15

Servicing

A: Removal Of Hob Top

1. Remove the panstands and each burner cap and

crown.

2. Lift the hob from off the working top.

3. Remove the two self tapping screws from each

burner and the two fixing screws on the right hand

side of the hob.

B: Removal Of the Hob Taps

(Isolate Electric Supply)

1. Follow the procedures in Section A.

2. With the aid of a 7mm spanner remove the clamping

bolt from the fixing clamp.

3. Loosen the pipe connection nut from the gas tap with

the aid of a 16mm spanner. Remove fixing clamps.

4. Reassemble in reverse order and carry out leak test.

C: Removal Of Mains Terminal Block

(Isolate Electric Supply)

1. Follow the procedures in Section A.

2. Disconnect supply flex connections from terminal

block.

3. From the underside of the hob remove 1 self tapping

screw from the terminal block.

4. Reassemble in reverse order.

D: Removal Of Burner

1. Follow the procedures in Section A.

2. With the aid of a 12mm spanner loosen off the pipe

connection nut.

3. From the underside of the hob remove 2 self tapping

screws from the burner body.

4. Reassemble in reverse order and carry out leak test.

E: Removal Of Ignitor Unit

(Isolate Electric Supply)

1. Follow the procedures in Section A.

2. Disconnect H.T. leads and the ignition switches

connector.

3. With the aid of a pair of thin nose pliers, pull the

spring clip sidewards off of the underside of the

ignitor.

4. Reassemble in reverse order and check with wiring

diagram for correct reconnection.

F: Remove Taps Ignition Switches

(Isolate Electric Supply)

1. Follow the procedures in Section A.

2. Disconnect the switches connector from the ignitor

unit and remove the supply cables pulling the tabs

connection off.

3. Reassemble in reverse order and check with wiring

diagram for correct reconnection.

