Page is loading ...

Operation,Repair,andParts

EcoQuip EcoQuip

EcoQuip

Vapor Vapor

Vapor

Abrasive Abrasive

Abrasive

Blast Blast

Blast

System System

System

334667B

EN

Vapor Vapor

Vapor

abrasive abrasive

abrasive

blast blast

blast

system. system.

system.

For For

For

professional professional

professional

use use

use

only. only.

only.

Not Not

Not

approved approved

approved

for for

for

use use

use

in in

in

explosive explosive

explosive

atmospheres atmospheres

atmospheres

or or

or

hazardous hazardous

hazardous

locations. locations.

locations.

Important Important

Important

Safety Safety

Safety

Instructions Instructions

Instructions

Readallwarningsandinstructionsinthismanual.Savethese

instructions.

125 psi (8.6 bar, 0.86 MPa) Maximum

Working Pressure

See page 2 for Model information.

PROVENQUALITY.LEADINGTECHNOLOGY.

Contents Contents

Contents

Models...............................................................2

RelatedManuals................................................2

Warnings...........................................................3

OEMSystemGuidelines.....................................5

SystemComponentIdentication.........................6

EQ300CandEQ600C..................................6

DataTrakControls........................................7

PressureReliefProcedure..................................8

Operation...........................................................9

ChecklistBeforeStarting..............................9

ConnectingtheBlastHoseandAir

Hose..............................................10

SettingUptheEquipment.............................11

BlastingTips................................................15

UsingtheWashFeature...............................17

RellingthePotwithAbrasive.......................18

ShuttingDown.............................................19

WinterizingtheEquipment............................21

Troubleshooting..................................................22

TroubleshootingExamples...........................26

Repair................................................................28

RepairingtheMainAirRegulator..................28

FlushingtheDiaphragmValve......................29

RepairingtheDiaphragmValve.....................30

CleaningtheAuto-VentValve.......................31

ReplacingtheDataTrakBattery....................32

ReplacingtheDataTrakFuse.......................33

Parts..................................................................34

EQ300CandEQ600C..................................34

Enclosure....................................................36

PressurePot................................................38

HoseSchematic.................................................39

VaporAbrasiveBlastSystemsand

Accessories..........................................40

EcoQuipSkidSystems.................................40

EcoQuipTrailerSystems..............................40

Mobile/SkidUnits.........................................41

TrailerUnits.................................................41

Hoses.........................................................42

Nozzles.......................................................42

CommonSpareParts...................................43

OtherAccessories........................................43

Dimensions........................................................44

TechnicalSpecications......................................45

GracoExtendedWarrantyforEcoQuip™

Components.........................................46

Models Models

Models

Part Part

Part

Description Description

Description

EQ300CEcoQuip300VaporBlastSystem

EQ600CEcoQuip600VaporBlastSystem

Related Related

Related

Manuals Manuals

Manuals

Manual Manual

Manual

Number Number

Number

Product Product

Product

313840DataTrak

333397Pump

334143

EQ300M,EQ600M

334142

EQ100M

334666

EQ200T,EQ400T

2

334667B

Warnings

Warnings Warnings

Warnings

Thefollowingwarningsareforthesetup,use,grounding,maintenance,andrepairofthisequipment.The

exclamationpointsymbolalertsyoutoageneralwarningandthehazardsymbolsrefertoprocedure-specic

risks.Whenthesesymbolsappearinthebodyofthismanualoronwarninglabels,referbacktothese

Warnings.Product-specichazardsymbolsandwarningsnotcoveredinthissectionmayappearthroughout

thebodyofthismanualwhereapplicable.

WARNING WARNING

WARNING

DUST DUST

DUST

AND AND

AND

DEBRIS DEBRIS

DEBRIS

HAZARD HAZARD

HAZARD

Useofthisequipmentcanresultinthereleaseofpotentiallyharmfuldustortoxicsubstances

fromtheabrasivebeingused,thecoatingsbeingremoved,andthebaseobjectbeingblasted.

