured blue must be connected to the terminal

marked with the letter N or coloured black. The wire

coloured brown must be connected to the terminal

marked with the letter L or coloured red. Neither core

must be connected to the earth terminal.

NOTE

This requirement is provided according to BRITISH

STANDARD 2769 1984.

Therefore, the letter code and colour code may not be

applicable to other markets except United Kingdom.

Information concerning airborne noise and vibration

The measured values were determined according to

EN50144.

The typical A-weighted sound pressure level: 82 dB (A).

Wear ear protection.

The typical weighted root mean square acceleration value

does not exceed 2.5 m/s

2

.

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

712

Code No. 99472574 N

Printed in Japan

Italiano

DICHIARAZIONE DI CONFORMITÀ CE

Si dichiara sotto nostra responsabilità che questo

prodotto è conforme agli standard o ai documenti

standardizzati EN50144, HD400, EN55014, EN60555

e/o EN50082-1 conforme alle direttive 73/23/CEE,

89/392/CEE e/o 89/336/CEE del concilio.

* Questa dichiarazione è applicabile ai prodotti cui sono

applicati i marchi CE.

Nederlands

EC VERKLARING VAN CONFORMITEIT

Wij verklaren onder eigen verantwoordelijkheid dat dit

produkt conform de richtlijnen of gestandardiseerde

documenten EN50144, HD400, EN55014, EN60555 en/

of EN50082-1 voldoet aan de eisen van EEG Bepalingen

73/23/EEG, 89/392/EEG en/of 89/336/EEG.

* Deze verklaring is van toepassing op produkten

voorzien van de CE-markeringen.

Español

DECLARACIÓN DE CONFORMIDAD DE LA CE

Declaramos bajo nuestra única responsabilidad que

este producto está de acuerdo con las normas o con

los documentos de normalización EN50144, HD400,

EN55014, EN60555 y/o EN50082-1, según indican las

Directrices del Consejo 73/23/CEE, 89/392/CEE y/o 89/

336/CEE.

* Esta declaración se aplica a los productos con marcas

de la CE.

English

EC DECLARATION OF CONFORMITY

We declare under our sole responsibility that this

product is in conformity with standards or standard-

ized documents EN50144, HD400, EN55014, EN60555

and/or EN50082-1 in accordance with Council Directives

73/23/EEC, 89/392/EEC and/or 89/336/EEC.

* This declaration is applicable to the product affixed

CE marking.

Deutsch

ERKLÄRUNG ZUR KONFORMITÄT MIT CE-REGELN

Wir erklären mit alleiniger Verantwortung, daß dieses

Produkt den Standards oder standardisierten

Dokumenten EN50144, HD400, EN55014, EN60555 und/

oder EN50082-1 in Übereinstimmung mit den Direktiven

des Europarats 73/23/EWG, 89/392/EWG und/order 89/

336/EWG entspricht.

*Diese Erklärung gilt für Produkte, die die CE-

Markierung tragen.

Français

DECLARATION DE CONFORMITE CE

Nous déclarons sous notre seule et entière respon-

sabilité que ce produit est conforme aux normes ou

documents normalisés EN50144, HD400, EN55014,

EN60555 et/ou EN50082-1 en accord avec les Directives

73/23/CEE, 89/392/CEE et/ou 89/336/CEE du Conseil.

*Cette déclaration s’applique aux produits désignés CE.

Hitachi Power Tools Europe GmbH

Siemensring 34, 47877 Willich, F. R. Germany

Hitachi Koki Co., Ltd.

Nippon Building, 6-2, Ohtemachi 2-chome,

Chiyoda-ku, Tokyo, Japan

K. Mitsuishi

95

/