Page is loading ...

Repair Center for Powertec Drives and Motors

460 Milford Parkway

Milford, OH . 45150

www.motorsystems.com

513-576-1725

Model

1000

Brushless DC Motor Control

I

NSTALLATION AND

O

PERATION

I

NSTRUCTION

M

ANUAL

J

UNE

, 2001

Model

1000

Installation and Operation Manual

Page

1

OFFICIAL 6/1/2001

I

II

I

NTRODUCTION

NTRODUCTIONNTRODUCTION

NTRODUCTION

WHAT IS A GENESIS SERIES BRUSHLESS DC DRIVE ?

The GENESIS series of drives were developed to operate very large Brushless DC motors. Large BLDC

motors were first made by POWERTEC Industrial Corporation in 1987.

Small BLDC motors have been in use for many years. The GENESIS series were the first drives that

were produced to operate really large BLDC motors. They range from fractional Horsepower (HP) to 300 HP.

Brushless DC motors and drives offer three significant benefits to the user:

1. Absolute Speed Control

2. High Efficiency

3. Low Maintenance.

ABSOLUTE SPEED CONTROL

The AC induction motor must “slip” in order to develop torque. “Slip” means that the rotor slows down

when loaded. The amount of slip varies with the load on the motor. When the motor load changes from no

load to full load, speed may change as much as 50 RPM. You must use extraordinary means to employ AC

motors in speed sensitive applications.

Traditional brush-type DC motors have “IR Losses.” These cause the speed of the motor to vary as the

load changes. “IR Losses” account for speed changes of as much as 2% of base speed. You can limit speed

changes to about 0.5% with a very expensive tachometer. That is still 8 or 9 RPM from no load to full load.

You must use extraordinary means to employ brush-type DC motors in speed sensitive applications.

Brushless DC drives and motors do not change speed when the load changes. This is true with the

standard product, right out of the box! This is very good for speed sensitive applications.

HIGH EFFICIENCY

AC induction motors are fairly efficient when operated across the line on plant power. Using an AC

variable speed inverter to control the speed of the AC motor adds power losses as heat in the drive. It also

creates additional losses in the motor. Total losses in the AC system approach 10% at the 100HP level.

Brush-type DC motor systems at 100 HP are relatively efficient, but the losses total about 8%.

Losses average less than 6% in Brushless DC systems at the 100 HP level.

At 100 HP, each percentage of losses is 750 watts. That’s 18 Kilo-Watt-Hours (KWH) per day, or about

6,500 KWH per year. A 2% increase in efficiency results in over $1,000 a year in direct energy savings.

LOW MAINTENANCE

An AC motor running on a variable speed AC drive produces a lot of heat. The motor needs lubrication

more often. It needs extra bearing changes. Heat also shortens the life of the motor.

Brush-type DC motors require frequent brush replacement. They need commutator service and field and

armature rewinding. They also require frequent lubrication and bearing changes due to heat.

Brushless DC motors need greasing, but oversize bearings and low heat output allow long bearing life.

Maintenance on a Brushless DC motor is minimal.

POWERTEC offers the GENESIS series for general purpose industrial use.

POWERTEC also offers a complete line of servo-duty rated drives and motors covering the range from

1/10 to 300 HP.

QUICK START - Page 3 TABLE OF CONTENTS - Page 5

Page

2

Model

1000

Installation and Operation Manual

6/1/2001 © copyright 1997 by Powertec

P4

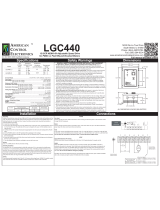

RUN

123456789101112131415161718

TB2

REMOVE

FOR

COAST

STOP

JP1

CURRENT

LIMIT

LED

ZERO

SPEED

RUN

LED

MIN SPD

MAX SPD

JOG SPD

DECEL

ACCEL

CLIM

STAB

GAIN

POWERTEC

JP2

SPEED CONTROLLER

BOARD

LED

POWER

GREEN

HS3

RED

HS2

RED

HS1

RED

TAC

RED/GREEN

BUS

RED/GREEN

ENABLE

YELLOW

CURRENT CONTROLLER

BOARD

STALL

RED

PL

RED

OV/UV

RED

IOC

RED

TB1

JP1

JP3

Model

1000

Installation and Operation Manual

Page

3

OFFICIAL 6/1/2001

Q

QQ

Q

UICK

UICK UICK

UICK

S

SS

S

TART

TARTTART

TART

Follow these steps to quickly set up and operate the Model 1000 Brushless DC drive. If you are not sure

of the procedure for any of the steps, consult the installation section (beginning on page 7).

CONNECTIONS

1.

Connect the proper three-phase AC power from a suitably rated switching device to the input terminals L1, L2,

and L3. Check the nameplate. The sequence of the phases is not important to the drive.

2.

Connect the power system ground to the GND terminal. Make sure the system ground is earth ground.

3.

Connect T1 of the motor to T1 of the drive. Connect T2 to T2, and T3 to T3. The order of connection is

important. The motor will not run with improper motor connections..

4.

Connect a ground wire from the motor’s ground lug to the GND terminal on the drive.

5.

Connect the encoder cable to the motor. Consult the drawing on page 2. The cable used should be a nine-

conductor shielded cable. The colors do not matter, but they aid in tracing wires. Connect the shield at both

ends of the cable (the shield continues inside the motor, but is not connected there).

6.

Connect a 10 Kilo-ohm Speed Potentiometer to TB2 terminals 9 (CW), 10 (Wiper), and 11 (CCW). Connect the

shield of the speed pot cable to TB2 terminal 12.

7.