•Foruseonlybysophisticatedusersfamiliarwithapplicablegovernmentalsafetyandindustrial

hygieneregulators.

•Useequipmentonlyinawell-ventilatedarea.

•Wearaproperlyt-testedandgovernmentapprovedrespiratorsuitableforthedustconditions.

•Followlocalordinancesand/orregulationsfordisposaloftoxicsubstancesanddebris.

EQUIPMENT EQUIPMENT

EQUIPMENT

MISUSE MISUSE

MISUSE

HAZARD HAZARD

HAZARD

Misusecancausedeathorseriousinjury.

•Donotoperatetheunitwhenfatiguedorundertheinuenceofdrugsoralcohol.

•Donotexceedthemaximumworkingpressureortemperatureratingofthelowestrated

systemcomponent.SeeTechnical Technical

Technical

Data Data

Data

inallequipmentmanuals.

•Donotusethisequipmentwithouthoserestraintsandcouplerpinsinstalledonallairand

blasthosecouplings.

•Donotblastunstableobjects.Thehighamountofuidowfromthenozzlecanpotentially

moveheavyobjects.

•Donotexceedloadratingoflifteyes.

•Donotoperateequipmentonorstandonanunstablesupport.Keepeffectivefootingand

balanceatalltimes.

•Useuidsandsolventsthatarecompatiblewithequipmentwettedparts.SeeTechnicalData

inallequipmentmanuals.Readuidandsolventmanufacturer’swarnings.Forcomplete

informationaboutyourmaterial,requestMSDSfromdistributororretailer.

•Donotleavetheworkareawhileequipmentisenergizedorunderpressure.

•TurnoffallequipmentandfollowthePressure Pressure

Pressure

Relief Relief

Relief

Procedure Procedure

Procedure

whenequipmentisnotinuse.

•Checkequipmentdaily.Repairorreplacewornordamagedpartsimmediatelywithgenuine

manufacturer’sreplacementpartsonly.

•Donotalterormodifyequipment.Alterationsormodicationsmayvoidagencyapprovals

andcreatesafetyhazards.

•Makesureallequipmentisratedandapprovedfortheenvironmentinwhichyouareusingit.

•Useequipmentonlyforitsintendedpurpose.Callyourdistributorforinformation.

•Routehosesandcablesawayfromtrafcareas,sharpedges,movingparts,andhotsurfaces.

•Donotkinkoroverbendhosesorusehosestopullequipment.

•Keepchildrenandanimalsawayfromworkarea.

•Complywithallapplicablesafetyregulations.

334667B 3

Warnings

WARNING WARNING

WARNING

BURN BURN

BURN

HAZARD HAZARD

HAZARD

Equipmentsurfacesanduidthatisheatedcanbecomeveryhotduringoperation.Toavoid

severeburns:

•Donottouchhotuidorequipment.

FIRE FIRE

FIRE

AND AND

AND

EXPLOSION EXPLOSION

EXPLOSION

HAZARD HAZARD

HAZARD

Flammablefumes,suchassolvent,inworkareacanigniteorexplode.Tohelppreventre

andexplosion:

•Useequipmentonlyinwellventilatedarea.

•Abrasivematerialexitingblastnozzlecangeneratesparks.Whenammableliquidsareused

neartheblastnozzleorforushingorcleaning,keeptheblastnozzleatleast20feet(6

meters)awayfromexplosivevapors.

•Keepworkareafreeofdebris,includingsolvent,ragsandgasoline.

•Keepaworkingreextinguisherintheworkarea.

