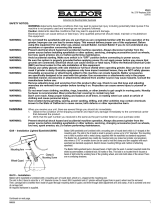

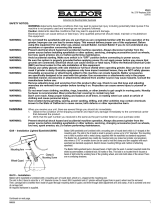

Baldor MN903 grinder is designed for safe and efficient grinding operations. It features a powerful motor for heavy-duty applications and a variety of safety features to protect users, including guards and a spark arrestor. The grinder's adjustable tool rest and eyeshield allow for precise control and visibility, while its sturdy construction ensures durability.

Baldor MN903 grinder is designed for safe and efficient grinding operations. It features a powerful motor for heavy-duty applications and a variety of safety features to protect users, including guards and a spark arrestor. The grinder's adjustable tool rest and eyeshield allow for precise control and visibility, while its sturdy construction ensures durability.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

Baldor MN903 User manual

- Type

- User manual

- This manual is also suitable for

Baldor MN903 grinder is designed for safe and efficient grinding operations. It features a powerful motor for heavy-duty applications and a variety of safety features to protect users, including guards and a spark arrestor. The grinder's adjustable tool rest and eyeshield allow for precise control and visibility, while its sturdy construction ensures durability.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Baldor Grinder 280F User manual

-

Baldor 602E-MT User manual

-

Baldor GLC30 User manual

-

Baldor DC10 User manual

-

Baldor AE8 User manual

-

Baldor TS25 Installation guide

-

Baldor-Reliance PC SEries Owner's manual

Baldor-Reliance PC SEries Owner's manual

-

Baldor DG3E User manual

-

Baldor Automatic Emergency Pow'r Products User manual

-

Baldor MN850 User manual

Other documents

-

Baldor-Reliance Grinders Owner's manual

Baldor-Reliance Grinders Owner's manual

-

Baldor-Reliance Belt Grinders Owner's manual

Baldor-Reliance Belt Grinders Owner's manual

-

Baldor-Reliance Grinder - Buffers Owner's manual

Baldor-Reliance Grinder - Buffers Owner's manual

-

Baldor-Reliance Tool Grinders Owner's manual

Baldor-Reliance Tool Grinders Owner's manual

-

Baldor-Reliance Polishing Lathes Owner's manual

Baldor-Reliance Polishing Lathes Owner's manual

-

Baldor-Reliance Belt Grinder-Buffer Model 602E-MT Owner's manual

Baldor-Reliance Belt Grinder-Buffer Model 602E-MT Owner's manual

-

Baldor-Reliance Dust Control Units Owner's manual

Baldor-Reliance Dust Control Units Owner's manual

-

Baldor-Reliance Buffers Owner's manual

Baldor-Reliance Buffers Owner's manual

-

Baldor-Reliance Eyeshield Owner's manual

Baldor-Reliance Eyeshield Owner's manual

-

Baldor-Reliance Wheel Replacement for Grinder Owner's manual

Baldor-Reliance Wheel Replacement for Grinder Owner's manual