Connect an Emergency Stop (ESTOP) button between TB2 terminals 6 and 7. Use a normally closed,

maintained open contact type pushbutton.

8.

Connect a normally closed, momentary type, STOP pushbutton between TB2 terminals 7 and 5.

9.

Connect a normally open, momentary type, RUN pushbutton between TB2 terminals 5 and 4.

10.

If desired, connect a normally open, momentary type, JOG pushbutton between TB2 terminals 5 and 13.

11.

If desired, connect a Forward-Reverse (FWD-REV) selector switch to TB2 terminals 17 and 14. Use a single-

pole, two-position switch. The switch should close a contact in the Reverse position.

START UP

1.

Before applying power, turn the speed pot fully counter-clockwise (CCW) and turn the CLIM pot fully counter-

clockwise. Do not connect the motor to a load for its initial run. Set FWD-REV to FWD.

2.

When you apply power, the PWR LED should light up GREEN immediately.

3.

When you apply power, the BUS LED should light up RED immediately.

4.

When power is on, the HS1, HS2, and HS3 LED’s may or may not be on RED, depending on the position of

the motor. Only one or two should light; never all three and never none.

5.

When power is on, the TAC LED may be OFF, RED, GREEN, or ORANGE.

6.

Within 30 seconds, the BUS LED should turn GREEN and the you should hear the charging contactor click as

it energizes. If this does not happen within 30 seconds, shut power off and consult the troubleshooting section.

7.

Press and release the START button. The RUN LED should light. The CURRENT LIMIT LED may come on at

this time because the CLIM pot is all the way counter-clockwise.

8.

Immediately after the RUN LED comes on, the ENABLE LED should light.

9.

Increase the speed pot reference to about 10% of its rotation from the CCW position.

10.

Turn the CLIM pot slowly clockwise. If the motor does not turn (HS1, HS2, HS3, and TAC will start blinking)

before CLIM is at 50%, turn the CLIM pot back down fully CCW. Consult the troubleshooting section.

11.

When the motor begins turning more than 10 RPM, the ZERO SPD LED should light up YELLOW.

12.

Leave the CLIM pot at 50 % and increase the speed pot to 50% of its rotation. Check the motor speed with a

hand-held tachometer. Adjust the MAX speed pot, if necessary to attain 50% speed.

13.

Turn the speed pot to 100% and measure the motor speed. Adjust MAX speed if necessary.

14.

Press the Normal Stop button and start again. Time the acceleration to full speed and set ACCEL time.

15.

Turn speed pot to 0% (CCW) and set MIN SPD potentiometer, if desired.

16.

Set STAB and GAIN to 50% of their rotation. Press the Normal Stop button. ENABLE should go OFF.

17.

Press the JOG button and set the JOG speed, if desired.

18.

Start the drive at any speed and switch the Forward-Reverse switch to check reversing.

19.

The motor is ready for service.

Page

4

Model

1000

Installation and Operation Manual

6/1/2001 © copyright 1997 by Powertec

REFERENCE PAGES

Model 1000 Dimensions Chart ...............................................................................................................8

Model 1000 AC

Input

Electrical Ratings Table ................................................................................... 10

Model 1000

Output

Electrical Ratings Table ...................................................................................... 12

Contactor Specifications .....................................................................................................................14

Dynamic Braking Resistors ................................................................................................................. 14

Model 1000 Control Connections Table ..............................................................................................16

Terminal Descriptions List ................................................................................................................... 18

PLC Interface Suggestions .................................................................................................................20

Digital Mode Notes .............................................................................................................................. 22

Analog Versus Digital Operation Comparison .....................................................................................24

Standard Basic Connection Diagram ................................................................................................... 26

Capacitor Board Location and Layout ..................................................................................................28

Current Controller Board Layout .......................................................................................................... 30

Speed Controller Board Layout ............................................................................................................30

Jumpers List ....................................................................................................................................... 30

LED Indicators .....................................................................................................................................32

Adjustments ......................................................................................................................................... 34

Simplified Power Schematic ................................................................................................................36

Semiconductor Diagrams......................................................................................................................36

Transistor Module Static Test ............................................................................................................... 38

Diode Bridge Test ................................................................................................................................ 40

Transistor Leakage Test .......................................................................................................................40

Encoder Waveforms and Connections .................................................................................................42

IOC Tests..............................................................................................................................................44

OV/UV Tests .........................................................................................................................................44

Block Diagram Speed and Current Controller boards .......................................................................... 46

Base Driver board- Layout and Connections ........................................................................................48

Model

1000

Installation and Operation Manual

Page

5

OFFICIAL 6/1/2001

TABLE OF CONTENTS

INTRODUCTION

..................................................................................................................................................... 1

QUICK START

......................................................................................................................................................... 3

REFERENCE PAGES

.......................................................................................................................................... 4

TABLE OF CONTENTS

...................................................................................................................................... 5

SPECIFICATIONS

................................................................................................................................................. 6

MOTOR PROTECTION

........................................................................................................................................ 7

WARRANTY

............................................................................................................................................................. 7

INSTALLATION

HOW DO I …

Physically Install

the Model 1000 Drive ? ........................................................................................................... 9

Connect AC Power

to the 1000 Drive ? ........................................................................................................... 11

Connect the Motor

to the 1000 Drive ? ............................................................................................................ 13

Install an

Output Contactor

? ........................................................................................................................... 15

Install

Dynamic Braking

? ................................................................................................................................. 15

Connect

Standard Control Circuits

? .............................................................................................................. 17

Get

RUN

, Zero Speed,

FAULT

, and

ENABLE

Information ? ............................................................................ 19

Connect an

ANALOG Speed Reference

?........................................................................................................ 21