PERSONAL PERSONAL

PERSONAL

PROTECTIVE PROTECTIVE

PROTECTIVE

EQUIPMENT EQUIPMENT

EQUIPMENT

Wearappropriateprotectiveequipmentwhenintheworkareatohelppreventseriousinjury,

includingeyeinjury,hearingloss,inhalationoftoxicfumes,andburns.Protectiveequipment

includesbutisnotlimitedto:

•Protectiveeyewear

•Protectiveshoes

•Gloves

•Hearingprotection

•Properlyt-testedandgovernmentapprovedrespiratorsuitableforthedustconditions

RECOIL RECOIL

RECOIL

HAZARD HAZARD

HAZARD

Blastnozzlemayrecoilwhentriggered.Ifyouarenotstandingsecurely,youcouldfalland

beseriouslyinjured.

4

334667B

OEMSystemGuidelines

OEM OEM

OEM

System System

System

Guidelines Guidelines

Guidelines

U.S. U.S.

U.S.

Metric Metric

Metric

SystemWeight(Dry)

450lb204kg

SystemWeight(Wet)

1600lb726kg

WaterTankSize(mustbewater

compatible)

100gallon(recommended)378liter(recommended)

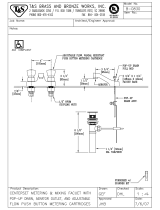

PumpInletFittingDixon6EM6-Bquickdisconnectinterchangeincluded

(3/4"NPTalsoonpump)

MinimumID3/4in.1.9cm

MaximumRecommendedPumpInlet

HoseLength

5ft

4.5m

Maximumrecommendedrisefromwater

tankoutlettopumpinlet

16in.41cm

AvailableGracoInlethoses(w/quick

disconnectinterchanges)

17C032

19in.length48cm

EQ1848

36in.length91cm

AvailableGracowatertankshutoffvalve

assembly(3/4"NPTmaleto6EM6-B

quickdisconnect)

EQ5131EQ5131

Compressor Compressor

Compressor

Size Size

Size

and and

and

Hose Hose

Hose

Length Length

Length

Minimum Minimum

Minimum

ID ID

ID

U.S. U.S.

U.S.

Metric Metric

Metric

185-600cfmcompressorandlessthan

100'hoselength

1.5in.38mm

Morethan600cfmcompressoror

greaterthan100'hoselength

2in.51mm

SeeVaporAbrasiveBlastSystemsandAccessories,page40forGracorecommendedblasthosesand

nozzles.

SeeDimensions,page44.

334667B 5

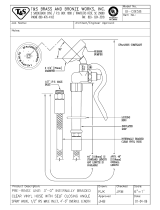

SystemComponentIdentication

Key: Key:

Key:

A

Cart

B

BlastControlSwitch

B2BlastNozzle

C

BlastHose

EPot

FBungPin

G

WaterTank

HWaterTankLid

JPotDumpValve

KAutoVentValve

L

BlastCheckValve

MAbrasiveBallValve

P

ControlBox

QEmergencyStop

RBlastAirRegulator

Key: Key:

Key:

S

AbrasiveMaterial

TPotPressureRegulator

U

PotPressureGauge

V

BlastAirPressureGauge

W

SelectorValve

XRinseBallValve

Y

AirSupplyConnection

Z

BlastConnection

ZA

PneumaticControlConnection

ZB

ElectricControlConnection

ZCSupplyAirPressureGauge

ZD

DataTrak(seeDataTrakControls,page7)

ZEAccessoryExtensionhose

ZFAbrasiveMedia

ZGFillPortCheckValve

DataTrak DataTrak

DataTrak

Controls Controls

Controls

8800000

83000

9

Key: Key:

Key:

RK

ResetKey—Resultsinfaults.Pressand

holdforthreesecondstoclearthebatch

totalizer.

CRCycle/Rate

BTBatchTotalizer

GTGrandTotalizer

334667B

7

PressureReliefProcedure

Pressure Pressure

Pressure

Relief Relief

Relief

Procedure Procedure

Procedure

FollowthePressureReliefProcedure

wheneveryouseethissymbol.