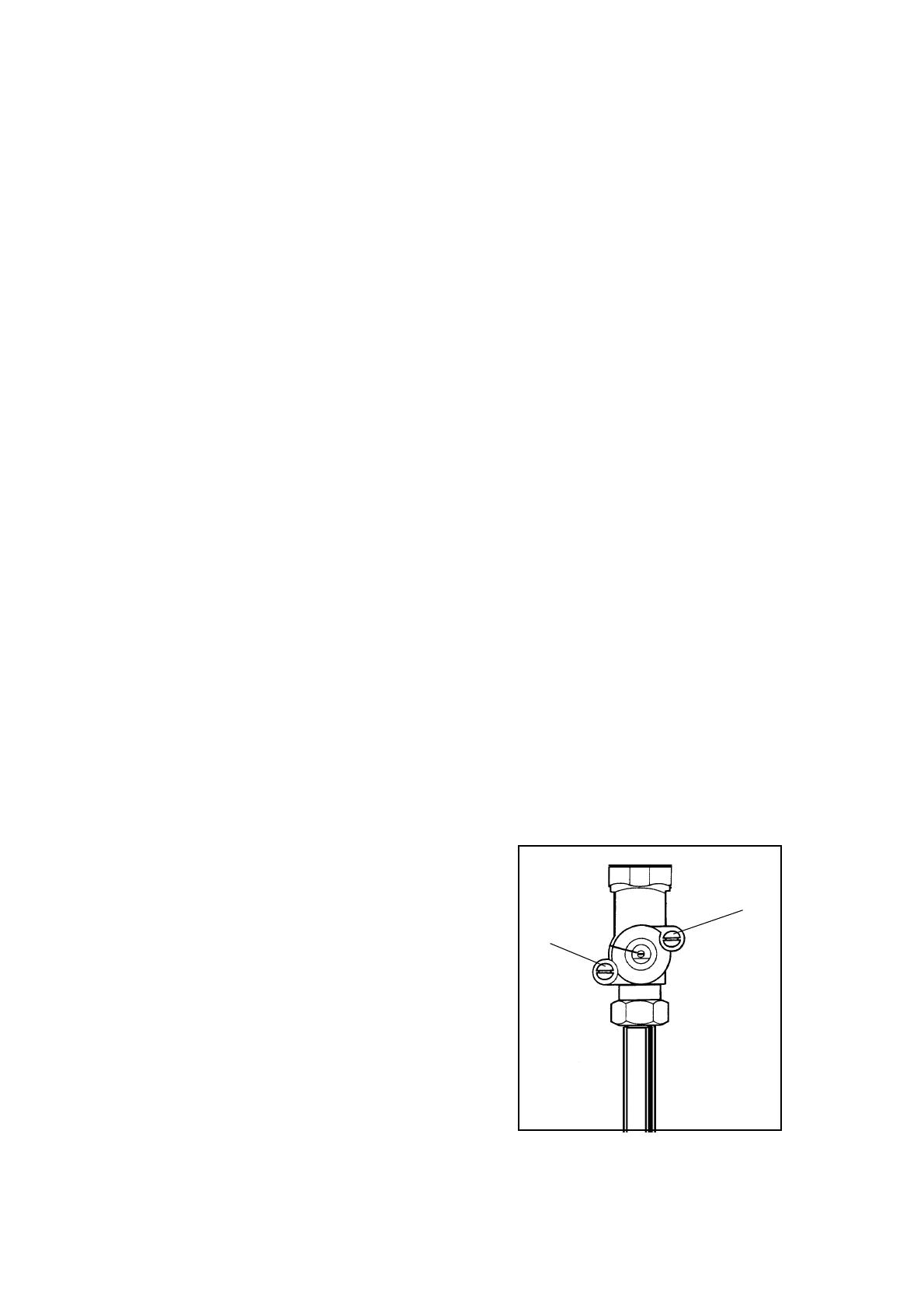

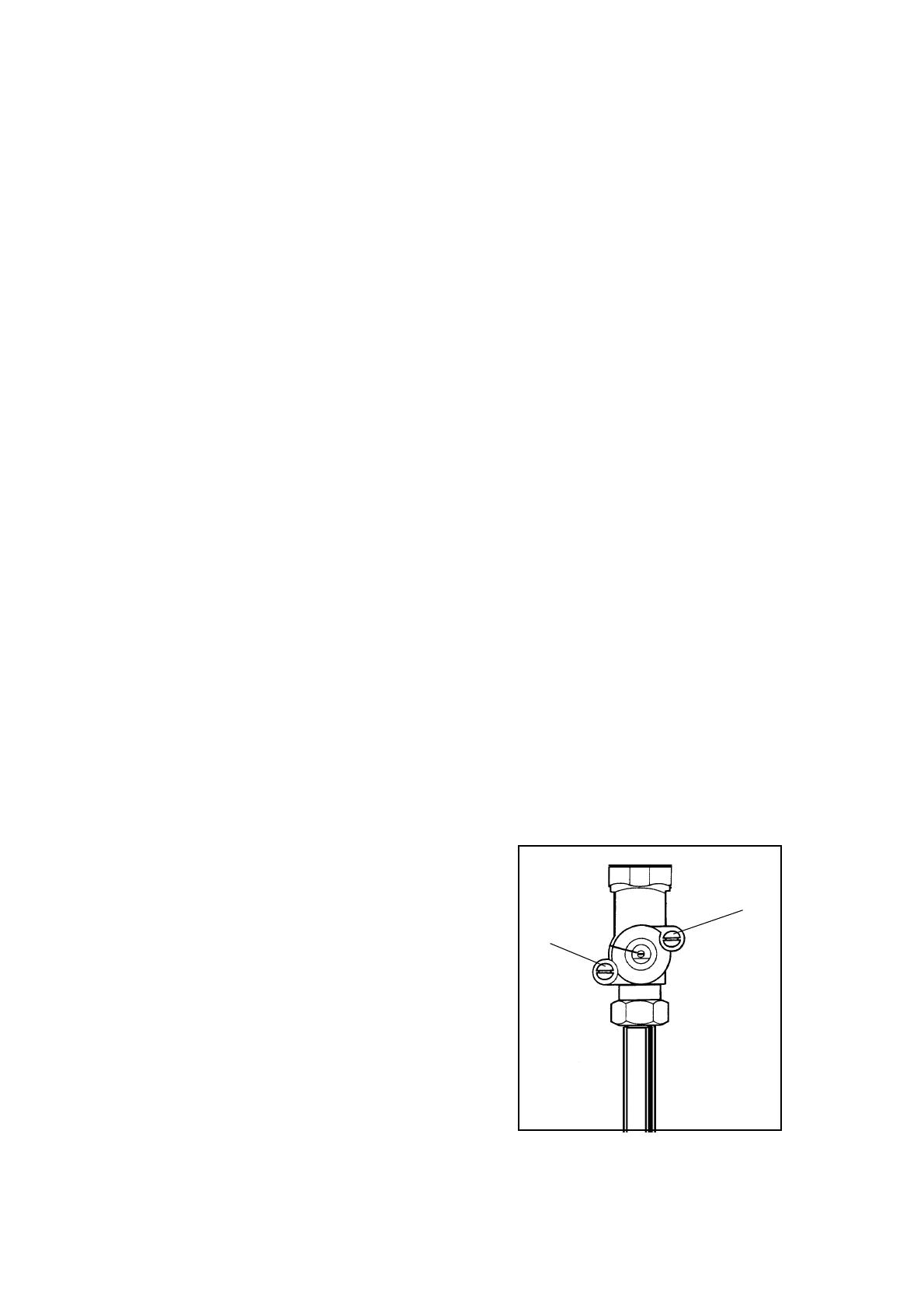

Technical Maintenance

Check at regular intervals the condition and

serviceability of the gas connection hose and pressure

regulator, if any is fitted; in case of malfunction, do

not repair but replace the whole faulty part.

To ensure a smooth and safe operation, it is necessary

to periodically grease the gas taps.

Act as follows:

1) Carry out steps 1 to 4 as explained in "Removal of

Hob Top" (see top of page).

2) Remove screws 1 and 2 (see diagram)

3) Remove the gas tap shaft and flange.

4) Slide out the Venturi tube, clean it thoroughly and

then apply a thin layer of grease of a non-soluble to

hydrocarbons type and suitable for gas taps.

5) Make sure that no axcess grease abstructs the gas

tap holes.

6) Refit everything very carefully following this pro-

cedure in reverse order.

FO 1042

1

2