Connect a

DIGITAL Speed Reference

? ........................................................................................................... 23

Connect a

DIGIMAX

? ..................................................................................................................................... 25

Installation Checklist

...................................................................................................................................... 27

START UP

WHAT HAPPENS WHEN I …

Apply Power

to the Model 1000 Drive ? ............................................................................................................ 29

Give the Start Command

to the Model 1000 Drive........................................................................................... 31

Give the Speed Command

to the Model 1000 Drive ........................................................................................ 33

Make an Adjustment

on the Model 1000 Drive................................................................................................. 35

TROUBLESHOOTING

Troubleshooting the Model 1000 Drive............................................................................................................... 37

Troubleshooting Chart - POWER LED ............................................................................................................... 39

Troubleshooting Chart - BUS LED...................................................................................................................... 41

Troubleshooting Chart - HS1, HS2, HS3, and TAC LED’s.................................................................................. 43

Troubleshooting Chart - RUN and ENBL LED’s ................................................................................................. 45

Troubleshooting Chart - TAC and ZERO SPEED LED’s .................................................................................... 47

Troubleshooting Chart - CURRENT LIMIT and PHAD LED’s ............................................................................. 49

Page

6

Model

1000

Installation and Operation Manual

6/1/2001 © copyright 1997 by Powertec

SPECIFICATIONS

ENVIRONMENTAL

ALTITUDE : Use above 3300 feet (1000 meters) requires de-rating.

De-rate at 3% of full rating for each additional 1100 feet (330 meters).

STORAGE TEMPERATURE : -40 °C to +65 °C (-40 °F to + 150 °F)

AMBIENT TEMPERATURE :

Chassis : Maximum air temperature of 55 °C (131 °F).

Nema1 : Maximum air temperature of 40 °C (104 °F).

RELATIVE HUMIDITY : Less than 95%, non-condensing.

POWER SOURCE :

Voltage : Nominal 230 VAC, 380 VAC, or 460 VAC per nameplate rating.

Voltage Tolerance : -10%, +10% of nominal rated voltage.

Phases : Three (Drive will not operate on single phase).

Frequency : 48 to 62 Hertz

KVA Required : KVA rating of source must be at least equal to Horsepower rating.

Max KVA Rating : 100 KVA (limited by input fuse AIC rating).

DIMENSIONS

Physical Dimensions : See page 8.

Approximate Weights :

1000 chassis : 30 pounds ( 66 kg ).

1000A chassis : 44 pounds ( 97 kg )

1000 Nema1 : 41 pounds ( 90 kg )

1000A Nema1 : 56 pounds ( 123 kg )

PERFORMANCE

Maximum Load : 150% for 1 minute out of 10 minutes.

Speed Regulation : 0.0% (on load change from no load to full load)

Speed Accuracy :

Analog Mode : +/- 1.0% typical with speed pot supplied by internal reference.

Linearity : +/- 0.5% typical with external reference source.

Digital Mode : 0.0 % typical ( +/- ¾ revolution of the motor shaft ).

Displacement power factor : 0.96 typical

ADJUSTMENTS

ACCELERATION TIME : 2 to 90 seconds with JP2 installed; 0.05 to 2 seconds with JP2 removed..

DECELERATION TIME : 2 to 90 seconds with JP2 installed; 0.05 to 2 seconds with JP2 removed..

Acceleration and deceleration times settable in analog mode only.

MAXIMUM SPEED : 600 to 5000 RPM ( motor dependent ), analog mode only.

MINIMUM SPEED : 0 to 15% of MAXIMUM SPEED with 5K speed potentiometer, analog mode only.

JOG SPEED : 0 to 30% of MAXIMUM SPEED, analog mode only.

CURRENT LIMIT : Adjustable from 0% to 150% of rated current, calibrated by Horsepower Resistor.

GAIN : 10 to 1 stiffness ratio

STABILITY : 20 to 1 dynamic response.

JUMPERS

SEE PAGE 30

LED INDICATORS

SEE PAGE 32

TERMINAL ASSIGNMENTS

SEE PAGE 18

Model

1000

Installation and Operation Manual

Page

7

OFFICIAL 6/1/2001

I

II

I

NSTALLATION

NSTALLATIONNSTALLATION

NSTALLATION

Underwriter’s Laboratories

®

requires this notice for UL

®

listed equipment.

This Notice applies to Brushless DC Drive Model Numbers 1000 and 1000A.

MOTOR PROTECTION CONSIDERATIONS

You are about to install a

GENESIS

Series Brushless DC (BLDC) drive. You need to consider how the motor will be

protected while it is in service. This is what the Model 1000 series drive provides :

1.

“F” Series

motors have an internal switch that opens at high winding temperatures. You must connect this

switch to the drive. Look up the method of connection in the drive manual. When the thermal switch opens, the drive

has to be shut down before high temperatures can cause damage.

2. The Model 1000 series drive provides motor current limiting. This protection is adjustable from 0% to 150% of

the drive’s rated output current.

3. The Model 1000 series drive provides an overcurrent trip. This shuts off the drive if peak currents greater than

300% of the RMS rating occur.

4. The Model 1000 drive provides fast clearing fuses in the AC input. It does not provide an input circuit breaker

unless you chose that option at the time of purchase. If you did not purchase an optional circuit breaker with the drive,

you must supply a switch for input power. You must do this in order to meet the requirements of the National Electrical

Code.

5.

GENESIS

series drives

do not provide running overload protection as described in Underwriters Laboratories

Industrial Control Equipment Specification 508. The user is responsible for complying with local codes and practices. If

you decide you need more protection, that protection must shut off the drive.