Thisequipmentstayspressurizeduntilpressure

ismanuallyrelieved.Tohelppreventserious

injuryfrompressurizeduid,suchassplashing

uid,followthePressureReliefProcedurewhen

instructed.

1.Turnthepotpressureregulator(PR)off.

2.Closetheabrasiveballvalve.

3.Turnthecompressoroffandclosetheinlet

ballvalve.Closethecompressorsupplyair

valve.Engagetheblastcontrolswitchtorelieve

pressureinthesystem.Thendisconnecttheair

inlethosefromthesystem.

4.Turntheselectorvalve(SL)toFILL.

5.Openthedumpvalve.

6.Verifythatthepotpressuregauge(PG)displays

zeropressure.

8 334667B

Operation

Operation Operation

Operation

Checklist Checklist

Checklist

Before Before

Before

Starting Starting

Starting

•Checkthecompressedairsupplyaccordingtoits

operatormanual.Makesuretheairbeingsupplied

iscleanandrelativelyfreeofmoistureandoil

topreventwatercontaminationoftheaircontrol

components.

•Makesureairdeliveryvalvesareclosedbeforethe

airsupplycompressorisstarted.

•Makesureallrequiredhoserestraintsandcoupler

pinsareinworkingconditionandproperlyinstalled.

•Makesuretheequipmentissituatedonlevel

ground.Failuretokeeptheunitonlevelground

willmakeitdifcultorimpossibletopurgeallofthe

airfromthepressurevessel.

•Makesuretheequipmentisproperlysupportedon

asurfacethatcanholditstotalweight.Theweight

ofallpersonnel,thematerialbeingblasted,and

anyabrasivebeingstoredmustalsobeconsidered

(seeTechnicalSpecications,page45).

•Makesurethewatertankwillremainfullysupplied

withcleanwatertoavoidanypossibilityofthe

pumprunningdryduringblasting.

•Makesurethatthepotiscleanandfreeofany

internaldebris.

•Makesuretousethecorrecttypeofblastcontrol.

Blastingwith150feet(45m)ormoreofblasthose

requirestheuseofanelectricblastcontrol.An

electricblastcontrolcanalsobeusedonhose

lengthsbelow150feet(45m).

•Makesuretheblasthoseislaidoutasstraightas

possiblebetweentheequipmentandtheworksite

(acoiledblasthosewilluncoilunderpressure).

NOTICE NOTICE

NOTICE

Sharpbendsintheblasthosecouldcausethe

abrasivetowearthroughthehoseandcause

prematurefailureofthehose.

•Makesuretherubbergasketineachhosecoupler

isinworkingcondition.

334667B 9

Operation

Connecting Connecting

Connecting

the the

the

Blast Blast

Blast

Hose Hose

Hose

and and

and

Air Air

Air

Hose Hose

Hose

1.Alwayspurgetheairsupplyhose15–20seconds

beforeconnectingtheairsupplyhosefromthe

compressor(oron-sitecompressedairsource)

tothepanel.Makesurealldebrisisclearedfrom

thehose.

2.Connectanappropriatelysizedair

supplyhosetotheairinlet.See

TechnicalSpecications,page45.

NOTE: NOTE:

NOTE:

Makesuretoproperlyinstallhose

restraintsandcouplerpinstothequick-coupler

andtheairline.Iftheholesonthequick-coupler

donotalign,thereissomethingwrongandthe

twocouplersarenotcompatible.DO DO

DO

NOT NOT

NOT

TURN TURN

TURN

ON ON

ON

THE THE

THE

AIR AIR

AIR

.Seekhelptogetthesituation

resolved.

3.Opentheairsupplyvalve(125psi,8.6Bar,0.86

MPamaximum).Ifnecessary,usearegulatorin

thesupplyairlinetomeetthesespecications.

OFF

START

RUN

NOTE: NOTE:

NOTE:

Makesuretheairsupplymeets

theappropriate appropriate

appropriate

air air

air

ow ow

ow

requirements. requirements.

requirements.

