Pentair CSP Series is a commercial-grade self-priming pump designed for use in swimming pools, spas, water parks, and other aquatic facilities. It features a rugged cast iron construction, enclosed bronze impeller, and bronze wear rings for long-lasting reliability. The pump's exceptional self-priming design allows it to be installed above or below water level, making it suitable for various applications. With a wide range of performance levels from 71⁄2 to 20 HP, the Pentair CSP Series can handle diverse pumping needs.

Pentair CSP Series is a commercial-grade self-priming pump designed for use in swimming pools, spas, water parks, and other aquatic facilities. It features a rugged cast iron construction, enclosed bronze impeller, and bronze wear rings for long-lasting reliability. The pump's exceptional self-priming design allows it to be installed above or below water level, making it suitable for various applications. With a wide range of performance levels from 71⁄2 to 20 HP, the Pentair CSP Series can handle diverse pumping needs.

-

1

1

-

2

2

-

3

3

-

4

4

Pentair CSP Series is a commercial-grade self-priming pump designed for use in swimming pools, spas, water parks, and other aquatic facilities. It features a rugged cast iron construction, enclosed bronze impeller, and bronze wear rings for long-lasting reliability. The pump's exceptional self-priming design allows it to be installed above or below water level, making it suitable for various applications. With a wide range of performance levels from 71⁄2 to 20 HP, the Pentair CSP Series can handle diverse pumping needs.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Pentair Challenger User manual

-

Pentair Max-E-Pro User manual

-

Pentair IntelliFlo VS+SVRS User manual

-

Pentair SuperMax User manual

-

Pentair 100 User manual

-

Pentair SuperFlo® VST Pool Pump Owner's manual

-

Pentair 4/100 User manual

-

Pentair VS-3050 User manual

-

Pentair SuperFlo High Performance Pump User manual

-

Pentair Pump User manual

Other documents

-

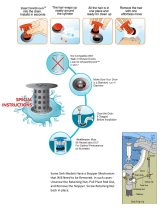

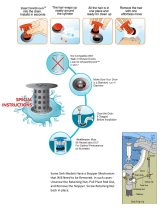

TubShroom SSNE425 User manual

TubShroom SSNE425 User manual

-

TubShroom TSGRE454 Installation guide

TubShroom TSGRE454 Installation guide

-

Raypak Pool Product Catalog User guide

-

STA-RITE STA-RITE Max-E-Pro Pool, Spa Pumps Owner's manual

-

Aqua Flo A Series User manual

Aqua Flo A Series User manual

-

Aqua Flo A Series User manual

Aqua Flo A Series User manual

-

3M Scotchkote™ Liquid Epoxy Coating 323 User guide

-

3M Scotchkote™ Hot Melt Patch Compound 226P, 5 lb. Box User guide

-

PT Coupling 5500420 User guide

-

3M Scotchkote™ Liquid Epoxy Coating 323 Application Gun Operating instructions