SUMMARY

OF WARRANTY AND DISCLAIMER

Powertec

manufactures Model 1000 Series Brushless DC (BLDC) motor controls. We warrant these units against

defects in materials and workmanship for a period of

two years

. This period begins on the date of original shipment

from the factory.

You must notify us in writing of a defect in materials or workmanship in a warranted unit. We

will, at our sole option,

repair or replace such defective parts as we deem necessary to restore the unit to service. We will make these repairs,

or replacement of parts, at the factory. Shipping charges to and from the factory and on-site service charges are the

responsibility of the user.

There is no other warranty. We do not warrant the fitness of purpose for the application intended. This warranty

does not cover accidental or intentional damage or accidental or intentional abuse. This warranty does not cover

results from defective or incorrect installation, interference with other equipment, or any other situation over which

Powertec

has no control.

This warranty does not cover any other claims, including, but not limited to, special, incidental, or consequential

damages.

Powertec

supplies this manual as a guide to the use of

our products. We have used our best efforts to compile this

information. If you find mistakes of fact in this manual, please notify your distributor or

Powertec

at once.

Do not use this device on a circuit capable of delivering more than

5000 RMS symmetrical Amperes at 500 VAC maximum voltage.

Page

8

Model

1000

Installation and Operation Manual

6/1/2001 © copyright 1997 by Powertec

M

ODEL

1000 D

IMENSIONS

CHASSIS UNITS

ENCLOSED UNITS

Model

1000

Installation and Operation Manual

Page

9

OFFICIAL 6/1/2001

H

OW

D

O

I …

PHYSICALLY INSTALL THE MODEL 1000 DRIVE?

WARNING:

DANGEROUS HIGH VOLTAGES ARE NORMAL IN THIS EQUIPMENT! WHEN THE AC INPUT POWER IS

REMOVED, THE CAPACITORS ARE NOT DISCHARGED AT ONCE! WAIT FIVE MINUTES AND THEN CHECK

TO BE SURE THAT THE CAPACITORS ARE DISCHARGED BEFORE WORKING ON THE DRIVE.

WARNING! :

IF YOU TESTED THE DRIVE BEFORE INSTALLATION, CHECK THE BUS VOLTAGE. YOU WANT TO MAKE

SURE THAT THE BUS CAPACITORS HAVE DISCHARGED.

Mount a Model 1000 series drive of the NEMA 1 style with the fuses at

the top. Do not block air flow around the unit. Free air must flow up through

the fins on the back of the drive.

The temperature of the air around the drive (the ambient) must not

exceed 40°C (104°F) with a relative humidity of 95% or less.

Leave at least 6 inches (150 mm) of open space on all sides of the

NEMA 1 box. Do not mount it directly above a heat source, such as another

drive. If you mount two drive units in line vertically, there must be at least 18

inches (450 mm) of open space between the units.

When you move the Model 1000 series drive chassis to an enclosure,

DO NOT handle the chassis by parts that may bend or come loose. This

applies to the front cover of the drive. Support the chassis by the outside

edges of the heatsink.

Mount the chassis style Model 1000 series drive in an upright position (fuses at

top) inside an enclosure. Mount the chassis this way to promote cooling air flow

through the heatsink fins.

The temperature of the air around the chassis (ambient) may not exceed 55 °C

(131 °F). Relative humidity should be 95% or less, non-condensing.

Avoid mounting one chassis directly above another. This will result in hot air from

the lower chassis flowing up into the upper chassis. Leave at least 12 inches (300

mm) of open space between them.

There must be a minimum free panel space of 3 inches (75 mm) above and

below the chassis. This allows proper air flow through the heatsink fins.

The total heat dissipation within the electrical enclosure, for chassis units,

determines the size. There is a list of the heat output of the Model 1000 series drives

in the table on page 10.

NEMA 1, NEMA 1A, and NEMA 12 ventilated boxes depend upon air flowing

through the enclosure for cooling. They must have an air flow of 1 CFM (cubic feet

per minute) per 10 watts of dissipation (1 cubic meter/minute per 350 watts).

The allowance for totally enclosed units is 1 square foot of enclosure surface per

7 watts of dissipation (75 watts per square meter). Surface area includes front, sides,

top and bottom surface areas. Enclosure surfaces not exposed to cooling air do not

count.

For further information, consult the publication THERMAL MANAGEMENT,

available from your distributor.

Use of the Model 1000 Series drive above 3300 ft (1000 meters) requires de-rating.

If the drive is to be stored, store it in its original packaging in a dry environment.

Storage temperature should be between -40°C and +65°C.

Mount with 1/4-20 bolts

and nuts in 4 places

Page

10

Model

1000

Installation and Operation Manual

6/1/2001 © copyright 1997 by Powertec

M

ODEL

1000 AC I

NPUT

E

LECTRICAL

R

ATINGS

NOMINAL

AC LINE

VOLTAGE

HORSE-

POWER

KILO-

WATTS

MAXIMUM

CONTINUOUS

AC LINE

CURRENT

INPUT

KVA

MAXIMUM

HEAT

OUTPUT IN

WATTS

230 ½ 0.37 1.4 0.550 35

230 ¾ 0.56 1.8 0.725 42

230 1 0.75 2.4 0.950 60

230 1.5 1.1 3.6 1.450 85

230 2 1.5 4.9 1.950 122

230 3 2.2 7.3 2.900 165

230 5 3.7 12.1 4.825 232

230 7.5 5.6 18.1 7.200 281

‡

230 10 7.5 23.9 9.525 385

380 1 0.75 1.5 0.975 36

380 1.5 1.1 2.2 1.450 55

380 2 1.5 2.9 1.925 70

380 3 2.2 4.4 2.875 105

380 5 3.7 7.3 4.810 142

380 7.5 5.6 10.9 7.150 178

‡

380 10 7.5 14.1 9.250 222

460 2 1.5 2.4 1.910 113

460 3 2.2 3.5 2.800 144

460 5 3.7 5.9 4.750 200

460 7.5 5.6 8.9 7.100 258

460 10 7.5 11.4 9.050 355

‡

460 15 11 17.8 14.150 475

Indicates 1000A models.