See

TechnicalSpecications,page45.

4.Connecttheblasthose,hoserestraints,control

hoses,andcouplerpins.

ti24706a

NOTE: NOTE:

NOTE:

Ifyouareusinganelectricblastcontrol,

checkalloftheelectricalconnectionsfromthe

paneltotheblastcontrol.

NOTICE NOTICE

NOTICE

Makesurenoelectricalconnectionswill

beexposedtowater.Exposuretowater

couldcauseashortcircuitanddamagethe

equipment.

10 334667B

Operation

Setting Setting

Setting

Up Up

Up

the the

the

Equipment Equipment

Equipment

1.Disconnecttheabrasivehoseatthecamand

groovewiththeabrasiveballvalveclosed.

NOTE: NOTE:

NOTE:

Ifthepotcontainswaterandabrasive

(especiallyunderpressure),releasingthecam

andgroovewiththeballvalveopenwillcausean

unintentionalreleaseofabrasive.

2.Flushwaterthroughthepotandoutthe

disconnectedabrasiveballvalvebeforellingthe

potwithwaterandabrasive.

3.Reconnecttheabrasivehose.

4.Disconnectthepumpinlethoseandushthe

watertanktoremoveanyremainingdebris.

Reconnectthepumpinlethose.

5.Fillthewatertankonlywithfreshwater,then

opentheinletballvalve.

6.Closetherinse,dump,andabrasiveballvalves.

7.

334667B

11

Operation

8.TurntheselectorvalvetoRINSE.

9.DisengagetheEmergencyStop.

NOTE: NOTE:

NOTE:

Thewaterpumpwillnotworkunlessthe

EmergencyStopisdisengaged.

10.Alignthebunghandlewiththepinslot,andthen

rmlypushandturnthehandle90°afterthepin

isbelowthebracketslot.Properengagementof

thepinwillholdthebungdownuntilitisreleased.

11.Add10gallons(30liters)offreshwaterto

thepot.Wearappropriatepersonalprotective

equipment,includinganappropriatelyt-tested

governmentapprovedrespiratorsuitableforthe

dustconditions.Addabrasivematerial(minimum

fourbags,maximumten50lb(23kg)bagsof

high-massabrasive,oreight50lb(23kg)bags

oflowmassabrasive).

1

2

10 gal

(30 L)

200-500 lb

(90-227 kg)

12.Useagardenhoseortherinsehosetowashthe

abrasiveintothepotandclearanyabrasivefrom

thebungandbungseal.

12

334667B

Operation

13.Whenthewaterlevelreachesthebungseal,

rotatethehandletoreleasethebungpin(this

willcausethebungtopopupagainsttheseal

andclosethebung).

14.TurntheselectorvalvetoFILL.

NOTE: NOTE:

NOTE:

Thewaterpumpshouldbegincycling.If

not,openthepotpressureregulatorenoughto

causethepumptorunat60cpm.

NOTE: NOTE:

NOTE:

Theautovent/purgevalvewillallowall

oftheairtrappedinthetopofthepottovent.

Whenairstopsventing,thepotpressuregauge

willstarttoregisterpressure.

15.Waitforpotpressuretoincrease.NOTE: NOTE:

NOTE:

It

cantakeuptoseveralminutesforthepotto

pressurize.

ti24824a

NOTE: NOTE:

NOTE:

Thebungcannotbepusheddownunless

allofthepressureinthepotisreleasedby

openingthedumpvalve.

16.Setthepotpressure30psi(2.0Bar,0.2MPa)

higherthantheintendedblastpressure.Quickly

openandclosethedumpvalveafterthepump

stalls.Relievepotpressureto40psi(2.7Bar,

0.27MPa)beforeclosingthedumpvalve.

Repeatuntilpotpressureisconsistent.

17.TurntheselectorvalvetoWASH.