N

OTES

The Model 1000 Series drives are designed to operate on power line frequencies from 48 to 62 hertz.

The

tolerance

of the input voltage is +10% to -10% of the nominal voltage listed on the nameplate. A service that

supplies AC motors, in addition to the drive, must be capable of supporting the starting current of the motors without dropping

more than 10%. If the drive is operating at a line voltage of less than 95% of the nominal line voltage, brief power line

disturbances may trip the drive.

Do not measure the input voltage while the drive is not running. This neglects the effects of load on the power source.

Measure the actual input line voltage while the control is operating the motor in a loaded condition.

Brief power line disturbances will not normally disturb the Model 1000 series drives. The Model 1000 series drives do not

generate significant noise back onto the power service. Events that distort the AC waveform may lower the bus voltage. These

may trigger an under-voltage or power loss condition.

One of the most frequent problems encountered with digital type equipment is electrical noise. Noise is a treacherous

problem that is capable of causing destructive results. It can also cause intermittent and annoying problems. The methods

used in the installation of the equipment plays a large part in prevention of electrical noise interference in operation. Any digital

type control requires that extra care be taken in installation. Pay attention to the grounding of the equipment, the shielding of

wires and cables, and the placement of wires in the conduit runs. Pay attention to the sections of this manual that address the

precautions against noise. This also applies to peripheral equipment.

When you use other manufacturer’s equipment in a system, follow their directions regarding noise suppression and

protection. Pay particular attention to power and grounding requirements.

Model

1000

Installation and Operation Manual

Page

11

OFFICIAL 6/1/2001

H

OW

D

O

I …

CONNECT AC POWER TO THE 1000 DRIVE?

Standard Model 1000 series Brushless DC drives will not operate on

single phase AC power.

Model 1000 series drives require a three-phase main power source with a

KVA rating

at least equal to the

HorsePower rating

of the drive.

However, the branch service rating (in KVA) supplying the drive must not

be more than 10 times the HP rating of the drive. If it is, you may need special

disconnecting means with a higher AC short-circuit current interrupting

capacity.

Model 1000 series drives do not include a disconnect for input power. The

user must supply a switch that meets applicable code requirements.

The maximum Interrupting Capacity (AIC) of the fuses is 5,000 amperes.

You will need a switch with a rating greater than 5,000 amperes if the short

circuit current on the service is greater.

You do not necessarily need an ISOLATION TRANSFORMER for

operation of the drive. You may want to use one, or you might need to meet

local code requirements. You may need to change the voltage level.

If you use a transformer, you will need one with a KVA rating at least as

large as the HP rating of the drive. If you use a transformer, we recommend a

delta/wye winding configuration. We also recommend that the transformer

have taps to raise or lower voltage.

The user protection supplied before the wires determines the sizes of the

power wires to the drive input. The table on the opposite page lists the full load

AC line currents of Model 1000 series drives.

The order of connection of the input phases is not important.

We size the main fuses to protect the semiconductor elements of the unit.

THEY MAY OR MAY NOT MEET THE REQUIREMENTS OF NATIONAL,

STATE AND/OR LOCAL ELECTRICAL CODES. The responsibility for meeting

the branch service protection and other code requirements and safety codes

belongs to the user.

NOTICE: THE AC LINE CURRENT OF THE BRUSHLESS DC DRIVE IS NOT

REPRESENTATIVE OF THE OUTPUT LOAD CURRENT TO THE

MOTOR!

The AC input current is directly proportional to the POWER output of the

motor. The only time the AC line current reaches its full value is when the

motor is operating at full speed with full load.

DO NOT ATTEMPT TO MEASURE MOTOR LOAD BY

MEASURING AC INPUT LINE CURRENT TO THE BLDC MOTOR

CONTROL.

TRANSFORMER

.

SEE FUSE

INPUT

BOARD

DRAWING

ON PAGE 8

L1

L2

L3

GND

MAIN

POWER

Page

12

Model

1000

Installation and Operation Manual

6/1/2001 © copyright 1997 by Powertec

MODEL 1000 FUSE BOARD

MODEL 1000 OUTPUT ELECTRICAL RATINGS

NOMINAL

AC LINE

VOLTAGE

HORSE-

POWER

KILO-

WATTS

MAXIMUM

CONTINUOUS

MOTOR

CURRENT

MAXIMUM

MOMENTARY

MOTOR

CURRENT

NOMINAL

HP

CALIBRATE

RESISTOR

230 ½ 0.37 2.2 3.3 68.1 K

230 ¾ 0.56 3.4 5.1 45.3 K

230 1 0.75 4.7 7.0 33.2 K

230 1.5 1.1 7.0 10.5 22.1 K

230 2 1.5 8.5 12.7 18.2 K

230 3 2.2 12.8 19.2 12.1 K

230 5 3.7 22.8 34.2 6.81 K

230 7.5 5.6 31.1 46.6 4.99 K

‡

230 10 7.5 41.5 61.1 3.74 K

380 1 0.75 2.7 4.0 56.2 K

380 1.5 1.1 3.9 5.8 39.2 K

380 2 1.5 4.7 7.0 33.2 K

380 3 2.2 7.8 11.7 20.0 K

380 5 3.7 14.1 21.1 11.0 K

380 7.5 5.6 18.8 28.2 8.25 K

‡

380 10 7.5 25.0 37.5 6.19 K

460 2 1.5 4.0 6.0 39.2 K

460 3 2.2 6.9 10.3 22.1 K

460 5 3.7 11.6 17.4 13.3 K

460 7.5 5.6 17.1 25.6 9.09 K

460 10 7.5 20.7 31.0 7.50 K

‡

460 15 11 31.1 46.6 4.99 K

‡

Indicates 1000A models.