18.Settheblastairpressure30psi(2.0Bar,0.2

MPa)lowerthanthepotpressurewhileblasting.

NOTE: NOTE:

NOTE:

Inordertoadjusttheblastpressure,the

blastcontrolmustbeengaged.Fortheinitial

setting,leavetheabrasiveballvalveclosed.

NOTE: NOTE:

NOTE:

Engageandreleasetheblastcontrol

handleeachtimetheblastregulatorisadjusted.

19.TurntheselectorvalvetoBLAST.

334667B 13

Operation

20.Opentheabrasiveballvalve.

NOTE: NOTE:

NOTE:

Makesurethepotpressurereturnstothe

initialsetting(itwillnotreturntotheinitialsetting

ifthemeteringvalveisclosed).

21.Engagetheblastcontrolswitchandbegin

blasting.

NOTE: NOTE:

NOTE:

Youmayhavetowait1–2minutesforthe

abrasivematerialtoreachthenozzle.

NOTE: NOTE:

NOTE:

Potpressureandblastpressureshould

equalizeduringblasting.Onlysetpotpressure

withtheabrasiveballvalveclosed.Neveradjust

potpressurewhileblasting.

22.Slowlyadjusttheabrasivemetervalvewhilethe

abrasiveisblastingfromthenozzle.Typical

adjustmentrangesfrom1/8to1/4turnopen.

NOTE: NOTE:

NOTE:

TheDataTrakcanbeusedtoassistin

settingthepumpcyclerate.Optimalabrasive

mediaconsumptiontypicallyoccurswiththe

cycleratesetat7–10cyclesperminute.

8800000

83000

9

NOTE: NOTE:

NOTE:

Useapieceoftestmaterialsimilarto

whatyouwillbeblasting.

NOTE: NOTE:

NOTE:

Alwaysstartasgentlyaspossibleand

thenincreasetheblastforceasnecessaryto

cleanwithoutdoinganydamagetothesubstrate.

Whenproperlyset,thepumpshouldcycle7-10

timesperminute.Highproductionrateusers

mayneedtoincreasecyclerateabove10cycles

perminute.

NOTE: NOTE:

NOTE:

Closetheabrasiveballvalvewhenever

youstopblastingformorethan2-3minutes.

Thiswillhelptoextendtheservicelifeofthe

diaphragmvalve.

14

334667B

Operation

Blasting Blasting

Blasting

Tips Tips

Tips

Whenrstlearningtheeffectsoftheblaster,geta

betterunderstandingoftheresultsbystartingata

shallowangle(closerto0°thanto90°)andkeep

thenozzleapproximately16in.(40cm)fromthe

application.Observetheresults,thenreducethe

distance,steepentheangle,andadjusttheblast

regulator.

Astheblastpressureisincreased,slowlyadjust

themeteringvalveandwatchtheDataTrakto

achieve7-10pumpcyclesperminute.See

DataTrakControls,page7.

NOTE: NOTE:

NOTE:

Theheavierandsmallertheabrasiveparticle

(i.e.80-grit),themoreaggressivetheresults.

Blasting Blasting

Blasting

on on

on

Higher Higher

Higher

Surfaces Surfaces

Surfaces

Whenblastingonasurfacehigherthanthe

equipment,makesurethatthereisalengthofblast

hoseonthegroundequalto10-20%oftheheight.

Thehoseonthegroundpreventsunspentabrasive

inthehosefromback-llingtheinternalplumbingof

thepanel.

Forexample:Whenblasting50feet(15m)straight

up,useatleast10feet(3m)ofblasthoseonthe

groundbeforetheblasthosegoesuptotheblasting

height.

334667B 15

Operation

Metering Metering

Metering

Valve Valve

Valve

Settings Settings

Settings

Thereisnoxedformulaforwhatworksbestineachapplication.Theinformationbelowworksbestforthe

majorityofthetime.Fromthisinitialsetting,adjustmentscanbemadeupordowntogetthefastestremoval

rateswithoutdamagetothesurface.