Model

1000

Installation and Operation Manual

Page

13

OFFICIAL 6/1/2001

H

OW

D

O

I …

CONNECT THE MOTOR TO THE 1000 DRIVE?

We ship every drive from the factory with A STANDARD CONNECTIONS card.

Connect the motor lead marked T1 to the

T1 terminal on the drive. Connect the T2 lead

to T2 on the drive, and connect T3 to T3.

Other connections to T1, T2, and T3 at the

motor will vary with the motor. The motor will

not operate correctly if the power wires from

motor to drive are not in the proper order.

Full load motor current determines the

wire size to the motor. The table on the

opposite page lists these currents.

Any high voltage, high frequency

equipment generates EMI and RFI.

YOU

MUST USE METALLIC CONDUIT TO

ENCLOSE MOTOR WIRES

BETWEEN THE

MOTOR AND THE DRIVE.

This will minimize

interference.

You must install a ground wire between

the motor frame and the drive chassis. There

is a ground lug in most motors. If there is no

ground lug, make a connection at any bolt in

the motor junction box.

THIS GROUND WIRE MUST BE RUN IN

ADDITION TO GROUNDING THE MOTOR FRAME TO ITS MOUNTING, WHICH IS REQUIRED BY

CODE.

The purpose of this separate ground is to equalize the potential between the motor's frame and the drive

chassis. There may be enough impedance to broadcast EMI and RFI even with the motor grounded to its

mounting frame. A direct wire connection between the motor frame and the drive chassis minimizes

interference in other equipment.

The encoder feedback cable must be a shielded cable. Connect the shield to TB1 terminal 1 on the

control end. Standard installation requires a nine-conductor shielded cable (Belden

™

part #9539 or equivalent).

The colors of this cable correspond to the colors of the wires in the motor and on the connection diagram. You

may interchange the Purple and White wires without ill effect.

The shield must be continuous from the motor to the control. Do NOT ground the shield at intermediate

points. This applies to all junction boxes installed between motor and control.

DO NOT USE THE SHIELD OF THE ENCODER CABLE AS AN ACTIVE CONDUCTOR!

If you want to use the motor thermal protector in a 120 VAC circuit, run it in wiring separate from the

cable. Use seven-conductor shielded cable. In this case, if the cable wire colors are different from the

diagram, you need to check them carefully for proper connections.

BLDC

MOTOR

T1 T2 T3

GND

1 2 3 4 5 6 7 8 9 S

T1

T2

T3

GND

Blue

Brown

Black

Orange

Red

Green

Yellow

16

1 2 3 4 5 6 7 89

TB1

18

1 2 3 4 5 6 7 89

TB2

Purple

White

SEE FUSE

INPUT

BOARD

DRAWING

ON PAGE 8

SEE MOTOR

MANUAL FOR

CORRECT

MOTOR

CONNECTIONS

Page

14

Model

1000

Installation and Operation Manual

6/1/2001 © copyright 1997 by Powertec

CONTACTOR SPECIFICATIONS

If you want to operate an Output or Dynamic Braking Contactor

directly from the Model 1000 or 1000A, you must choose a coil that

draws less than 50 milliamps DC.

The Output Contactor drawing on page 15 shows the

connections for direct operation of the contactor (use the same

connections for Dynamic Braking). The coil must be 48VDC and

draw less than 50 ma DC (2.4 Watts). This is the most power

available from the Model 1000 series drive’s supplies.

To use a 115VAC or 230 VAC coil, you need a 156-012

Contactor Control board, as shown in the drawing on page 15. Use

the same drawing for the Output Contactor. Maximum current for the

Contactor Control board is 1 Amp at 230 VAC.

You need three normally open power poles and a normally open

auxiliary for an Output Contactor. The contactor does not make or

break with current in the power contacts. Choose the contact ratings

only on the basis of carrying the current.

For Dynamic Braking, you need three normally closed power

poles and a normally open auxiliary. The contacts make with current

present, but they do not break current in the dynamic braking

operation. Choose contacts accordingly.

The contactor outline sketched at left is from the SH-04 series by

AEG Industries. The model used for the Output Contactor is part

number SH-04.40 and the Dynamic Braking is SH-04.13. Contact

ratings are 16 Amps.

DYNAMIC BRAKING RESISTORS

We choose DB resistors for their ability to absorb high inrush currents and to accept large amounts of

power for short periods of time. Typical DB resistors can absorb ten times their power rating for up to five

seconds. The resistors must then cool down to ambient temperature before they can dissipate their full rating

again (usually a few minutes). It is possible to extend the ratings by about three times with power resistors by

forced-air cooling.

You can derive an approximate value of dynamic braking resistor from the bus voltage and the full load

current on the nameplate of the motor:

Bus Voltage X 0.47

Each Resistor Value ~ -----------------------------------

Motor FLA

Three resistors (or groups of resistors) are necessary. The power rating of each should be:

Power > 0.02 X (Buss Voltage)

2

/ (Resistor Value)

These formulas are very general, and results will vary from motor to motor. For dynamic braking tailored

to your application, consult

Powertec

Engineering.

1.77"

1.66"

13 21 31 41

A1

14 22 32 42 A2

TOP VIEW

BOTTOM VIEW

1.25"

0.19"

1.54"

Model

1000

Installation and Operation Manual

Page

15

OFFICIAL 6/1/2001

H

OW

D

O

I …

CONNECT AN OUTPUT CONTACTOR?

When you use an output contactor with the Model 1000, you

MUST interlock the output contactor with the Emergency Stop.

You WILL damage the drive if you do not interlock it.

Requirements for the Model 1000 series are:

1. The contactor must close its main power contacts

BEFORE it enables the drive;

2. The contactor may only open its contacts AFTER

disabling the drive.

It is important to note that the contactor does not make

or break current.

The figure at left shows the connections for a 48VDC output

contactor (such as AEG part number SH-04.40-ODC, which is

available from

POWERTEC

).

In this configuration, the contactor energizes on a run

command and de-energizes ONLY on an emergency stop. The

contactor stays energized during normal stops.

POWERTEC

makes an optional track mount PC board (Part

# 156-012) for sequencing of contactors with AC coils.

DO NOT BREAK THE GROUND CONNECTION OR THE CABLE

CONNECTIONS WITH THE OUTPUT CONTACTOR.

H

OW

D

O

I …

CONNECT DYNAMIC BRAKING?

You MUST interlock the contactor with the

Emergency Stop when using Dynamic Braking. You

will damage the drive and/or the resistor banks if

you do not properly interlock the contactor.

The requirements are:

1. The contactor must open the main power

contacts BEFORE the drive is enabled; AND

2. The contactor may only close its contacts

AFTER disabling the drive.

The AEG SH-04.13-ODC contactor is suitable

to the circuitry above. The figure on the left shows

the connections for using a POWERTEC 156-012

Contactor Control board to control a larger

contactor or a contactor with an AC coil.

In this configuration, the contactor energizes

when there is a run command and de-energizes

ONLY on an emergency stop. The contactor stays

energized during normal stops.

BLDC

MOTOR

T1

T2

T3

G

T1

T2

T3

M

181 2 3 4 5 6 7 814

TB2

MOTOR

THERMAL

M

M aux

RUN STOP

EMER

STOP

CONTACTOR

3 POLE N.O.

1 N.O. aux

48VDC COIL

@ 2.4 W

GND

9 10 11 12 13

JOG

6

CONTACTOR

3 POLE N.C.

1 N.O. AUX

COIL < 230VAC

Page

16

Model

1000

Installation and Operation Manual

6/1/2001 © copyright 1997 by Powertec

M

ODEL

1000 C

ONTROL

C

ONNECTIONS

MOTOR

THERMAL

STD:

CONNECT FROM

TB2-8

TO

TB2-6**

Normally closed bi-metallic thermal switch in the motor. THE

MOTOR THERMAL SWICH MUST BE USED TO PROPERLY

PROTECT THE MOTOR! When the motor thermal switch opens,

the drive must be shut off to prevent damage to the motor

from overheating.

EMERGENCY

STOP

+24VDC

ON

TB2-7

STD: N/C PB

FROM

TB2-7

TO

TB2-6**

Voltage must be present to RUN or JOG. When removed,

ENABLE REQUEST is blocked immediately (see page 31) and

all control functions are disabled. Do not connect voltage to

terminal with permanent jumper. In RAMP STOP mode, this is

the only way to stop the drive.

RAMP STOP

+24VDC

ON

TB2-5

S

TD

: N/C PB

FROM

TB2-7

TO TB

2-5

Voltage must be present to maintain RUN mode after a

momentary START is removed. When voltage is removed, the

drive decelerates to zero speed at the DECEL rate and shuts

off if RAMP STOP jumper JP2 is installed. Otherwise drive

shuts off immediately and the motor coasts to a stop.

START /

RUN

+24VDC

ON

TB2-4

STD: N/O PB

FROM

TB2-5

TO TB

2-4

Voltage must be applied to initiate RUN mode. When it is

removed, drive shuts off unless +24VDC is present at TB2-5.

RUN LED turns on when +24VDC is applied to TB2-4. RUN

LED turns off and RUN relay drops out when voltage is

removed from both TB2-4 and TB2-5.

RUN

CONTACT

TB2-1

AND

TB2-2

Normally open dry contact which closes when START is

energized and opens when RUN relay drops out (see above).

The RUN contact does not open on a FAULT unless the fault

removes the voltages from TB2-4 and TB2-5. The RUN contact

does not close on JOG and opens in RAMP STOP mode.

ZERO

SPEED

OUTPUT

: TB2-16

COMMON

: TB2-12

Open collector transistor output referenced to TB2-12. Rated

at 50 mADC @ 50 VDC max. This output operates only in RUN,

JOG, or RAMP STOP modes. The ZERO SPEED output turns

on at about 10 RPM and off at about 5 RPM. The ZERO

SPEED output shuts off if ENABLE LED shuts off.

JOG

+24VD

C ON

TB2-13

STD: N/O PB FROM

TB2-5

TO

TB2-13

Voltage must be applied to initiate JOG mode. JOG mode will

be maintained only as long as the voltage is present. When

the voltage is removed, the drive will go to RAMP STOP mode

if COAST TO STOP jumper JP2 is installed. Otherwise the

drive shuts off and the motor coasts to a stop.