Normalsettingsare:110psi(7.5Bar,0.75MPa)initialpotsetting,lessthan1/2turnopenmeteringvalve,

blastingpressureat80psi(5.5Bar,0.55MPa).Forapplicationsrequiringhigherperformance,use

high-performanceabrasive(theheaviestmass@80grit)suchasGarnet,andthehighestpressuresthe

compressorcansupport.Theinitialpotpressureshouldalwaysbe30psi(2.0Bar,0.2MPa)abovethe

intendedblastpressure.

Graduallymakeadjustmentstomeetthespecicrequirementsforeachapplication.Higherblastpressures

willrequireturningtheabrasivemeteringvalveslightlymoreopen(andviceversa).Maketheadjustments

(seeDataTrakControls,page7)toachieve7-10cyclesperminutetobethemostefcient(cutatthefastest

ratewhileusingtheleastamountofabrasive).Blastingpressurescanrangebetween30-120psimax

(2.0Bar,0.2MPa–8.2Bar,0.82MPa).

Unlikeconventionalsandblasting,higherpressuresdonotnecessarilymeanbettercleaning.Nozzledistance

andtheangletothesurfacehasaneffectonperformance,asdoestheblastpressure.Choiceofabrasive

alsohasagreateffect.High-performanceabrasiveproducesthebestperformanceandcansaveenough

timetomakeupthedifferenceincost.

NOTE: NOTE:

NOTE:

Blastingwith150+feetofblasthoserequirestheuseofanelectricblastcontrol.

Grit Grit

Grit

Size Size

Size

Blast Blast

Blast

Pressure Pressure

Pressure

Abrasive Abrasive

Abrasive

Dose Dose

Dose

Blast Blast

Blast

Angle Angle

Angle

Notes Notes

Notes

General General

General

40/70

60-80psi(4.1Bar,

0.41MPa-5.5Bar,

0.55MPa)

1/4to1/2turns

35°-65°

Whentheblast

pressureis

increased,the

abrasivedoseturns

willalsoneedtobe

increased.

Wood Wood

Wood

80(usingalow

massabrasive

likeglass)

40-50psi(2.7Bar,

0.27MPa-3.4Bar,

0.34MPa)

1/8to1/4turns

15°-30°

Donotwash,asit

mayraisethewood

grain.Brushoff

excessabrasiveafter

thewooddries.

Steel Steel

Steel

80-100(using

ahigh-mass

abrasivelike

Garnet)

100-120psi(6.8Bar,

0.68MPa-8.2Bar,

0.82MPa)

1/4–1/2turns

65°-85˚

Whentheblast

pressureis

increased,the

abrasivedoseturns

willalsoneedtobe

increased.

Fiberglass Fiberglass

Fiberglass

40-70lowmass

45-65psi(3.1Bar,

0.31MPa-4.4Bar,

0.44MPa)

1/8to1/4turns

35°-45˚

Whentheblast

pressureis

increased,the

abrasivedoseturns

willalsoneedtobe

increased.

16 334667B

Operation

Using Using

Using

the the

the

Wash Wash

Wash

Feature Feature

Feature

Thewashfeaturecausesair-drivenwater(without

abrasive)toblastandrinseareasthathavealready

beenblastedwithabrasive.Itisalsoaconvenient

featureforushingabrasivefromtheblasthose.

NOTICE NOTICE

NOTICE

Therewillalwaysbesomeresidualabrasivein

theblasthose.Neverusethewashfeatureon

anysurfaceotherthanwhereyouhaveblasted,or

intendtoblast.Itwillaffect/dullthesurface.

NOTICE NOTICE

NOTICE

Donotusethewashfeatureonwoodthathas

beenblasted.Itcoulddamagethewoodandcause

thegraintorise.Waitforthewoodtodryandthen

useabroom,brush,orvacuumtoremoveany

residualabrasive.