REVERSE

+24VDC

ON

TB2-14

STD

: N/

O

PB

FROM

TB

2-17

TO TB

2-14

Voltage must be applied to make motor go in reverse direction

(forward direction is defined as clockwise rotation of shaft

looking at output shaft end). In analog mode, applying or

removing voltage causes drive to decelerate to zero speed

and accelerate to set speed in opposite direction. In digital

mode, input frequency must be reduced to zero until motor

stops, then re-applied to go in opposite direction.

FAULT

OUTPUT

OUTPUT

COLLECTOR

: TB1-12

E

MITTER

: TB1-13

Optically coupled transistor output (isolated). Rated at 50

mADC @ 50 VDC. Turns on when bus has achieved proper

level. Output is off when any trip occurs.

ANALOG/

DIGITAL

SWITCH

+24VDC

ON

TB1-10

REFERENCE TB

1-9

TB

1-9

IS NOT DRIVE

COMMON

Apply voltage to switch to DIGITAL mode. TB1-10 and TB1-9

are electrically isolated from the board power supplies. The

negative side of the +24VDC used for the input must be

connected to TB1-9. External frequency must be applied to

terminal 11. Terminal 9 is also common for this frequency.

** NOTE:

TB2-6 is a dead terminal. It is used as a tie point.

Model

1000

Installation and Operation Manual

Page

17

OFFICIAL 6/1/2001

H

OW

D

O

I …

CONNECT STANDARD CONTROL CIRCUITS?

If you are using an output contactor or dynamic

braking, see page 15

.

The table on the opposite page lists the functions,

connections and descriptions of the control circuits of the

Model 1000. Read the descriptions of the operations of

these circuits carefully, since there are some differences

between operation in analog and digital modes.

The control circuits of the POWERTEC Brushless DC

Drive Models 1000 and 1000A motor controls operate on

48 VDC. This results from using the positive and negative

24 VDC unregulated power supplies. Using 48VDC helps to

balance the load of relays and other devices on the

supplies.

The maximum current from each of the raw supplies is

50 milliamps. Due to this supply limitation, you must use an

external supply when you use several external relays.

THE POWER SUPPLIES OF THE MODELS 1000 AND

1000A SHOULD NOT BE USED FOR EXTERNAL

EQUIPMENT! We make an optional power supply (part #

127-101) available for additional 24 VDC power.

It is possible to operate the control circuits with a

variety of devices. Standard operator devices are O.K.. The

current flowing through these devices is very small. When

locating pushbuttons more than 30 feet away from the drive,

you should consider using 120 VAC control circuits.

There is a desire in some cases to place a jumper

across the Emergency Stop terminals, rather than to install ESTOP buttons. Because the drive has a

ramp to stop capability, this could set up an UNSAFE situation. IT IS STRONGLY RECOMMENDED

THAT AN EMERGENCY STOP BUTTON (or an ESTOP relay) BE CONNECTED TO THE DRIVE! This

should be of the MAINTAINED CONTACT TYPE.

T

HE MOTOR THERMAL MUST BE USED TO

PROPERLY

PROTECT THE MOTOR

!

You can use the "two-wire" control method by connecting a contact or switch between terminals 7

and 4 on TB2. Leave off the RAMP STOP and START buttons. This DOES NOT disable the RAMP STOP

function. The only way to disable the RAMP STOP function is removing the RAMP STOP jumper.

The RAMP STOP function in the analog mode shorts the analog reference input to zero. This causes

the motor to decelerate to zero speed before shut-down. In digital mode, you must reduce the external

frequency to zero, or the RAMP STOP circuitry will not function.

Note that the JOG function OVERRIDES the RUN function. If you activate the JOG input while the

RUN mode is in operation, it will change the motor speed to JOG speed.

RAMP

STOP

EMER

STOP

TO

MOTOR

THERMAL

TB2

16151413121110987654321 1817

START

JOG

FWD REV

Page

18

Model

1000

Installation and Operation Manual

6/1/2001 © copyright 1997 by Powertec

TERMINAL DESCRIPTIONS

- M

ODEL

1000

AND

1000A

TB1 CURRENT CONTROLLER BOARD (141-108)

1 Dedicated Shields and Ground connection

2 HS1 position encoder

3 HS3 position encoder

4 HS2 position encoder

5 HS4 speed encoder

6 HS5 speed encoder

7 Encoder Common for encoder ONLY

8 Encoder +5 VDC for encoder ONLY

9 Isolated Common for terminals 10 and 11

10 Auto/Manual Selection +24 VDC for Digital Mode

11 External Frequency Input +24 VDC Square Wave

12 Collector of FAULT transistor

13 Emitter of FAULT transistor

14 Drive Load output -2VDC = 150%

15 Auxiliary Supply output +15VDC for extra encoder

16 Power Supplies Common

TB2 SPEED CONTROLLER BOARD (141-107)

1 RUN contact closes on RUN

2 RUN contact 1 Amp 125 VAC

3 -24 VDC raw supply 50 ma max

4 RUN input +24VDC to RUN

5 RUN hold +24VDC to maintain RUN

6 SPARE tie point for motor thermal

7 Emergency STOP +24VDC to RUN

8 +24 VDC RUN Logic Supply 50 ma max

9 +10 VDC reference supply

10 Speed reference input 0 to +10VDC

11 Minimum speed connection for speed pot

12 Signal common

13 Jog input +24VDC to JOG

14 Forward/Reverse input +24VDC to reverse **

15 Frequency output open collector to common

16 Zero speed output open collector to common

17 +24VDC raw supply 50 ma max

18 Current reference (velocity error) 0 to +10VDC

TB3 CAPACITOR BOARD (141-106)

1 Horsepower calibration resistor

2 No connection

3 Horsepower calibration resistor

*+24 VDC source for forward/reverse input must be must be from TB2 terminal 17 ONLY.

/