1.Closetheabrasiveballvalve.

2.TurntheselectorvalvetoWASH.

3.Blast1–2minutesuntiltheabrasiveiscleared

fromthehose.

4.Theequipmentisnowreadytowashany

previouslyblastedsurfaces.

334667B

17

Operation

Relling Relling

Relling

the the

the

Pot Pot

Pot

with with

with

Abrasive Abrasive

Abrasive

1.Closetheabrasiveballvalve.

2.TurntheselectorvalvetoRINSE.

3.Openthedumpvalveslowlytorelievethewater

pressureinthepot.

NOTE: NOTE:

NOTE:

Bepreparedtocapturethewaterthat

willbedrainedfromthepot.Alldisposalsmust

complywithnational,state,andlocalregulations.

4.Afterallofthepressureinthepothasbeen

relieved,engagethebungpinbycompressing

thespringandturningthehandle90°toholdthe

bungintheopenposition.

5.Addtheabrasive(minimumfourbags,maximum

ten50lb(23kg)bagsofhigh-massabrasive

oreight50lb(23kg)bagsoflow-mass

abrasive)andcontinuetheproceduresfrom

SettingUptheEquipment,page11.

NOTE: NOTE:

NOTE:

Morewatermayneedtobedrainedfrom

thepottoallowadditionalabrasivetobeadded.

18 334667B

Operation

Shutting Shutting

Shutting

Down Down

Down

1.Whenyouhavenishedblasting,performwash

untilalloftheabrasiveisushedfromtheblast

hose.SeeUsingtheWashFeature,page17.

2.TurntheselectorvalvetoRINSE,andwiththe

abrasiveballvalveclosed,continuetoblastuntil

waterisclearedfromthehose.Thisistodrythe

insideofthehoseforstorage.

3.Opentheabrasiveballvalve,thenopenthedump

valveuntilthepotpressuregaugereads0psi.

Closetheabrasiveballvalveanddumpvalve.

NOTE: NOTE:

NOTE:

Short-termshutdownisnowcomplete.

Iftheuntilwillbeshutdownformorethan24

hours,proceedtothenextstep.

4.Disconnecttheabrasiveballvalvecam-lockby

removingthecouplerpinsandpullingtherings

outanduptopullthetwocamsawayfromthe

groove.

5.Holdabucketunderthecam-lockcoupler,then

turntheselectorvalvetoWASH.Thiswillclean

debrisfromthecam-lockcouplerandgasket.

NOTE: NOTE:

NOTE:

Makesurethegasketisinplaceafterthe

procedure.

NOTE: NOTE:

NOTE:

Besuretocatchtheunspentabrasive

thatwillbewashedoutofthepanelplumbingand

outofthegroovetting.

6.TurntheselectorvalvetoFILL.Thiswillhelp

pushtheabrasiveoutthroughtheabrasivehose.

7.Placeabucketundertheabrasivehose.Slowly

openandclosetheabrasiveballvalvetoush

abrasivematerialfromthepot.Repeatseveral

times.Oncenoabrasivematerialowsfromthe

hose,closetheabrasiveballvalve.

NOTE: NOTE:

NOTE:

Estimatethata5gallonpailwillbe

neededforeachbagofabrasivestillinthepot.

Coverthebucketsduringstoragesodebrisdoes

notcontaminatetheabrasive.

334667B 19

Operation

8.Engagethebungpintoholdthebungopenand

allowairtoenter.

9.Opentheabrasiveballvalveandushthepotof

anyremainingabrasivematerial.

10.Closethepotbungandconnectthe

abrasivehose.Relievepressure

tocompletesystemshutdown(see

PressureReliefProcedure,page8).

NOTE: NOTE:

NOTE:

Thesystemmustbewinterizedifitwill

beexposedtotemperaturesbelowfreezing.See

WinterizingtheEquipment,page21.

20 334667B

/